Abstract

Short-term aging of asphalt binders is an inevitable phenomenon during mix production and laydown that significantly affects the rheological properties of asphalt binders and further contributes to the deterioration of pavement performance. This paper presents a new short-term aging model for asphalt binders. The new model focuses on the binder viscosity as the target property and incorporates the rheological activation energy for the model development. It consists of four model coefficients and two essential binder specific inputs (i.e. viscosity and rheological activation energy of the unaged asphalt binder). The rheological activation energy is calculated from the conventional properties of unaged asphalt binders like penetration, kinematic viscosity, and absolute viscosity measured at various temperatures or from the known Viscosity Temperature Susceptibility parameters (i.e. “A-VTS” values) of unaged asphalt binders. The global model coefficients are determined using data extracted from the long-term pavement performance database. The short-term aging is verified to increase the rheological activation energy of the asphalt binder to a certain amount which is linearly proportional to that of the unaged binder. It is also found that the new model delivers more accurate viscosity prediction capabilities over the existing binder aging model. The new model is then validated through data collected from multiple independent data sources. The validation results indicate that the new model provides fairly accurate predictions in both laboratory and field short-term aging. Thus, it can be concluded that the new model is a good candidate for the short-term aging prediction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Aging is a phenomenon that affects the physical properties, rheological properties as well as the chemical composition of asphalt binder when exposed to aging agents over time. Rheological testing of asphalt binder can be used to account for the effect of aging on rheological properties such as binder viscosity while the effect of aging binder chemical composition has been studied by numerous researchers using the Fourier-transform infrared spectroscopy (FTIR) method e.g., [1,2,3,4,5]. As shown in Fig. 1, the aging of asphalt binder usually takes place in two consecutive stages, namely the short-term aging that occurs during mixing, transporting, and paving operations, and the long-term aging that an asphalt mixture suffers from over the entire service life of the pavement. In general, as the binder ages, its chemical composition is altered, which further results in the change of its rheological properties. For instance, with the increase of the binder to aging, ketones of asphalt binder are formed, leading to the formation of binder components that contribute to the production of asphaltenes. Accordingly, asphalt viscosity progressively increases, which makes the binder become harder and more brittle [6,7,8].

A wide range of studies have shown that the aging of the asphalt binder contributes to the rapid deterioration of flexible pavements [9,10,11,12,13,14,15]. It adversely increases the susceptibility of asphalt pavements to cracking, raveling and moisture damage, leading the pavement to be more prone to the premature failure, which further reduces the pavement serviceability and lifetime. Thus, accurate characterization of the effects of the short-term and the long-term aging on asphalt binders is necessary for the accurate prediction of binder and mixture long-term properties (such as stiffness), evaluation of their effect on long-term performance of flexible pavements and also for the development of binder specifications. Within the scope of this study, we will only focus on the short-term aging predictions for asphalt binders. The investigation and documentation of long-term aging will be detailed in future work.

As stated previously, the short-term aging occurs primarily during mix production, in which the asphalt binder is mixed thoroughly with aggregates with hot air introduced at elevated temperatures. This production process, on one hand, facilities the oxidation between oxygen and asphalt binder due to thin asphalt binder films, on the other hand, it enables the heating to volatilize the lighter fractions (i.e. aromatic and resin) from the binder and increase the larger and stiffer fraction (i.e. asphaltene) [16, 17]. Thus, the short-term aging can be described as a combined result of rapid volatilization and oxidation. The effect of short-term aging on asphalt binder can be evaluated through laboratory testing or predicted using suitable aging model. For the laboratory testing, the Thin Film Oven (TFO) and the Rolling Thin Film Oven (RTFO) test have been identified as the routine short-term aging tests incorporated into AASHTO standard due to their capabilities of capturing the aging mechanism [18, 19]. In these two tests, the binder with a thin film is exposed to continuous heat and air flow at 163 °C for 5 h and 85 min, respectively, which expect to produce the aging effects equivalent to the average site conditions. With regard to the model predictions, the effect of short-term aging on the asphalt binder is generally quantified using a Global Aging System (GAS) [20]. The model makes use of a statistical equation to establish an empirical relationship between the unaged and the short-term aged viscosity in log–log scale, which has been implemented into the current AASHTOWare Pavement ME Design for the level-3 pavement design [21]. However, this model lacks of physical significance because it is developed based on a regression analysis. Also, implementation of this model involves the selection of a code value, which was intended to increase the model accuracy. Unfortunately, there is no explicit guidance to quantify this code value. Instead, local experience with individual asphalt types is suggested as the best solution. This significantly affects the applicability of the model for practical applications and also affects the reliability of the prediction result.

