Abstract

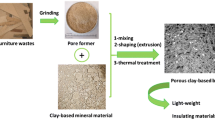

The development of agricultural waste–doped fired bricks is an important step toward achieving lightweight eco-efficient bricks with improved thermal insulation property. Recent research in masonry has been tailored towards the production of energy-efficient building by incorporating waste materials as additives. This effectuates a safe waste disposal, cost effectiveness, and also serve as a giant stride towards environmental sustainability. This study examines the viability of using walnut shell as additive in fired clay at various firing temperatures. Pulverized walnut shell was added to clay at a proportion of 0–10 wt.% by weight of clay. The samples were fired at temperatures of 950 °C and 1100 °C. The samples were probed for mechanical properties and durability. Morphology of the brick samples were examined under scanning electron microscope. The result of the research showed increased water absorption and specific heat capacity while mechanical and bulk density were observed to reduce. Linear shrinkage and thermal conductivity reduced with increase in walnut content of which linear shrinkage and thermal conductivity values experienced at 1100 °C was higher than at 950 °C. Resistance of bricks to salt crystallization increased with firing temperature. All samples met various standard requirement for masonry except sample prepared with 10 wt.% walnut shell whose compressive and flexural strengths fell below the required standard. The study established the use of walnut shell for development of sustainable energy-efficient bricks.

Similar content being viewed by others

Data availability

All data employed in support to the outcomes in the study are included in this article.

References

Abdeen H, Shihada S (2017) Properties of fired clay bricks mixed with waste glass. J Sci Res Rep 13(4):1–9. https://doi.org/10.9734/jsrr/2017/32174

Abdulwahid MY, Abdullah SF (2020) The utilization of walnut shells as a partial replacement of sand in mortar mixes. Struct Concr 22(S1). https://doi.org/10.1002/suco.202000108.

Adazabra AN, Viruthagiri G, Kannan P (2017) Influence of spent shea waste addition on the technological properties of fired clay bricks. J Build Eng 11:166–177. https://doi.org/10.1016/j.jobe.2017.04.006

Adediran AA, Balogun OA, Akinwande AA, Adesina OS, Olasoju OS (2020) Influence of chemical treatment on the properties of cement-paper hybrid composites for ceiling board application. Heliyon 6(7):e04512. https://doi.org/10.1016/j.heliyon.2020.e04512

Aeslina AK, Noor AS (2012) An overview of wastes recycling in fired clay bricks. Int J Integr Eng 4(2):53–69

Agayi CO, Karakayaci Ö (2020) The role of changing housing policies in housing affordability and accessibility in developing countries: the case of Kenya. J Contemp Urban Aff (JCUA) 4(2):49–58. https://doi.org/10.25034/ijcua.2020.v4n2-5

Aiken TA, Russell M, McPolin D, Gavin B, Nugent L, Bagnall L (2022) Effect of molar ratios and curing conditions on the moisture resistance of magnesium oxychloride cement. J Mater Civ Eng 34(2):04021426

Akanni PO, Oke AE, Omotilewa OJ (2014) Implications of rising cost of building materials in Lagos State Nigeria. SAGE Open 4(4):215824401456121. https://doi.org/10.1177/2158244014561213

Akinsipe O, Kornelius G (2017) Chemical and thermodynamic processes in clay brick firing technologies and associated atmospheric emissions metrics-a review. J Pollut Eff Control 05(02):1–12. https://doi.org/10.4176/2375-4397.1000190

Akinwande A, Adediran A, Balogun O, Bello O, Barnabas A, Balogun P, Adesina O (2020) Evaluation of the influence of waste glass powder (WGP) on the thermo-mechanical performance of fired ceramics. Acta Metallurgica Slovaca 26(3):84–94. https://doi.org/10.36547/ams.26.3.605

Aouba L, Bories C, Coutand M, Perrin B, Lemercier H (2016) Properties of fired clay bricks with incorporated biomasses: cases of olive stone flour and wheat straw residues. Constr Build Mater 102:7–13. https://doi.org/10.1016/j.conbuildmat.2015.10.040

ASTM 293/C293M (2016) Standard test methods for flexural strength of masonry bricks (using simple beam with centre-point loading), ASTM International, West Conshohocken, PA. www.astm.org.

