Abstract

Hydroxyapatite (HAp) has been widely applied in the area of tissue engineering, however, its poor mechanical properties limit it in load bearing biomedical application. To improve the mechanical integrity of HAp, this study reports the synthesis, optimization and the significance of processing parameters on the physic-mechanical properties of HAp. The HAp was produced from biogenic source through at 900 °C. The L9 Taguchi orthogonal array was employed, considering two processing parameters namely, HAp particle size (100, 300, and 600 \(\mathrm{\mu m}\)) and compaction load (3, 6, and 9 KN). The raw bones (RB) and the synthesized HAp were characterized for phase structure and functional groups analysis. The analysis showed the characteristics of a typical calcium phosphate material. The multiple response optimization revealed that 600 \(\mathrm{\mu m}\) particle size 6 KN compaction load are the optimal processing parameters in the manufacturing of high biomedical performance HAp.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hydroxyapatite is a very strong tissue engineering material [1,2,3] but has poor mechanical properties [4,5,6]. Method of compaction and sintering temperature technique are widely used in the manufacturing of HAp scaffolds suitable for load bearing application of human bones [7, 8]. Compaction protocol is the application of uniaxial loading to enhance the density of a dry powder material. Sintering temperature is an important parameter affecting the microstructure and mechanical properties of ceramic. It has been reported in the literature that particle size has a resultant effect on physical, microstructural and mechanical properties [9]. Research has also shown that increase in sintering temperature increases the mechanical properties of HAp [4, 10], however, the effect of compaction pressure and particle size of HAp has not been adequately explored.

Literature has revealed that fewer studies have been conducted on the use of Taguchi grey relational anlaysis (GRA) for the optimization of processing conditions on HAp multiple biomedical characteristics. Different researchers have employed different optimization methods to obtain processing parameters for better performance response of a processed material [9, 11, 12], but this study employs Taguchi-GRA as a multi-objective optimization technique by integrating for the first time the porosity of HAp, which is an essential performance response of a biomedical material. In addition, the hardness and the compressive characteristics of HAp were optimized. This study considers for the first time the effect of particle size on the physical and mechanical properties of HAp. The quantitative and qualitative effect of compaction pressure on the multi-objective characteristics HAp was also investigated. Hence, the suitable processing conditions for better biomedical characteristics were determined and validated with interaction modeling. This study was conducted using Minitab 16 and Origin 2019 Software for the optimization and characterization analysis. There was no consideration of standard deviation because this study presents a holistic optimization analysis using Taguchi-GRA with the help of MINITAB Software. The MINITAB Software averaged the three replicated data for each response and used the average for GRA. The specific focus of this study is on the GRA, which brought out the GRG value as the multi-performance biomedical response.

Mechanical processing

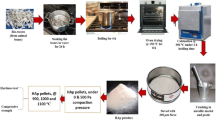

HAp was synthesized from biogenic dumping site in an Abattoir through thermal synthesis at 900 °C in a furnace. The RB and HAp at 900 °C (HAp-900) were characterized using XRD and FTIR machines.

The average crystallite size of RB and HAp at 900 °C was computed from their XRD data generated from Origin software using Scherrer equation (Eq. 1):

where D is the average crystallite size of the pronounced peaks noticed on the XRD spectral; K is the Scherrer’s constant, \(\lambda \) is the X-ray wavelength; \(\beta \) is the broadening angle in radians; and \(\theta \) is the Bragg’s angle in radians.

The synthesized HAp was turned into powder through metallic mortar and pestle and 100, 300 and 600 μm mesh sieve. The three different powders were pelletized with Universal testing machine (UTM) under 3, 6 and 9 KN loading. The pellets were left for natural drying for 24 h before they were subsequently sintered at 900 °C. See Fig. 1 for design methodological overview.

All the sintered pellets were mechanically characterized with micro hardness Vickers indentation tester (MV1-PC/Mh-v Cm) and with UTM for compressive strength analysis. Next, the porosity of the sintered pellets was computed using Eq. (2):

where P is the porosity, \({W}_{HAp}\) is the weight of HAp, \({V}_{HAp}\) is the volume of HAp, \({D}_{HAp}\) is HAp typical density which is 3.16 g/cm3 [10].

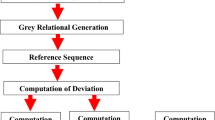

The mechanical data and porosity were analyzed using Taguchi-GRA technique with the help of Minitab 16 Software. Note that the three replicated data of each performance response was subjected and averaged into GRA for analysis. The data were computed step by step to obtain grey relational grade (GRG) for Taguchi optimization. The step by step equations to obtaining GRG is as shown next:

Note that xi (k) represents normalized data for the ith number of experiment, while yi (k) reprents the initial sequence of the data statistical mean.

\({\Delta }_{oi}\left(k\right)\), xo (k), and xi (k) represent deviation and reference data, respectively.