2 Motivation and objectives

It is well known that the short-term aging during mix production and laydown directly determines the starting point of the long-term field aging. Incorrect predictions of the effects of short-term aging may lead to the erroneous prediction of both the short and long-term aged binder properties and further affect the prediction of the long-term asphalt mixture properties and pavement performance [22,23,24]. This paper presents a new short-term asphalt aging predictive model for asphalt binders. The model accounts for the effect of aging on the binder rheology through the introduction and use of a parameter termed the “rheological activation energy” into the predictive equation. The binder viscosity (also called absolute viscosity) will be selected as the target property for the model development due to the following two reasons. First, the aging effect can be easily quantified through the binder viscosity. Second, the viscosity is one of the most representative viscoelastic properties for asphalt binder and has a direct relationship with key mixture properties, including modulus and other viscoelastic properties. Data collected from multiple sources will be used for the model development as well as the model validation.

This paper is organized as follows: First, the concept of rheological activation energy is briefly reviewed. Then, the development of the new short-term aging model is detailed, including data collection, determination of model coefficients, verification of model and comparison with existing binder aging predictive model. Subsequently, the model validation is presented using data extracted from multiple sources, but independent of those used for the model development. Finally, the last section summarizes the major contributions of this study.

3 Concept of rheological activation energy

The viscosity of a fluid intrinsically reflects its viscous flow characteristics. From the perspective of thermodynamics, this viscous flow can be characterized as a thermally activated rate process. A concept of rheological activation energy was put forward by Henry Eyring in 1936 to model the viscous flow at a molecular level [25]. When a viscous fluid, like an asphalt binder, starts to flow, two adjacent molecular layers will slide over each other and the intermolecular forces will cause resistance to flow. The resistance will further result in an activation energy barrier that the molecules must overcome to move to an adjacent vacant site so as to initiate the relative flow. This energy required to overcome the intermolecular resisting force is termed the rheological activation energy [25]. As the temperature increases, the intermolecular forces of the interacting molecules decreases, thus reducing the activation energy required to initiate the viscous flow. As a result, the viscosity or the resistance to flow decreases. The relationship between viscosity of the asphalt binder and temperature can be identified using the rheological activation energy [26, 27], as shown in Eq. (1):

The more general form of this equation is given as:

where \(\eta\) is the binder viscosity; \(A_{\text{r}}\), \(E_{\text{ar}}\) are the rheological kinetics, which are binder rheological pre-exponential factor and activation energy, respectively; \(R\) is the universal gas constant, 8.3145 J/K mol; \(T_{\text{R}}\) is the test temperature at which the viscosity is measured.

In previous studies [28, 29], the rheological activation energy of asphalt binders subjected to field aging conditions has been determined from laboratory testing of asphalt field cores and back-calculated modulus data of the Falling Weight Deflectometer (FWD). It was found that the rheological activation energy increases with increasing field aging time. Other researchers also selected the rheological activation energy as an index to characterize the temperature susceptibility of asphalt binder as well as to assess the performance of modified asphalt binder. Salomon and Zhai [26, 30] measured the rheological activation energy using the rotational viscometry test for various types of asphalt binders based on Eq. (2) and identified this activation energy had a range of 55–90 kJ/mol. They also found that the rheological activation energy can be utilized to effectively quantify the effect of film thickness, asphalt type, aging condition, polymer content and type on the temperature susceptibility of asphalt binders. Haider et al. [31] reported the rheological activation energy measured from the conventional tests and the dynamic shear rheometer tests for twenty two neat and modified asphalt binders ranged from 100 to 150 kJ/mol. The measured rheological activation energy was also found to correlate reasonably well with the binder rheological properties (e.g., \({{G^{*} } \mathord{\left/ {\vphantom {{G^{*} } {\left( {\sin \delta } \right)}}} \right. \kern-0pt} {\left( {\sin \delta } \right)}}\) and \(G^{*} \sin \delta\)). An aged asphalt binder was also observed to have a higher activation energy that the original binder. Jamshidi et al. [27] utilized the rheological activation energy to interpret the physical phase of different types of recovered binder blend as a function of the temperature and found more activation energy was needed by the recovered asphalt binder than the virgin binder to cause the viscous flow. Hasan et al. [32] used the rheological activation energy to evaluate the effects of foaming agents on the viscosity of the foamed asphalt binder and found that the addition of foaming agents to an asphalt binder lowers the activation energy of the foamed asphalt binder and thus increases its workability. The above studies indicate that the rheological activation energy is a reliable parameter that can be used to characterize the change in the asphalt binder viscosity due to the varying conditions that affects the binder properties such as binder modification and aging.