ASTM C 1314–18 (2018) Standard test methods for compressive strength of masonry prisms, ASTM International. West Conshohocken, PA. www.astm.org.

ASTM C326–09 (2014) Standard test method for drying and firing shrinkage of ceramic whiteware clays, ASTM International. West Conshohocken, PA.www.astm.org.

ASTM C373–88 (2006) Standard test method for water absorption, bulk density, apparent porosity and apparent specific gravity of fired white ware products, ASTM International. West Conshohocken, PA. www.astm.org.

ASTM C62–07 (2017) Standard specification for building brick (solid masonry units made from clay or shale). ASTM International. West Conshohocken, PA. www.astm.org.

ASTM C67–07 (2007) Standard test method for sampling and testing bricks and structural clay tile. ASTM International. West Conshohocken, PA. www.astm.org.

ASTM C90–16a (2017) Standard specification for load bearing concrete masonry unit, ASTM International. West Conshohocken, PA. www.astm.org.

ASTM D4318–17e1 (2017) Standard test method for liquid limit, plastic limit and plastic index of soils. ASTM International. West Conshohocken, PA.www.astm.org.

ASTM D6913/D6913M – 17 (2017) Standard test methods for particle size distribution (radiation) of soils using sieve analysis, ASTM International. West Conshohocken, PA. www.astm.org.

ASTM E1225–13(2013) Standard test method for thermal conductivity of solids using guarded-comparative –longitudinal heat flow technique, ASTM International, West Conshohocken, PA. www.astm.org.

ASTM E1269–11 (2018) Standard test method for determining specific heat capacity by differential scanning calorimetry, ASTM International, West Conshohocken, PA. www.astm.org.

Bakhsh EM, Khan SB, Akhtar K, Danish EY, Fagieh TM, Qiu C, Sun Y, Romanovski V, Su X (2022) Simultaneous preparation of humic acid and mesoporous silica from municipal sludge and their adsorption properties for U(VI). Colloids Surf, A 647:129060. https://doi.org/10.1016/j.colsurfa.2022.129060

Balogun OA, Akinwande AA, Adediran AA, Ikubanni PP, Shittu SA, Adesina OS (2021) Experimental study on the properties of fired sand–clay ceramic products for masonry applications. J Mater Civ Eng 33(2):04020445. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003532

Barbieri L, Andreola F, Lancellotti L (2013) Taurino R (2013) Preliminary study on characterization and valorisation in clay matrix bricks. Waste Manage 33(11):2307–2315. https://doi.org/10.1016/j.wasman.2013.03.014

Benlalla A, Elmoussaouiti M, Dahhou M, Assafi M (2015) Utilization of water treatment plant sludge in structural ceramics bricks. Appl Clay Sci 118:171–177. https://doi.org/10.1016/j.clay.2015.09.012

Biopowders (2021) https://www.bio-powder.com/en/walnut-shell, Retrieved 28–02–2021.

BIS (Bureau of Indian Standards) (1970) Specification for coarse and fine aggregates from natural sources for concrete. BIS 383. New Delhi, India: BIS.

BIS (Bureau of Indian Standards) (1980) Method of test for soil. BIS 2720 Part 3. New Delhi, India: BIS.

Bories C, Borredon M-E, Vedrenne E, Vilarem G (2014) Development of eco-friendly porous fired clay bricks using pore-forming agents: a review. J Environ Manage 143:186–196. https://doi.org/10.1016/j.jenvman.2014.05.006

Bruno AW, Gallipoli D, Perlot C, Kallel H (2020) Thermal performance of fired and unfired earth bricks walls. J Build Eng 28:101017. https://doi.org/10.1016/j.jobe.2019.101017

BSI (British Standard Institution) (1990) Methods of test for soils for civil engineering purpose. Chemical and electrochemical testing. BSI 1377–2. London: BSI

Bwayo E, Obwoya SK (2014) Coefficient of thermal diffusivity of insulation brick developed from sawdust and clays. J Ceram 2014:1–6. https://doi.org/10.1155/2014/861726

Chen Y, Zhang Y, Chen T, Zhao Y, Bao S (2011) Preparation of eco-friendly construction bricks from hematite tailings. Constr Build Mater 25(4):2107–2111. https://doi.org/10.1016/j.conbuildmat.2010.11.025

