Abstract

Cracking of concrete must be avoided during the hardening phase in order to minimize the risk of durability problems in the future, such as corrosion of the reinforcement, water tightness and damages due to frost. Estimation of the risk of early age cracking requires knowledge of the combined effects from temperature development and mechanical behaviour during the hydration. In the present paper, the influence of fly ash on the young concrete behaviour has been investigated. The concrete is based on a Swedish cement aimed for civil engineering structures, and the fly ash is of class F. A comparison of crack risks between concrete containing fly ash in different amounts with concrete without fly ash is presented. Also a previously tested concrete containing limestone filler is considered. The fly ash was added to replace a part of the aggregate, which gives a higher heat evolution. However, a numerical stress analysis showed that the risk for early age through cracking for a typical civil engineering structure is significantly decreased in the mixes containing fly ash. The denotation typical civil engineering structure is used here for concrete structures such as tunnels, bridges, and ramps of common cross-section dimensions. In the case of fly ash added to concrete by a partial replacement of cement, the crack risk will probably be further decreased. For a self-balancing structure of young concrete there is no restraint from adjacent structures, and the temperature and moisture gradients within the young concrete cause self-stresses governed by equilibrium with zero external forces for any cut. The estimated risk for surface cracking on a self-balancing wall or slab was not improved by an addition of fly ash. It is probably an effect of the increased heat development, which most likely counteracts the positive effect of the increased early age creep for concrete containing fly ash. If the heat evolution decreases when cement is partly replaced with fly ash, the use of fly ash might reduce the risk of surface cracks.

Similar content being viewed by others

References

Wallin K, Emborg M, Jonasson J-E (1997) [Värme ett alternative till kyla (in Swedish)] Heating an alternative to cooling, technical report 1997:15. Division of Structural Engineering, Luleå University of Technology

Emborg M, Bernander S (1994) Assessment of risk of thermal cracking in hardening concrete. J Struct Eng 120(10):2893–2912

Berry EE, Malhotra VM (1980) Fly ash for use in concrete—a critical review. ACI J 77(2):59–73

Bilodeau A, Malhotra VM (2000) High-volume fly ash system: concrete solution for sustainable development. ACI Mater J 97(1):41–48

Davis RE, Carlson RW, Kelly JW, Davis HE (1937) Properties of cement and concretes containing fly ash. In: Proceedings of the American concrete institute, vol 33, pp 577–612

Lane RO, Best JF (1982) Properties and use of fly ash in portland cement concrete. Concr Int 81–92

Cannon RW (1968) Proportioning fly ash concrete mixes for strength and economy. ACI J 65(11):969–979

Lane RO (1983) Effects of fly ash on freshly mixed concrete. Concr Int 50–53

EN 450 (1995) Fly ash for concrete—definitions, requirements and quality control. European Committee for Standardization, Brussels

EN 206-1 (2000) Concrete—part 1: specification, performance, production and conformity. European Committee for Standardization, Brussels

SS 13 70 03 (2004) Concrete—application of EN 206-1 in Sweden (in Swedish). Swedish Standards Institute, Stockholm

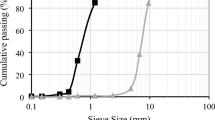

Utsi S (2008) Performance based concrete mix-design, Aggregate and micro mortar optimization applied on self-compacting concrete containing fly ash. Doctoral Thesis, Division of Structural Engineering, Luleå University of Technology

Hedlund H (2000) Hardening concrete—measurements and evaluation of non-elastic deformation and associated restraint stresses. Doctoral Thesis, Division of Structural Engineering, Luleå University of Technology

Carlswärd J (2006) Shrinkage cracking of steel fibre reinforced self compacting concrete overlays—test methods and theoretical modelling. Doctoral Thesis, Division of Structural engineering, Luleå University of Technology

Emborg M (1989) Thermal stresses in concrete structures at early ages. Division of Structural engineering. Doctoral Thesis, Luleå University of Technology

Groth P (2000) Fibre reinforced concrete—fracture mechanics methods applied on self-compacting concrete and energetically modified binders. Doctoral Thesis, Division of Structural Engineering, Luleå University of Technology

Jonasson J-E (1994) Modelling of temperature, moisture and stresses in young concrete. Doctoral Thesis, Division of Structural Engineering, Luleå University of Technology

Larson M (2003) Thermal crack estimation in early age concrete—models and methods for practical application. Doctoral Thesis, Division of Structural Engineering, Luleå University of Technology

Nilsson M (2003) Restraint factors and partial coefficients for crack risk analyses of early age concrete structures. Doctoral Thesis, Division of Structural Engineering, Luleå University of Technology

Westman G (1999) Concrete creep and thermal stresses. Doctoral Thesis, Division of Structural Engineering, Luleå University of Technology

Nurse RW (1949) Steam Cur Concr. Mag Concr Res 1:79–88

Saul AGA (1951) Principles underlying the steam curing of concrete at atmospheric pressure. Cem Concr Res 2:216–224

Bergström SG (1953) Curing temperature age and strength of concrete. Mag Concr Res 4:61–66