\({\xi }_{i}\left(k\right)\) represents grey relational coefficient (GRC) of a response data, which is in terms of the minimum deviation (Δmin) and maximum deviation (Δmax). \(\zeta \) represents the differentiating coefficient ranging from 0 to 1 (0 \(\sim \) 1), however, equal coefficient of 0.5 is often assigned to each response data.

\({\gamma }_{i}\) represents GRG value for the ith experimental number and n is the total number of responses.

Analysis of variance (ANOVA) was used to examine the contribution of each processing condition on the mechanical response.

Results and discussion

The Fourier transform infrared (FT-IR) spectra of RB and HAp-900 are shown in Fig. 2 (by the left). The FT-IR spectra revealed the fundamental component of calcium-phosphate-based materials, namely, phosphate and hydroxyl groups for both the RB and the HAp. Also, there is a reflection of some other functional groups on the two samples, which are characteristic stretching modes of O–H bands at about 3600 and 3000 cm−1. CO2 around 2500 cm−1, \({CO}_{3}^{2-}\) around 1700 and 1200 cm−1, and, \({PO}_{4}^{3-}\) around 960, 600 and 500 cm−1. The difference between the spectrum of RB and the HAp is noticed for all the bands of the two samples. These differences are indicative of the degree of carbonate ion substitution and the disappearance of absorbed water after calcination. These peaks are characteristics are peculiar to calcium phosphate-based materials and are in agreement with the literature [13, 14].

Figure 2 (by the right) shows the XRD patterns RB and HAp-900. All reflections displayed as patterns are peculiar characteristics of the hexagonal phase of hydroxyapatite [Ca10(PO4)6(OH)2] as asserted Abifarin et al. [13] and Kumar et al. [15], and the obtained patterns are in agreement with Obada et al. [2]. It is noticed that the XRD patterns for RB displayed a lower and broader reflections. This can be ascribed to the low crystallinity of the HAp phase in the samples. However, a prominent and narrower reflections observed after the calcination at 900 °C indicated that the crystallinity of the HAp phase formed were more evident. The prominent peaks noticed on the XRD spectral of RB and HAp-900 were formed at angle 2 \(\theta \), which are, respectively, 32.54° and 32.40°. This observation is in agreement with literature [2, 7], that calcium phosphate-based materials do have prominent peaks between 30 and 35o of 2 \(\theta \). In addition, the crystallite sizes of RB and HAp-900 are 3.55 nm and 14.18 nm, respectively. These results confirmed the science that the broader the XRD band of a considered peak, the smaller the crystallite size [2, 16]. It is important to note that crystallite size is only a relative value of particle size, but not the actual particle size. A bulk singular particle size has grain size, grain size contains crystallite size, crystallite size contains unit cell, and unit cell contains molecule/atom [16].

Table 1 presents the mechanical data, porosity and GRG values of the 9 designed experimental runs based on Taguchi technique. A higher GRG value shows a solid relationship [17,18,19]. Consequently, GRG values in Table 1 was analyzed with Taguchi design technique and the result is presented in Fig. 3. The results highlight the combination of the process parameters that boost overall physico-mechanical response of HAp. Figure 3b shows that the highest GRG value exists at level 3 of particle size and level 2 of compaction load. In other words, the optimal processing conditions for the manufacturing of load bearing biomedical HAp scaffold considering the three significant performance characteristics are 600 \(\mu m\) particle size and 6 KN compaction load. In Fig. 3a, the interaction plot further validates that HAp with high GRG value can be obtained within 3 to 6 KN compaction loads and around 500 to 600 \(\mu m\) particle size. No relativity in the mechanical properties and porosity of the fabricated scaffolds because mechanical integrity is a function of varying conditions. In other words, hardness was done by non-destructive indentation, investigating how resistive the material is to toughness, while compressive test is a destructive test by compression. Also note that GRG is the overall performance response of the three characteristics (hardness, compressive and porosity).

To examine the significance and percentage of contribution of processing conditions on GRG value of HAp, an ANOVA was performed for the grey relational grade at a 95% CI. Considering the three responses (compressive strength, hardness, and porosity), Table 2 shows that particle size has the most significant contribution on GRG value with a contribution of 49.76%, followed by compaction load with a contribution of 27.28%, then the residual error with a contribution of 22.96%. This quantitative data are also validated by the presented qualitative data in Fig. 2b. The low and non-closeness of R values imply the impact of residual error, hence it is recommended to conduct a deeper study on other likely factors that may be responsible on the overall physico-mechanical properties of HAp.

Conclusion and recommendation

HAp has been successfully synthesized and characterized from raw bovine bones. The FTIR and XRD patterns confirmed the characteristic XRD peaks and functional groups spectra peculiar to HAp. This study has been able to present for the first time, the optimal setting conditions with the consideration of particle size for the manufacturing of HAp suitable for load bearing biomedical application. The results showed that 600 \(\mu m\) particle size and 6 KN compaction load are the optimal processing conditions to manufacture biomedically enhanced HAp. This study recommends further analysis on some other significant processing conditions of the produced HAp. In addition, biological and mechanical reliability is a worthwhile future study.

