Abstract

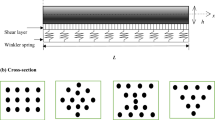

For mechanistic based pavement design, it is necessary to know the stiffness of materials used for road construction. In the European standard EN 12697-26, several experimental tests are proposed to measure the modulus of bituminous mixtures. However, bituminous materials exhibit strong viscoelastic behavior. Hence, the stiffness of this specific material depends not only on the sample geometry but also on the loading law (strain or stress curve versus time). As a consequence, comparison between these different tests, performed in time or frequency domain, is not straight forward. The present paper focuses on measurement of secant modulus using the Indirect tensile (IT) test and comparison with complex modulus. In the IT test, the loading law is not systematically controlled. So, it is important to investigate the influence of the loading waveform on the test result. For this study, the case of a High Modulus Bituminous Mixture for base course (French EME) has been considered. Its viscoelastic behavior has been firstly determined using complex modulus measurements and using Prony series model. An intermediate step, based on an original master curve construction method is used. Doing so, the viscoelastic model is validated on the time domain by simulating direct tensile tests. The case of IT test is then considered. The Prony series model is conformed against IT test results for which the force waveform is known. For this last test, the dependance of the Poisson ratio with temperature and loading time is highlighted. Assuming a purely elastic behavior in isotropic compression, a formula, able to derive the viscoelastic Poisson ratio from the complex modulus is presented. Finally, a theoretical parametric study considering the IT loading waveform is undertaken. It appears that the correction factor given in the standard EN 12697-26 cannot be applied at all temperatures. Actually, this correction factor should be material dependent. This study has been carried out in the framework of collaboration between LCPC and USIRF (Union des Syndicats de l’Industrie Routière française).

Similar content being viewed by others

Notes

Actually, the modelling of the IT test should be revised more in detail taking into account the time and temperature dependance of ν. In particular, the straight forward time/space decomposition of the problem introduced here does not apply anymore.

The closest experimental condition of complex modulus measurement to the indirect tensile test is = 1 Hz. f ≈ 1/(2π*124 ms).

References

De La Roche C, Di Benedetto H, Doubanneh E (1999) Fiabilité des essais de module complexe sur enrobés. Comparaison d’essais en flexion et en traction compression. Eurobitume Workshop on “Performance related Properties for bituminous binders”, Luxembourg, May 1999

Di Benedetto H, Partl M, Francken L, De La Roche C (2001) Stiffness testing for bituminous mixtures. Mater Struct 34(236):66–70

Gourdon JL, Piau JMM (1996) Mesure du module des enrobes bitumineux – Module secant versus Module complexe (Measuring the modulus of bituminous mixtures—Secant modulus versus complex modulus). Internal LCPC report

Olard F, Noel F, Loup F (2006) Modulus testing in indirect tension mode. Road Mater Pavement Des 7(4):543–554

Ping W-V, Xiao Y (2008) Empirical correlation of indirect tension resilient modulus and complex modulus test result for asphalt concrete mixtures. Road Mater Pavement Des 9:177–200 (EATA 2008)

Nunn ME, Smith TM (1997) Improvements to the indirect tensile stiffness modulus test. In: TRL Paper PA 3209/96, 2nd European conference on performance and durability of bituminous materials, 17–18 April 1997

Chailleux E, Rammond G, Such C, de La Roche C (2006) A mathematical-based master-curve construction method applied to complex modulus of bituminous materials. Road Mater Pavement Des 7:75–92 (EATA 2006)

Booij HC, Thoone GPJM (24) 1982. Generalization of Kramers-Kronig transforms and some approximations of relations between viscoelastic quantities Rheol Acta(21):1–15

Rowe GM, Hakimzadeh S, Blankenship P, Mahboub KC (2009) Evaluation of aspects of E* test using HMA specimens with varying void contents. In: Transportation research board annual meeting

Ferry J-D (1980) Viscolelastic properties of polymers. Wiley, New York

Tschoegl NW (1989) The phenomenological theory of linear viscoelastic behaviour. An introduction. Springer-Verlag, New York, pp 143–145

Cost TL, Becker EB (1970) A multidata method of approximate Laplace transform inversion. Int J Numer Methods Eng 2:207–219

Coleman TF, Li Y (1996) A reflective Newton method for minimizing a quadratic function subject to bounds on some of the variables. SIAM J Optim 6(4):1040–1058

Hammoum F, Chailleux E, Nguyen H-N, Erhlacher A, Piau J-M, Bodin D (2009) Experimental and numerical analysis of crack initiation and growth in thin film of bitumen. Road Mater Pavement Des 10(1):39–61

Alfrey T (1944) Non-homogeneous stresses in viscoelastic media. Q Appl Math 2(113):113–119

Lacroix A, Khandan AAM, Kim R (2007) Predicting the resilient modulus of asphalt concrete from the dynamic modulus. In: Proceedings of TRB 2007

Di Benedetto H, Delaporte B, Sauzéat C (2007) Three-dimensional linear behaviour of bituminous materials: experiments and modelling. Int J Geomech ASCE 7:149–157

Acknowledgments

The authors would like to acknowledge MM, Triquigneaux J.-P., Carbonneau X., Pouteau B., Loup F. and Dayde R. who have actively participated to this study through the funding of USIRF (Union des Syndicats de l’Industrie Routière française).

Author information

Authors and Affiliations

Corresponding author

Appendix 1: Poisson ratio in the case an elastic response of the material under isotropic loading condition

Appendix 1: Poisson ratio in the case an elastic response of the material under isotropic loading condition

Hypothesis: The viscoelastic response of the material is assumed to originate only from shear strains and stresses whereas the volumetric response is supposed to be only purely elastic. Such an assumption derives from the fact that under a constant compression state of stress, only shear strain can significantly evolve in a long duration, whereas it is not possible for volumetric negative strain.

