Abstract

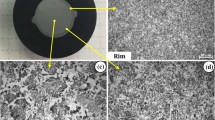

Investigations on the fatigue strength of steel reinforcement bars (rebars) mainly involves fatigue tests with hot rolled (HR) and cold worked (CW) steels. However, in the last few decades, HR and CW rebars were replaced by quenched and self-tempered (QST) rebars with hardened surface layer. There still remains a lack of research on fatigue strength of QST rebars especially in the very high cycle domain i.e., number of stress cycles surpassing 5 million. This study is part of a further detailed investigation on the fatigue behaviour of HR, CW and QST rebars in the very high cycle domain. It aims to investigate the fatigue performance of QST rebars axially tested at number of stress cycles in the range of 106–108. A preliminary study of the gripping method is followed by fatigue test results including non-destructive inspection of the rebar surface and fractographic analyses. The rebar surface is examined with liquid penetrant to reveal fatigue crack location and size in specific frequency interval monitored during the tests. Fractured surface analyses are performed by scanning electron microscopy to detect the location from where fatigue cracks initiate. Cross sectional area reduction resulting from fatigue crack propagation is also determined. Fractographic investigations are compared with the fractured surfaces of HR, CW and QST rebars from the literature.

Similar content being viewed by others

References

ASM (1992) Handbook: Fractography. ASM International, New York

ASTM (2010) Standard practice for statistical analysis of linear or linearized stress-life (s-n) and strain-life (\(\epsilon\)-n) fatigue data. E739–10 ASTM, West Conshohocken

Donnell M, Spencer W, Abel A (1986) Fatigue of tempcore reinforcing bars-the effect of galvanizing. In: Australasian conference on the mechanics of structures and materials, 10th, vol 2, Adelaide

D’Angelo L, Rocha M, Nussbaumer A, Brühwiler E (2014) S-n-p fatigue curves using maximum likelihood method for fatigue resistance curves with application to straight and welded rebars. EUROSTEEL, Naples

Economopoulos M, Respen Y, Lessel G, Steffs G (1975) Application of the tempcore process to the fabrication of high yield strength concrete-reinforcing bars. CRM Metall Rep 45:3–19

Fehlmann P (2012) Zur ermüdung von stahlbetonbrücken. PhD thesis, Diss., Eidgenössische Technische Hochschule ETH Zurich, Nr. 20231, 2012

Hanson JM, Burton KT, Hognestad E (1968) Fatigue tests of reinforcing bars-effect of deformation pattern. J PCA Res Dev Lab 10:2–13

ISO (2010) Steel for the reinforcement and prestressing of concrete-test methods-part 1: reinforcing bars, wire rod and wire. 15630-1 International Organization for Standardization, Geneva

Mallett GP (1991) Fatigue of reinforced concrete: state-of-the-art review /2. HMSO, London

Nikolaou J, Papadimitriou GD (2005) Impact toughness of reinforcing steels produced by (i) the tempcore process and (ii) microalloying with vanadium. Int J Impact Eng 31(8):1065–1080

Rehm G, Russwurm D (1977) Assessment of concrete reinforcing bars made by the tempcore process. CRM Metall Rep 51:3–16

Rocha M, Brühwiler E, Nussbaumer A (2015) Geometrical and material characterisation of quenched and self-tempered steel reinforcement bars. J Mater Civil Eng, ASCE (under review)

Schläfli M (1999) Ermüdung von brückenfahrbahnplatten aus stahlbeton. PhD thesis, EPFL

Thandavamoorthy T (1999) Static and fatigue of high-ductility bars reinforced concrete beams. J Mater Civil Eng 11(1):41–50

Tilly G (1979) Fatigue of steel reinforcement bars in concrete: a review. Fatigue Fract Eng Mater Struct 2(3):251–268

Tilly G (1984) Fatigue testing and performance of steel reinforcement bars. Mater Constr 17(1):43–49

Virmani Y, Wright W, Nelson R (1991) Fatigue testing for thermex reinforcing bars. Public Roads 55(3)

Zheng H, Abel A (1998) Stress concentration and fatigue of profiled reinforcing steels. Int J Fatigue 20(10):767–773

Zheng H, Abel AA (1999) Fatigue properties of reinforcing steel produced by tempcore process. J Mater Civil Eng 11(2):158–165

Acknowledgments

The authors are grateful to Danièle Laub from the Interdisciplinary Centre For Electron Microscopy (CIME) at EPFL for her advices and help with the sample preparation for the microscopic analyses. We are also grateful to Prof. Francesco Stellacci from the Supramolecular Nanomaterials and Interfaces Laboratory (SuNMIL) who provided the laboratory space for the preparation of the samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rocha, M., Michel, S., Brühwiler, E. et al. Very high cycle fatigue tests of quenched and self-tempered steel reinforcement bars. Mater Struct 49, 1723–1732 (2016). https://doi.org/10.1617/s11527-015-0607-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-015-0607-5