Abstract

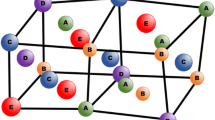

According to Zhang et al. (Prog Mater Sci 61:1, 2014, https://doi.org/10.1016/j.pmatsci.2013.10.001), High-Entropy Alloys (HEAs) are an emerging class of advanced materials that contain multiple elements in equiatomic or near equiatomic concentrations. In recent years, extensive efforts have been made to design HEAs with suitable microstructures and superior properties. This work reports the preliminary results of fabrication and characterization of three HEAs (TiVCrAl, TiVCrMn, TiVCrMo) with equiatomic compositions. These HEAs were designed with the purpose of producing a single-phase BCC, according to calculations with the HEAPS (Martin et al. in Comput Phys Commun 278:108398, 2022, https://doi.org/10.1016/j.cpc.2022.108398) and CALPHAD programs. Microstructures consisting of BCC + C14 Laves phases (Mn), a mixture of two cubic phases (Mo) and a single BCC phase, were found, basically consistent with CALPHAD predictions, although the phase volume fractions and compositions were not accurately predicted.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

High-entropy alloys (HEAs) represent a promising class of multicomponent materials with tailorable properties/functionalities [1], for example, a good combination of strength and ductility [2], high creep resistance [3], tunable magnetic behavior [4], and interesting hydrogen storage properties [5]. Metal hydrides with a body-centered cubic (BCC) structure are promising hydrogen storage materials that can accommodate hydrogen in interstitial sites, in many cases without a change in crystal structure [6]. Because of their relatively low molar weight, transition metal-based alloys containing Ti, V, and Cr can absorb relatively large amounts of hydrogen [7]. Chromium and vanadium show a BCC structure at all temperatures below their melting points, while titanium transforms from a HCP structure to a BCC structure above 882 °C; therefore, over a wide range of compositions, TiVCr alloys form solid solutions (SS) with a BCC structure. Hydrogen storage capacities in these alloys have been reported as high as ~ 4 wt%, but in many cases some fraction of the hydrogen content is difficult to release [8]. To overcome these limitations, introduction of adequate substitutional element(s) in this ternary system has been actively pursued.

Manganese and molybdenum have been added to improve the hydrogen storage properties of TiVCr alloys [9]; both elements, having a BCC structure, may promote the same structure in quaternary TiVCrMn and TiVCrMo alloys. On the other hand, aluminum is known to enhance the hydrogen storage properties of V-based alloys [10]. For these reasons, in the present work, additions of Mn, Mo, and Al have been made with the aim of both preserving a BCC SS in TiVCr alloys and improving their hydrogen storage properties. However, there is limited information on the equilibrium phases in TiVCrX (X = Al, Mn, Mo) systems. Hence, TiVCr-based, quaternary alloys have been produced and characterized in relation to their phases and corresponding compositions. These alloys have been produced with equiatomic compositions in accordance with the principles of high-entropy alloys in which solid solution phases become the equilibrium phases.

Materials and methods

In a preliminary exploration, the High-Entropy Alloys Predicting Software (HEAPS) [2] has been used to assess the likelihood of forming an equilibrium BCC phase in equimolar TiVCrMn, TiVCrMo, and TiVCrAl alloys. Following this, the phase stability as a function of temperature of the investigated HEAs was calculated with CALPHAD (CALculation of PHAse Diagram; Thermo-Calc 2022b, THEA3 v 1.0 database).

All the alloys were fabricated by arc melting under high-purity Argon (pressure ≤ 10−5 Torr) in the presence of a titanium getter. The nominal purity of the raw materials used in this study is 99.95% for Cr, Mo, and Mn; 99.9% for Ti; 99.70% for V, and 99.99% for Al. Each button (20 g) was re-melted seven times to insure composition uniformity. TiVCrAl and TiVCrMn buttons were cast in a copper mold, while the TiVCrMo button was left to solidify in the crucible of the arc-melting furnace as its viscosity turned out to be much higher compared to the other alloys.

