Abstract

This study unveils a sustainable, easily recyclable biocomposite, leveraging the dynamic nature of covalently adaptive bonds in a vitrimer matrix. The fabrication involved a fatty acid-derived vitrimer as the polymer matrix and multi-layered, nonwoven flax mat as reinforcing scaffold. The incorporation of these fibers significantly improved the mechanical performance of the vitrimer matrix uniformly. The ester-based covalently adaptive network plays a crucial role in enabling exceptional fiber-matrix bonding, as well as recyclability. The vitrimer matrix dissolves in ethylene glycol through transesterification, facilitating complete material recovery and biocomposite recycling without compromising the original properties of the matrix and reinforcing fibers.

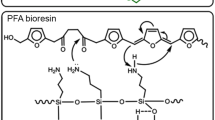

Graphical abstract

Similar content being viewed by others

Data availability

Data that support the findings of this study are available from the lead and corresponding authors upon reasonable request. Additional data have been added to supplementary information.

References

A.I. Osman, M. Hefny, M.I.A. Abdel Maksoud, A.M. Elgarahy, D.W. Rooney, Recent advances in carbon capture storage and utilisation technologies: A review. Environ. Chem. Lett. 19, 797 (2021)

H. Kaur, S. Abedi, C.-C. Chen, Estimating CO2 solubility in aqueous Na+–K+–Mg2+–Ca2+–Cl––SO42–solutions with electrolyte NRTL–PC-SAFT model. J. Chem. Eng. Data 67, 1932 (2022)

H. Kaur, C.-C. Chen, Thermodynamic modeling of CO2 absorption in aqueous potassium carbonate solution with electrolyte NRTL model. Fluid Phase Equilib. 505, 112339 (2020)

L.T.J. Korley, T.H. EppsIii, B.A. Helms, A.J. Ryan, Toward polymer upcycling—Adding value and tackling circularity. Science 373, 66 (2021)

H. Kaur, H. Tun, M. Sees, C.-C. Chen, Local composition activity coefficient model for mixed-gas adsorption equilibria. Adsorption 25, 951 (2019)

S. Gupta, T. Sohail, M. Checa, S.S. Rohewal, M.D. Toomey, N. Kanbargi, J.T. Damron, L. Collins, L.T. Kearney, A.K. Naskar: Enhancing composite toughness through hierarchical interphase formation (Adv Sci 6/2024). Advanced Science 11 (2024).

P. Taynton, H. Ni, C. Zhu, K. Yu, S. Loob, Y. Jin, H.J. Qi, W. Zhang, Repairable woven carbon fiber composites with full recyclability enabled by malleable polyimine networks. Adv. Mater. 28, 2904 (2016)

X. Yan, Y. Yang, H. Hamada, Tensile properties of glass fiber reinforced polypropylene composite and its carbon fiber hybrid composite fabricated by direct fiber feeding injection molding process. Polym. Compos. 39, 3564 (2018)

P.T. Williams, A. Cunliffe, N. Jones, Recovery of value-added products from the pyrolytic recycling of glass-fibre-reinforced composite plastic waste. J. Energy Inst. 78, 51 (2005)

G. Jiang, S.J. Pickering, G.S. Walker, N. Bowering, K.H. Wong, C.D. Rudd, Soft ionisation analysis of evolved gas for oxidative decomposition of an epoxy resin/carbon fibre composite. Thermochim. Acta 454, 109 (2007)

M.L. Longana, R.J. Tapper, L.G. Blok and I. Hamerton: Recycling of fiber reinforced thermosetting composites, in Fiber reinforced composites (Elsevier2021), pp. 561.

B. Wang, S. Ma, S. Yan, J. Zhu, Readily recyclable carbon fiber reinforced composites based on degradable thermosets: a review. Green Chem. 21, 5781 (2019)

S.J. Rowan, S.J. Cantrill, G.R.L. Cousins, J.K.M. Sanders, J.F. Stoddart, Dynamic covalent chemistry. Angew. Chem. Int. Ed. 41, 898 (2002)

R.J. Wojtecki, M.A. Meador, S.J. Rowan, Using the dynamic bond to access macroscopically responsive structurally dynamic polymers. Nat. Mater. 10, 14 (2011)

F. Meng, M.O. Saed, E.M. Terentjev, Rheology of vitrimers. Nat Commun 13, 5753 (2022)

M. Capelot, M.M. Unterlass, F. Tournilhac, L. Leibler, Catalytic control of the vitrimer glass transition. ACS Macro Lett. 1, 789 (2012)

S.S. Rohewal, N. Kanbargi, R. Young, L. Kearney, J. Damron, H. Hinton, L. Tetard and A.K. Naskar: Fast relaxing sustainable soft vitrimer with enhanced recyclability. Polymer Chemistry (2023).

