Abstract

The standard methods used to determine the mechanical properties of single aggregate particles have shortcomings. Indeed, methods that are commonly used to measure the strength of irregular particles do not provide their elastic modulus and are also only semi-quantitative. The aim of this work is to determine more accurately both the tensile strength and the elastic modulus of single coarse aggregate particles using the point load test fitted with tungsten carbide semi-spheres and coupled with a linear transducer. In the experiment, the poles of the particles are made flat and parallel at the points of contact with the semi-spheres of the apparatus, allowing to estimate the elastic modulus of aggregates in accordance to Hertz contact theory. Glass particles of different shapes (spheres, cubes, and prisms) were used as reference material to validate the experimental method and establish the optimal conditions to conduct the test. These conditions consisted of a deformation rate of 0.2 mm/min, a blunt 4.0-mm diameter cylinder piston for spherical particles, while two 14.0-mm diameter semi-spheres in the case of rectangular particles (cubes/prisms). It is also hereby proposed to measure the tensile strength of irregularly-shaped particles by a modified version of Hiramatsu and Oka’s formula using the equivalent core diameter. The proposed method was then applied to measure the strength and modulus of coarse granite aggregate particles (25.0 to 9.5 mm). It demonstrated that the variability of the elastic modulus and tensile strengths of the individual aggregate particles was quite significant, confirming the importance of using the proposed improved method to qualify materials for structural (high strength) concrete, or to simulate/predict the mechanical behavior of concrete.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Coarse aggregates represent about 45% of the volume of the concrete. They influence the structural performance of concrete, with an impact in the elastic modulus and the compressive strengths of concretes higher than 50 MPa [1,2,3,4]. In spite of the significance of the contribution of aggregates in concrete, there is not yet a widely accepted standard method available to measure the mechanical properties of single aggregate particles. Methods that are available are limited to determining the load involved in fragmentation (due to impact) of particles assembled in groups, allowing only qualitatively to assess their strength [5].

Presently, mechanical properties of single aggregate particles are often determined using uniaxial quasi-static compression tests [6], in which one of the most used configurations is the Point Load Test (PLT) [7]. PLT has the advantage of using universal testing machines, that are commonly found in civil engineering laboratories. Tests were used to qualify particles of many rock types (gneiss, granites, quartzite, diorite, basalt, limestone, marble) for geotechnical applications [15,16,17], railway ballast [18, 19], or coarse aggregates used in concrete [20]. Tensile strengths of the rock particles (from 4 to 30 mm of size) are significantly variable, varying from about 3 to 9 times even for a material with the same mineralogical origin. For instance, the tensile strength of granite particles contained in the 10–30 mm size range varied from 10 to 45 MPa [18, 19].

Different approaches have been used to conduct the test: some researchers prefer to work with force control systems [6, 8, 9], while others favor displacement control [10,11,12,13,14,15], without a consensus on which condition is preferable. In American Standard ASTM D 4179, the control is done by force rate (4.40–44.00 N/s) whereas in Japanese's standard JIS Z 8841; the control is done by displacement rate (0.15–0.30 mm/s).

The ASTM D 5731: 2016 standard procedure uses the concept PLT to estimate the point load strength index of irregular rocks particles. In this test, the end part of the compressive fixtures is semi-spherical with 5 mm radius to ensure a point load contact. However, different fixtures have been proposed for single-particle point load tests. Blunt cylindrical indenters or large parallel platens have been used for estimating the tensile strength of regular-shaped (spheres [16, 17], cubes and prisms [15]) as well as irregularly-shaped particles [18,19,20].The types of fracture for regularly-shaped particles were similar to those expected using the point load test method. While testing irregularly-shaped particles has the benefit of convenience, it is responsible for generating large scatter in the data [7, 20], since optimal loading conditions cannot be ensured. On the other hand, testing particles shaped into spheres or other regular geometries has the benefit of full control of loading conditions but at the expense of large effort in sample preparation.

Some studies have shown that it is possible to estimate the elastic properties of single particles during the quasi-static uniaxial compression test by Hertz contact theory. To satisfy this theory (plane-spherical contact), two rigid flat plates have been used to apply the load to spherical particles or those that are perceived as such and a Linear Variable Differential Transducer (LVDT) to determine the particle displacement during the elastic contact [21, 22]. This test arrangement has limited application for coarse aggregates, since they are never truly spherical and the effort to machine them into this shape is formidable. On the other hand, the risks of assuming that stresses in irregularly shaped particles are indeed equivalent to those in a sphere are too large. Furthermore, particle irregularity and the accumulation of damage during deformation of the particle may affect the development of the Hertz contact area, making it imprecise for determining of the elastic modulus. In testing irregularly-shaped particles, Portnikov and Kalman [21] showed that only 63% of the tests could be considered valid, and this amount seemed to improve as the particles approached a spherical shape.

