Abstract

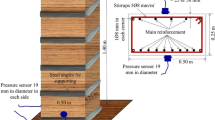

This paper concerns the problem of the experimental assessment of the casting position factor incomparison to the current normative guidelines. Our experiment was performed on three types of concrete: high-performance concrete (HPC), high-performance self-compacting concrete (HPSCC) and normal strength concrete (NSC) used as a reference. The HPC and the HPSCC were made in respectively, two and four different variants that differed in the content of silica fume. To assess the casting position factor, three types of elements with heights of 480, 800 and 1600 mm were used. In each element, a ribbed reinforcing bar with a diameter of 16 mm was embedded perpendicularly to the direction of concreting. The bond was examined using pull-out test. The test results showed that regardless of the type and composition of concrete, the linear change of the casting position factor with element’s height was observed. No significant differences in the changes of the casting position factor with height were noted between the HPC and the HPSCC. The experiment revealed that the new generation concretes were characterized by a much lower value of the casting position factor in comparison to the current normative guidelines.

Similar content being viewed by others

References

ACI 318, Building Code Requirements for Structural Concrete, American Concrete Institute, 2014.

ACI Committee 408, Suggested development, splice and standard hook provisions for deformed bars in tension, Concr. Int. 1 (7) (1979) 47–61.

AASHTO LRFD Highway Bridge Design Specifications, American Association of State Highway and Transportation Officials, Washington, 2007.

EN 1992, Design of Concrete Structures, Part 1-1: General Rules, and Rules for Buildings, European Committee for Standardization, 2008.

FIB Bulletin No. 65. Model Code 2010. Final Draft Volume 1, 2012.

FIB Bulletin No. 10. Bond of Reinforcement in Concrete, State of the Art. Report prepared by Task Group Bond Models, former CEB, Task Group 5.2.CH-1015, Lausanne, 2000.

P. Dybeł, K. Furtak, Assessment of the casting position factor in reinforced concrete elements in view of experimental studies, Arch. Civ. Eng. 60 (2) (2014) 209–221.

P. Dybeł, K. Furtak, The effect of ribbed reinforcing bars location on their bond with high-performance concrete, Arch. Civ. Mech. Eng. 15 (4) (2015) 1070–1077.

B.S. Hamad, M.S. Itani, Bond strength of reinforcement in high-performance concrete: the role of silica fume, casting position, and superplasticizer dosage, ACI Mater. J. 95 (5) (1998) 411–499.

J.O. Jirsa, J.E. Breen, Influence of Casting Position and Shear on Development and Splice Length – Design Recommendation. Research Report No. 242-3F, Center for Transportation Research, The University of Texas at Austin, 1981.

J.J. Luke, B.S. Hamad, J.O. Jirsa, J.E. Breen, The Influence of Casting Position on Development and Splice Length of Reinforcing Bars. Research Report No. 242-1, Center for Transportation Research, Bureau of Engineering Research, University of Texas at Austin, 1981.

P.R. Jaunty, D. Mitchell, M.S. Mirza, Investigation of top bar effects in beams, ACI Mater. J. 85 (3) (1988) 251–257.

A. Castel, T. Vidal, K. Viriyametanont, R. Francois, Effect of reinforcing bar orientation and location on bond with self-consolidating concrete, ACI Struct. J. 103 (4) (2006) 559–567.

K.G. Trezos, I.P. Sfikas, G.G. Pasios, Influence of water-to-binder ratio on top-bar effect and on bond variation across length in self-compacting concrete specimens, Cem. Concr. Compos. 48 (2014) 127–139.

P.L. Domone, A review of the hardened mechanical properties of self-compacting concrete, Cem. Concr. Compos. 29 (1) (2007) 1–12.

M.O. Valcuende, C. Parra, J. Benlloch, Premebility, porosity and compressive strength of self-compacting concretes, Mater. Constr. 55 (280) (2005) 17–25.

G. de Schutter, P.J.M. Bartos, P. Domone, J. Gibbs, Self-compacting Concrete, Whittles Publishing, Dunbeath, 2008.

Y.W. Chan, Y.G. Chen, Y.S. Liu, Development of bond strength of reinforcement steel in self-consolidating concrete, ACI Struct. J. 100 (4) (2003) 490–498.

P. Desnerck, Compressive, bond and shear behaviour of powder-type self-compacting concrete. Ph.D. thesis, Universiteit Gent, 2011. p. 343.

M. Valcuende, C. Parra, Bond behaviour of reinforcement in self-compacting concretes, Constr. Build. Mater. 23 (2009) 162–170.

A. Schiessl, K. Zilch, The effects of the modified composition of SCC on shear and bond behaviour, in: K. Ozawa, M. Ouchi (Eds.), Proceedings of Second International RILEM Symposium on Selfcompacting Concrete, Tokyo, (2001) 501–506.

M.R. Esfahani, M. Lachemi, M.R. Kianoush, Top-bar effect of steel bars in selfconsolidating concrete, Cem. Concr. Compos. 30 (2008) 52–60.

T.A. Söylev, R. François, Effects of bar-placement conditions on steel-concrete bond, Mater. Struct. 39 (2006) 211–220.

K.H. Khayat, K. Manai, A. Trudel, In situ mechanical properties of wall elements cast using self-consolidating concrete, ACI Mater. J. 94 (6) (1997) 491–500.

K.H. Khayat, Use of viscosity-modifying admixture to reduce top-bar effect of anchored bars cast with fluid concrete, ACI Mater. J. 95 (2) (1998) 158–167.

K.G. Trezos, I.P. Sfikas, K. Orfanopoulos, Bond of self-compacting concrete incorporating silica fume: top-bar effect, effects of rebar distance from casting point and of rebar-to-concrete relative displacements during setting, Constr. Build. Mater. 73 (2014) 378–390.

K.G. Trezos, I.P. Sfikas, M. Palmos, E. Sotiropoulou, Top-bar effect in self-compacting concrete elements, in: K.H. Khayat, D. Feys (Eds.), Design, Production and Placement of Self-Consolidating Concrete. Proceedings of SCC2010 RILEM Conference, Montreal, Canada, September 26–29, 2010, RILEM Book Series, vol. 1, Springer, New York, 2010 367–378.

I.P. Sfikas, K.G. Trezos, Effect of composition variations on bond properties of selfcompacting concrete specimens, Constr. Build. Mater. 41 (2013) 252–262.

A. Foroughi, S. Dilmaghani, H. Famili, Bond strength of reinforcement steel in self-compacting concrete, Int. J. Civ. Eng. 6 (1) (2008) 24–33.

EN 10080, Steel for the Reinforcement of Concrete, 2007.

RILEM TC, RILEM Recommendations for the Testing and Use of Constructions Materials, RC 6 Bond Test for Reinforcement Steel. Pull-Out Test, 1983, E&FN SPON, 1994.

EN 12390-3, Testing Hardened Concrete. Compressive Strength of Test Specimens, 2009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dybeł, P., Kucharska, M. Experimental assessment of the casting position factor of reinforcing bars in high performance concretes (HPC, HPSCC). Archiv.Civ.Mech.Eng 19, 127–136 (2019). https://doi.org/10.1016/j.acme.2018.09.005

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/j.acme.2018.09.005