Abstract

The application of polymers in medicine requires sterilization while retaining material structure and properties. This demands detailed analysis, which we show exemplarily for the sterilization of PLLA/PDLA core–shell nanofibers with ethylene oxide (EtO). The electrospun patch was exposed to EtO gas (6 vol% in CO2, 1.7 bar) for 3 h at 45 °C and 75% rel. humidity, followed by degassing under pressure/vacuum cycles for 12 h. GC–MS analysis showed that no residual EtO was retained. Fiber diameters (~ 520 ± 130 nm) of the patches remained constant as observed by electron microscopy. Young’s modulus slightly increased and the elongation at break slightly decreased, determined at 37 °C. No changes were detected in 1H-NMR spectra, in molar mass distribution (GPC) or in crystallinity measured for annealed samples with comparable thermal history (Wide Angle X-Ray Scattering). Altogether, EtO emerged as suitable sterilization method for polylactide nanofibers with core–shell morphology.

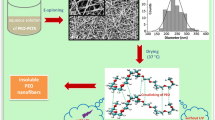

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In fundamental and applied biomaterial research, tremendous effort is spent on ensuring that an employed polymer, as well as potential degradation products are not cytotoxic and the material shows biocompatibility in the envisioned application [1]. Any contamination of the biomaterial should be avoided, which involves any potential residuals from synthesis and processing such as solvents, monomers, or catalysts. Furthermore, sterility is a mandatory requirement. Only few sterilization procedures are approved by the authorities [2] and are suitable for terminal sterilization of a device. These sterilization techniques comprise application of dry heat or steam [3], irradiation [4] e.g. with gamma rays, and treatment with ethylene oxide [5]. All of these may have an impact on material structure, composition, and properties [6]. Therefore, a suitable sterilization technique has to be carefully selected for a specific polymeric device, and thorough analysis has to be performed to show that no, minor, or reproducible and desired change of the material occurs upon sterilization. The analysis has to comprise methods allowing evaluation of the material at different levels, including quantification of residuals of the sterilization agent, mechanical properties, as well as changes in the chemical structure, composition, and morphology including crystallinity (see Fig. 1).

Polylactides (PLA) are a polymer family based on l- and/or d-lactide repeating units with diverse microstructures. They are considered as green polymers, as the monomer can be produced biotechnologically, and as the polymers are degradable also in the environment [7]. While homopolymers from l- or d-lactide are semicrystalline, an additional phase can be observed in their blends as poly(l-lactide) (PLLA) and poly(d-lactide) (PDLA) can form stereocomplex crystallites of high Tm and high physical stability. We have designed and fabricated electrospun core–shell PLLA/PDLA nanofiber patches having this option of stereocomplex formation in view [8]. In these patches, the individual fibers consist of a lower weight average molar mass (Mw) PLLA core and a higher Mw shell, in which stabilizing PLA stereocomplexes [9, 10] can be formed at the interface between the two layers by annealing. In this way, the material properties and functionality can be tailored by the architectural design of the fibers without employing elaborated syntheses. Nonwoven patches based on these fibers are envisioned for biomedical applications hence requiring sterilization. For this purpose, treatment with ethylene oxide gas was selected, as the low glass transition temperature Tg of polylactides of around 58 °C suggests form change upon heating, while irradiation is typically associated with undesired degradation or crosslinking [11]. In the following, we compare core/shell nanofiber patches before and after sterilization, report a GC–MS experiment to quantify residual EtO, scanning electron microscopy to determine the fiber structure, tensile tests for the mechanical properties of the patches, 1H NMR spectroscopy and GPC for characterizing the molecular structure and chemical composition, as well as WAXS studies for quantifying the crystallinity. Based on these results we will conclude on the suitability of this sterilization technique for polylactide based core–shell nanofiber meshes.

Materials and methods

Electrospinning and sterilization

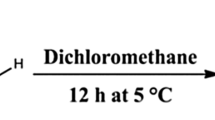

Electrospinning was performed as reported in ref. [8]. The setup (Linari Engineering, 56,121 Pisa, Italy) included voltage supply, rotatory drum collector, and two syringe pumps. The electrospinning process was performed inside a transparent plastic chamber connected with humidity control using a co-axial needle module (Linari Engineering, inner blunt tip needle = gauge 21, outer = gauge 15). Solutions of 5 wt% PDLA (Mw = 147 kg mol−1, Corbion, Amsterdam, the Netherlands) in HFIP and 12 wt% of a 1:5 mixture of high (Mw = 145 kg mol−1, Corbion, Amsterdam, the Netherlands) and low molar mass PLLA (Mw = 27 kg mol−1, Sigma-Aldrich, Munich, Germany) in the same solvent were prepared. A polypropylene film was wrapped over the rotatory drum collector for collecting deposited fiber mesh. The drum collector was rotated at 10 rpm and an applied voltage of 20 kV was maintained during the course of electrospinning. As-spun samples and samples annealed at 100 °C for 2 h were sterilized in an automated ethylene oxide sterilizer (SteriVit 100, DMB Apparatebau, Wörrstadt, Germany) with a gas (6 Vol% EtO in 94 Vol% CO2) exposure at 45 °C and 75% rel. humidity for 3 h, followed by desorption in more than 250 pressure/vacuum cycles between + 0.6 bar and − 0.76 bar over 12 h.

