Abstract

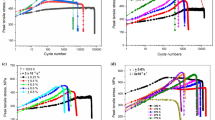

Low-cycle fatigue (LCF) behavior of a thermomechanically treated Fe 500 grade rebar has been evaluated under high-strain ranges to understand its seismic performance. The total strain-controlled LCF tests have been performed at five different strain (1.0, 2.0, 3.0, 4.0 and 5.0%) ranges at ambient temperature until failure maintaining a constant true strain rate of 1 × 10−3 s−1 and a fixed strain ratio of − 1. Fatigue data have been analyzed following strain-life relationship; while, macro- and micro-features of the failed specimens have been critically examined under SEM. Evaluation of fatigue behavior has been supplemented by microstructural characterization apart from measurements of hardness and tensile property. Continued cyclic softening has been observed till failure, and the cyclic yield strength is found to be significantly lower than the monotonic one. Cross-sectional microhardness measurements of rebar before and after fatigue reveals significant reduction in hardness specifically in the rim region with tempered martensite microstructure. The strain-life relationship accurately predicts the cyclic plastic behavior of the selected rebar which also exhibits non-Masing behavior. The fatigue crack is always found to initiate from the transverse rib root and propagates along the rim region following the rib.

Similar content being viewed by others

References

S.K. Paul, S. Majumder, S. Kundu, Low cycle fatigue behaviour of thermo mechanically treated bar. Mater. Des. 58, 402–411 (2014)

G.A. Chang, J.B. Mander, Seismic Energy Based Fatigue Damage Analysis of Bridge Columns: Part I—Evaluation of Seismic Capacity, Technical Report NCEER-94-0006, National Center for Earthquake Engineering Research, State University of New York, 1994

A. Apostolopoulos, T. Matikas, G. Kodzhaspirov, Structural integrity of steel bar under seismic loads. Mater. Phys. Mech. 25, 22–29 (2016)

F.C. Filipou, E.P. Popov, V.V. Bertero, Effect of Bond Deterioration on Hysteretic Behaviour of Reinforced Concrete Joints, Report UCB/EERC-83/19, Earthquake Engineering Research Centre, University of California, 1983

S.K. Kunnath, A. Kanvinde, Y. Xiao, G. Zhang, Effects of Buckling and Low Cycle Fatigue on Seismic Performance of Reinforcing Bars and Mechanical Couplers for Critical Structural Members, Technical Report, University of California, 2009

V. Goryany, V. Radsinsky, Thermomechanical treatment of reinforcing steel. J. Mining Metall. 38(3–4), 171–177 (2002)

A. Ray, D. Mukerjee, S.K. Sen, A. Bhattacharya, S.K. Dhua, M.S. Prasad, N. Banerjee, A.M. Popli, A.K. Sahu, Microstructure and properties of thermomechanically strengthened reinforcement bars: a comparative assessment of plain-carbon and low-alloy steel grades. J. Mater. Eng. Perform. 6, 335–343 (1997)

Helgason, J.M. Hanson, N.F. Somes, W.G. Corley, E. Hongestad, Fatigue Strength of High-Yield Reinforcing Bars, Transportation Research Board, National Research Council, 1976

H. Zheng, A. Abel, Stress Concentration and fatigue of profiled reinforcing steels. Int. J. Fatigue 10, 763–773 (1998)

C.A. Apostolopoulos, M.P. Papadopoulos, Tensile and low cycle fatigue behavior of corroded reinforcing steel bars S400. Constr. Build. Mater. 21(4), 855–864 (2007)

R.A. Hawileh, J.A. Abdalla, F. Oudah, K. Abdelrahman, Low-cycle fatigue life behaviour of BS 460B and BS B500B steel reinforcing bars. Fatigue Fract. Eng. Mater. Struct. 33, 397–407 (2010)

Y. Shi, M. Wang, Y. Wang, Experimental and constitutive model study of structural steel under cyclic loading. J. Constr. Steel. Res. 67(8), 1185–1197 (2011)

G.M. Sheng, S.H. Gong, Investigation of low cycle fatigue behavior of building structural steels under earthquake loading. Acta Metall. Sinica 10(1), 51–55 (1997)

G.W. Butcher, Seismic problems in structural engineering (Int. Steel Seismic Des. Semin, Christchurch, 1968)

Building Code Requirements for Structural Concrete (ACI 318-08) and Commentary (ACI318R-08), American Concrete Institute (ACI) Committee 318, Farmington Hills, Michigan, 2008

J.A. Abdalla, R.A. Hawileh, F. Oudah, K. Abdelrahman, Energy-based prediction of low cycle fatigue life of BS460B And BS500B steel bars. Mater. Des. 30, 4405–4413 (2009)

G. Jha, A.K. Singh, N. Bandyopadhyay, O.N. Mohanty, Seismic resistant reinforcing bars. Prac. Fail. Anal. 1(5), 53–56 (2001)

S.K. Paul, P.K. Rana, D. Das, S. Kundu, High and low cycle fatigue performance comparison between micro-alloyed and TMT rebar. Constr. Build. Mater. 54, 170–179 (2014)

