Abstract

Pt–Mo nanoparticles supported by MWCNT were synthesized by wet impregnation and applied to desulfurize extra-heavy crude oil. Structural, morphological, and chemical characterizations confirmed uniform dispersion of Pt and Mo on MWCNT surfaces. The Pt–Mo nanoparticles had crystallite sizes ranging from 1.7 to 28 nm. The catalysts were used in the aquathermolysis of UTSIL crude oil, showing good stability and activity. Sulfur was reduced by 50% at 50°C and 80% at 100°C. FT-IR spectroscopy revealed the formation of hydrogenated aromatic rings and a decrease in sulfonic groups during desulfurization.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Global energy demand is increasing, and conventional oil reserves are declining, which has led to worldwide interest in heavy and extra-heavy oil.[1,2,3] However, difficulty in extraction arises from the high sulfur content in heavy hydrocarbons, which is related to its high viscosity.[2,4,5,6] Aquathermolysis is used to improve the extraction of heavy and extra-heavy crude oil by injecting hot water or ionic liquids and sometimes catalysts to reduce the viscosity.[6,7] Hyne first proposed the hydrogenation mechanism for reducing viscosity in heavy crude oil.[8] Nowadays, it is well known that thiols, disulfide sulfides, sulfoxides, and thiophenes are responsible for the high viscosity and are present in the molecular chain of heavy and extra-heavy crude oil. Therefore, it has been proposed that hydrodesulfurization should be included in the aquathermolysis process to reduce viscosity.[6,9,10]

Many catalysts have been employed in the aquathermolysis process to alter the structure of extra-heavy crude oil, remove sulfur molecules that interact with hydrogen, and permanently reduce the viscosity of the crude oil.[10,11] The first catalysts used for the aquathermolysis process were monometallic, such as molybdenum carbide catalysts.[12] The catalyst systems that comprise groups of VIB and VIIIB elements on the periodic table have been widely used dispersing on a support with a high specific surface area.[2,13,14] A very efficient group of catalysts for hydrodesulfurization comprises those based on Ni and Mo nanoparticles, supported Ni and Mo alloys, or Ni-Mo and Co-Mo on alumina and titania supports.[15,16,17,18] Lately, laminar carbides have been tested for desulfurization with good results, but high metallic and catalyst loading were used in the tests.[2,19]

Despite the great progress obtained with conventional catalysts, they are not sufficiently active and selective to meet future requirements imposed on fuels in terms of the allowed content of sulfur and aromatics.[20] For a more efficient catalyst, there are numerous approaches, such as changing the active component of the catalyst, variation in the method of preparation, and modification of the support.[21,22] Currently, works on improving processes are oriented toward the modification of the Al2O3 support, using new media like carbides or multiwall carbon nanotubes (MWCNT), modifying the active phase with an additive,[23,26] or the use of noble metals or other metals to non-conventional Co, Ni, Mo, and W.[23,26] An important aspect to consider is the temperature process of aquathermolysis in the activity of the catalysts since the catalysts lose their activity at low temperatures.[27] Hence, more research is focusing on making this process more economical.

In this work, we propose the use of Pt and Mo nanoparticles catalysts supported on MWCNT using low concentrations of metal for the aquathermolysis process to study its efficacy to desulfurize extra-heavy crude oil at low temperatures. Platinum serves as a catalytic site for hydrogenation reactions. The features of molybdenum make the catalyst a technologically feasible candidate for application in extra-heavy oils.

Experimental

Synthesis and characterization

Platinum and molybdenum nanoparticles were deposited on MWCNT supports (Aldrich, 14 nm in diameter and 10 µm in length on average) by an impregnation method using platinum acetylacetonate ((CH3-COCHCO-CH3)2Pt, Aldrich, 97%) and molybdenum acetylacetonate ((MoO2(CH3COCH2COCH2)2), Aldrich, 98%) as precursors. MWCNT were previously treated with acid media (H2SO4/HNO3 (3/3 v/v)), washed with distilled water, and dried at 80°C for 24 h. The precursors and treated MWCNT were mixed with isopropanol at 1200 rpm to obtain Pt:Mo ratios of 0:10 (Mo10), 2:8 (Pt2Mo8), 5:5 (Pt5Mo5), 8:2 (Pt8Mo2), and 10:0 wt % (Pt10). NaBH4 was used as a reducing agent.