Chen C, Wang Y, Adua L, Bai H (2020) Reducing fossil fuel consumption in the household sector by enabling technology and behavior. Energy Res Soc Sci 60:101402. https://doi.org/10.1016/j.erss.2019.101402

Cultrone G, Aurrekoetxea I, Casado C, Arizzi A (2020) Sawdust recycling in the production of light weight brick: how the amount of additives and firing temperature influence the physical properties of the bricks. Constr Build 235:117436. https://doi.org/10.1016/j.conbuildmat.2019.117436

Członka S, Strąkowska A, Kairytė A (2020) Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym Testing 87:106534. https://doi.org/10.1016/j.polymertesting.2020.106534

Członka S, Strąkowska A, Kairytė A (2020) Application of walnut shells-derived biopolyol in the synthesis of rigid polyurethane foams. Materials 13(12):2687. https://doi.org/10.3390/ma13122687

De Silva GHMJS, Perera BVA (2018) Effect of waste rice husk ash (RHA) on structural, thermal and acoustic properties of fired clay bricks. J Build Eng 18:252–259. https://doi.org/10.1016/j.jobe.2018.03.019

Del Coz Díaz JJ, García Nieto PJ, Domínguez Hernández J, Suárez Sánchez A (2009) Thermal design optimization of lightweight concrete blocks for internal one-way spanning slabs floors by FEM. Energy Build 41(12):1276–1287. https://doi.org/10.1016/j.enbuild.2009.08.005

Demir I (2008) Effect of organic residues addition on the technological properties of clay bricks. Waste Manage 28(3):622–627. https://doi.org/10.1016/j.wasman.2007.03.019

Demirbaş A (2002) Fuel Characteristics of olive husk and walnut, hazelnut, sunflower, and almond shells. Energy Sources 24(3):215–221. https://doi.org/10.1080/009083102317243601

Deraman R, Abdullah A, Nagapan S, Abas N, Suratkon A, Hasmori M (2018) Improving thermal conductivity of fired clay brick using sawdust waste. Asian J Tech Vocat Educ Train 4(2018):1–8

Elert K, Cultrone G, Navarro CR, Pardo ES (2003) Durability of bricks used in the conservation of historic buildings — influence of composition and microstructure. J Cult Herit 4(2):91–99. https://doi.org/10.1016/s1296-2074(03)00020-7

Elert K, Cultrone G, Navarro CR, Pardo ES (2003) Durability of bricks used in the conservation of historic buildings - influence of composition and microstructure. J Cult Herit 4(2):91–99. https://doi.org/10.1016/s1296-2074(03)00020-7

Eliche-Quesada D, Leite-Costa J (2016) Use of bottom ash from olive pomace combustion in the production of eco-friendly fired clay bricks. Waste Manage 48:323–333. https://doi.org/10.1016/j.wasman.2015.11.042

Eliche-Quesada D, Corpas-Iglesias FA, Pérez-Villarejo L, Iglesias-Godino FJ (2012) Recycling of sawdust, spent earth from oil filtration, compost and marble residues for brick manufacturing. Constr Build Mater 34:275–284. https://doi.org/10.1016/j.conbuildmat.2012.02.079

Eliche-Quesada D, Felipe-Sesé MA, López-Pérez JA, Infantes-Molina A (2017) Characterization and evaluation of rice husk ash and wood ash in sustainable clay matrix bricks. Ceram Int 43(1):463–475. https://doi.org/10.1016/j.ceramint.2016.09.181

Eloukabi H, Sghaier N, Ben Nasrallah S, Prat M (2013) Experimental study of the effect of sodium chloride on drying of porous media: the crusty–patchy efflorescence transition. Int J Heat Mass Transf 56(1–2):80–93. https://doi.org/10.1016/j.ijheatmasstransfer.2012.09.045

Folorunso DO (2018) Characterization and value enhancement of some Nigerian refractory materials for thermal insulation. IOSR J Mech Civ Eng 15(3):79–86

Folorunso DO, Olubambi P, Borode JO (2014) Characterization and value qualitative analysis of some Nigerian clay deposit for refractory application. ISOR J Appl Chem 7(9):40–47