For an asphalt binder subjected to short-term aging, the volatilization and oxidation increase the concentration of the polar molecules and therefore strengthen the intermolecular forces. These stronger interactions within the asphalt binder will further lead to a higher resistance to flow and thus a higher rheological activation energy. Several studied have shown that after short-term aging, the asphalt binder has a rheological activation energy at least 5 kJ/mol higher than the original binder [26, 27, 31]. All these results imply that the increase in viscosity due to the short-term aging might be characterized through the change of rheological activation energy. The concept of the rheological activation energy will be used for the development of the short-term aging model in this paper.

4 Development of short-term aging model based on rheological activation energy

4.1 Formulation of short-term aging model

As mentioned previously, short-term aging of asphalt binders refers to the age hardening that occurs during mix production, transportation and paving. This age hardening is a combined result of volatilization and chemical composition change of the asphalt binder due to exposure to high temperature and oxidation. The chemical composition of the asphalt binder as well as the temperature are two major factors contributing to the short-term aging of asphalt binders [15, 20, 33, 34]. Since the mechanism of the short-term aging is relatively unique compared to that of the long-term aging, the short-term aged viscosity can be represented as a sum of unaged viscosity and a hardening increment in the natural logarithm form [35,36,37]:

where \(\eta_{t = 0}\) is the short-term aged binder viscosity; \(\eta_{i}\) is the unaged binder viscosity; \(\Delta \ln \eta_{\text{s}}\) is the hardening increment due to short-term aging; subscript “s” stands for short-term aging.

This hardening increment is in principle due to increase intermolecular forces at the molecular scale which consequently results in an increased activation energy barrier. This implies that the hardening increment in Eq. (3) can be represented as a function of increasing binder rheological activation energy. The hardening increment can be therefore expressed as:

where \(\Delta A_{\text{rs}} ,\Delta E_{\text{ars}}\) are the rheological pre-exponential factor and activation energy of hardening increment, respectively.

To further establish the relationship between unaged and short-term aged viscosity, it is assumed that the rheological activation energy of the hardening increment has a linear relationship with that of the unaged binder, as given by:

where \(k_{\text{s}} ,t_{\text{s}}\) are constants; \(E_{{{\text{ar}}\left( i \right)}}\) is the rheological activation energy of unaged asphalt binder.

For an unaged asphalt binder, the results of its rheological kinetics indicate that the unaged rheological pre-exponential factor (\(\ln A_{{{\text{r}}\left( i \right)}}\)) is linearly related to unaged rheological activation energy (\(E_{{{\text{ar}}\left( i \right)}}\)). This linear relationship is demonstrated by Fig. 3 of this paper, in which the R2 value of the linear fit is as high as 0.9927. Thus, it can be inferred that \(\ln \left( {\Delta A_{\text{rs}} } \right)\) and \(\Delta E_{\text{ars}}\) also have the following linear relationship due to an analogous mathematical nature:

where \(m_{\text{s}} ,n_{\text{s}}\) are constants; \(\ln A_{{{\text{r}}\left( i \right)}}\) is the rheological pre-exponential factor of unaged asphalt binder.

By inserting Eq. (5) into Eq. (6), one can obtain:

in which \(a_{\text{s}} = m_{\text{s}} k_{\text{s}}\); \(b_{\text{s}} = m_{\text{s}} t_{\text{s}} + n_{\text{s}}\).

Where \(a_{s} ,b_{s}\) are constants.

Substituting Eqs. (4), (5) and (7) into Eq. (3) yields:

Equation (8) is the final expression for the short-term aging model presented and evaluated in this paper. It can be observed that for the sake of predicting the short-term aged viscosity, this model requires two inputs, i.e. viscosity and rheological activation energy of the unaged asphalt binder. Four global model coefficients (i.e. \(a_{\text{s}} ,b_{\text{s}} ,k_{\text{s}} ,t_{\text{s}}\)) also need to be determined, which will be detailed in the following sections.

4.2 Data collected from the long-term pavement performance (LTPP) database

In this study, data used for the global model coefficient determination were collected from the long-term pavement performance (LTPP) database. This database contains creditable laboratory-measured data sources covering penetration at 25 °C, kinematic viscosity at 135 °C, and absolute viscosity at 60 °C for various types of binder from different manufacturers in both unaged and laboratory short-term (RTFO or TFO) aged conditions. Among them, the penetration and the kinematic viscosity can be converted to the absolute viscosity at the corresponding temperature. The conversion will be described in the next section. All the measured and converted absolute viscosities will facilitate the rheological activation energy calculation as well as the global model coefficients determination. Depending on data availability, a total number of 208 pavement sections from the United States and Canada were selected. Considering each section may have multiple pavement layers, 446 qualifying viscosity data records were finally collected from the LTPP database for the model development. More detailed information about data collection is presented in “Appendix”.