Impregnated MWCNT were filtered and dried at 80°C overnight, placed in a horizontal quartz tube reactor, and reduced at 350°C with hydrogen gas bubbling for 1 h (H2 bubbles were generated by a Zn° + HCl reaction and introduced by connecting a hose to the quartz reactor). The crystal structure, particle size, and morphology of the Pt–Mo/MWCNT catalysts were analyzed by X-ray diffraction (XRD, Siemens D5000 using Cu-Kα radiation), transmission electron microscopy (TEM, JEOL JEM ARM 200CF, and EDS detector with window of 100 mm2), and scanning electron microscopy (SEM, JEOL JSM 6701F coupled with an EDS detector, Oxford Inca X-ACT).

Aquathermolysis reaction

To evaluate the catalytic performance in desulfurization, the Pt–Mo/MWCNT samples were tested in the aquathermolysis reaction with UTSIL extra-heavy oil, which has a viscosity of 1.133 Pa·s. The experiments were carried out by placing heavy crude oil and seawater (1:1) with 0.3 wt % Pt–Mo/MWCNT catalysts in a reactor at a pressure of 3 MPa. Experiments were conducted at 100°C, 50°C, and 25°C for 24 h. The effectiveness of different catalyst samples on the desulfurization of extra-heavy crude oil was evaluated by comparing the sulfur content before and after the reaction using a Fourier Transform Infrared (FT-IR) spectrometer (Perkin Elmer Spectrum Two).

Results and discussion

Structural and morphological characterization

Typical MWCNT morphology was observed in all SEM micrographs (Fig. 1). The diameter of the nanotubes was in the range of 4.7 to 34 nm, still diameters of 14 nm were predominant, and the cross-section of their edges could be distinguished (not to be confused with nanoparticles or agglomerates of nanoparticles). In the Pt10/MWCNT sample, only nanoparticles and agglomerates of Pt were observed, and on samples of Pt8Mo2/MWCNT, Pt5Mo5/MWCNT, and Pt2Mo8/MWCNT, Pt and Mo nanoparticles were detected as the EDS results confirmed at the bottom of each image; the Mo-Pt-C contents for (a)–(d) samples were 0–8.6–91.4, 0–7.1–92.9, 4.2–5.5–90.3, and 19.3–2.1–78.6 wt %, respectively. The molybdenum peak did not appear in the Pt8Mo2/MWCNT spectrum, possibly because of the small content in this sample. However, increasing the content of molybdenum increases the Mo peak signal.

Figure 2 shows the typical XRD patterns of the catalysts. According to the PDF2 2004 data base, the broad reflections at 2θ = 39.7°, 46.2°, 67.5°, 81.2°, and 85.7° belong to small Pt crystallites (card No. 00-065-2868). The Pt crystallite size was estimated to be about 10.5–28.2 nm using the Scherrer equation without instrumental error value and the (111) reflection. The reflection at 2θ = 26.2° corresponds well with the (002) plane of the hexagonal graphite structure (card No. 00–075-1621), which has been previously assigned to CNTs, this peak is overlapped with the peaks of MoO3 and Mo13O33. A characteristic peak of the oxidized graphite structure at 13.6° in 2 theta was observed,[27] some authors suggest that when this peak disappears occur a particle impregnation in the oxidized surface.[28] The intensity of the Pt reflection gradually increases with higher content. For molybdenum, there were two oxides, Mo13O33 (card No. 00-082-1930) and MoO3 (card No. 00-085-2405), which contributed to the peak broadening of MWCNT at 26.2° in 2θ.