Data availability

Not applicable.

Code availability

Not applicable.

References

I. Ielo, G. Calabrese, G. De Luca, S. Conoci, Recent advances in hydroxyapatite-based biocomposites for bone tissue regeneration in orthopedics. Int. J. Mol. Sci. 23(17), 9721 (2022)

D.O. Obada, E.T. Dauda, J.K. Abifarin, D. Dodoo-Arhin, N.D. Bansod, Mechanical properties of natural hydroxyapatite using low cold compaction pressure: effect of sintering temperature. Mater. Chem. Phys. 239, 122099 (2020)

J.K. Abifarin, O.A. Owolabi, New insight to the mechanical reliability of porous and nonporous hydroxyapatite. J. Aust. Ceram. Soc. (2022). https://doi.org/10.1007/s41779-022-00812-4

J.K. Abifarin, M.U. Suleiman, E.A. Abifarin, F.B. Fidelis, O.K. Oyelakin, D.I. Jacob, M.Y. Abdulrahim, Fabrication of mechanically enhanced hydroxyapatite scaffold with the assistance of numerical analysis. Int. J. Adv. Manuf. Technol. (2021). https://doi.org/10.1007/s00170-021-08184-y

D.O. Obada, E.T. Dauda, J.K. Abifarin, N.D. Bansod, D. Dodoo-Arhin, Mechanical measurements of pure and kaolin reinforced hydroxyapatite-derived scaffolds: a comparative study. Mater. Today: Proc. 38, 2295–2300 (2021)

S.M. George, C. Nayak, I. Singh, K. Balani, Multifunctional hydroxyapatite composites for orthopedic applications: a review. ACS Biomater. Sci. Eng. 8(8), 3162–3186 (2022)

E.C. Hammel, O.R. Ighodaro, O.I. Okoli, Processing and properties of advanced porous ceramics: an application based review. Ceram. Int. 40(10), 15351–15370 (2014)

J.K. Abifarin, D.O. Olubiyi, E.T. Dauda, E.O. Oyedeji, Taguchi grey relational optimization of the multi-mechanical characteristics of kaolin reinforced hydroxyapatite: effect of fabrication parameters. Int. J. Grey Syst. 1(2), 20–32 (2021)

J.K. Abifarin, Taguchi grey relational analysis on the mechanical properties of natural hydroxyapatite: effect of sintering parameters. Int. J. Adv. Manuf. Technol. (2021). https://doi.org/10.1007/s00170-021-07288-9

Y. Zusho, S. Kobayashi, Improvement of pore orientation and mechanical properties for hydroxyapatite–alumina composite porous scaffolds. Adv. Compos. Mater. (2022). https://doi.org/10.1080/09243046.2022.2122235

J.C. Ofodu, J.K. Abifarin, Employment of probability based multi-response optimization in high voltage thermofluids. Vojnoteh. Glas. 70(2), 393–408 (2022)

J.K. Abifarin, J.C. Ofodu, Determination of an efficient power equipment oil through a multi-criteria decision making analysis. Vojnoteh. Glas. 70(2), 433–446 (2022)

J.K. Abifarin, D.O. Obada, E.T. Dauda, D. Dodoo-Arhin, Experimental data on the characterization of hydroxyapatite synthesized from biowastes. Data Brief 26, 104485 (2019)

V.N. Scheverin, M.F. Horst, V.L. Lassalle, Novel hydroxyapatite-biomass nanocomposites for fluoride adsorption. Res. Eng. 16, 100648 (2022)

A. Kumar, K. Biswas, B. Basu, On the toughness enhancement in hydroxyapatite-based composites. Acta Mater. 61(14), 5198–5215 (2013)

A.A. Chernov, Modern crystallography III: crystal growth (Springer Science & Business Media, Germany, 2012), p.36

M.O. Esangbedo, J.K. Abifarin, Cost and quality optimization taguchi design with grey relational analysis of halloysite nanotube hybrid composite: CNC machine manufacturing. Materials 15(22), 8154 (2022)

J.K. Abifarin, C. Prakash, S. Singh, Optimization and significance of fabrication parameters on the mechanical properties of 3D printed chitosan/PLA scaffold. Mater. Today: Proc. 50, 2018–2025 (2022)

J. Abifarin, J. Ofodu, Modeling and grey relational multi-response optimization of chemical additives and engine parameters on performance efficiency of diesel engine. Int. J. Grey Syst. 2(1), 16–26 (2022)

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. This research did not receive any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of the authors, the corresponding author declares no conflict of interest.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abifarin, F.B., Musa, Z. & Abifarin, J.K. Mechanical processing of hydroxyapatite through sintering and multi-objective optimization technique for biomedical application. MRS Advances 8, 532–537 (2023). https://doi.org/10.1557/s43580-023-00517-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-023-00517-1