4.3 Calculation of rheological activation energy

It should be mentioned that prior to the determination of the four global model coefficients, the rheological activation energy of each unaged asphalt binder \(E_{{{\text{ar}}\left( i \right)}}\) has to be calculated. A straightforward way to determine this parameter is linearly plotting \(\ln \eta_{i}\) versus \({1 \mathord{\left/ {\vphantom {1 {RT_{\text{R}} }}} \right. \kern-0pt} {RT_{\text{R}} }}\) based on Eq. (2) and then \(E_{{{\text{ar}}\left( i \right)}}\) can be obtained from the slope of the fitting line. Constructing such a fitting line requires the viscosity values at least three different temperatures for the unaged asphalt binder, which can be obtained through either of the following two approaches depending on the availability of the known binder conventional properties:

Approach 1 The conventional properties of the unaged asphalt binder, including for example penetration, kinematic viscosity at 135 °C, and absolute viscosity at 60 °C, as well as viscosity at other temperatures, as available. For instance, Eqs. (9)–(10) are used to separately convert the penetration value and the kinematic viscosity to the absolute viscosity at the corresponding temperature. It is to be noted that the softening point can also be converted to the dynamic viscosity through Eq. (11) [20]. However, this kind of conversion has a relatively high variation, which has been identified in the previous statistical analysis [20]. Thus, to avoid introducing any significant conversion-associated error, the softening point will not be converted to the viscosity in this study.

Approach 2 The conventional properties are unavailable but the Viscosity Temperature Susceptibility parameters (i.e. “A-VTS” values) are known for the unaged asphalt binder. For this case, the unaged viscosity at different temperatures can be computed using Eq. (12) [38]:

$$\log \eta_{{\left( {T_{\text{R}} = 25\,^\circ {\text{C}}} \right)}} = 1050.12 - 226.01\log \left[ {{\text{PEN}}_{{\left( {T_{\text{R}} = 25\,^\circ {\text{C}}} \right)}} } \right] + 0.389\left\{ {\log \left[ {{\text{PEN}}_{{\left( {T_{\text{R}} = 25\,^\circ {\text{C}}} \right)}} } \right]} \right\}^{2}$$(9)$$\eta_{{\left( {T_{\text{R}} = 135\,^\circ {\text{C}}} \right)}} = \nu * \rho_{{\left( {T_{\text{R}} = 135\,^\circ {\text{C}}} \right)}}$$(10)$$\eta_{{\left( {T_{\text{R}} = {\text{R}}\& {\text{BT}}} \right)}} = 1300000$$(11)$$\log - \log \eta = A + {\text{VTS}}\log T_{\text{R}}$$(12)where \(\eta_{{\left( {T_{\text{R}} = 25\,^\circ {\text{C}}} \right)}} , \, \eta_{{\left( {T_{\text{R}} = {\text{R}}\& {\text{BT}}} \right)}} , \, \eta_{{\left( {T_{\text{R}} = 135\,^\circ {\text{C}}} \right)}}\) are the viscosity at 25 °C, softening point, and 135 °C, respectively, in centipoise; \({\text{PEN}}_{{\left( {T_{\text{R}} = 25\,^\circ {\text{C}}} \right)}}\) is the penetration number at 25 °C, in tenths of a millimeter; \({\text{R}}\& {\text{BT}}\) is the softening point, in Fahrenheit; \(\nu\) is the kinematic viscosity, in cSt; \(\rho_{{\left( {T_{\text{R}} = 135\,^\circ {\text{C}}} \right)}}\) is the density of asphalt binder at 135 °C, in g/cm3; \(A,{\text{ VTS}}\) are the A and VTS values of asphalt binder, respectively.

Based on the viscosities determined at different temperatures, a linear plot of \(\ln \eta_{i}\) against \({1 \mathord{\left/ {\vphantom {1 {RT_{\text{R}} }}} \right. \kern-0pt} {RT_{\text{R}} }}\) can be generated, from which the rheological kinetics of the asphalt binder (i.e. \(A_{\text{r}}\), \(E_{\text{ar}}\)) can be easily obtained. Figure 2 presents two examples of such a plot of rheological kinetics for two representative LTPP sections used in this study. Once the rheological kinetics of all the sections are obtained, they are plotted against each other in Fig. 3. It is obvious that \(\ln A_{{{\text{r}}\left( i \right)}}\) is linearly related to \(E_{{{\text{ar}}\left( i \right)}}\) with R2 higher than 0.98. It can also be observed from Fig. 3 that for most of the selected pavement sections, the rheological activation energy of the unaged asphalt binder ranges from 80 to 200 kJ/mol, which is in good agreement with that reported in literature [27, 31].