The objective of the work is to determine the tensile strength and elastic modulus of single coarse aggregate particles using PLT coupled with an LVDT, without the need to assume that irregularly-shaped particles are spheres. A new test arrangement to determine elastic modulus of particles was proposed through cutting the particle surfaces and then subjecting them to compression using semi-spherical fixtures fitted to the apparatus, so that geometrical requirements for application of Hertz contact theory are properly met. In this setup, a well-defined force–displacement curve and more accurate/valid results are obtained, since the superficial irregularities of the particles are eliminated. The method is initially validated for glass, a reference and model material, and then its applicability to aggregates is demonstrated for granite particles contained in the 25.0–9.5 mm size range.

2 Background

2.1 Measurement of strength of single particles

According to the theory of elasticity, the strength of a particle can only be defined when the state of stresses generated by loading is known [23]. Hiramatsu and Oka [24] applied a pair of concentrated loads in artificially produced epoxy particles of different shapes (spheres, cubes, rectangular prisms, etc.), and demonstrated by photoelasticity that the stress states of the particles with different shapes were quite similar in the vicinity of the load axis.

Analyzing the maximum stress theoretically for a spherical particle, the authors [20] proposed estimating the tensile strength (σt) using Eq. 1, considering only the breakage force (Fb) and the distance between the points of application of the compressive loads (D):

It is known that the strength of brittle materials is affected by the size, position, and distribution of defects in the solid body [25]. Such defects result in internal stress concentrations in the brittle solids limiting their strength, as explained using principles from Griffith’s theory. For particulate materials, the larger the volume of the particle, the higher the probability that critical defects are contained in it, and the lower their tensile strength [9]. Several experimental studies have shown that even when particles with homogeneous composition, such as glass, are tested, their breakage strength is very scattered [9, 12, 26].

Regarding the influence of particle size or volume (that includes the variation of height and shape of particles) on tensile strengths, Brook [27] proposed an expression (Eq. 2), which corrects the strength estimation of irregularly-shaped rock particles by using an equivalent core diameter (De). De represents the diameter of the core that has the same minimum cross-sectional area as the irregular body, and that is calculated using Eq. 3. The largest dimension of an elongated particle is usually tested in contact with the plane. Ac is the minimum cross-sectional area of the irregular body (minimum width—W × distance between the point loads—D), given by Eq. 4. This expression is considered valid under some particle geometric rules [27, 28].

In the literature, strengths have been measured for different shapes of railway ballast aggregates using the De concept [28]. Indeed, a standard procedure with this concept is used nowadays to estimate the point load strength index of irregular rocks particles (ASTM D 5731: 2016).

2.2 Measurement of the elastic properties

During compression, the contact area of a spherical particle of diameter d in contact with a blunt (flat) stiff punch is a circle of growing diameter [29]. The relationship between the force (Fel) and the displacement (s) during elastic deformation of the particle follows a power law relationship, as described by Hertz contact theory [30]:

where E* is the effective modulus of contact, given by:

Equation 6 is a result of the stiffness of the materials in contact, that is, of the particle (kp) and the load application punches (kt):

E and µ are the elastic moduli and Poisson’s coefficients of the materials involved in the contact, respectively. Generally, the stiffness of the punches is known, and then the elastic modulus of the particle under compression can be determined from obtaining the effective modulus of contact from the force–displacement curve. Whenever Et ≫ Ep the term kt in Eq. 6 can often be disregarded.

When the load is applied at the two poles of the particle, two symmetric contact areas are formed, and the total displacement measured (S) is the sum of the displacement of both contacts (S = 2 s). Then Eq. 5 leads to Eq. 9. The mean contact stiffness during elastic deformation in the normal direction (\(K_{N,el}\)) (Eq. 10) can then be calculated from the gradient of Eq. 9.

Due to the parabolic relationship between F and s, the contact stiffness increases with displacement (S), in a strain-hardening response that is typical of a Hertzian contact. This value will increase reaching a maximum value in the yield point (Y) [21, 22], where elastic–plastic deformation may occur. The point has been confirmed from the growing deviation between the experimental and theoretical Hertz force–deformation curve, as well as in the reduction of the median stiffness contact [21].

Another approximate method of estimating the effective contact modulus is by using Eq. 11, as suggested by Tavares [7]. It is estimated from the relationship between the strength of the particles (σt—Eq. 1) and the fracture energy (En—Eq. 12). The fracture energy needs to be corrected by mass (mp) and particle density (ρp), calculating the volumetric specific fracture energy—Ev (Eq. 13):

where β = \(\frac{{m_{\text{p}} }}{{D_{\text{n}}^{3} \rho_{\text{p}} }}\) or Vp/D3n is the particle shape factor, Dn is the nominal particle diameter (represented by the second largest particle size, Fig. 7—“Appendix”) and Vp is the particle volume.