German RM (1985) 1985. Plenum Press, New York, Liquid phase sintering

Ghalehnovi M, Roshan N, Taghizadeh A, AsadiShamsabadi E, Ali Hadigheh S, De Brito J (2022) Production of environmentally friendly concrete incorporating bauxite residue and silica fume. J Mater Civ Eng 34(2):04021423

Gualtieri ML, Gualtieri AF, Gagliardi S, Ruffini P, Ferrari R, Hanuskova M (2010) Thermal conductivity of fired clays: Effects of mineralogical and physical properties of the raw materials. Appl Clay Sci 49(3):269–275. https://doi.org/10.1016/j.clay.2010.06.002

Gupta S, Huinink HP, Prat M, Pel L, Kopinga K (2014) Paradoxical drying of a fired-clay brick due to salt crystallization. Chem Eng Sci 109:204–211. https://doi.org/10.1016/j.ces.2014.01.023

Gupta N, Gedam VV, Moghe C, Labhasetwar P (2017) Investigation of characteristics and leaching behavior of coal fly ash, coal fly ash bricks and clay bricks. Environ Technol Innov 7:152–159. https://doi.org/10.1016/j.eti.2017.02.002

Hallet V, Pedersen MT, Lothenbach B, Winnefeld F, De Belie N, Pontikes Y (2022) Hydration of blended cement with high volume iron-rich slag from non-ferrous metallurgy. Cem Concr Res 151:106624

Hurynovich A, Kwietniewski M, Romanovski V (2021) Evaluation of the possibility of utilization of sewage sludge from Wastewater Treatment Plant – case study. Desalin Water Treat 227:16–25. https://doi.org/10.5004/dwt.2021.27199

Ige O, Danso H (2022) Experimental characterization of adobe bricks stabilized with rice husk and lime for sustainable construction. J Mater Civ Eng 34(2):04021420

Janbuala S, Wasanapiarnpong T (2015) Effect of rice husk and rice husk ash on properties of lightweight clay bricks. Key Eng Mater 659:74–79. https://doi.org/10.4028/www.scientific.net/KEM.659.74

Janbuala S, Wasanapiarnpong T (2016) Lightweight clay brick ceramic prepared with bagasse addition. ARPN J Eng Appl Sci 1:8380–8384

Janbuala S, Kitthawee U, Aermbua M, Laoratanakul P (2013) Effect of rice husk ash to mechanical properties of clay bricks. Adv Mater Res 770:50–53. https://doi.org/10.4028/www.scientific.net/amr.770.50

Johari I, Said S, Hisham B, Bakar A, Ahmad ZA (2010) Effect of the change of firing temperature on microstructure and physical properties of clay bricks from Beruas (Malaysia). Sci Sinter 42(2):245–254. https://doi.org/10.2298/sos1002245j

Kamarou M, Kuzmenkov M, Korob N, Kwapinski W, Romanovski V (2020) Structurally controlled synthesis of calcium sulphate dihydrate from industrial wastes of spent sulphuric acid and limestone. Environ Technol Innov 17:100582. https://doi.org/10.1016/j.eti.2019.100582

Kamarou M, Korob N, Romanovski V (2021) Structurally controlled synthesis of synthetic gypsum derived from industrial wastes: sustainable approach. J Chem Technol Biotechnol 96(11):3134–3141. https://doi.org/10.1002/jctb.6865

Kamarou M, Korob N, Hil A, Moskovskikh D, Romanovski V (2021) Low-energy technology for producing anhydrite in the CaCO3 – H2SO4 – H2O system derived from industrial wastes. J Chem Technol Biotechnol 96(7):2065–2071. https://doi.org/10.1002/jctb.6740

Kamarou M, Korob N, Kwapinski W, Romanovski V (2021) High-quality gypsum binders based on synthetic calcium sulfate dihydrate produced from industrial wastes. J Ind Eng Chem 100:324–332. https://doi.org/10.1016/j.jiec.2021.05.006

Kang X, Zhu X, Shu X, Liu J (2022) Hydration of clinker phases in Portland cement in the presence of graphene oxide. J Mater Civ Eng 34(2):04021425

