Abstract

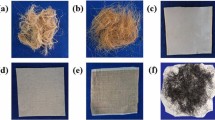

This work presents the influence of the wetting and drying cycles on the tensile behavior of the strain-hardening cement-based composites reinforced with natural curauá fiber. The 3 sets of 10 dog bone shape specimens were prepared and submitted to the cycles. After 15, 30 and 45 cycles the composites were tested under tensile load in wet (5 specimens) and dry conditions (5 specimens) and compared to the reference specimens. After the cycles, composites presented strain-softening behavior. The residual fiber stress and strain at rupture were verified on fibers extracted from the composites submitted to the tensile test. This procedure was applied to the determination of the matrix environment influence on fiber properties after accelerated aging cycles. The strain-softening behavior of the composites submitted to the wetting and drying cycles was correlated with the fiber-matrix interfacial observations under a microscope and highlighted by fiber pull-out work indicators. The strain-softening behavior is strongly related to the natural fiber volume change and defibrillation induced by the moisture movement during aging.

Similar content being viewed by others

References

Li VC (2003) On engineered cementitious composites (ECC). A review of the material and its applications. J Adv Concr Technol 1:215–230. https://doi.org/10.3151/jact.1.215

van Zijl GPAG, Wittmann FH, Oh BH et al (2012) Durability of strain-hardening cement-based composites (SHCC). Mater Struct 45:1447–1463. https://doi.org/10.1617/s11527-012-9845-y

Gram HE (1986) Durability studies of natural organic fibres in concrete, mortar or cement. In: Developments in fibre reinforced cement and concrete. RILEM symphosium, Sheffield

Snoeck D, Smetryns PA, De Belie N (2015) Improved multiple cracking and autogenous healing in cementitious materials by means of chemically-treated natural fibres. Biosyst Eng 139:87–99. https://doi.org/10.1016/j.biosystemseng.2015.08.007

Soltan DG, das Neves P, Olvera A et al (2017) Introducing a curauá fiber reinforced cement-based composite with strain-hardening behavior. Ind Crops Prod 103:1–12. https://doi.org/10.1016/j.indcrop.2017.03.016

Fidelis MEA, Toledo Filho RD, de Silva AF et al (2016) The effect of accelerated aging on the interface of jute textile reinforced concrete. Cem Concr Compos 74:7–15. https://doi.org/10.1016/j.cemconcomp.2016.09.002

Rodrigues de CS, Zukowski B, Figueiredo SC, Santos LA (2015) Modification of cellulose-cement composites by admixture of sugar cane bagasse ash. In: RILEM proceedings Pro 96. RILEM Publications, SARL, Bagneux, vol 1, pp 569–576

Toledo Filho RD, Scrivener K, England GL, Ghavami K (2000) Durability if alkali-sensitive sisal and coconut fibres in cement mortar composites. Cem Concr Compos 22:127–143

Melo Filho JA, Silva FA, Toledo Filho RD (2013) Degradation kinetics and aging mechanisms on sisal fiber cement composite systems. Cem Concr Compos 40:30–39

Methacanon P, Weerawatsophon U, Sumrasin N et al (2010) Properties and potential application af the selected natural fibers as limited life geotextiles. Carbohydr Polym 83:1090–1096

John MJ, Thomas S (2008) Biofibres and biocomposites. Carbohydr Polym 71:343–363

Dittenber DB, GangaRao HVS (2012) Critical reveiew of recent publications on use of natural composites in infrastructure. Compos Part A Appl Sci Manuf 43:1419–1429

Uzomaka OJ (1976) Characteristics of akwara as a reinforcing fibre. Mag Concr Res 28:162–167

Mai YW, Hakeem MI (1984) Slow crack growth in cellulose fibre cements. J Mater Sci 19:501–508

Litherland KL, Oakley DR, Proctor BA (1981) The use of accelerated ageing procedures to predict the long term strength of GRC composites. Cem Concr Res 11:455–466. https://doi.org/10.1016/0008-8846(81)90117-4

Wei J, Meyer C (2014) Degradation rate of natural fiber in cement composites exposed to various accelerated aging environment conditions. Corros Sci 88:118–132. https://doi.org/10.1016/j.corsci.2014.07.029