Figure 3 shows the TEM micrograph of the Pt2Mo8/MWCNT catalyst and the EDS spectrum of a Mo13O33 nanoparticle. The spectrum shows Al, Si, Cr, Fe, Co, and Ni, which come from the TEM column, and C and Cu, which are from the lacey carbon and copper grids. The presence of molybdenum oxide nanoparticles was confirmed by EDS; the Mo-Pt-C contents for Mo10/MWCNT, Pt2Mo8/MWCNT, Pt5Mo5/MWCNT, Pt8Mo2/MWCNT, and Pt10/MWCNT samples were 6.9-0-93.1, 11-3.7-85.3, 4.7-5.1-90.2, 5.2-7.8-87, and 0-8.6-91.4 wt. %, respectively, taking into account the initial amounts of these elements for the synthesis. On the other hand, the difference between EDS-SEM and EDS-TEM quantifications is due that the first is a bulk technique and the second is a local technique, including the effect of lateral resolutions from EDS spectrometers. The interplanar distance value of 0.1906 nm was calculated from the HRTEM image, which corresponds to the (142) plane of Mo13O33. The particle sizes of Mo oxides and Pt varied from 1.7 nm to 4.8 nm and from 10.3 nm to 28 nm, respectively.

Catalytic performance

Figure 4 shows the FT-IR spectrum of UTSIL extra-heavy crude oil after treatment with and without the different catalysts. The first band at 3446 cm−1 was attributed to –OH stretching, which appeared more intense for extra-heavy crude oil without catalysts and less intense for the Pt8Mo2/MWCNT. This can be attributed to sea water from aquathermolysis reaction with UTSIL extra-heavy oil and the different ratios of active metal in the catalysts that react. The strong bands at 2918 and 2851 cm−1 observed after the reaction were the absorption peaks of C–H groups, indicating the hydrogenation reaction of bonds in heavy crude oil molecules. The Pt8Mo2/MWCNT catalyst presented more effect on hydrogenation for crude oil.

The peak at 1460 cm−1 is from –CH2 flexion (scissor) of C–C bonds, and the one at 1368 cm−1 is from flexion (rock) of –CH3. Both vibrations are attributed to aliphatic components. The FT-IR spectrum indicates that the extra-heavy crude oil contains a condensed aromatic ring, while the peak at 1598 and another at 1646 cm−1 denote stretching of the C=C bond of the aromatic ring with a polar substitute.[29] These bands decrease more with the Pt8Mo2/MWCNT catalyst.

Sulfonic acid groups in the heavy crude oil could be detected with bands attributed to sulfur compounds. The band at 1100 cm–1 was from SO2 stretching, and the others at 957, 815, 724, and 564 cm–1 were from flexion bands of out-of-plane S–O bonding.[14,28] These sulfonic acid groups decreased in the FT-IR spectrum when the extra-heavy crude oil was treated with the aquathermolysis process with the catalysts in the following order: sample without catalysts < Pt10/MWCNT < Pt2Mo8/MWCNT < Mo10/MWCNT < Pt5Mo5/MWCNT < Pt8Mo2/MWCNT. The comparison shows that the amount of molybdenum had the most influence on the bond breaking with sulfur, while platinum had more influence on the hydrogenation process of molecules of extra-heavy crude oil.

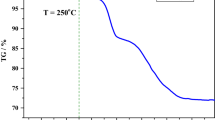

Temperature analysis

The increase in temperature is an important factor for the catalysts and improves the desulfurization of extra-heavy crude oil. Fig. A presents the comparative analysis results of the Pt8Mo2/MWCNT catalyst with extra-heavy crude oil at temperatures of 100, 50, and 20°C in the aquathermolysis process. The results indicate that at 100°C, there was more desulfurization of extra-heavy crude oil than at 50 and 20°C. The bands of sulfonic acid groups decreased at higher temperatures.

Time analysis

Fig. B shows the effect of time on the aquathermolysis process for the extra-heavy crude oil treated with Pt8Mo2/MWCNT catalyst. From 0 to 24 h, the bands belonging to the sulfonic groups decrease with increasing desulfurization time. The best performance of desulfurization was found at 24 h.

Conclusions

The SEM analysis revealed the presence of Pt in the catalysts synthesized. Mo element was not identified when is in a low concentration possibly due to their very small size and broad dispersion over carbon nanotubes. Using XRD, two different crystalline phases of molybdenum oxide (MoO3 and Mo13O33) and Pt were identified, and the carbonaceous nature of MWCNT was verified. The absence of a peak at 2θ of 13.6° suggested that the impregnation of particles by this method occurs on the oxidized surface of MWCNTs.