Kar Y (2011) Co-pyrolysis of walnut shell and tar sand in a fixed-bed reactor. Biores Technol 102(20):9800–9805. https://doi.org/10.1016/j.biortech.2011.08.022

Karaman S, Ersahin S, Gunal H (2006) Firing temperature and firing time influence on the mechanical properties of clay bricks. J Sci Ind Res 65:153–159

Kazmi SMS, Abbas S, Munir MJ, Khitab A (2016a) Exploratory study on the effect of waste rice husk and sugarcane bagasse ashes in burnt clay bricks. J Build Eng 7:372–378. https://doi.org/10.1016/j.jobe.2016.08.001

Kazmi SMS, Abbas S, Saleem MA, Munir MJ, Khitab A (2016b) Manufacturing of sustainable clay bricks: utilization of waste sugarcane bagasse and rice husk ashes. Constr Build Mater 120:29–41. https://doi.org/10.1016/j.conbuildmat.2016.05.084

Kazmi SMS, Munir MJ, Patnaikuni I, Wu YF, Fawad U (2018) Thermal performance enhancement of eco-friendly bricks incorporating agro-wastes. Energy Build 158:1117–1129. https://doi.org/10.1016/j.enbuild.2017.10.056

Kizinievič O, Kizinievič V, Pundiene I, Molotokas D (2018) Eco-friendly fired clay brick manufactured with agricultural solid waste. Arch Civ Mech Eng 18(4):1156–1165. https://doi.org/10.1016/j.acme.2018.03.003

Lin KL (2007) Use of thin film transistor liquid crystal display (TFT-LCD) waste glass in the production of ceramic tiles. J Hazard Mater 148(1–2):91–97. https://doi.org/10.1016/j.jhazmat.2007.02.004

Lin KL, Huang LS, Shie JL, Cheng CJ, Lee CH, Chang TC (2013) Elucidating the effects of solar panel waste glass substitution on the physical and mechanical characteristics of clay bricks. Environ Technol 34(1):15–24. https://doi.org/10.1080/09593330.2012.679693

Long L, Ye H (2015) The roles of thermal insulation and heat storage in the energy performance of the wall materials: a simulation study. Sci Rep 6(1):24181. https://doi.org/10.1038/srep24181

Long L, Ye H (2020) Effects of thermophysical properties of wall materials on energy performance in an active building. Energy Procedia 75:1850–1855. https://doi.org/10.1016/j.egypro.2015.07.161

Loryuenyong V, Panyachai T, Kaewsimork K, Siritai C (2009) Effects of recycled glass substitution on the physical and mechanical properties of clay bricks. Waste Manage 29(10):2717–2721. https://doi.org/10.1016/j.wasman.2009.05.015

Mehedi T, Hafizur S, Nazrul SM (2012) Characterization of bricks making soil: Engineering. Elemental and Thermal Aspect 35(1):109–118

Morel J, Mesbah A, Oggero M, Walker P (2001) Building houses with local materials: means to drastically reduce the environmental impact of construction. Build Environ 36(10):1119–1126. https://doi.org/10.1016/S0360-1323(00)00054-8

Mukhtar MM, Amirudin R, Mohamad I (2016) Housing delivery problems in developing countries: a case study of Nigeria. J Facil Manag 14(4):315–329. https://doi.org/10.1108/JFM-12-2015-0037

Munir MJ, Abbas S, Nehdi ML, Kazmi SMS, Khitab A (2018) Development of eco-friendly fired clay bricks incorporating recycled marble powder. J Mater Civ Eng 30(5):04018069. https://doi.org/10.1061/(asce)mt.1943-5533.0002259

Muñoz VP, Morales OMP, Letelier GV, Mendívil GMA (2016) Fired clay bricks made by adding wastes: assessment of the impact on physical, mechanical and thermal properties. Constr Build Mater 125:241–252. https://doi.org/10.1016/j.conbuildmat.2016.08.024

Muñoz Velasco P, Morales Ortíz MP, MendívilGiró MA, Muñoz Velasco L (2014) Fired clay bricks manufactured by adding wastes as sustainable construction material – a review. Constr Build Mater 63:97–107. https://doi.org/10.1016/j.conbuildmat.2014.03.045