3 Experimental design, materials and methods

3.1 Method development: influence of parameters

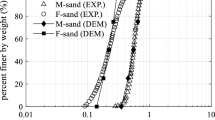

Soda-lime glass was used as the reference material as it is brittle [31] and isotropic, with homogeneous composition, non-porous, and with well-known mechanical properties. Tensile strength (σt), Poisson's ratio (µ) and elastic modulus (E) of soda lime glass were taken as 69 MPa, 0.23 and 69 GPa, respectively [25]. Different geometries of test pieces were tested, namely spheres (diameters equal to 4.0, 9.5 and 15.8 mm), cubes (15.0 × 15.0 × 15.0 mm) and rectangular prisms (15.0 × 30.0 mm). High-precision glass spheres were obtained from a commercial supplier. The other glass geometries (cubes and rectangular prisms) were prepared from cutting 15.0 mm-thickness glass plates using a water jet cutting machine with garnet as abrasive (Omax, Model 2652 Precision JetMachining Center).

Mechanical tests were conducted using an INSTRON electromechanical dual-column testing machine (model 5569), equipped with a 50 kN load cell. Different fixtures were required for the various particle shapes tested (Fig. 1). A 70 mm hard steel (ASTM D6) thread flange was used to fix the different endings to the fixture. Both ending parts (upper and lower) were fitted to the testing machine with the aid of 12.7 mm-diameter pins. The lower plate was designed to attach to the LVDTs, while the upper plate was designed to be in direct contact with the LVDTs. In the upper apparatus, an acrylic protector was attached to two threaded openings (to protect from an unexpected detachment of fragments from specimen breakage). Punches with three different endings were designed for load application: 4.0 and 38.0 mm diameter flat cylindrical tempered steel and 14.0 mm diameter semi-spherical tungsten carbide (WC).

In order to apply Hertz contact theory (contact between flat-spherical body) and the strength equations, spherical particles were tested with a flat (blunt) punch, whereas particles containing flat surfaces (cubes and prisms) were tested using the semi-spherical punch. In the case of the semi-spherical punch, sponge and brass rings were used to assist in proper sample placement, and both presented a larger diameter than the semi-sphere. During the test, when the compressive load was applied, the sponge ring was compressed, thus avoiding the particle from spinning and providing the expected contact between the sample and the semi-sphere bottom fixture.

As part of the test procedure development, experiments were conducted at different test conditions, namely displacement rate and type of ending parts (flat cylinders and semi-spherical ending), to analyze their influence on the precision and accuracy of the measurements.

3.1.1 Effect of rate of displacement for glass

Deformation rate has been known to affect the propagation of cracks and the strength of brittle materials [32, 33]. Quasi-static conditions [7] correspond to displacement rates in which the duration of contact is sufficient to allow stresses to propagate and balance throughout the particle [7]. These experiments aimed to analyze if an increase in displacement rate could influence the measured mechanical properties (tensile strength and elastic modulus) of the particles.

The displacement rates of 0.1, 0.2, 0.5 and 1.0 mm/min were tested. For each displacement rate studied, ten 9.5 mm diameter glass spheres were tested by applying a compression load using the 38.0 mm cylindrical termination punch, so that a total of 40 tests were conducted. Results were used only to analyze the accuracy and precision of the method, through comparisons of averages and standard deviations. No attempt was made to describe probabilistic distributions of strengths and elastic moduli values of the glass particles.

3.1.2 Flat cylinder endings and sphere sizes

In the experiments it was investigated if a reduction in contact area would affect the elastic modulus or the strength. Based on the results of experiments given in 3.1.1, the following tests were conducted at the set strain rate of 0.2 mm/min. Glass spheres with nearly identical size (d = 9.5 mm) were tested with the flat 4 mm-diameter cylinder ending, with a total of 10 tests, and results were compared to those obtained using the 38.0 mm cylindrical termination, with everything else constant. In order to investigate the influence of the diameter of the bead on the mechanical properties of glass, 4.0 mm and 15.8 mm diameters spheres were tested using the flat 4.0 mm-diameter cylinder ending.

3.1.3 Semi-spherical endings tested in cubes and rectangular prisms

The use of semi-spherical tungsten carbide of 14.0 mm diameter endings at the fixture was tested on glass cubes and prisms. The purpose of this test configuration, in which the load application punch is the spherical body, and the sample surface is flat, is the estimation of the elastic modulus of the particle by Hertz contact theory. Ten glass cubes (15.0 × 15.0 mm) and ten rectangular glass prisms (15.0 × 30.0 mm) were subjected to testing.

In addition, different equations used to estimate strength (Eqs. 1, 2) were compared, besides the effect of particle shape on strength, through comparison of strengths measured with spheres, cubes, and prisms, all at a nearly constant distance between points of load application (D = 15.0–16.0 mm).