4.4 Determination of global model coefficients

With the completion of data collection and rheological activation energy calculation, the next step is to determine the global model coefficients, which consists of the two major steps:

Step 1 For both unaged and RTFO (or TFO) aged asphalt binders, convert the penetration at 25 °C and the kinematic viscosity at 135 °C to the absolute viscosity using Eqs. (9) and (10), respectively, then obtain the measured viscosities at three different temperatures (i.e. 25 °C, 60 °C, and 135 °C) for all the pavement sections used.

Step 2 Substitute the measured unaged viscosity along with the calculated unaged rheological activation energy into Eq. (8), and then adopt the least-squares regression method to best-fit the measured RTFO (or TFO) aged viscosities to determine the four global model parameters. With the determined model parameters, the short-term aged viscosity for each section can be then predicted.

The determined global model coefficients are listed in Table 1, while the model fitting results are summarized in Fig. 4. To gain a better visual comparison, Fig. 4 also presents the fitting results for the three different groups of data points which correspond to different temperatures (i.e. 25 °C, 60 °C, and 135 °C). In order to evaluate the goodness of model fit, a statistical analysis was performed to calculate the coefficient of determination (R2) and the standard error of predicted values divided by the standard deviation of measured values (Se/Sy).They are defined by Eqs. (13) and (14), respectively. Statistically, a larger value of R2 and a smaller value of Se/Sy indicate a higher accuracy of the predictive model.

where \(x\) is the measured short-term aged viscosity, which is obtained from Step 1; \(y\) is the predicted short-term aged viscosity, which is determined from Step 2; \(\bar{x}\) is the mean value of measured short-term aged viscosity; \(n\) is the size of the sample; \(p\) is the number of regression.

It can be observed from Fig. 4 that the results from the new short-term aging model show a relatively high degree of precision and accuracy without a notable bias. The R2 value of this model reaches up to 0.9479, while the Se/Sy value is as low as 0.2283.

4.5 Model verification and comparison with existing model

In order to evaluate the predictive capabilities of the new model, viscosity predictions obtained using the proposed model is compared with those obtained using the GAS model. The same dataset used for the proposed model development was applied to the GAS model for the prediction of short-term aged viscosity. The core equation in the GAS model is given as [20]:

in which \(a_{0} = 0.054405 + 0.004082 \times {\text{code}}\); and \(a_{1} = 0.972035 + 0.010886 \times {\text{code}}\).

Where \(a_{0} ,a_{1}\) are model parameters; \({\text{code}}\) is the hardening resistance value.

The predicted versus measured viscosities from the GAS model at three temperatures (i.e. 25 °C, 60 °C, and 135 °C) are plotted alongside with the predicted viscosity using the proposed model, as shown in Online Resource 1. Values of \(R^{2}\) and \({{S_{\text{e}} } \mathord{\left/ {\vphantom {{S_{\text{e}} } {S_{\text{y}} }}} \right. \kern-0pt} {S_{\text{y}} }}\) of the GAS model are then calculated using Eqs. (13)–(14), which are also compared with those obtained from the proposed model. The comparison results are summarized in Table 2. Visually, data points of the proposed model lie on or around the equality line for all the three data sets. However, significant deviations can be observed from the GAS model. Based on the data point distribution patterns exhibited in Online Resource 1, it can be inferred that in most cases, the GAS model under predicts the short-term aged viscosity at intermediate temperature (25 °C) while it over predicts it at high temperature (135 °C). The statistical analysis results listed in Table 2 also show that new model delivers more accurate viscosity prediction capabilities evident in the resulting higher values of \(R^{2}\) as well as lower values of \({{S_{\text{e}} } \mathord{\left/ {\vphantom {{S_{\text{e}} } {S_{\text{y}} }}} \right. \kern-0pt} {S_{\text{y}} }}\).

5 Model validation

The validation of the proposed short-term aging model involves examining the model applicability in two aspects: (1) predicting the viscosity of laboratory short-term aged binder using the data collected from multiple data sources; and (2) predicting the viscosity of field short-term aged binder extracted from the instance of pavement laydown.