Naganathan S, Mohamed AYO, Mustapha KN (2015) Performance of bricks made using fly ash and bottom ash. Constr Build Mater 96:576–580. https://doi.org/10.1016/j.conbuildmat.2015.08.068

Obidiegwu EO, Esezobor DE, Agunsoye JO, Lawal GI (2015) Enhancement of insulating refractory properties of selected Nigeria fire-clays using coconut shell. J Miner Mater Charact Eng 03(06):458–468. https://doi.org/10.4236/jmmce.2015.36048

Okunade EA (2008) The effect of wood ash and sawdust admixtures on the engineering properties of a burnt laterite-clay brick. J Appl Sci 8(6):1042–1048. https://doi.org/10.3923/jas.2008.1042.1048

Olajide O, Michael O, Terna T (2015) Production and characterization of aluminosilicate refractory brick using Unwana Beach silica sand, Ekebedi and Unwana clays. Br J Appl Sci Technol 5(5):461–471. https://doi.org/10.9734/BJAST/2015/12532

Pel L, Sawdy A, Voronina V (2010) Physical principles and efficiency of salt extraction by poulticing. J Cult Herit 11(1):59–67. https://doi.org/10.1016/j.culher.2009.03.007

Phonphuak N, Chindaprasirt P (2018) Utilization of sugarcane bagasse ash to improve properties of fired clay brick. Chiang Mai J Sci 45(4):1855–1862

Phonphuak N, Kanyakam S, Chindaprasirt P (2016) Utilization of waste glass to enhance physical–mechanical properties of fired clay brick. J Clean Prod 112:3057–3062. https://doi.org/10.1016/j.jclepro.2015.10.084

Raimondo M, Dondi M, Mazzanti F, Stefanizzi P, Bondi P (2007) Equilibrium moisture content of clay bricks: the influence of the porous structure. Build Environ 42(2):926–932. https://doi.org/10.1016/j.buildenv.2005.10.017

Raimondo M, Dondi M, Gardini D, Guarini G, Mazzanti F (2009) Predicting the initial rate of water absorption in clay bricks. Constr Build Mater 23(7):2623–2630. https://doi.org/10.1016/j.conbuildmat.2009.01.009

Romanovskaia E, Romanovski V, Kwapinski W, Kurilo I (2021) Selective recovery of vanadium pentoxide from spent catalysts of sulfuric acid production: Sustainable approach. Hydrometallurgy 200:105568. https://doi.org/10.1016/j.hydromet.2021.105568

Romanovski V, Klyndyuk A, Kamarou M (2021) Green approach for low-energy direct synthesis of anhydrite from industrial wastes of lime mud and spent sulfuric acid. J Environ Chem Eng 9(6):106711. https://doi.org/10.1016/j.jece.2021.106711

Romanovski V, Romanovskaia E, Moskovskikh D, Kuskov K, Likhavitski V, Mehmet FA, Beloshapkin S, Matsukevich I, Khort A (2021) Recycling of iron-rich sediment for surface modification of filters for underground water deironing. J Environ Chem Eng 9(4):105712. https://doi.org/10.1016/j.jece.2021.105712

Romanovski V, Zhang L, Su X, Smorokov A, Kamarou M (2022) Gypsum and high quality binders derived from water treatment sediments and spent sulfuric acid: chemical engineering and environmental aspects. Chem Eng Res Des 184:224–232. https://doi.org/10.1016/j.cherd.2022.06.008

Sakir A, Naganathan S, Mustapha KN (2013) Development of bricks from waste material: a review paper. Aust J Basic Appl Sci 7:812–818

Seppälä J, Heinonen T, Pukkala T, Kilpeläinen A, Mattila T, Myllyviita T, Antti A, Peltola H (2019) Effect of increased wood harvesting and utilization on required greenhouse gas displacement factors of wood-based products and fuels. J Environ Manage 247:580-587J. https://doi.org/10.1016/j.jenvman.2019.06.031

Shakir AA, Naganathan S, Mustapha KN (2013) Properties of bricks made using fly ash, quarry dust and billet scale. Constr Build Mater 41:131–138. https://doi.org/10.1016/j.conbuildmat.2012.11.077