Phase identification and lattice parameters were determined by X-ray diffraction (XRD) using Cu Kα (λ = 0.1541 nm) radiation. The microstructures of the alloys were characterized by scanning electron microscopy (SEM), and x-ray energy dispersive spectrometry (EDS), in particular to determine the chemical composition, spatial distribution, and volume fraction of the different phases.

Results

HEAPS allows the evaluation of multicomponent alloys to test for the likelihood of formation of particular phases, based on the evaluation of several parameters and criteria [11]. Some criteria (referred to as MC) test for solid solutions (SS) or intermetallic compounds (IM); LSS criteria test for crystal structures in solid solution; and ImF criteria test specifically for IM formation. The predictions of some of these criteria in HEAPS, applied to equimolar compositions at 727 °C, are presented in Table 1.

In the three cases, criteria MC1 and MC2 predict SS phases, while MC6 predicts multi-phase solid solutions (MPSS). Criterion LSS1 predicts BCC structures, but LSS2 predicts a BCC phase only in TiVCrAl. On the other hand, ImF1 suggests the absence of topologically closed-packed (TCP) phases (Laves, σ, μ, R, among other IM phases) for TiVCrAl and TiVCrMn, but predicts a TCP phase for TiVCrMo. The ImF3 criterion (specifically addressing the presence of Laves phases) predicts its formation only in TiVCrMn. These calculations allowed us to confirm the possibility of producing equimolar TiVCrAl, TiVCrMn, and TiVCrMo alloys with a BCC phase as the major phase in their microstructures.

By using the CALPHAD computational tool with the THEA 3 thermodynamic database, the phase equilibria in all three quaternary systems were calculated as a function of temperature (down to 500 °C). The calculated amounts of equilibrium phases as a function of temperature are shown in Fig. 1a, c, e. As shown in this figure, the CALPHAD calculations predict a BCC SS as the predominant phase for all the investigated alloys at temperatures above 800 °C and up to their solidus temperatures.

For TiVCrMn (Fig. 1a), a C14 Laves phase is predicted to coexist with the BCC phase at temperatures below 800 °C. This agrees with the experimental observations of Yu et al. [12], as their alloys (Ti40V20Cr10Mn30, Ti40V24Cr10Mn26, Ti40V28Cr10Mn22) consist of two phases, BCC SS and C14 Laves; in addition, Yoo et al. [13] found that the Laves phase (coexisting with a BCC phase) appeared when the Mn concentration was increased to 10 at.% in alloys with compositions Ti32V25Cr43−YMnY; (0 ≤ Y ≤ 10).

In the case of TiVCrMo (Fig. 1c), a second (ordered) BCC phase (strictly speaking, a simple cubic CsCl-type structure) coexists with a disordered BCC phase at temperatures below 800 °C; this quaternary system has been previously evaluated using CALPHAD in [14] and the phase equilibria of the ternary Ti–M1–M2 (M1 = Cr, V and M2 = Mo) systems in [15]. Hu et al. [14] present calculated isothermal section of equimolar TiVCrMo at 600 °C that include a two-phase region of αCr2Ti (IM) and β2 (BCC SS). On the other hand, Lee et al. [15] show that the addition of Mo (to ternary equimolar TiVCr alloys) expands the single-phase BCC field. Our predictions do not match with these previous calculations probably due to the composition differences. However, Raufast et al. [16] report the effect of Mo addition on TiVCr BCC alloys; in their alloy with higher Mo content (Ti20Cr44V3Mo33), two BCC phases are found; however, with lower Mo contents, a single BCC structure is generated.

In Fig. 1e, the CALPHAD calculations for TiVCrAl predict the formation of a small amount of the AlTi3 phase (∼ 0.05 volume fraction at 500 °C; Table 2) that coexists with the BCC phase at temperatures below 600 °C. This agrees with the experimental observations of Qiu et al. [17] and the calculated equilibrium phases by Mao et al. [18]. The AlTiVCr alloy of Qiu et al. [17] exhibits a single BCC phase without IM phases. Furthermore, Mao et al. [18], using the TCHEA1 database, predicted a disordered BCC phase at temperatures lower than 1600 °C that transforms into an ordered BCC phase at around 692 °C, which in turn starts decomposing at 527 °C into some intermetallic phases.