Freisleben HP, Pedersen EJ (1977) [Måleinstrument til control af betons haerdning (in Danish)] Maturity computer for controlled curing and hardening of concrete. J Nordic Concr Fed 1:21–25

Byfors J (1980) Plain concrete at early ages. Swedish Cement and Concrete Re-search Institute, Stockholm, Fo/Research 3:80

ASTM C 1074-04 (2004) Standard practice for estimating concrete strength by the maturity method. ASTM International, West Conshohocken, PA, 2003. doi:10.1520/C0033-03

Jonasson J-E (1984) Slipform construction—calculations for assessing protection against early freezing, CBI Forskning/Research 4.84. Swedish Cement and Concrete Research Institute, Stockholm

Ekerfors K (1995) Mognadsutveckling i ung betong, temperaturkänslighet, hållfasthet och värmeutveckling (in Swedish). Maturity development for young concrete, temperature sensitivity, strength growth and heat evolution. Licentiate Thesis, Division of Structural Engineering, Luleå University of Technology

Ekerfors K, Jonasson J-E (2000) Maturity development in young concrete—temperature sensitivity, strength and heat development. Nordic Concrete Research, Publication No 25

Kanstad T, Hammer TA, Bjøntegaard Ø, Sellevold EJ (1999) Mechanical properties of young concrete—evaluation of test methods for tensile strength and modulus of elasticity—determination of model parameters. NOR-IPACS report STF22 A99762, ISBN 82-14-01062-4

Bjøntegaard Ø (1999) Thermal dilation and autogenous deformation as driving force to self-induced stresses in high performance concrete. Doctoral Thesis, Norwegian University of Science and Technology

Bosnjak D (2001) Self-induced cracking problems in hardening concrete structures. Doctoral Thesis, Norwegian University of Science and Technology

Atrushi DS (2003) Tensile and compressive creep of early age concrete: testing and modelling. Doctoral Thesis, Norwegian University of Science and Technology

Ji G (2008) Cracking risk of concrete structures in the hardening phase. Doctoral Thesis, Norwegian University of Science and Technology

EC2 (2004) Eurocode 2: design of concrete structures—part 1–1: general rules and rules for buildings, EN 1992-1-1. European Committee for Standardization, Brussels

Bažant ZP, Chern J (1985) Concrete creep at variable humidity: constitutive law and mechanisms. Mater Struct 18:1–20

Thelandersson S (1987) Modelling of combined thermal and mechanical action in concrete. J Eng Mech 113(6):893–906

Jonasson J-E (1977) Datorprogram för icke-linjära beräkningar i betong med hänsyn till svinn, krypning och temperatur (in Swedish). Computer program for non-linear analyses of concrete in view of shrinkage, creep and temperature, CBI Forskning/Research 7:77. Swedish Cement and Concrete Research Institute, Stockholm

Jonasson J-E, Westman G (2001) Conversion of creep data to relaxation data by the program RELAX, IPACS report. Division of Structural Engineering, Luleå University of Technology, ISBN 91-89580-45-1

Jonasson J-E (2010) Data for crack risk analysis of young concrete with and without fly ash, technical report. Division of Structural Engineering, Luleå University of Technology, ISSN 1402-1536

Emborg M, Bernander S, Ekerfors K, Groth P, Hedlund H (1997) [Temperatursprickor i betongkonstruktioner - Beräkningsmetoder för hydratationsspänningar och diagram för några typfall (inSwedish)] Thermal Cracking in concrete structures—calculation methods for hydration stresses and diagrams for some typical cases, Technical Report 1997:02. Division of Structural Engineering, Luleå University of Technology

ConTeSt Pro—Users Manual (2008) A program for temperature and strength calculations in concrete. JEJMS Concrete AB, Luleå

Bernander S (1998) Practical measures to avoiding early age thermal cracking in concrete structures. In: Springenschmidt (ed) RILEM report 15 entitled prevention of thermal cracking in concrete at early ages. RE & FN Spon, London, pp 255–314

Utsi S, Jonasson J-E (2007) Evaluation of the risk for early thermal cracking in SCC. In: 5th international RILEM symposium on self-compacting concrete, 3–5 September, 2007, Ghent, pp 545–550

Riding KA, Poole JL, Schindler AK, Juenger MCG, Folliard KJ (2008) Quantification of effects of fly ash type on concrete early age cracking. ACI Mater J March–April 2008, pp 149–155

Lee HK, Lee KM, Kim BG (2003) Autogenous shrinkage of high-performance concrete containing fly ash. Mag Concr Res 2003, ff, No. 6, December 507–515

Acknowledgments

The authors of the paper acknowledge The Development Fund of the Swedish Construction Industry SBUF, Swerock AB, Cementa AB and PEAB for financial support. The laboratory tests have been performed in cooperation with personnel from Complab at Luleå University of Technology, which is hereby acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Utsi, S., Jonasson, JE. Estimation of the risk for early thermal cracking for SCC containing fly ash. Mater Struct 45, 153–169 (2012). https://doi.org/10.1617/s11527-011-9757-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-011-9757-2