C.A. Apostolopoulos, Mechanical behavior of corroded reinforcing steel bars S500s tempcore under low cycle fatigue. Constr. Build. Mater. 21(7), 1447–1456 (2007)

Y. Lv, G. Sheng, Z. Huang, High strain and low cycle fatigue behaviors of rebars produced by QST and V-N microalloying technology. Constr. Build. Mater. 48, 67–73 (2013)

Instron Company, 825 University Ave Norwood, MA, 02062-2643, USA, 1946

B.K. Panigrahi, S.K. Jain, Impact toughness of high strength low alloy TMT reinforcement ribbed bar. Build. Mater. Sci. 4, 319–324 (2002)

A. Modi, D.A. Hindolia, R. Sharma, Sequential improvement of quenching-selftempering-thermal-treatment rolling process for a modern manufacturing system—a case study, Int. J. Innov. Eng. Technol. 4, 100–111 (2014)

S. Kundu, A. Mukhopadhyay, S. Chatterjee, S. Chandra, Modelling of microstructure and heat transfer during controlled cooling of low carbon wire rod. ISIJ Int. 44(7), 1217–1223 (2004)

R.W. Hertzberg, Deformation and fracture mechanics of engineering materials (Wiley, New York, 1989)

J. Schijve, The stress intensity factor of small cracks at notches. Fatigue Eng. Mater. Struct. 5(1), 77–90 (1982)

J. Polak, M. Klesnil, P. Lukas, On the cyclic stress-strain curve evaluation in low cycle fatigue. Mater. Sci. Eng. 28, 109–117 (1977)

D.E. Laughlin, K. Hono, Physical Metallurgy, 5th edn. (Elsevier, Amsterdam, 2014)

B. Das, A. Singh, Understanding strain controlled low cycle fatigue response of P91 steel through experiment and cyclic plasticity modeling. Fusion Eng. Des. 138, 125–137 (2019)

H.J. Roven, E. Nes, Cyclic deformation of ferritic steel–I. Stress–strain response and structure evolution. Acta Metall. 39(8), 1719–1733 (1991)

D. Ye, S. Matsouka, N. Nagashima, N. Suzuki, The low-cycle fatigue, deformation and final fracture behaviour of an austenitic stainless steel. Mater. Sci. Eng. A 415, 104–117 (2006)

H.-F. Chai, C. Laird, Mechanisms of cyclic softening and cyclic creep in low carbon steel. Mater. Sci. Eng. 93, 159–174 (1987)

S.K. Paul, S. Sivaprasad, S. Dhar, S. Tarafder, Key issues in cyclic plastic deformation: experimentation. Mech. Mater. 43, 705–720 (2011)

A. Plumtree, H.A. Abdel-Raouf, Cyclic stress–strain response and substructure. Int. J. Fatigue 23, 799–805 (2001)

S.C. Roy, S. Goyal, R. Sandhya, S.K. Ray, Low cycle fatigue life prediction of 316 L(N) stainless steel based on cyclic elasto-plastic response. Nucl. Eng. Des. 253, 219–225 (2012)

P.V.R. Narendra, K. Prasad, E.H. Krishna, V. Kumar, K.D. Singh, Low cycle fatigue (LCF) behavior and cyclic plasticity modeling of E250A mild steel. Structures 20, 594–606 (2019)

L.F. Coffin Jr., A Study of The Effects of Cyclic Thermal Stresses on A Ductile Metal, Knolls Atomic Power Laboratory, University of Michigan, Michigan, 1953

Y. Zhang, C.L. Hu, Z. Zhao, A.P. Li, X.L. Xu, W.B. Shi, Low cycle fatigue behaviour of A Cr–Mo–V matrix-type high-speed steel used for cold forging. Mater. Des. 44, 612–621 (2013)

P.C. Chakraborti, M.K. Mitra, Microstructural response on the room temperature low cycle fatigue behaviour of two high strength duplex ferrite–martensite steels and a normalised ferrite-pearlite steel. Int. J. Fatigue 28, 194–202 (2006)

K. Parmar, H. Rathod, Comparison of A rebar with a plain surface and a deformed axis over HYSD rebars, Int. J. Eng. Res. Technol. 1(7) (2012)

S. Majumdar, R. Ali, A. Kumar, A. Deb, Optimum rib design in TMT rebars to enhance fatigue life while retaining bond strength, J. Mater. Civ. Eng. 30(3), 04017313 (2018)

J. Schijve, Fatigue of Structures and Materials (Springer, Dordrecht, 2008)

B. Das, Md. A. Bakkar, N. Khutia, D. Das, Low Cycle Fatigue Performance of TMT Rebar, in 5th International Conference on Materials Processing and Characterization, India, 2017

Acknowledgments

The authors would like to thank for the support and cooperation received from the Centre of Excellence on Microstructurally Designed Advanced Materials Development, TEQIP-II and also providing all the necessary facilities for carrying out this study. Authors would also like to acknowledge the Tata Steel, Jamshedpur, India, for supplying the material.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bakkar, M.A., Kanrar, B., Saha, R. et al. High-Strain Low-Cycle Fatigue Behavior of Thermomechanically Treated Rebar. J Fail. Anal. and Preven. 20, 1029–1037 (2020). https://doi.org/10.1007/s11668-020-00911-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00911-z