The XRD patterns of the as-cast alloys are shown in Fig. 1b, d, f. TiVCrMo and TiVCrAl are apparently composed of a single BCC phase. However, notice that the width of the diffraction peaks from TiVCrMo is significantly wider than those from TiVCrAl. On the other hand, in the XRD pattern from TiVCrMn (Fig. 1b), we identified a C14 Laves phase and a BCC phase. The presence of the C14 Laves phase agrees with the experimental observations of Yu et al. [12] and Yoo et al. [13]. Our results basically corroborate the thermodynamic predictions for TiVCrMn; however, the predicted AlTi3 second phase in TiVCrAl was not found by XRD, perhaps due to the small volume fraction expected for this phase.

Figure 2 shows backscattered electron (BSE) micrographs of the as-cast alloys. The average chemical composition of the samples, as determined by EDS analysis over an area of about 240 × 160 µm, is shown on each micrograph in Fig. 2. In Fig. 2a, the darker regions correspond to the BCC phase and the brighter regions correspond to the C14 Laves phase; in this phase, the results in Table 2 clearly exhibit higher Mn and Ti concentrations, with corresponding decreases in V and Cr contents. In summary, for the TiVCrMn alloy, the phases expected from the thermodynamic predictions agree with the results found by XRD; however, the predicted phase compositions and volume fractions are not consistent with the experimental results. At this time, the reason for these differences is not known, but it is likely that the lack of thermodynamic data on quaternary Laves phases may be of relevance in this case.

In the case of the TiVCrMo alloy, a well-defined dendritic structure is observed in Fig. 2b, with the average composition close to the expected nominal composition. The spot EDS analyses indicate that the dendrites (brighter regions) are enriched with higher melting point elements (Mo and V), while the dark, interdendritic regions are enriched with Ti and Cr. The predicted phase compositions and the volume fractions are not consistent with the experimental results, but it should be kept in mind that the as-cast microstructure may not be the equilibrium structure in this alloy and we reserve judgment until a more suitable alloy is available.

Finally, the microstructure of the TiVCrAl alloy (Fig. 2c) exhibits a single-phase structure, with an average composition close to the nominal composition. Notice also that no sign of a second phase (e.g., AlTi3) is evident at this magnification.

Conclusions

HEAPS and Calphad calculations were used to ascertain the stability of BCC phases in equiatomic alloys of TiVCrAl, TiVCrMn, and TiVCrMo. The results of these calculations have been compared with characterization of the as-cast alloys with mixed outcomes. All the as-cast HEAs were mainly composed of a BCC solid solution. In addition to this phase, the TiVCrMn alloy contained a C14 Laves phase, while the TiVCrMo alloy probably contained two BCC solid solution phases with similar lattice parameters. The type of phases predicted by HEAPS and CALPHAD broadly agrees with the experimental observations, although the actual compositions of the phases exhibit significant differences with the predicted values.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Prog. Mater. Sci. 61, 1 (2014). https://doi.org/10.1016/j.pmatsci.2013.10.001

K. Liu, S.S. Nene, M. Frank, S. Sinha, R.S. Mishra, Appl. Mater. Today 15, 525 (2019). https://doi.org/10.1016/j.apmt.2019.04.001

S. Sun, P. Gao, G. Sun, Z. Cai, J. Hu, S. Han, J. Lian, X. Liao, J. Alloys Compd. 830, 154656 (2020). https://doi.org/10.1016/j.jallcom.2020.154656

Y. Zhang, J. Zhu, Z. Hao, W. Hao, Z. Mo, L. Li, Mater. Des. 229, 111894 (2023). https://doi.org/10.1016/j.matdes.2023.111894

J. Barale, J.R. Ares, P. Rizzi, M. Baricco, J.F. Fernandez-Rios, J. Alloys Compd. 947, 169497 (2023). https://doi.org/10.1016/j.jallcom.2023.169497

B. Coluzzi, A. Biscarini, G. Mazzolai, F.M. Mazzolai, A. Tuissi, F. Agresti, S. Lo Russo, A. Maddalena, P. Palade, G. Principi, J. Alloys Compd. 456, 118 (2008). https://doi.org/10.1016/j.jallcom.2007.02.021