Details of characterization methods are specified in the Supporting Information.

Results and discussion

The nonwovens from coaxial PLLA/PDLA nanofibers were prepared by electrospinning [8]. The patch was annealed by heating to 100 °C for 2 h prior to the ethylene oxide sterilization, allowing for relaxation and some crystallization, though for comparison some data are reported for as-spun materials. SEM images (Fig. 1a/b) of the annealed patches before/after sterilization did not display obvious changes, and closer analysis showed that the fiber diameters (523 ± 129 nm vs. 521 ± 162 nm) were retained within the margin of error.

GC–MS analysis proved that the sterilized samples did not have any detectable ethylene oxide residuals (see Fig. 2a and Supporting Information Fig. S1). The mechanical properties determined at 37 °C in water (Fig. 2b), showed small differences for the patches before and after the sterilization. The Young’s modulus (13 ± 2 to 18 ± 4 MPa, statistically significant according to paired t test) and tensile strength (1.5 ± 0.1 to 1.9 ± 0.6 MPa) increased after sterilization, while the elongation at break decreased (from 55 ± 12 to 40 ± 12%, statistically significant according to paired t test). This means that there was a trend for an increased stiffness of the material after sterilization, which is in accordance with literature on the sterilization of polylactide [12].

a GC trace of the DMSO extract of an annealed PLLA/PDLA patch after sterilization (bottom) in comparison to a spiked DMSO sample (top). b Representative stress–strain curves from tensile tests of the patches at 37 °C in a water bath before (black line) and after (red dots) sterilization. c GPC traces of the polymer dissolved in CHCl3 before (black line) as well as after (red dots) sterilization. The molar mass and its distribution are identical

Polymer composition and molar mass were investigated in solution by 1H NMR (Supporting Information Fig. S2) and GPC (Fig. 2c). There were no changes observed in the NMR spectra. The differences in molar mass determined by GPC before sterilization (Mn = 58.5 kg mol−1, Mw = 102.0 kg mol−1, Đ = 2.35) and after sterilization (Mn = 58.0 kg mol−1, Mw = 96.5 kg mol−1, Đ = 1.92) are in the margin of error of the method. This suggests that there were no chemical changes occurring in the polymer system. In steam sterilization of polyesters, hydrolysis is a typical occurrence, which would result in reduction of molar mass and an increase of polydispersity. In irradiation based sterilizations, radical reactions regularly take place that would change the chemical structure, and when crosslinking occurs, would result in an increase of molar mass and/or formation of insoluble residues. None of these processes were observed. The broad peak in GPC is due to the polymer composition; while the patch is formed from coaxial spun PLLA and PDLA, for the discussed characterizations, the polymer is dissolved completely and therefore a mixture of the lower Mw PLLA and higher Mw PDLA is investigated here, giving the observed PDI and tailing.

In WAXS studies, the degree of crystallinity (DOC) and type of crystallites can be determined. PLA homocrystallites (HC) give reflections at 16.5°, 19°, and 22°, while stereocrystallites (SC) give peaks at 12°, 21°, and 24° [13]. The WAXS curves before and after crystallization were basically identical for the annealed patches (Fig. 3a), with a calculated DOC of 19 ± 1% and 18 ± 1% being constant, considering the error of the method. SC formation can only occur on the interface of the two layers, but HC can form in the whole matrix, so the HC peaks are much more prominent. When sterilizing as-spun patches, crystallinity determined by WAXS increased (Fig. 3b) from 0 to 5.7 ± 1%. The temperature, at which the sterilization was conducted (45 °C), is below, but close to, the glass transition temperature of PLA. Water uptake into the polymer matrix furthermore reduces Tg, and as the sterilization is performed in the presence of water vapor, the mobility of the polymer chains in the sample apparently increased so that some crystallization could occur, along with chain relaxation. The EtO gas additionally may have had a plasticizing effect [14]. From annealing studies it is however known that for a strong increase in PLA crystallinity a prolonged heating to clearly above Tg is required [8], and as that did not occur, in the annealed samples no further increase of crystallinity was observed.