3.2 Testing single aggregate particles

A sample of about 3 kg of natural coarse granite aggregates supplied in the metropolitan region of São Paulo (Brazil) was collected. Sample preparation consisted of sieving so that the material contained in the 25.0 to 9.5 mm size range was selected for testing. The test method was applied to 40 selected particles contained in this fraction. Aggregates in this size range represent the coarsest size commonly used in concrete. Due to its volume, those are more likely to have the largest (critical) defects and, consequently, to have the lowest strength.

In order to allow estimating the elastic modulus using Hertz elastic contact theory, the plane-spherical contact between the particle and the load application punch was ensured. Since the aggregate particles presented irregular and rough surfaces, cutting of two opposing surfaces along the largest dimension of each particle were generated with the aid of a high precision cutting equipment (Accuton-50, Struers).

3.3 Determination of the mechanical properties

The tensile strength and the elastic modulus were calculated from the measured force–displacement curve, with the aid of the load cell and the LVDT, until breakage. The tensile strength of spheres was determined using Hiramatsu and Oka's approach (Eq. 1) [24]. In the case of particles with cubic and prismatic shapes the equation proposed by Brook [27] and ASTM D5731: 2016 [34] was also applied using the equivalent diameter (De) (Eq. 2). In this De is the equivalent core diameter that has the minimum cross-sectional area of the particle, which in this work was considered at the load application point.

A two-stage process was used for estimating the elastic modulus of the particles (Fig. 8—“Appendix”). In the first stage, the extent of the curve corresponding to the region of elastic deformation of the particle was analyzed. For each fractured particle, the median contact stiffness (KN) was estimated from the linear fitted slope of the measured points after dividing the experimental curve into 25 sections, according to the procedure proposed by Portnikov and Kalman [21]. The elastic region is characterized by increasing median contact stiffness with cumulative displacement until the yield point (Y), from which the elastic–plastic deformation associated with a moderate decrease in stiffness initiated. In the second step, it was verified if the elastic deformation region (until the yield point—Y) adhered to the Hertz theoretical curve, based on a simplified version of Eq. 9, given by Fel = C*s1.5 where C is an empirical constant obtained in fitting the force-displacement data until the yield point.

Whenever data adhered to the Hertz contact theory, the contact area of the deformable particle in this elastic region presented a comparatively circular or elliptical geometry, and then the modulus of elasticity could be calculated using Eq. 6. The effective modulus of contact (E*) was determined with E* = 3C/ \(\sqrt {\text{d}}\), where d is the diameter of the spherical body taking part in the contact. High stiffness materials were used in punch to prevent them from deforming or damaging during the test. In the case of the flat cylindrical of tempered steel punch, Et,steel was taken as 210 GPa and μt,steel as 0.28, whereas in the case of the semispherical tungsten carbide punch, Et,wc was taken as 406 GPa and μt,wc as 0.30.

Poisson’s ratio for glass particle was taken as μp, glass 0.23 [25] and for granite (μp, granite) 0.24 [35]. The Hertzian particle stiffness (kp) was estimated from Eq. 6. The Fracture energy was estimated from the area of the force versus displacement graph (Eq. 12).

For the granite aggregates, reference Hertz theoretical curves were constructed for comparison with the experimental force–displacement curves. These curves were constructed considering extreme values of elastic modulus found in the literature for the granite aggregates, namely 40 GPa (Ep, minimum) and 70 GPa (Ep, maximum) [35].

4 Results and discussion

4.1 Method development: influence of parameters

4.1.1 Effect of rate of displacement for glass

This study was conducted with the aim of identifying the most appropriate condition to run the experiments, rather than a detailed study of strain rate effects on the mechanical properties. Figure 2 presents loads versus displacement curves for glass spheres (d = 9.5 mm) tested with the flat cylindrical punch (38.0 mm diameter) at different displacement rates (0.1 to 1.0 mm/s). The fitting Hertz theoretical curve and the contact stiffness are also plotted on the graph for one of the results (curve analyzed) since no large differences between results were observed. The yield point (Y) was not seen, so that the behavior may be considered perfectly elastic, without any plastic deformation, as already observed by other authors [21].

For the lower displacement rates (0.1 and 0.2 mm/min), the curves are less variable than the curves obtained at higher rates (0.5 and 1.0 mm/min). Indeed, Table 1 shows that tensile strengths (Eq. 1) and elastic moduli were less variable at the lower displacement rates (0.1 and 0.2 mm/min). On the basis of results from this, the deformation rate of the test was set to 0.2 mm/min.