First, a number of 36 viscosity data records containing conventional binder properties at various temperatures for both the unaged and laboratory short-term (RTFO or TFO) aged asphalt binder (16 different types of asphalt binder) were collected from four independent literature sources, as summarized in Table 3. The short-term aged viscosity for each data record is then predicted through the proposed short-term aging model and plotted against the corresponding measured viscosity, as shown in Fig. 5. It can be observed that the predicted viscosity is in a relatively good agreement with the measured one and the R2 value of the model fitting is 0.8475, while the Se/Sy is 0.3906. Considering that the experimental errors inherently exist in the measurements of the various conventional binder properties, these fitting results are reasonably acceptable. Thus, it can be concluded that the new model suffices to provide the satisfactory accuracy for the laboratory short-term aging prediction.

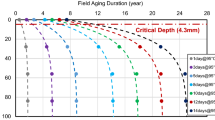

To further validate the applicability of the new model, a new set of data was collected from the SHRP-A-314 Report [43]. The advantage of this report is that it contains high quality conventional binder properties information for binders that are extracted at the time of pavement mix/laydown. A total of 164 viscosity data records from 65 different pavement sections were collected from this report for the model validation. Figure 6 shows the result of the model validation for field short-term aged binders. It can be seen from Fig. 6 that the model delivers acceptable results with all the data points located around the equality line without any significant bias in predictions. The \(R^{2}\) values of the predictions at three different temperatures are greater than 0.80, while \({{S_{\text{e}} } \mathord{\left/ {\vphantom {{S_{\text{e}} } {S_{\text{y}} }}} \right. \kern-0pt} {S_{\text{y}} }}\) values are relatively small (the largest one is only 0.4228). The result shows that the new model gives a fairly good prediction of the short-term aged viscosity subjected to the field mix/laydown condition.

6 Conclusions

This paper presents a new short-term aging model for asphalt binders. The rheological activation energy is incorporated into the new model to capture the physical mechanism of the short-term aging from the perspective of intermolecular interactions. It is found that when an asphalt binder is subjected to the short-term aging, its rheological activation energy increases to a certain amount which is linearly proportional to that of the unaged asphalt binder. The new short-term aging model contains four model coefficients and two essential binder specific inputs (i.e. viscosity and rheological activation energy of the unaged asphalt binder). The rheological activation energy can be calculated from the conventional properties of asphalt binders like penetration, kinematic viscosity, and absolute viscosity measured at various temperatures or from the known Viscosity Temperature Susceptibility parameters (i.e. “A-VTS” values) of unaged asphalt binders. A large data set is collected from the long-term pavement performance (LTPP) database to determine the four global model coefficients, which includes 446 viscosity data records collected from the 208 pavement sections over the United State and Canada. Compared to the existing short-term aging predictive model (i.e. GAS model), the new aging model delivers more accurate viscosity prediction capabilities with higher values of \(R^{2}\) as well as lower values of \({{S_{\text{e}} } \mathord{\left/ {\vphantom {{S_{\text{e}} } {S_{\text{y}} }}} \right. \kern-0pt} {S_{\text{y}} }}\). Viscosity data records collected from multiple independent data sources also validate that this new model has capability to provide fairly accurate predictions in both laboratory and field short-term aging.

The model developed in this study is based on the viscosity data collected at intermediate (25 °C) and high (60 °C and 135 °C) temperatures, which lack of the low temperature viscosity data. Considering that aging increases the brittleness and stiffness of asphalt binders, it would further result in an increased probability of the occurrence of low temperature cracking of asphalt mixtures. Thus, in a continued study, more viscosity data (especially the low temperature viscosity data) will be collected to further validate the proposed model at the full range of temperature.

Change history

06 July 2020

The article "A new short-term aging model for asphalt binders based on rheological activation energy", written by "Derun Zhang, Bjorn Birgisson, Xue Luo, Ibrahim Onifade", was originally published electronically on the publisher���s Internet portal (currently SpringerLink) on 24 June 2019 without open access.