Zukowski B, de Silva FA, Toledo Filho RD (2017) The influence of hot water washing cycles on tensile properties of curauá fiber. In: 17th international conference on non-conventional materials and technologies (17thNOCMAT 2017). “Construction for sustainability, green composites, materials and technologies,” Merida, Yucatan, Mexico, pp 516–526

Ferreira SR, Silva FDA, Lima PRL, Toledo Filho RD (2015) Effect of fiber treatments on the sisal fiber properties and fiber-matrix bond in cement based systems. Constr Build Mater 101:730–740. https://doi.org/10.1016/j.conbuildmat.2015.10.120

Zhou J, Qian S, Ye G et al (2012) Improved fiber distribution and mechanical properties of engineered cementitious composites by adjusting the mixing sequence. Cem Concr Compos 34:342–348. https://doi.org/10.1016/j.cemconcomp.2011.11.019

Magalhães M (2013) Influence of local raw materials on the mechanical behaviour and fracture process of PVA-SHCC. Mater Res 17:146–156. https://doi.org/10.1590/S1516-14392013005000163

Zukowski B, dos Santos ERF, dos Santos Mendonça YG et al (2018) The durability of SHCC with alkali treated curaua fiber exposed to natural weathering. Cem Concr Compos 94:116–125. https://doi.org/10.1016/j.cemconcomp.2018.09.002

ASTM International (2003) ASTM C1557—03e1 standard test method for tensile strength and Youngs modulus of fibers

Butler M, Mechtcherine V, Hempel S (2009) Experimental investigations on the durability of fibre-matrix interfaces in textile-reinforced concrete. Cem Concr Compos 31:221–231. https://doi.org/10.1016/j.cemconcomp.2009.02.005

Pan X, Shi Z, Shi C et al (2017) A review on concrete surface treatment part I: types and mechanisms. Constr Build Mater 132:578–590. https://doi.org/10.1016/j.conbuildmat.2016.12.025

Pan X, Shi Z, Shi C et al (2017) A review on surface treatment for concrete—part 2: performance. Constr Build Mater 133:81–90. https://doi.org/10.1016/j.conbuildmat.2016.11.128

Al-Kheetan MJ, Rahman MM, Chamberlain DA (2018) A novel approach of introducing crystalline protection material and curing agent in fresh concrete for enhancing hydrophobicity. Constr Build Mater 160:644–652. https://doi.org/10.1016/j.conbuildmat.2017.11.108

Ferreira SR, de Andrade SF, Lima PRL, Toledo Filho RD (2015) Effect of natural fiber hornification on the fiber matrix interface in cement based composite systems. Key Eng Mater 668:118–125. https://doi.org/10.4028/www.scientific.net/KEM.668.118

Ferreira SR, de Silva FA, Lima PRL, Toledo Filho RD (2017) Effect of hornification on the structure, tensile behavior and fiber matrix bond of sisal, jute and curaua fiber cement based composite systems. Constr Build Mater 139:551–561. https://doi.org/10.1016/j.conbuildmat.2016.10.004

Fan LT, Gharpuray MM, Lee YH (1987) Biotechnology monographs—cellulose hydrolysis. Springer, Berlin

Ferreira SR, Lima PRL, Silva FA, Toledo Filho RD (2014) Effect of sisal fiber hornification on the fiber-matrix bonding characteristcs and bending behavior of cement based composites. Key Eng Mater 600:421–432. https://doi.org/10.4028/www.scientific.net/KEM.600.421

Santos R, Ferreira S, Oliveira G et al (2017) Impact of alkaline hornification in jute fibers on the tensile strength. MOJ Polym Sci. https://doi.org/10.15406/mojps.2017.01.00026

Santos R, Ferreira S, Oliveira G et al (2018) Influence of alkaline hornification treatment cycles on the mechanical behavior in curaua fibers. Macromol Symp. https://doi.org/10.1002/masy.201800096

Acknowledgements

The authors thank the National Council for Scientific and Technological Development (CNPq, Brazilian National Science Agency) for the support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zukowski, B., dos Santos Mendonça, Y.G., de Andrade Silva, F. et al. Effect of moisture movement on the tensile stress–strain behavior of SHCC with alkali treated curauá fiber. Mater Struct 53, 49 (2020). https://doi.org/10.1617/s11527-020-01486-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-020-01486-9