Conclusions

The present study demonstrates that electrospun patches of coaxial spun PLLA/PDLA show only minor changes upon sterilization with ethylene oxide. This was confirmed on a morphological level (electron microscopy), by physicochemical characterization (NMR spectroscopy, GPC, WAXS) as well as by tensile tests. The slight increase of Young’s modulus and decrease of elongation at break cannot be attributed to the crystallinity (see WAXS). One potential explanation could be that the softening of the polymer at 45 °C and increased pressure during the sterilization may have led to a small amount of interfiber bonding, though this was not obvious in the SEM images. Potentially, the EtO treatment led to chemical changes on the surface that are however occurring to only a small weight fraction of the material so that other methods, such as X-ray induced photoelectron spectroscopy (XPS), are required to detect such changes [15, 16]. Such potential changes in chemistry may also have an effect on the mechanical properties, e.g. because of reduced fiber mobility. As the observed macroscopic changes were only slight, potential for applicability is not impaired. Altogether, ethylene oxide sterilization is therefore suitable for such materials and fulfills an important requirement in their further development for biomedical applications. The study furthermore exemplarily shows, on which different levels polymer characterization is required to evaluate a sterilization technique. It should be noted that polymers containing nucleophilic groups may react with ethylene oxide and therefore chemical composition might have to be examined in even more detail. The very low amount of hydroxyl end groups in the present polymers make this process very unlikely in the studied system.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

D.F. Williams, Biomaterials 35(38), 10009 (2014)

Q.Q. Qiu, W.Q. Sun, J. Connor, in Comprehensive Biomaterials II. ed. by P. Ducheyne (Elsevier, Oxford, 2017), p. 180

W.J. Rogers, in Sterilisation of Biomaterials and Medical Devices, Woodhead Publishing Series in Biomaterials 46, ed. by S. Lerouge, A. Simmons (Woodhead Publishing, Oxford, Cambridge, Philadelphia, New Delhi 2012), p. 20

R.S. Benson, Nucl. Instrum. Methods Phys. Res. Sect. B 191, 752 (2002)

J. Horakova, P. Mikes, A. Saman, V. Jencova, A. Klapstova, T. Svarcova, M. Ackermann, V. Novotny, T. Suchy, D. Lukas, Mater. Sci. Eng. C 92, 132 (2018)

Y.H. An, F.I. Alvi, Q. Kang, M. Laberge, M.J. Drews, J. Zhang, M.A. Matthews, C.R. Arciola, Int. J. Artif. Organs 28(11), 1126 (2005)

A. Marszalek-Harych, D. Jedrzkiewicz, J. Ejfler, Cell Mol. Biol. Lett. 22, 28 (2017)

A. T. Neffe, Q. Zhang, P. J. Hommes-Schattmann, W. Wang, X. Xu, B. S. Ahmad, G. R. Williams and A. Lendlein, J. Mater. Res. (2021). https://doi.org/10.1557/s43578-021-00260-z

K. Tashiro, N. Kouno, H. Wang, H. Tsuji, Macromolecules 50(20), 8048 (2017)

V. Izraylit, P.J. Hommes-Schattmann, A.T. Neffe, O.E. Gould, A. Lendlein, Eur. Polym. J. 137, 109916 (2020)

M. Bednarek, K. Borska, P. Kubisa, Molecules 25(21), 4919 (2020)

N.A. Weir, F.J. Buchanan, J.F. Orr, D.F. Farrar, A. Boyd, Biomaterials 25(18), 3939 (2004)

H. Tsuji, Macromol. Biosci. 5(7), 569 (2005)

E. H. Immergut, H. F. Mark, in Plasticization and Plasticizer Processes, ed. by N. A. J. Platzer (ACS Publications, Washington D.C., 1965) p. 1

R. Franca, D.A. Mbeh, T.D. Samani, C. Le Tien, M.A. Mateescu, L.H. Yahia, E. Sacher, J. Biomed. Mater. Res. Part B 101(8), 1444 (2013)

F. Brétagnol, H. Rauscher, M. Hasiwa, O. Kylián, G. Ceccone, L. Hazell, A.J. Paul, O. Lefranc, F. Rossi, Acta Biomater. 4(6), 1745 (2008)

Acknowledgments

This project has received funding from the European Union's Seventh Framework Programme for Research, Technological Development, and Demonstration under grant agreement no. 604049 and by the Helmholtz Association through program‐oriented funding.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Neffe, A.T., Zhang, Q., Hommes-Schattmann, P.J. et al. Ethylene oxide sterilization of electrospun poly(l-lactide)/poly(d-lactide) core/shell nanofibers. MRS Advances 6, 786–789 (2021). https://doi.org/10.1557/s43580-021-00058-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43580-021-00058-5