L. Matějka, S. Pokomý, K. Dušek, Network formation involving epoxide and carboxyl groups: Course of the model reaction monoepoxide-monocarbonic acid. Polym. Bull. 7, 123 (1982)

J. Seo, L.T. Kearney, M.D. Toomey, J.K. Keum, A.K. Naskar, Polyester-based epoxy vitrimer integrating spent coffee ground as a natural filler. Composite B 260, 110756 (2023)

A. Moreno, M. Morsali, M.H. Sipponen, Catalyst-free synthesis of lignin vitrimers with tunable mechanical properties: Circular polymers and recoverable adhesives. ACS Appl. Mater. Interfaces 13, 57952 (2021)

Y. Xu, K. Odelius, M. Hakkarainen, One-pot synthesis of lignin thermosets exhibiting widely tunable mechanical properties and shape memory behavior. ACS Sustain. Chem. Eng. 7, 13456 (2019)

W. Zhao, Z. Feng, Z. Liang, Y. Lv, F. Xiang, C. Xiong, C. Duan, L. Dai, Y. Ni, Vitrimer-cellulose paper composites: A new class of strong, smart, green, and sustainable materials. ACS Appl. Mater. Interfaces 11, 36090 (2019)

T.L. Sun, T. Kurokawa, S. Kuroda, A.B. Ihsan, T. Akasaki, K. Sato, M. Haque, T. Nakajima, J.P. Gong, Physical hydrogels composed of polyampholytes demonstrate high toughness and viscoelasticity. Nat. Mater. 12, 932 (2013)

J.-Y. Sun, X. Zhao, W.R.K. Illeperuma, O. Chaudhuri, K.H. Oh, D.J. Mooney, J.J. Vlassak, Z. Suo, Highly stretchable and tough hydrogels. Nature 489, 133 (2012)

A. Chatterjee, S. Kumar, H. Singh, Tensile strength and thermal behavior of jute fibre reinforced polypropylene laminate composite. Composites Commun. 22, 100483 (2020)

J. Flynn, A. Amiri, C. Ulven, Hybridized carbon and flax fiber composites for tailored performance. Mater. Des. 102, 21 (2016)

E.A. Papon, A. Haque, Fracture toughness of additively manufactured carbon fiber reinforced composites. Addit. Manuf. 26, 41 (2019)

K. Yu, Q. Shi, M.L. Dunn, T. Wang, H.J. Qi, Carbon fiber reinforced thermoset composite with near 100% recyclability. Adv. Func. Mater. 26, 6098 (2016)

C. Luo, W. Wang, W. Yang, X. Liu, J. Lin, L. Zhang, S. He, High-strength and multi-recyclable epoxy vitrimer containing dual-dynamic covalent bonds based on the disulfide and imine bond metathesis. ACS Sustain. Chem. Eng. 11, 14591 (2023)

Acknowledgments

Research is supported by the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy (EERE), Vehicle Technologies Office (VTO) Program. Dynamic mechanical analysis of vitrimer composites conducted by SSR and MTD was supported by the U.S. Department of Energy, Office of Science, Basic Energy Sciences, Materials Sciences and Engineering Division [FWP# ERKCK60].

Funding

This research at Oak Ridge National Laboratory, managed by UT-Battelle, LLC, for the U.S. Department of Energy (DOE) under contract DE-AC05-00OR22725, was sponsored by the Office of Energy Efficiency and Renewable Energy, Vehicle Technologies Office Program. Dynamic mechanical analysis of vitrimer composites conducted by SSR and MTD was supported by the U.S. Department of Energy, Office of Science, Basic Energy Sciences, Materials Sciences and Engineering Division [FWP# ERKCK60].

Author information

Authors and Affiliations

Contributions

SSR: conceptualization, methodology, investigation, writing—original draft. ZY: conceptualization, writing—review and editing. LTK: conceptualization, writing—review and editing, supervision. MDT: conceptualization, writing—review and editing. HKG: conceptualization, methodology. AKN: conceptualization, writing—reviewing, supervision, funding acquisition.

Corresponding authors

Ethics declarations

Conflict of interest

Coauthor Hicham K. Ghossein is CEO and Founder of Endeavor Composites, Inc. For the rest of the authors, there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This manuscript has been authored by UT-Battelle, LLC, under contract DE-AC05-00OR22725 with the US Department of Energy (DOE). The US Government retains, and the publisher, by accepting the article for publication, acknowledges that the US Government retains a nonexclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this manuscript, or allow others to do so, for US Government purposes. DOE will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan).

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rohewal, S.S., Yu, Z., Kearney, L.T. et al. Flax fiber-reinforced fatty acid vitrimer biocomposite with enhanced chemical recyclability. MRS Communications (2024). https://doi.org/10.1557/s43579-024-00556-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/s43579-024-00556-1