References

Petersen JC (1984) Chemical composition of asphalt as related to asphalt durability: state of the art. Transp Res Rec 999:13–30

Lu X, Isacsson U (2002) Effect of ageing on bitumen chemistry and rheology. Constr Build Mater 16:15–22

Das PK, Kringos N, Birgisson B (2014) Microscale investigation of thin film surface ageing of bitumen. J Microsc 254(2):95–107

Hofko B, Alavi MZ, Grothe H, Jones D, Harvey J (2017) Repeatability and sensitivity of FTIR ATR spectral analysis methods for bituminous binders. Mater Struct 50:187. https://doi.org/10.1617/s11527-017-1059-x

Hofko B, Porot L, Falchetto AC et al (2018) FTIR spectral analysis of bituminous binders: reproducibility and impact of ageing temperature. Mater Struct 51:45. https://doi.org/10.1617/s11527-018-1170-7

Petersen JC (1993) Asphalt oxidation—an overview including a new model for oxidation proposing that physicochemical factors dominate the oxidation kinetics. Fuel Sci Technol Int 11(1):57–87

Petersen JC, Glaser R (2011) Asphalt oxidation mechanisms and the role of oxidation products on age hardening revisited. Road Mater Pavement Des 12(4):795–819

Sirin O, Paul DK, Kassen E (2018) State of the art study on aging of asphalt mixtures and use of antioxidant additives. Adv Civ Eng 2018:1–18

Woo WJ, Chowdhury A, Glover CJ (2008) Field aging of unmodified asphalt binder in three Texas long-term performance pavements. J Transp Res Rec 2051:15–22

Glover CJ, Liu GL, Rose AA et al (2014) Evaluation of binder aging and its influence in aging of hot mix asphalt concrete: technical report. Research Report No. FHWA/TX-14/0-6613-1, Texas Transportation Institute, The Texas A&M University System, College Station, Texas, USA

Luo X, Gu F, Ling M et al (2018) Review of mechanistic-empirical modeling of top-down cracking in asphalt pavements. Constr Build Mater 191:1053–1070

Hofko B, Handle F, Eberhardsteiner L et al (2015) Alternative approach toward the aging of asphalt binder. J Transp Res Board 2505:24–31. https://doi.org/10.3141/2505-04

Frigio F, Raschia S, Steiner D, Hofko B, Canestrari F (2016) Aging effects on recycled WMA porous asphalt mixtures. Constr Build Mater 123:712–718

Zhang J, Simate GS, Hu X et al (2017) Impact of recycled asphalt materials on asphalt binder properties and rutting and cracking performance of plant-produced mixtures. Constr Build Mater 155:654–663

Hofko B, Falchetto AC, Grenfell J et al (2017) Effect of short-term ageing temperature on bitumen properties. Road Mater Pavement Des 18(S2):108–117. https://doi.org/10.1080/14680629.2017.1304268

Lolly R (2013) Evaluation of short term aging effect of hot mix asphalt due to elevated temperature and extended aging time. Thesis, Arizona State University, Tempe, Arizona, USA

Miró R, Martínez AH, Navarro FM et al (2015) Effect of ageing and temperature on the fatigue behavior of bitumens. Mater Des 86:129–137

AASHTO (2009) Effect of heat and air on asphalt materials (thin-film oven test). AASHTO T 179-05, Washington

AASHTO (2013) Effect of heat and air on a moving film of asphalt binder (rolling thin-film oven test). AASHTO T 240-13, Washington

Mirza MW, Witczak MW (1996) Development of a global aging system for short and long term aging of asphalt cements. J Assoc Asphalt Paving Technol 64:393–430

ARA Inc. (2004) Guide for mechanistic-empirical design of new and rehabilitated pavement structure, part 2: design Inputs, Chapter 2. Material Characterization, Draft Final Report 1-37A, National Cooperative Highway Research Program, Transportation Research Board, Washington, D.C

Dinegdae YH, Onifade I, Jelagin D et al (2015) Mechanics-based top-down fatigue cracking initiation prediction framework for asphalt pavements. Road Mater Pavement Des 16(4):907–927

Onifade I, Dinegdae YH, Birgisson B (2017) Hierarchical approach for fatigue cracking performance evaluation in asphalt pavements. Front Struct Civ Eng 11(3):257–269

Dinegdae YH, Birgisson B (2018) Effects of truck traffic on top-down fatigue cracking performance of flexible pavements using a new mechanics-based analysis framework. Road Mater Pavement Des 19(1):182–200

Eyring H (1936) Viscosity, plasticity, and diffusion as examples of absolute reaction rates. J Chem Phys 4:283–291

Salomon D, Zhai H (2002) Ranking asphalt binders by activation energy for flow. J Appl Asphalt Binder Technol 2(2):1–9

Jamshidi A, Hamzah MO, Shahadan Z et al (2014) Evaluation of the rheological properties and activation energy of virgin and recovered asphalt binder blends. J Mater Civ Eng 27(3):04014135. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001024

Luo X, Gu F, Lytton RL (2015) Prediction of field aging gradient in asphalt pavements. J Transp Res Board 2507:19–28

