Abstract

In this work, we propose to extend the Ovarlez and Roussel model, for estimating lateral form pressure exerted by fresh concrete, to low casting rates and long duration formwork filling. In this case, the assumption of a linear increase of the concrete yield stress with time at rest is imprecise. This assumption is valid for approximately 1 h at rest after placing and may lead to an overestimation of the lateral pressure for a longer period. Based on chemical arguments and experimental observations, it has been shown that the yield stress increases exponentially over time. The same fundamental physical assumptions made by Ovarlez and Roussel are used to predict the lateral pressure exerted on formwork. Comparison of the proposed model with experimental measurements shows that, pressure can be predicted with an accuracy comparable to the Ovarlez and Roussel model for casting times less than 1 h.

Similar content being viewed by others

References

Billberg PH, Roussel N, Amziane S, Beitzel M, Charitou G, Freund B, Gardner JN, Grampeix G, Graubner C, Keller L, Khayat KH, Lange DA, Omran AF, Perrot A, Proske T, Quattrociocchi R, Vanhove Y (2014) Field validation of models for predicting lateral form pressure exerted by SCC, Cement and Concrete Composites

Proske T, Graubner C-A (2007) Pressure on formwork using SCC—Experimental studies and modeling. Fifth RILEM international symposium on Self-Compacting Concrete, Ghent

Khayat KH, Omran AF (2011) Field monitoring of SCC formwork pressure and validation of prediction models. J Concr Int 33:33–39

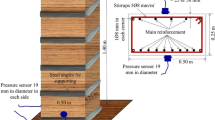

Perrot A, Amziane S, Ovarlez G, Roussel N (2009) SCC formwork pressure: influence of steel rebars. Cem Concr Res 39:524–528

Tchamba JC, Amziane S, Ovarlez G, Roussel N (2008) Lateral stress exerted by fresh cement paste on formwork: laboratory experiments. Cem Concr Res 38:459–466

Ovarlez G, Roussel N (2006) A physical model for the prediction of lateral stress exerted by self-compacting concrete on formwork. Mater Struct 39:269–279

Gardner JN, Keller L, Quattrociocchi R, Charitou G (2012) Field investigation of formwork pressure using self-compacting concrete. Concr Int 34:41–47

Lange DA, Birsch B, Henschen J, Lieu Y-S, Struble T-DFL (2008) Modeling formwork pressure of SCC. In: Shah ESP (ed) 3rd North American Conference on the design and use of Self-compacting concrete, Chicago, pp 295–300

Graubner C-A, Boska E, Motzko C, Proske T, Dehn F (2012) Formwork pressure induced by highly flowable concrete—design approach and transfer in practice, Structural concrete journal of the FIB 1

Beitzel M (2010) Modeling fresh concrete pressure of normal and self-compacting concrete. In: Khayat KH, Feys D Sixth RILEM international symposium on SCC, Fourth American conference on the design and use of self-compacting concrete, Montreal, pp 243–254

Billberg PH (2003) Form pressure generated by self-compacting concrete 3rd international RILEM symposium on Self-Compacting Concrete Reykjavik, Island, pp 271–280

Assaad J, Khayat KH (2003) Variation of formwork pressure with thixotropy of self-consolidating concrete. ACI Mater J 100:29–37

Lecompte T, Perrot A, Picandet V, Bellegou H, Amziane S (2011) Cement-based mixes: shearing properties and pore pressure. Cem Concr Res 42:139–147

Roussel N (2005) Steady and transient flow behaviour of fresh cement pastes. Cem Concr Res 35:1656–1664

Roussel N (2006) A thixotropy model for fresh fluid concretes: theory, validation and applications. Cem Concr Res 36:1797–1806

Lootens D, Jousset P, Martinie L, Roussel N, Flatt RJ (2009) Yield stress during setting of cement pastes from penetration tests. Cem Concr Res 39:401–408

Sleiman H, Perrot A, Amziane S (2010) A new look at the measurement of cementitious paste setting by Vicat test. Cem Concr Res 40:681–686

Mahaut F, Mokeddem S, Chateau X, Roussel N, Ovarlez G (2008) Effect of coarse particle volume fraction on the yield stress and thixotropy of cementitious materials. Cem Concr Res 38:1276–1285

Perrot A, Lecompte T, Khelifi H, Brumaud C, Hot J, Roussel N (2012) Yield stress and bleeding of fresh cement pastes. Cem Concr Res 42:937–944

Perrot A, Lecompte T, Estellé P, Amziane S (2013) Structural build-up of rigid fiber reinforced cement-based materials. Mater Struct 46(9):1561–1568

Khayat KH, Omran AF, Naji S, Billberg P, Yahia A (2012) Field-oriented test methods to evaluate structural build-up at rest of flowable mortar and concrete. Mater Struct 45:1547–1564

Khayat K, Assaad J, Mesbah H, Lessard M (2005) Effect of section width and casting rate on variations of formwork pressure of self-consolidating concrete. Mater Struct 38:73–78

Assaad J, Khayat K (2006) Effect of casting rate and concrete temperature on formwork pressure of self-consolidating concrete. Mater Struct 39:333–341

Khayat K, Assaad J (2008) Measurement systems for determining formwork pressure of highly-flowable concrete. Mater Struct 41:37–46

Amziane S (2006) Setting time determination of cementitious materials based on measurements of the hydraulic pressure variations. Cem Concr Res 36:295–304

Andriamanantsilavo NR, Amziane S (2004) Maturation of fresh cement paste within 1- to 10-m-large formworks. Cem Concr Res 34:2141–2152

Assaad J, Khayat KH (2004) Variation of lateral and pore water pressure of self compacting concrete at early age. ACI Mater J 101:310–317

Keller H, Plank J (2013) Mineralisation of CaCO3 in the presence of polycarboxylate comb polymers. Cem Concr Res 54:1–11

Roussel N, Ovarlez G, Garrault S, Brumaud C (2012) The origins of thixotropy of fresh cement pastes. Cem Concr Res 42:148–157

Wallevik JE (2009) Rheological properties of cement paste: thixotropic behaviour and structural breakdown. Cem Concr Res 39:14–29

Subramaniam KV, Wang X (2010) An investigation of microstructure evolution in cement paste through setting using ultrasonic and rheological measurements. Cem Concr Res 40:33–44

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Perrot, A., Pierre, A., Vitaloni, S. et al. Prediction of lateral form pressure exerted by concrete at low casting rates. Mater Struct 48, 2315–2322 (2015). https://doi.org/10.1617/s11527-014-0313-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-014-0313-8