Abstract

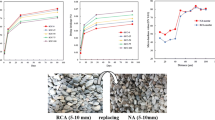

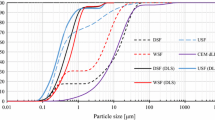

The fresh and hardened properties of self-compacting concrete (SCC) depend on number of factors such as paste composition, paste content, aggregate content, aggregate gradation etc. In the present investigation, the influence of the packing density of aggregates on the properties of SCC was evaluated. Experiments were conducted to measure the packing density for different combinations of aggregates precisely. A ternary packing diagram (TPD) was developed based on the packing density of measured and interpolated data. Considering the limitations in generalising the TPD and the difficulty involved in adopting mathematical models for aggregates, an attempt was made to establish a simple method for the selection of the combination of aggregates resulting in maximum packing density from the particle size distribution of aggregates (represented by the Coefficient of uniformity—C u). Further, studies were extended to investigate the effect of aggregate packing density on fresh and hardened SCC properties. The results indicate that for a constant paste volume and paste composition, with increase in packing density of aggregates, the fresh properties and the compressive strength of SCC were improved positively. An attempt was also made to identify the influence of 10 different proportions of aggregates having the same packing density on the properties of SCC. The results indicate that at the same aggregate packing density, the fresh concrete properties were influenced significantly by the choice of the aggregate combination, while there was little or no influence on the hardened properties. Furthermore, the experimental data obtained was used for supplementary validation of the existing model (compressible packing model) for predicting the packing density and the fresh behaviour of SCC.

Similar content being viewed by others

References

Andreasen AHM, Andersen J (1930) Uber die beziehung zwischen kornabstufung und zwischenraum in produkten aus losen kornern (mit einigen experimenten). Kolloid Z 50:217–228

Goltermann P, Johansen V, Palbol L (1997) Packing of aggregates: an alternative tool to determine the optimal aggregate mix. ACI Mater J 94(5):435–443

Glavind M, Pedersen EJ (1999) Packing calculations applied for concrete mix design. In: Proceedings of creating with concrete, University of Dundee, pp 1–10

Johansen V, Andersen PJ (1991) Particle packing and concrete properties. Material Science of Concrete II. The American Ceramic Society, Westerville, pp 111–147

Joisel A (1952) Composition des betons hydrauliques. Ann IITBTP 58:992–1065

Fuller WB, Thompson SE (1907) The laws of proportioning concrete. Trans Am Soc Civ Eng 59:67–172

Senthil Kumar V, Santhanam M (2003) Particle packing theories and their application in concrete mixture proportioning: a review. Indian Concr J 77:1324–1331

Romagnoli M, Siligardi C (2004) Comparison of models for dense particle packing. In: Proceedings of Congresso, AIMAT Ancona, 29 Giugno-2, Luglio

Dewar JD (1999) Computer modelling of concrete mixtures. E & F N Spon, London

De Larrard F (1999) Concrete mixture proportioning—a scientific approach. E and FN Spon, London

Jones MR, Zheng L, Newlands MD (2002) Comparison of particle packing models for proportioning concrete constituents for minimum voids ratio. Mater Struct 35:301–309

Andersen PJ (1990) Control and monitoring of concrete production. PhD Thesis, Academy of Technical Sciences, The Technical University of Denmark

Standish N, Yu AB (1987) Porosity calculations of ternary mixtures of particles. Powder Technol 49(3):249–253

Ridgway K, Tarbuck KJ (1968) Particulate mixture bulk densities. Chem Proc Eng 49:103–105

IS 12269 (2004) Specification for 53 grade ordinary portland cement. Bureau of Indian Standards

ASTM 127 (2001) Standard test method for density, relative density (specific gravity), and absorption of coarse aggregate. American Society for Testing and Materials Standards, West Conshohocken

ASTM C 128 (2001) Standard test method for density, relative density (specific gravity), and absorption of fine aggregate. American Society for Testing and Materials Standards, West Conshohocken

ASTM C 29 (2001) Standard test method for bulk density (Unit Weight) and voids in aggregate. American Society for Testing and Materials Standards, West Conshohocken

IS 2386 (2002) Methods of test for aggregates in concrete—Part I: particle size and shape. Bureau of Indian Standards, New Delhi

Fasshauer GE (2007) Meshfree approximation methods with MATLAB. World Scientific Company, River Edge

McGeary RK (1961) Mechanical packing of spherical particles. J Am Ceram Soc 44(10):513–522

Hazen A (1892) Some physical properties of sands and gravels. Massachusetts State Board of Health. Annual Report, pp 539–556

Nanthagopalan P, Santhanam M (2009) Experimental investigations on the influence of paste composition and content on the properties of self-compacting concrete. Construct Build Mater 23:3443–3449

ASTM C 1621 (2006) Standard test method for passing ability of self-compacting concrete by J ring. American Society for Testing and Materials Standards, West Conshohocken

De Larrard F (2009) Concrete optimisation with regards to packing density and rheology. In: Proceedings of 3rd International RILEM symposium on Rheology of cement suspensions such as fresh concrete, Iceland, pp 1–8

Acknowledgments

The authors wish to express their sincere thanks to Dr. F. de Larrard, LCPC Centre de Nantes, France for giving insights about the CPM model and for having technical discussions. The authors extend their thanks to Dr. Antony Vijesh, Assistant Professor, Department of Mathematics, Indian Institute of Technology Indore, India for his help regarding the interpolation of experimental data.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nanthagopalan, P., Santhanam, M. An empirical approach for the optimisation of aggregate combinations for self-compacting concrete. Mater Struct 45, 1167–1179 (2012). https://doi.org/10.1617/s11527-012-9824-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-012-9824-3