Luo X, Gu F, Lytton RL (2017) Kinetics-based aging prediction of asphalt mixtures using field deflection data. Int J Pavement Eng. https://doi.org/10.1080/10298436.2017.1293262

Salomon D, Zhai H (2004) Asphalt binder flow activation energy and its significance for compaction effort. In: Proceeding of 3rd euroasphalt and eurobitume congress, Book II, Paper 116, pp 1754–1762

Haider SW, Mirze MW, Thottempudi AK et al (2011) Characterization temperature susceptibility of asphalt binders using activation energy for flow. In: Proceeding of the transportation and development institute congress, Chicago, United States; 2011, pp 493–503

Hasan MRM, You Z, Yang X et al (2017) Quantification of physicochemical properties, activation energy, and temperature susceptibility of foamed asphalt binders. Constr Build Mater 153:557–568

Lund JW, Wilson JE (1984) Evaluation of asphalt aging in hot mix plants. J Assoc Asphalt Paving Technol 53:1–18

Gómez WDF, Rondón QH, Reyes LF (2013) A review of asphalt and asphalt mixture aging. Ingenieria e Investigacion 33(1):5–12

Glover CJ, Davison RR, Domke CH et al (2005) Development of a new method for assessing asphalt binder durability with field validation. Research Report No. FHWA/TX-05/1872-2, Texas Transportation Institute, The Texas A&M University System, College Station, Texas, USA

Glover CJ, Martin AE, Chowdhury A et al (2009) Evaluation of binder aging and its influence in aging of hot mix asphalt concrete: literature review and experimental design. Research Report No. FHWA/TX-08/0-6009-1, Texas Transportation Institute, The Texas A&M University System, College Station, Texas, USA

Glover CJ, Han R, Jin X et al (2014) Evaluation of binder aging and its influence in aging of hot mix asphalt concrete: technical report. Research Report No. FHWA/TX-14/0-6009-2, Texas Transportation Institute, The Texas A&M University System, College Station, Texas, USA

ASTM (2012) Standard practice for viscosity-temperature chart for asphalt binders. ASTM D2493, West Conshohocken

McLeod NW (1996) Relationship of paving asphalt temperature susceptibility as measured by PVN to paving asphalt specifications, asphalt paving mixture design and asphalt pavement performance. J Assoc Asphalt Paving Technol 58:410–489

Srivastava A, Rooijen RV (2000) Bitumen performance in hot and arid climates. In: Paper prepared for pavement seminar for the Middle East and North Africa region: innovative road rehabilitation and recycling technologies, new policies and practices in pavement design and execution, Amman, Jordan, October 24–26

Kumbargeri YS, Biligiri KP (2016) Understanding aging behavior of conventional asphalt binders used in India. Transp Res Procedia 17:282–290

Sirin O, Paul DK, Kassem E et al (2017) Effect of ageing on asphalt binders in the State of Qatar: a case study. Road Mater Pavement Des 18:165–184

Finn FN, Yapp MT, Coplantz JS et al (1990) Asphalt properties and relationship to pavement performance: literature review. Research Report No. TM-UCB-A-003A-90-3, ARE Inc, Scotts Valley, California, USA

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised due to a retrospective Open Access order.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix: Data collection from long-term pavement performance (LTPP) database

Appendix: Data collection from long-term pavement performance (LTPP) database

Data used in this study for the model development were collected from the long-term pavement performance (LTPP) online database, which included the following conventional properties for both the unaged and RTFO (or TFO) aged asphalt binders:

Penetration at 25 °C;

Absolute viscosity at 60 °C; and

Kinematic viscosity at 135 °C.

A number of 208 pavement sections from the United States and Canada including 446 qualifying viscosity data records were finally collected, which covered various types of asphalt binder that were used for different asphalt layers, such as AC-20/Pen 120-150/AR-1000 graded virgin asphalt binders, and modified asphalt binders using natural latex, reclaimed rubber, block copolymer, etc. as modifiers. According to the climate criterion, the collected pavement sections are classified into four different climate zones, namely the Wet No-Freeze (WNF), Wet-Freeze (WF), Dry No-Freeze (DNF), and Dry-Freeze (DF) zone. An overview of distribution of all the pavement sections selected in different climate zones is given in Fig. 7. The number of pavement sections in each climate zone is summarized in Table 4, while the raw data that are used for the model development are listed in Table 5.

Distribution of the selected pavement sections from LTPP database [11]

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Zhang, D., Birgisson, B., Luo, X. et al. A new short-term aging model for asphalt binders based on rheological activation energy. Mater Struct 52, 68 (2019). https://doi.org/10.1617/s11527-019-1364-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-019-1364-7