The TEM analysis of MWCNT and catalyst samples confirmed the presence of molybdenum oxides and Pt nanoparticles. Nanoparticles of Mo were smaller than those of Pt, and they had a good distribution over MWCNT. The FT-IR spectrum confirmed that the catalyst with a Pt:Mo ratio of 8:2 presented the best effect on hydrogenation for crude oil and desulfurization for the samples of extra-heavy crude oil. The increased temperature was a factor that improved the desulfurization of extra-heavy oil. More time in the aquathermolysis process increased the desulfurization for the sample of extra-heavy crude oil with catalysts. It is important to develop bimetallic catalysts containing elements that influence the bond breaking with sulfur, unlike molybdenum, and elements with influence on the hydrogenation process, unlike platinum, for further optimization of the aquathermolysis process.

Data availability

Data will be made available on request.

References

Y. Chen, Y. Wang, J. Lu, C. Wu, The viscosity reduction of nano-keggin-K3PMo12O40 in catalytic aquathermolysis of heavy oil. Fuel 88, 1426–1434 (2009)

J.R. Olvera, G. Gutiérrez, A. Romero, A. Medina, V. Garibay-Febles, L. Arceo, Use of unsupported, mechanically alloyed NiWMoC nanocatalyst to reduce the viscosity of aquathermolysis reaction of heavy oil. Catal. Commun. 43, 131–135 (2014)

J.I. Villa-Quezada, L. García, C.M. López, S.A. Mora-Quezada, A. García, Evaluation of solid catalysts used in petroleum refinery and its regeneration potential. Rev. Mex. Ing. Quim. 17(3), 927–940 (2018)

A. Hart, A review of technologies for transporting heavy crude oil and bitumen via pipelines. J Petrol Explor Prod Technol 4, 327–336 (2014). https://doi.org/10.1007/s13202-013-0086-6

Iskandar F., Dwinanto E., Abdullah M., Khairurrijal, O. Muraza. (2015). Viscosity reduction of heavy oil using nanocatalyst in aquathermolysis reaction. Advance Publication Article J-STAGE Advance Published date: 10 July

W. Chuan, L. Guang-Lun, Y. Chuan-jin, S. Ke-ji, G. Ping-yuan, C. Yan-bin, Mechanism for reducing the viscosity of extra-heavy oil by aquathermolysis with an amphiphilic catalyst. J. Fuel Chem. Technol. 38(6), 684–690 (2010)

F. Zhao, Y. Liu, Y. Wu, X. Zhao, L. Tan, Study of catalytic aquathermolysis of heavy oil in presence of hydrogen donor. Chem. Technol. Fuels Oils 48(4), 273–276 (2012)

J. Hyne, P. Clark, R. Clarke, J. Koo, J. Greidanus, J. Tyrer et al., Aquathermolysis of heavy oil. Rev. Tec. Intevep 2, 87–94 (1982)

Y. Chen, J. He, Y. Wang, P. Li, GC-MS used in study on the mechanism of the viscosity reduction of heavy oil through aquathermolysis catalyzed by aromatic sulfonic H3PMo12O40. Energy 35, 3454–3460 (2010)

H. Hua-rui, Su. Hui-jun, G. Chen, J.-R. Zhao, Li. Hong, Viscosity reduction of heavy oil by aquathermolysis with coordination complex at low temperature. Open Fuels Energy Sci. J. 8, 93–98 (2015)

M.A. Alvarez-Amparan, L. Cedeno-Caero, Cumene hidroperoxide effect on the oxidative desulfurization. Rev. Mex. Ing. Quim. 13(3), 787–797 (2014)

L.D.B. Arceo, E. Orozco, H. Mendoza-León, E.P. González, F.L. Guerrero, V.G. Febles, Nanostructures obtained from a mechanically alloyed and heat treated molybdenum carbide. J. Alloys Compd. 434, 799–802 (2007)

I. Eswaramoorthi, V. Sundaramurthy, N. Das, A.K. Dalai, J. Adjaye, Application of multi-walled carbon nanotubes as efficient support to NiMo hydrotreating catalyst. Appl. Catal. A: General 339, 187–195 (2008)

L. Wei, Z. Jian-hua, J.-H. Qi, Application of nano-nickel catalyst in the viscosity reduction of Liaohe extra-heavy oil by aquathermolysis. J Fuel Chem Technol 35(2), 176–180 (2007)

