Abstract

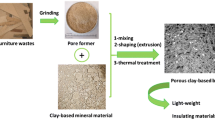

This paper shows a research for lightweight bricks development, by improving thermal properties, which has been carried out in partnership with a brick factory. The aim is to describe the thermal behavior of fired clay bricks made by spent coffee grounds in order to obtain better enclosure insulation. Organic substances combust within the matrix, during the firing process and an increased porosity is obtained. Therefore brick thermal conductivity is reduced. However, this porosity influences other parameters that determine the usability of the bricks, such as the percentage of water absorption and compressive strength, mainly. Several tests have been conducted for different percentages of waste in order to obtain bricks that meet with the regulatory requirements, settled by standards but with the minimum thermal conductivity. The results have been analyzed and related to previous researches concluding that is possible to add 17 % of waste while bricks compressive strength is above 10 N/mm2 which means they can be used for structural purposes. However bricks made by adding 17 % must be coated, therefore must not be used for facing bricks. In this case thermal conductivity is reduced up to 50 %.

Similar content being viewed by others

References

Agudelo-Vera CM, Mels AR, Keesman KJ, Rijnaarts HHM (2011) Resource management as key factor for sustainable urban planning. J Environ Manag 92:2295–2303

United Nations (2011) World population prospects: the 2010 revision. United Nations Department of economic and social affairs (DESA), New York

ESA-UN World population prospects: the 2007 revision population database. http://esa.un.org/unup

Intergovernmental Panel on Climate Change (2001) Climate change 2001: mitigation. Cambridge University Press, Cambridge

Wouter P (2004) Energy Performance of building: assessment of innovative technologies, ENPER-TEBUC, Final Report

Lakatos A, Kalmár F (2013) Investigation of thickness and density dependence of thermal conductivity of expanded polystyrene insulation materials. Materials and Structures/Materiaux et Constructions 46–7:1101–1105

Badescu V, Sicre B (2003) Renewable energy for passive house heating Part I. Building description. Energy Build 35:1077–1084

Zukowski M, Haese G (2010) Experimental and numerical investigation of a hollow brick filled with perlite insulation. Energy Build 42:1402–1408

Morales MP, Juárez MC, Muñoz P, Gómez JA (2011) Study of the geometry of a voided clay brick using non-rectangular perforations to optimise its thermal properties. Energy Build 43:2494–2498

Laustsen G (2007) Reduce–recycle–reuse: guidelines for promoting perioperative waste management. AORN J 85–4:717–728

Muñoz Velasco P, Morales Ortíz MP, Mendívil Giró MA, Muñoz Velasco L (2014) Fired clay bricks manufactured by adding wastes as sustainable construction material—a review. Constr Build Mater 63:97–107

Sutca M, Akkurt S (2009) The use of recycled paper processing residues in making porous brick with reduced thermal conductivity. Ceram Int 35:2625–2631

Kadir AA, Mahajerani A, Roddick F, Buckeridge J (2010) Density, strength, thermal conductivity and leachate characteristics of light-weight fired clay bricks incorporating cigarette butts. Int J Civil Environ Eng 2–4:179–184

El Fgaier F, Lafhaj Z, Chapisseau C (2013) Use of clay bricks incorporating treated river sediments in a demonstrative building: Case of Study. Constr Build Mater 48:160–165

Dolores La Rubia-García M et al (2012) Assesment of olive mill solid residue (pomace) as an additive in lightweight brick production. Constr Build Mater 36:495–500

Turgut P (2008) Limestone dust and glass powder wastes as new brick material. Materials and Structures/Materiaux et Constructions 41–5:805–813

ICO. International Coffee Organization. Available from: http://www.ico.org/. Accessed 13 June 2014

Limousy L et al (2013) Gaseous products and particulate matter emissions of biomass residential boiler fired with spent coffee grounds pellets. Fuel 107:323–329

Caetano NS, Silvaac VFM, Mata TM (2012) Valorization of coffee grounds for biodiesel production. Chem Eng Trans 26:267–272

Zuorro A, Lavecchia R (2012) Spent coffee grounds as a valuable source of phenolic compounds and bioenergy. J Clean Prod 34:49–56

Bilal Muhammad et al (2013) Waste biomass adsorbents for copper removal from industrial waste water—a review. J Hazard Mater 263:322–333

Azouaou N, Sadaoui Z, Djaafri A, Mokaddem H (2010) Adsorption of cadmium from aqueous solution onto untreated coffee grounds: equilibrium, kinetics and thermodynamics. J Hazard Mater 184:126–134

Plaza MG, González AS, Pevida C, Pis JJ, Rubiera F (2012) Valorisation of spent coffee grounds as CO2 adsorbents for postcombustion capture applications. Appl Energy 99:272–279

Eliche-Quesada D et al (2011) The use of different forms of waste in the manufacture of ceramic bricks. Appl Clay Sci 52:270–276

Web site of laboratory in charge of clay tests. http://www.laboratoriocarpi.com. Accessed 13 June 2013

Bok JP et al (2012) Fast pyrolysis of coffee grounds: Characteristics of product yields and biocrude oil quality. Energy 47:17–24