4.1.2 Flat cylinder endings and sphere sizes

The effect of reducing the diameter of the flat cylinder punch and the effect of changing the sphere size on mechanical properties is at this moment studied, from experiments with the deformation rate set to 0.2 mm/min. In these experiments, the sphere is in contact with two flat cylinder punches (4.0 mm diameter and area of approximately 12.6 mm2), which is significantly lower than the circle area of the cylinder punch with 38.0 mm diameter (area ~ 1,13 mm2) used in item 4.1.1, so that the flat area was reduced approximately 90 times.

Figure 3a presents force versus displacement profiles of the glass spheres subjected to compression with the flat cylinder ending (diameter 4.0 mm). All curves presented perfectly elastic behavior until breakage, as shown for one curve of the results of each spheres diameter in Fig. 3b.

The results for spheres with d = 9.5 mm were similar to those obtained for the flat cylinder ending with the larger area (Fig. 2). We observed that the response curves are more variable when the area of the flat cylinder punch is reduced, which is likely due to the reduction of the moment of inertia of the tool. However, it was not considered critical and, since it is more practical to align the fixture and the sample, it was decided to carry out additional experiments with the 4.0 mm diameter flat cylinder punch.

The change in sphere diameters from 4.0 to 15.9 mm increased the contact stiffness; however, the particle stiffness (or Elastic modulus) for the glass spheres of different sizes did not change in the same order (Table 2), being similar for the larger spheres (d = 9.5 and d = 15.9 mm).

The force necessary for fracture increased with the size of the sphere (Table 2); however, this increase did not represent an increase in tensile strength. Indeed, a reduction of tensile strength (~ 0.6 times, on average) was observed with an increase in size of the glass spheres, as expected [9, 22, 23], given the increases in the number and size of defects with the volume of the particles.

4.1.3 Testing of cubes and rectangular prisms using semi-spherical endings

Figure 4 shows the experimental force versus displacement curves of the glass cubes and prisms tested using the 14 mm diameter semi-spherical tungsten carbide ending. It shows that Hertzian contact was also valid for the two rigid semi-spheres endings in contact with the flat glass specimen, since the behavior of the force versus displacement curve (or contact stiffness) was similar to that obtained for the spherical particles compressed between flat-ended fixtures, that is, fully elastic behavior until rupture. The diameter used in Eq. 9 is the diameter of the tungsten carbide semi-sphere.

The values of effective modulus of contact of the glass cubes (15.0 × 15.0 mm) and of the glass prisms (15.0 × 30.0 mm) were slightly higher than those of the 15.9 mm diameter glass spheres. This is not surprising, given the higher elastic modulus (and stiffness) of the tungsten carbide semi-spheres endings (Et,wc = 406 GPa and µt,wc = 0.30) used in the experiments with cubes/prisms in comparison to those of the steel plates (Et,steel = 210 GPa and µt,steel = 0.28), used in the compression of glass spheres. As such, the term kt in Eq. 6 should be accounted for, in particular when the elastic properties of materials in contact change.

Differences between the effective modulus of contact of the cubes and the prisms compared with that of spheres reduced when the particle stiffness was analyzed. The average particle stiffness (kp) of the cubes and the prisms was only slightly higher than that of the sphere, as the influence of tool kt was properly accounted for. Indeed, the values of elastic modulus of the cubes and the prisms (Table 3) were consistent with those expected (~ 69 GPa) and also similar to those already reported in Table 2 for spheres.

In the expression proposed by Hiramatsu and Oka [24] (Eq. 1), the tensile strength of the particle is estimated considering only the distance between the point loads (D). These values were nearly the same for tests using cubes/prisms (D = 15.0 mm) and part of the spheres (D = 15.9 mm). Nevertheless, since the volumes of the particles were different, it is incorrect to assume that the tensile strengths of spheres, cubes, and prisms would be the same, even if the load application distance (D) would not vary. It is known that the tensile strength varies as a function of the volume of the particle [9, 26], since the larger the volume of the particle the higher the probability to find large defects inside them. The experiment highlighted these differences, as well as on surface finish and route used in material production. Indeed, the volumes of the prism (15.0 × 30.0 mm), the cube (15.0 × 15.0 mm) and the sphere (diameter 15.9 mm) were quite different: ~ 6750, 3375, and 2145 mm3, respectively.

Using Hiramatsu and Oka's equation, tensile strengths of the cubes (15.0 × 15.0 mm) and of the prisms (15.0 × 30.0 mm) were assumed to be equivalent to that of a sphere (diameter 15.0 mm) of ~ 1767 mm3 volume. The tensile strengths appear overestimated, as the 15.0 mm-diameter sphere volume is 2–4 times lower than that of the cube and prism.