Silva RV, de Brito J, Lye CQ, Dhir RK (2017) The role of glass waste in the production of ceramic-based products and other applications: a review. J Clean Prod 167:346–364. https://doi.org/10.1016/j.jclepro.2017.08.185

Sutcu M, Akkurt S (2009) The use of recycled paper processing residues in making porous brick with reduced thermal conductivity. Ceram Int 35(7):2625–2631. https://doi.org/10.1016/j.ceramint.2009.02.027

Sutcu M, del Coz Díaz JJ, ÁlvarezRabanal FP, Gencel O, Akkurt S (2014) Thermal performance optimization of hollow clay bricks made up of paper waste. Energy Build 75:96–108. https://doi.org/10.1016/j.enbuild.2014.02.006

Sutcu M, Alptekin H, Erdogmus E, Er Y, Gencel O (2015) Characteristics of fired clay bricks with waste marble powder addition as building materials. Constr Build Mater 82:1–8. https://doi.org/10.1016/j.conbuildmat.2015.02.055

Taurino R, Ferretti D, Cattani L, Bozzoli F, Bondioli F (2019) Lightweight clay bricks manufactured by using locally available wine industry waste. J Build Eng 26:100892. https://doi.org/10.1016/j.jobe.2019.100892

Tsega E, Mosisa A, Fufa F (2017) Effects of firing time and temperature on physical properties of fired clay bricks. Am J Civil Eng 5(1):21–26. https://doi.org/10.11648/j.ajce.20170501.14

Uchechukwu Elinwa A (2006) Effect of addition of sawdust ash to clay bricks. Civ Eng Environ Syst 23(4):263–270. https://doi.org/10.1080/10286600600763149

UNE EN 12370 (2020) Natural stone test methods - determination of resistance to salt crystallization.

Wolff E, Schwabe WK, Conceição SV (2015) Utilization of water treatment plant sludge in structural ceramics. J Clean Prod 96:282–289. https://doi.org/10.1016/j.jclepro.2014.06.018

Yaras A (2020) Combined effects of paper mill sludge and carbonation sludge on characteristics of fired clay bricks. Constr Build Mater 249:118722. https://doi.org/10.1016/j.conbuildmat.2020.118722

Zalyhina V, Cheprasova V, Belyaeva V, Romanovski V (2021) Pigments from spent Zn, Ni, Cu, and Cd electrolytes from electroplating industry. Environ Sci Pollut Res 28:32660–32668. https://doi.org/10.1007/s11356-021-13007-4

Zalyhina V, Cheprasova V, Romanovski V (2021) Pigments from spent chloride-ammonium zinc plating electrolytes. J Chem Technol Biotechnol 96(10):2767–2774. https://doi.org/10.1002/jctb.6822

Zalyhina V, Cheprasova V, Romanovski V (2022) Paper industry slag for the production of building ceramics. J Chem Technol Biotechnol. https://doi.org/10.1002/JCTB.7174

Zhang S, Dong R, Wang M, Jia W, Lu Z (2020) Synthesis mechanisms on waste poplar fiber lightweight biomass bricks. J Clean Prod 246:118981

Acknowledgements

The authors of this research appreciate the Department of metallurgical and materials engineering, and the Department of Agricultural and Resource Economics of the Federal University of Technology Akure.

Author information

Authors and Affiliations

Contributions

Abel Adeize Barnabas: conceptualization, methodology, investigation, formal analysis, data curation, writing original draft, and editing. Oluwatosin Abiodun Balogun: conceptualization, methodology, investigation, formal analysis, data curation, writing original draft, and editing. Abayomi Adewale Akinwande: investigation, formal analysis, data curation, review, and editing. John Friday Ogbodo: investigation, formal analysis, data curation, review, and editing. Akeem Oladele Ademati: investigation, formal analysis, data curation, review, and editing. Enesi Isaac Dongo: investigation, formal analysis, data curation, review, and editing. Valentin Romanovski: formal analysis, data curation, visualization, writing—review and editing.

Corresponding authors

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Barnabas, A.A., Balogun, O.A., Akinwande, A.A. et al. Reuse of walnut shell waste in the development of fired ceramic bricks. Environ Sci Pollut Res 30, 11823–11837 (2023). https://doi.org/10.1007/s11356-022-22955-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-22955-4