J. Liu, J. Xu, S. Sleiman, X. Chen, S. Zhu, H. Cheng, J. Huot, Int. J. Hydrogen Energy 46, 28709 (2021). https://doi.org/10.1016/j.ijhydene.2021.06.137

S.W. Cho, G. Shim, G.S. Choi, C.N. Park, J.H. Yoo, J. Choi, J. Alloys Compd. 430, 136 (2007). https://doi.org/10.1016/j.jallcom.2006.04.068

P. Lv, C. Zhong, D. Huang, X. Zhou, Z. Liu, D. Huang, Int. J. Hydrogen Energy 47, 459 (2022). https://doi.org/10.1016/j.ijhydene.2021.10.029

T. Kuriiwa, A. Kamegawa, M. Okada, T. Maruyama, in Proceedings 18th World Hydrogen Energy Conference 2010, ed. by D. Slolten, T. Grube (Forschungszentrums Jülich GmbH, Zentralbibliothek, Verlag, Essen, 2010), p. 151

P. Martin, C.E. Madrid-Cortes, C. Cáceres, N. Araya, C. Aguilar, J.M. Cabrera, Comput. Phys. Commun. 278, 108398 (2022). https://doi.org/10.1016/j.cpc.2022.108398

X.B. Yu, Z. Wu, B.J. Xia, N.X. Xu, J. Alloys Compd. 372, 272 (2004). https://doi.org/10.1016/j.jallcom.2003.09.153

J.H. Yoo, G. Shim, C.N. Park, W.B. Kim, S.W. Cho, Int. J. Hydrogen Energy 34, 9116 (2009). https://doi.org/10.1016/j.ijhydene.2009.08.064

B. Hu, J. Wang, C. Wang, Y. Du, J. Zhu, Calphad 55, 103 (2016). https://doi.org/10.1016/j.calphad.2016.08.003

J.Y. Lee, J.H. Kim, H.M. Lee, J. Alloys Compd. 297, 231 (2000). https://doi.org/10.1016/S0925-8388(99)00557-5

C. Raufast, D. Planté, S. Miraglia, J. Alloys Compd. 617, 633 (2014). https://doi.org/10.1016/j.jallcom.2014.07.089

Y. Qiu, Y.J. Hu, A. Taylor, M.J. Styles, R.K.W. Marceau, A.V. Ceguerra, M.A. Gibson, Z.K. Liu, H.L. Fraser, N. Birbilis, Acta Mater. 123, 115 (2017). https://doi.org/10.1016/j.actamat.2016.10.037

H. Mao, H.L. Chen, Q. Chen, J. Phase Equilib. Diffus. 38, 353 (2017). https://doi.org/10.1007/s11669-017-0570-7

Acknowledgments

PCC-N (CVU-924250) thanks CONAHCYT for a doctoral scholarship. Authors gratefully thank LANE-Cinvestav (SEM), C. Falconi’s group, and O. Solorza’s group at Cinvestav by the use of experimental facilities. We acknowledge Z. Rivera-Alvarez for their valuable technical support throughout the study; S. Citalán (Cinvestav-Saltillo) for XRD measurements and V. Lopez-Hirata (ESIQIE-IPN) for Calphad calculations. This work was supported by the Centro de Investigacion y de Estudios Avanzados del Instituto Politecnico Nacional (Cinvestav-IPN).

Author information

Authors and Affiliations

Contributions

PCC-N contributed toward analysis, experiments, writing, and editing. IAF contributed toward experiments. KSA contributed toward supervision. MF-E contributed toward experiments. AS-R contributed toward resources and supervision. JGC-M contributed toward conceptualization, methodology, resources, editing, supervision, and project administration. All authors have read and approved the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cintron-Nuñez, P.C., Figueroa, I.A., Suarez-Alcantara, K. et al. Design, fabrication, and characterization of high-entropy alloys (HEAs) of the type TiVCrX (X = Al, Mn, Mo). MRS Advances 8, 1188–1193 (2023). https://doi.org/10.1557/s43580-023-00692-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-023-00692-1