-

The strain/stress law writes:

$$ \varepsilon^{*} = {\frac{{\sigma^{*} }}{{2\mu^{*} }}} + {\text{tr}}(\sigma^{*} )\left[ {\frac{1}{9K} - {\frac{1}{{6\mu^{*} }}}} \right]I $$(26)with μ* being the complex shear modulus (temperature and frequency dependent) and K being the elastic bulk modulus. For f → ∞, the law ε*/σ* must be purely elastic. So, we can defined E inf and νinf such as:

$$ \left\{ {\begin{array}{*{20}c} {K = {\frac{{E_{\inf } }}{{3 \cdot \left( {1 - 2\upsilon_{\inf } } \right)}}}} \\ {\mu \left( {f \to \infty } \right) = {\frac{{E_{\inf } }}{{2 \cdot (1 - \upsilon_{\inf } )}}}} \\ \end{array} } \right. $$(27) -

Let us look at this law in case of a simple cyclic compression test for which:

$$ \sigma^{*} = \left[ {\begin{array}{*{20}c} {\sigma_{xx} } & 0 & 0 \\ 0 & 0 & 0 \\ 0 & 0 & 0 \\ \end{array} } \right] $$(28)then

$$ \varepsilon_{xx}^{*} = {\frac{{\sigma_{xx}^{*} }}{{2\mu^{*} }}}* + \sigma_{xx}^{*} \left[ {\frac{1}{9K} - {\frac{1}{{6\mu^{*} }}}} \right] = \sigma_{xx}^{*} \left[ {\frac{1}{9K} + {\frac{1}{{3\mu^{*} }}}} \right] $$(29)so

$$ E^{*} = {\frac{{\sigma_{xx}^{*} }}{{\varepsilon_{xx}^{*} }}} = {\frac{{9K\mu^{*} }}{{3K + \mu^{*} }}} $$(30)Beside

$$ \varepsilon_{yy}^{*} = \sigma_{xx}^{*} \left[ {\frac{1}{9K} - {\frac{1}{{6\mu^{*} }}}} \right] $$(31)So, the complex Poisson ratio value is given by:

$$ \upsilon^{*} = - {\frac{{\varepsilon_{yy}^{*} }}{{\varepsilon_{xx}^{*} }}} = \frac{1}{2} \cdot {\frac{{3K - 2\mu^{*} }}{{3K + \mu^{*} }}} $$(32) -

Now, let’s express ν* as a function of E*:

Equation 30 gives:

$$ \mu^{*} = {\frac{{3KE^{*} }}{{9K - E^{*} }}} $$(33)$$ \upsilon^{*} = \frac{1}{2} \cdot {\frac{{3K - 2{\frac{{3KE^{*} }}{{9K - E^{*} }}}}}{{{\frac{{3KE^{*} }}{{9K - E^{*} }}} + 3K}}} = \frac{1}{2} - {\frac{{E^{*} }}{6K}} $$(34)Finally, taking into account Eq. 27, the complex Poisson ratio writes:

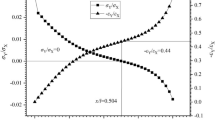

$$ \upsilon^{*} = \frac{1}{2} - \left( {\frac{1}{2} - \upsilon_{\inf } } \right){\frac{{E^{*} }}{{E_{\inf } }}} $$(35)It can be observed that:

$$ \upsilon^{*} (f \to o) = \frac{1}{2} - \left( {\frac{1}{2} - \upsilon_{\inf } } \right){\frac{{E_{0} }}{{E_{\inf } }}} \approx 0.5 $$(36)since E 0 ≪ E inf in case of bituminous materials.

And

$$ \upsilon^{*} (f \to \infty ) = \frac{1}{2} - \left( {\frac{1}{2} - \upsilon_{\inf } } \right){\frac{{E_{\inf } }}{{E_{\inf } }}} = \upsilon_{\inf } $$(37)

Glossary

- \( \delta_{\text{moy}}^{{(T_{j} ,T_{j + 1} )}} (\omega ) \)

-

Arithmetic mean of phase angles measured at frequency ω and at temperatures T j and T j+1

- C ref1 and C ref2

-

Coefficient of WLF law for a reference temperature of T ref

- |z*|

-

Complex number modulus z

- ν*

-

Complex Poisson’s ratio

- E* = E1 + iE2

-

Complex stiffness modulus

- E inf

-

E*(ω → ∞)

- F

-

Force (N)

- f

-

Frequency (Hz)

- E0, E i , τ i

-

Parameters of generalized Maxwell model

- δ

-

Phase angle (° ou rad)

- ν

-

Poisson’s ratio

- ω = 1/2πf

-

Pulsation (rad/s)

- E(t)

-

Relaxation modulus (MPa)

- ε

-

Strain

- σ

-

Stress

- T

-

Temperature (°C)

- h

-

Thickness of disk in indirect tensile test (m)

- a T (T1, T2)

-

Translation coefficient between isotherms T 1 and T 2 written as a function of log(ω). The coefficient a T is defined as follows:

E*(T1,ω) = E*(T2,a T (T1,T2)ω)

In particular a T (T 2, T 2) = 1

- z

-

Variation in disk diameter during indirect tensile test (m)

- νinf

-

ν*(ω → ∞)

Rights and permissions

About this article

Cite this article

Chailleux, E., de La Roche, C. & Piau, JM. Modeling of complex modulus of bituminous mixtures measured in tension/compression to estimate secant modulus in indirect tensile test. Mater Struct 44, 641–657 (2011). https://doi.org/10.1617/s11527-010-9655-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-010-9655-z