Qiao W et al (2013) Thermophilic anaerobic digestion of coffee grounds with and without waste activated sludge as co-substrate using a submerged AnMBR: system amendments and membrane performance. Bioresour Technol 150:249–258

Liu K, Price GW (2011) Evaluation of three composting systems for the management of spent coffee grounds. Bioresour Technol 102:7966–7974

Pujol D et al (2013) The chemical composition of exhausted coffee waste. Ind Crops Prod 50:423–429

Hachicha R et al (2012) Co-composting of spent coffee ground with olive mill wastewater sludge and poultry manure and effect of Trametes versicolor inoculation on the compost maturity. Chemosphere 88:677–682

Tokimoto T et al (2005) Removal of lead ions in drinking water by coffee grounds as vegetable biomass. J Colloid Interface Sci 281–1(1):56–61

Mussattoa SI et al (2011) A study on chemical constituents and sugars extraction from spent coffee grounds. Carbohydr Polym 83:368–374

Hirata M et al (2002) Adsorption of dyes onto carbonaceous materials produced from coffee grounds by microwave treatment. J Colloid Interface Sci 254:17–22

Fasfous II, Rehan SE, Dawoud JN (2012) Simultaneous pre-concentration of oxyfluorfen and chlorpyrifos in environmental water samples using spent coffee grounds as SPE sorbents. Jordan J Chem 7–2:203–220

Demir I (2008) Effect of organic residues addition on the technological properties of clay bricks. Waste Manag 28:622–627

Muñoz P, Juárez MC, Morales MP, Mendívil MA (2013) Improving the thermal transmittance of single-brick walls built of clay bricks lightened with paper pulp. Energy Build 59:171–180

EN 772-16:2011. Methods of test for masonry units—part 16: Determination of dimensions

EN 772-20:2000/A1:2005. Methods of test for masonry units—Part 20: Determination of flatness of faces of masonry units

UNE-EN 12667:2002 Thermal performance of building materials and products. Determination of thermal resistance by means of guarded hot plate and heat flow meter methods. Products of high and medium thermal resistance

EN 12664-2001. Thermal performance of building materials and products. Determination of thermal resistance by means of guarded hot plate and heat flow meter methods. Dry and moist products of medium and low thermal resistance

EN 771-1:2011. Specification for masonry units—part 1: clay masonry units

EN 1745:2002. Masonry and masonry products—methods for determining design thermal values

EN ISO 7500-1:2004/AC:2009 Metallic materials—verification of static uniaxial testing machines—part 1: tension/compression testing machines—verification and calibration of the force-measuring system

UNE 67-026 (2002). Methods of test for mansory units. Part 1. Determination of compressive strength

Eliche-Quesada D, Corpas-Iglesias FA, Pérez-Villarejo L, Iglesias-Godino FJ (2012) Recycling of sawdust, spent earth from oil filtration, compost and marble residues for brick manufacturing. Constr Build Mater 34:275–284

Chemani B, Chemani H (2012) Effect of adding sawdust on mechanical-Physical properties of ceramic bricks to obtain lightweight building material. World Acad Sci Eng Technol 71:11–23

Chiang KY et al (2009) Lightweight bricks manufactured from water treatment sludge and rice husks. J Hazard Mater 171:76–82

Demir I, Serhat Baspinar M, Orhan M (2005) Utilization of kraft pulp production residues in clay brick production. Build Environ 40:1533–1537

Demir I (2006) An investigaton on the production of construction brick with processed waste tea. Build Environ 41:1274–1278

Andrad FA, Al-Qureshi HA, Hotza D (2011) Measuring the plasticity of clays: a review. Appl Clay Sci 51:1–7

Haigh SK, Vardanega PJ (2014) Fundamental basis of single-point liquid limit measurement approaches. Appl Clay Sci 102:8–14

Martínez-García C, Eliche-Quesada D, Pérez-Villarejo L, Iglesias-Godino FJ, Corpas-Iglesias FA (2012) Sludge valorization from wastewater treatment plant to its application on the ceramic industry. J Environ Manag 95:343–348

ASTM C62-10 Standard specification for building brick (Solid Masonry Units Made From Clay or Shale)

Código Técnico de la Edificación. Documento Básico de Seguridad Estructural. CTE. DB-SE-F

Lakatos A, Csáky I, Kalmár F. Thermal conductivity measurements with different methods: a procedure for the estimation of the retardation time. Mater Struct. DOI 10.1617/s11527-013-0238-7 (in press)

García-Ten J, Orts MJ, Saburit A, Silva G (2010) Thermal conductivity of traditional ceramics. Part II: influence of mineralogical composition. Ceram Int 36:2017–2024

Acknowledgments

We would like to specially acknowledge the participation in this research of the Herederos Ceramica Sampedro S.A., that has granted the use of their facilities as well as specialized staff that has made the realization of this I+D+I project possible.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Muñoz Velasco, P., Mendívil, M.A., Morales, M.P. et al. Eco-fired clay bricks made by adding spent coffee grounds: a sustainable way to improve buildings insulation. Mater Struct 49, 641–650 (2016). https://doi.org/10.1617/s11527-015-0525-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-015-0525-6