R.M. Rahimi, L. Rashidi, A. Vafajoo, M. Rashtchi, Preparation of Co–Mo supported multi-wall carbon nanotube for hydrocracking of extra heavy oil. J. of Ind. and Eng. Chem. 20(6), 4298–4303 (2014)

Z. Le, L. Xiangyun, L. Dadong, G. Xiadong, Study on high-performance unsupported Ni–Mo–W hydrotreating catalyst. Catal. Commun. 12, 927–931 (2011)

A.R. Katritzky, S.M. Allin, Aquathermolysis: reactions of organic compounds with superheated water. Acc. Chem. Res. 29, 399–406 (1996)

J.G. Speight, Heavy and extra-heavy oil upgrading technologies (Gulf Professional Publishing, 2013)

H. Fan, Y. Zhang, Y. Lin, The catalytic effects of minerals on aquathermolysis of heavy oils. Fuel 83, 2035–2039 (2004)

W. Wang, S. Wang, Y. Wang, H. Liu, Z. Wang, A new approach to deep desulfurization of gasoline by electrochemically catalytic oxidation and extraction. Fuel Process. Technol. 88, 1002–1008 (2007)

J.G. Colín-Luna, A.K. Medina-Mendoza, J.A. De los Reyes, J. Escobar, J.A. Montoya de la Fuente, R.P. Suarez, Effect of Si/Al ratio in deep hydrodesulfurization of Pt/Al-MCM41 catalysts. Rev. Mex. Ind. Quim. 12(2), 271–282 (2013)

R.I. Yocupicio, J.N. Dıaz de Leon, T.A. Zepeda, S. Fuentes, Study of CoMo catalysts supported on hierarchical mesoporous zeolites for hydrodesulfurization of dibenzothiophene. Rev. Mex. Ing. Quim. 16(2), 503–520 (2017)

J. Greff, T. Babadagli, Use of nano-metal particles as catalyst under electromagnetic heating for in-situ heavy oil recovery. J. Petrol. Sci. Eng. 112, 258–265 (2013)

M.H. Li, Y.L. Su, The overview of the heavy oil explotation Neimenggu. Chem. Indust. 3, 110–112 (2005)

O. Muraza, A. Galadima, Aquathermolysis of heavy oil: a review and perspective on catalyst development. Fuel 157, 219–231 (2015)

Yu. Guo-Rui Li, Y.A. Chen, Y.-L. Che, Catalytic aquathermolysis of super-heavy oil: cleavage of C-S bonds and separation of light organosulfurs. Fuel Process. Technol. 153(1), 94–100 (2016)

Z. Khansari, P. Kapadia, N. MahinpeyIan, D. Gates, A new reaction model for low temperature oxidation of heavy oil: experiments and numerical modeling. Energy 64(1), 419–428 (2014)

A.B. Asefa, Reduced graphene oxide-intercalated graphene oxide nano-hybrid for enhanced photoelectrochemical water reduction. J. Nanostruct. Chem. 10, 9–18 (2020)

M.R. Nivitha, P. Edamana, J.M. Krishnan, Ageing in modified bitumen using FTIR spectroscopy. Int. J. of Pavement Eng. 17, 7 (2016)

Acknowledgments

The author E.T-S would like to acknowledge the IPN for the financial support through the project, SIP20230499.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

Conceptualization: ETS and MOA; methodology: SCC, and GT; validation: MOA, OGRV, and CMRG; formal analysis: SCC and GT; investigation: ETS and MOA; resources: ETS, SCC, and GT; writing—original draft preparation: ETS; writing—review and editing: ET-S, SC–C, and MO-A.; visualization: GT; supervision: OGRV and CMRG; project administration: CMRG. All authors have read and agreed to the published version of the manuscript. Authorship must be limited to those who have contributed substantially to the work reported.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Torres-Santillan, E., Ortega-Aviles, M., Capula-Colindres, S. et al. Pt–Mo/MWCNT catalysts for desulfurization of extra-heavy crude oil at low temperature. MRS Communications (2024). https://doi.org/10.1557/s43579-024-00541-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/s43579-024-00541-8