The glass particles of different shapes showed the types of rupture considered valid by ASTM D 5731: 2016 and Brook [27] (Fig. 9—“Appendix”). Using the ASTM D 5731: 2016 equation —Eq. 2, the cross-section area (usually the minimum one) is the most critical parameter to estimate the tensile strength of the particle, as the fracture is induced through this plane. This formula takes into consideration two particle dimensions, as opposed to only one in the Hiramatsu equation. The cross-sectional areas of the cubes and prisms were identical (~ 225 mm2). The equivalent core diameter was then calculated using Eq. 3 (De = 16.93 mm) and tensile strengths were estimated using Eq. 2. The volume of the 16.93 mm-diameter sphere is equivalent to 2538 mm3 and was found to be similar to that of the cube and prisms.

Tensile strengths estimated considering the equivalent core diameter (ASTM procedure) were in closer agreement (R2 = 0.84) with the volumes of irregular (different shaped) particles, ensuring results that were consistent with the literature [9, 12, 26] (Fig. 5a). In Fig. 5b the unique relationship between tensile strength and the specific-volume fracture energy-adjusted by particle shape factors, as suggested by Tavares and King [36] (Eq. 11) was demonstrated to be valid. Results from using this equation were close to those obtained using the mean value of the particles (spheres, cubes, and prisms) obtained by fitting the value to the Hertz relationship (~ 68.5 GPa).

4.2 Testing single aggregate particles

It is worth noting that tests with aggregates only started after the calibration of the test apparatus using reference material (prismatic glass particle), to ensure accuracy in terms of elastic moduli determination, which was rather constant in the case of glass prisms. In order to consider results of tensile strength valid, the types of rupture also need to be considered valid. Indeed, most of coarse aggregate particles (80%) broke in two planes (Fig. 10—“Appendix”) as results of mechanical testing with the semi-spherical ending (14.0 mm diameter). This type of rupture is considered valid by ASTM D 5731: 2016 and Brook [27], also validating the application of Eq. 2 to determine the strength of the aggregate particles.

The fitted Hertz theoretical model is also shown for comparison (Eq. 8) in Fig. 6a. Theoretical reference curves were constructed using values of elastic modulus and Poisson’s ratio available in the literature for granite (Ep,granite = 40 and 70 GPa and μp,granite = 0.24). Most of the measured values of elastic modulus of the particles were within the range of these values from the literature [35]. Typical contact stiffness curves for the granite aggregate particles tested are shown in Fig. 10b. Whereas the yield point pointed in the literature [21, 22] is observed; granite aggregates exhibited predominantly elastic behavior, with only a modest elastic–plastic region.

The method used to estimate the modulus of elasticity based on Hertz contact mechanics appears to be valid since the experimental curves were in good agreement with Hertz contact theory curves fitted on the basis of values of elastic moduli found in the literature for granite [35]. The condition required is the preparation of a flat surface of the aggregate and spherical contact from the tungsten carbide apparatus, as previously tested and validated for glass, the reference material.

Both modulus of elasticity and strength results showed significant variation, ranging from 18 to 67 GPa (3.7 times) and 3.2 to 14.5 MPa (4.5 times), respectively. The strength results presented variations that were similar to those found in the literature, that is, 3 to 4 times for granite particles [18, 19]. A population of aggregate particles of the same type of rock may present different mechanical properties, depending on their location within the mineral deposit and/or their state of weathering, since different populations of flaws, both in terms of size and distribution, may be present in each of them.

5 Conclusions

In this study the tensile strength and the elastic modulus of single coarse aggregate particles were determined using PLT coupled with an LVDT, without assuming that irregular particles are spheres. For this, single particle compression tests were performed initially using glass particles as reference material to validate experimental conditions and, afterwards, tested in coarse granite aggregates.

The mechanical properties of single glass particles of different shapes were precisely estimated using compression-point load tests with an LVDT measurement fitted to parallel steel plates. A strain rate of 0.2 mm/min was recommended since it allowed obtaining more uniform force–displacement profiles. Spherical particles can be tested using steel flat-cylinder endings (diameter 4.0 mm), whereas particles with flat contact surfaces, such as cubes and prisms, can be tested with two tungsten carbide semi-spheres at the ending of the fixtures. Tensile strengths of different-shaped particles seem to be more accurately predicted by Hiramatsu and Oka's equation using the equivalent core diameter (ASTM procedure). The Hertzian elastic body contact theory can be used to estimate the elastic modulus.

The test method was demonstrated to be appropriate to estimate the strength and elastic modulus of coarse granite aggregates. The tungsten carbide punch with a diameter of 14.0 mm was used for the application of the load and particles were previously cut to create two opposing flat surfaces that were parallel to their largest dimension. More consistent results were obtained using this method than those found in literature that assume irregular particles as spheres [21], since Hertz elastic contact conditions were guaranteed, and concentration of tension of irregular particles was avoided. Elastic moduli and tensile strengths of the coarse granite aggregate particles were found to vary significantly, which demonstrates the importance of testing in order to qualify these materials for structural (high strength) concrete, and/or, to simulate/predict the mechanical behavior of concrete.

