Abstract

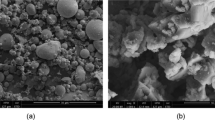

Cement based brittle matrix composites that show deflection hardening called high performance fiber reinforced cementitious composites (HPFRCC) have the potential of offering high resiliency and environmentally sustainable benefits in numerous applications. HPFRCCs have been used in numerous applications; however, more information is needed to fully understand, predict the behavior, and add functionality to HPFRCCs. This experimental research program aims to develop and characterize a new type of HPFRCC, composed of polyvinyl alcohol microfibers, carbon nanofibers (CNF), and a high volume of fly ash to form a self-sensing HPFRCC. Processing of the CNF and the HPFRCC composite matrix are studied to ensure adequate fresh mix properties and fiber dispersion. The multi-functionality of the CNFs allow for increased mechanical properties and enhanced strain and damage sensing capabilities. Digital image correlation was used extensively to capture the tensile strain and provide a visualization of the behavior of the composite under increasing displacements. CNF contents of 0.167, 0.333, 0.5, and 1.0 % were studied. Through laser diffraction analysis, sonication of CNF in a CNF/water/superplasticizer solution was found to improve particle dispersion. Mechanical testing showed that dosages of CNFs less than or equal to 0.333 % increased compressive strength, tensile strength, and stiffness. CNF had little effect on tensile ductility and toughness. Piezoresistive self-sensing strain measurement was achieved in all specimens. The addition of CNF improved the strain-sensing and allowed for stronger correlations between measured strains and correlated gauge factors. Ultimately, a CNF content of 0.333 % showed optimal results in terms of enhanced mechanical properties and self-sensing behavior for strain.

Similar content being viewed by others

References

Li VC (2004) Strategies for high performance fiber reinforced cementitious composites development. In: Proceedings of international workshop on advances in fiber reinforced concrete, Bergamo, Italy, Sept 2004, pp 93–98

Naaman AE (2007) High performance fiber reinforced cement composites: classification and applications. In: CBM-CI international workshop, NED University of Engineering and Technology, Karachi, Pakistan

Parra-Montesinos G (2005) High-performance fiber-reinforced cement composites: an alternative for seismic design of structures. ACI Struct J 102(5):668–675

Wen S, Chung D (2003) A comparative study of steel- and carbon-fibre cement as piezoresistive strain sensors. Adv Cem Res 15(3):119–128

Tyson B, Al-Rub R, Yazdanbakhsh A, Grasley Z (2011) Carbon nanotubes and carbon nanofibers for enhancing the mechanical properties of nanocomposite cementitious materials. J Mater Civ Eng 23(7):1028–1035

Metaxa ZS, Konsta-Gdoutos MS, Shah SP (2013) Carbon nanofiber cementitious composites: effect of debulking procedure on dispersion and reinforcing efficiency. Cement Concr Compos 36:25–32

Sanchez F, Zhang L, Ince C (2009) Multi-scale performance and durability of carbon nanofiber/cement composites. Nanotechnol Constr 3:345–350

Yazdanbakhsh A, Grasley Z, Tyson B, Al-Rub R (2010) Distribution of carbon nanofibers and nanotubes in cementitious composites. Transp Res Rec 2142:89–95

Khattab A, Zhang P, Shou W, Khattak M (2013) Process development and characterization of spraying carbon nanofibers over fabrics for reinforcing polymer composites. Polym Compos 35(8):1629–1635

Metaxa ZS, Konsta-Gdoutos MS, Shah SP (2010) Mechanical properties and nanostructure of cement-based materials reinforced with carbon nanofibers and polyvinyl alcohol (PVA) microfibers. ACI Spec Publ 270:115–124

Hou T-C, Lynch J (2005) Monitoring strain in engineered cementitious composites using wireless sensors. In: Proceedings of the international conference on fracture (ICF XI), Turin, Italy, 20–25 Mar

Chen P, Chung D (1993) Carbon fiber reinforced concrete as an electrical contact material for smart structures. Smart Mater Struct 2(3):181–188

Baeza F, Galao O, Zornoza E, Garcés P (2013) Multifunctional cement composites strain and damage sensors applied on reinforced concrete (RC) structural elements. Materials 6(3):841–855

Mehta K (2001) Reducing the environmental impacts of concrete. Concr Int 23(10):61–66

Şahmaran M, Li V (2010) Engineered cementitious composites: can composites be accepted as crack-free concrete? Transp Res Rec 2164:1–8

Bendapudi S, Saha P (2011) Contribution of fly ash to the properties of mortar and concrete. Int J Earth Sci Eng 4(6):1017–1023

Wang S, Li VC (2007) Engineered cementitious composites with high-volume fly ash. ACI Mater J 104(3):233–241

Zhang Z Qian S (2013) Investigating self-healing capacity of micro-cracked ECC with different volume of fly ash. In: Proceedings of the 4th international conference on self-healing materials, Ghent, Belgium, June 2013, pp 652–655

Yang EH (2007) Designing added functions in engineered cementitious composites. (Doctoral thesis, University of Michigan). Ann Arbor, Michigan

Li M, Li V (2012) Rheology, fiber dispersion, and robust properties of Engineered Cementitious Composites. Mater Struct 46(3):405–420

ASTM (2015) ASTM C39/C39M-15a standard test method for compressive strength of cylindrical concrete specimens. ASTM International, West Conshohocken

Li M, Lin V, Lynch J, Li V (2012) Multifunctional carbon black engineered cemetitious compoisites for the protection of critical infrastructure. In: Proceedings of the sixth international RILEM conference on high performance fiber reinforced cement composites, Ann Arbor, MI, June 2011, pp 99–106

Konsta-Gdoutos M, Aza C (2014) Self sensing carbon nanotube (CNT) and nanofiber (CNF) cementitious composites for real time damage assessment in smart structures. Cem Concr Compos 53:162–169

Acknowledgments

The authors would like to acknowledge the support by graduate student Wan Shou in the Composite Materials Laboratory at UL Lafayette, undergraduate student researcher Tommy Philayvanh, and Mark LeBlanc from the UL Lafayette Department of Civil Engineering for their contributions to this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hardy, D.K., Fadden, M.F., Khattak, M.J. et al. Development and characterization of self-sensing CNF HPFRCC. Mater Struct 49, 5327–5342 (2016). https://doi.org/10.1617/s11527-016-0863-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-016-0863-z