Change history

30 July 2019

This article was published with an erroneous name of one of the authors and therefore has been corrected.

06 July 2020

The article ������Improved method to measure the strength and elastic modulus of single aggregate particles������, written by ������Natalia V. Silva, S��rgio C. Angulo, Aline da Silva Ramos Barboza, David A. Lange, Lu��s M. Tavares������, was originally published electronically on the publisher���s Internet portal (currently SpringerLink) on 6 July 2019 without open access.

Abbreviations

- A c :

-

Minimum cross-sectional area

- B :

-

Breakage point

- C :

-

Emprirical constant

- D :

-

Diameter of spherical body

- D :

-

Distance between loading points

- D n :

-

Nominal diameter

- D e :

-

Equivalent core diameter

- E * :

-

Effective modulus of contact

- E t :

-

Elastic modulus of the punch

- E p :

-

Elastic modulus of the particle

- E n :

-

Fracture energy

- E v :

-

Specific-volume fracture energy

- F :

-

Applied force

- F b :

-

Breakage force

- F el :

-

Force during elastic deformation

- k p :

-

Particle stiffness

- k t :

-

Punch stiffness

- K N-el :

-

Contact stiffness during elastic deformation

- m p :

-

Particle mass

- s :

-

Displacement

- S :

-

Total displacement

- ∆s :

-

Displacement variation

- V p :

-

Volume of the particle

- W :

-

Minimum width

- Y :

-

Yield point

- σ t :

-

Tensile strength

- μ p :

-

Poisson’s coefficient of the particle

- μ t :

-

Poisson’s coefficient of the punch

- β :

-

Shape factor

- ρ p :

-

Particle density

References

Giaccio G, Rocco C, Violini D, Zappitelli J, Zerbino R (1992) High-strength concretes incorporating different coarse aggregates. Mater J 89:242–246

Aitcin PC, Mehta PK (1990) Effect of coarse aggregate characteristics on mechanical properties of high-strength concrete. Mater J 87:103–107

Beushausen H, Dittmer T (2015) The influence of aggregate type on the strength and elastic modulus of high strength concrete. Constr Build Mater 74:132–139. https://doi.org/10.1016/j.conbuildmat.2014.08.055

Alexander MG, Mindess S (2008) Aggregates in concrete. Taylor & Francis, London

Neville AM (2011) Properties of concrete, 5th edn. Pearson, New York

Portnikov D, Kalman H, Aman S, Tomas J (2013) Investigating the testing procedure limits for measuring particle strength distribution. Powder Technol 237:489–496

Tavares LM (2007) Chapter 1 breakage of single particles: quasi-static. In: Salman A, Ghadiri M, Hounslow M (eds) Handbook of powder technology. Elsevier, Amsterdam, pp 3–68. https://doi.org/10.1016/s0167-3785(07)12004-2

Yashima S, Kanda Y, Sano S (1987) Relationships between particle size and fracture energy or impact velocity required to fracture as estimated from single particle crushing. Powder Technol 51:277–282

Yashima S, Saito F (1979) Size effects of particle compressive strength of brittle Solids. Sci Rep Res Inst Tohoku Univ Ser Phys Chem Metall 27:31–42

Antonyuk S, Heinrich S, Tomas J, Deen NG, Van Buijtenen MS, Kuipers JAM (2010) Energy absorption during compression and impact of dry elastic-plastic spherical granules. Granul Matter 12:15–47. https://doi.org/10.1007/s10035-009-0161-3

Antonyuk S, Tomas J, Heinrich S, Mörl L (2005) Micro-macro breakage behavior of elastic-plastic granulates by compression. Chem Eng Technol 28:623–629. https://doi.org/10.1002/ceat.200407060

Huang J, Xu S, Yi H, Hu S (2014) Size effect on the compression breakage strengths of glass particles. Powder Technol 268:86–94. https://doi.org/10.1016/j.powtec.2014.08.037

Russell A, Schmelzer J, Müller P, Krüger M, Tomas J (2015) Mechanical properties and failure probability of compact agglomerates. Powder Technol 286:546–556. https://doi.org/10.1016/j.powtec.2015.08.045

Russel A, Müller P, Tomas J (2013) Material behavior of spherical elastic-plastic granules under diametrical compression. Patiata, India

Ahmadi Sheshde E, Cheshomi A (2015) New method for estimating unconfined compressive strength (UCS) using small rock samples. J Pet Sci Eng 133:367–375. https://doi.org/10.1016/j.petrol.2015.06.022

Cheshomi A, Sheshde EA (2013) Determination of uniaxial compressive strength of microcrystalline limestone using single particles load test. J Pet Sci Eng 111:121–126. https://doi.org/10.1016/j.petrol.2013.10.015

Cheshomi A, Mousavi E, Ahmadi-Sheshde E (2015) Evaluation of single particle loading test to estimate the uniaxial compressive strength of sandstone. J Pet Sci Eng 135:421–428. https://doi.org/10.1016/j.petrol.2015.09.031

Lim WL, McDowell GR, Collop AC (2004) The application of Weibull statistics to the strength of railway ballast. Granul Matter 6:229–237

McDowell GR, Lim WL, Collop AC (2003) Measuring the strength of railway ballast. Ground Eng 36:25–28

Pepe M, Grabois TM, Silva MA, Tavares LM, Toledo Filho RD (2018) Mechanical behaviour of coarse, lightweight, recycled and natural aggregates for concrete. Proc Inst Civ Eng Constr Mater. https://doi.org/10.1680/jcoma.17.00081

Portnikov D, Kalman H (2014) Determination of elastic properties of particles using single particle compression test. Powder Technol 268:244–252. https://doi.org/10.1016/j.powtec.2014.08.011

Antonyuk S, Tomas J, Heinrich S, Mörl L (2005) Breakage behaviour of spherical granulates by compression. Chem Eng Sci 60:4031–4044. https://doi.org/10.1016/j.ces.2005.02.038

Timoshenko S, Goodier JN (1951) Theory of elasticity. McGraw-Hill, New York

Hiramatsu Y, Oka Y (1966) Determination of the tensile strength of rock by a compression test of an irregular test piece. Int J Rock Mech Min Sci 3:89–99

Callister WD, Rethwisch DG (2014) Materials science and engineering: an introduction, 9th edn. Wiley, Hoboken

Kschinka BA, Perrella S, Nguyen HCBR, Bradt RC (1986) Strengths of glass spheres in compression. J Am Ceram Soc 69:467–472

Brook N (1985) The equivalent core diameter method of size and shape correction in point load testing. Int J Rock Mech Min Sci Geomech Abstr 22:61–70. https://doi.org/10.1016/0148-9062(85)92328-9

Koohmishi M, Palassi M (2016) Evaluation of the strength of railway ballast using point load test for various size fractions and particle shapes. Rock Mech Rock Eng 49:2655–2664. https://doi.org/10.1007/s00603-016-0914-3

Johnson KL (1982) One hundred years of hertz contact. ImechE, London

Hertz H (1882) Über die Berührung fester elastischer Körper. Reine Angew. 92:156–171

Dowling NE (2013) Mechanical behavior of materials: engineering methods for deformation, fracture, and fatigue, 4th edn. Pearson, Boston

Yashima S, Kanda Y, Saito F, Sasaki T, Iijima M (1973) Mechanical properties of brittle materials and their single fracture under dynamic loads. Sci Rep Res Inst Tohoku Univ Ser A Phys Chem Metal 37:1218–1226

Yashima S, Shoichi M, Saito F (1979) Single particle crushing under slow rate of loading. Sci Rep Res Inst Tohoku Univ Ser A Phys Chem Metal 28:116–133

American Society of Testing and Materials (2008) ASTM Standard D 5731—Determination of the Point Load Strength Index of Rock and Application to Rock Strength Classifications

Sbrighi N (2011) Agregados Naturais, Britados e Artificiais para Concreto. In: Concreto Ciênc. E Tecnol., 1a, Instituto Brasileiro do Concreto, São Paulo

Tavares LM, King RP (1998) Single-particle fracture under impact loading. Int J Miner Process 54:1–28. https://doi.org/10.1016/S0301-7516(98)00005-2

Acknowledgements

Natalia V. Silva and Sérgio C. Angulo received research scholarship grants of FAPESP Numbers 2016/02902-0 and 2016/19974-3, respectively. Sérgio C. Angulo also received a research grant from CNPq, process 305564/2018-8. The information and views set out in this study are those of the authors and do not necessarily reflect the opinion of FAPESP or CNPq. Luís Marcelo Tavares received the research grant from CNPq process 310293/2017-0. David A. Lange received support from the RECAST University Transportation Center established at Missouri University of Science and Technology.

Funding

The study was funded by a research project entitled “Granulometric concepts and advanced processing applied to ecoefficient concrete” between the University of Sao Paulo (USP) and InterCement S.A, as well as by the National Institute of Science and Technology “Advanced Eco-Efficient Cement-Based Technologies”, between USP and CNPq agency.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article was published with an erroneous name of one of the authors and therefore has been corrected.

The original version of this article was revised due to a retrospective Open Access order.

Appendix 1

Appendix 1

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Silva, N.V., Angulo, S.C., da Silva Ramos Barboza, A. et al. Improved method to measure the strength and elastic modulus of single aggregate particles. Mater Struct 52, 77 (2019). https://doi.org/10.1617/s11527-019-1380-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-019-1380-7