Abstract

Colorectal cancer, which is difficult to treat and has a high recurrence rate, is a challenging target. Here, we propose a novel multi-layered sheet-like device with photothermal switching for the achievement of both hyperthermia and local chemotherapy. The device was fabricated by modifying polydopamine on the surface of a polymer thin film (nanosheet) and combining it with a drug-loaded poly(lactic acid) nanosheet, and was demonstrated to control the drug release reversibly. It is suggested that several percent of loaded drug was repeatedly released by irradiating near-infrared light, indicating the high potential of minimally invasive long-term treatment of colorectal cancer.

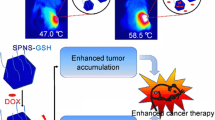

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cancer ranks as a leading cause of death and a principal barrier to increasing life expectancy in every country of the world. In particular, colorectal cancer ranks third for incidence and second for mortality.[1] Standard therapies of cancer treatment include surgical treatment, chemotherapy and radiation therapy, and those therapies are selected and sometimes combined depending on the type and stage of cancer. Colorectal cancer patients with stages I and II are generally recommended to take a surgical treatment, however, complete removal of malignant tumors is sometimes difficult and the risk of recurrence is high. Also, complications such as bleeding, perforation, and wound infection are concerns during surgery because the intestinal membrane is thin and weak in the colon and rectum. On the other hand, 67% of colon cancer patients with stage III and 61% of rectal cancer patients with stage III were reported to receive adjuvant chemotherapy or radiotherapy in addition to surgical treatment to lower the risk of recurrence.[2] However, these therapies are nonspecific and cause strong damage on healthy cells, and side effects are concerns. Therefore, effective chemotherapy which can non-invasively control the release of drugs at the target tissue, is expected for patients with colorectal cancer after surgical treatment.

Photothermal therapy (PTT) is one of the new cancer treatments that have recently been attracted much attention.[3] Photothermal reagents are accumulated in a target tumor and near-infrared light (650–1350 nm) is irradiated to the target site, resulting in a high local temperature (> 43°C) to kill the cancer cells. Since cancer cells are more heat-sensitive than healthy cells, heating of cancer cells for a certain period of time induces selective apoptosis and necrosis.[4,5] In PTT, inorganic compounds such as copper-based compounds,[6] gold nanorods,[7] and quantum dots[8] were used as photothermal conversion reagents which absorb near-infrared light to generate heat. These photothermal reagents remain in the body for a long time due to their non-biodegradability which would result in biotoxicity and adverse side effects. Moreover, there are limitations for long time use and the number of use due to fragmenting or deteriorating.[9]

On the other hand, polydopamine (PDA) is an organic polymer that has been attracting attention in recent years and has high biocompatibility, high biodegradability, high adhesive strength, and superior optical properties.[10,11] PDA has catechol groups that exhibit high adhesiveness; it can be attached to a variety of substrate surfaces such as polymers, metal oxides, and semiconductors, and is widely used for surface functionalization of biomedical devices.[12] Moreover, PDA has a photothermal conversion property for PTT since it has absorption in a wide range of wavelengths from ultraviolet to near-infrared light.[10,13] Liu et al. reported strong near-infrared absorption of PDA nanoparticles and up to 40% photothermal conversion efficiency. When PDA nanoparticles were injected into mice bearing 4T1 tumors and then tumors were exposed to an 808 nm laser, most of the tumor tissue was necrotic.[14] However, PDA nanoparticles were likely to be trapped in a reticuloendothelial system such as the spleen and liver, and it is requested to construct a specific delivery system to tumor sites in the colon and rectum.

To this end, we proposed to use free-standing polymer thin films (referred to as “nanosheets”) with a thickness of tens to hundreds of nanometers. Nanosheets are so flexible that they can adhere to skin or organ surfaces without glues, through physical adhesive such as van der Waals force.[15] Taking advantage of unique properties of nanosheets, we have developed materials for wound dressing,[15] anti-adhesive film,[16] or electrodes for EMG measurement.[17] Moreover, Yamagishi et al. reported the modification of the surface of the nanosheet with PDA for chemical adhesion between the nanosheet and tissue surface.[18] By using a nanosheet modified with PDA, a LED device can be attached to a tumor site and can conduct PDT.

In this study, we prepared a PDA-modified poly(caprolactone) (PCL) nanosheet for photothermal conversion and evaluated their photothermal behavior to investigate their feasibility for PTT. PCL is one of representative biodegradable and biocompatible polymers and a nanosheet made of PCL is considered appropriate as a base material for PDA modification in terms of its flexible and stretchable properties.[19] Moreover, in order to improve the therapeutic effect, we conceived the idea of using local chemotherapy in combination with heat treatment. Drug-loaded and release-controlled layers were fabricated using our nanosheet-layering technology and a control released system was achieved using heat generated from PDA by photothermal conversion. Since it is hard to control the drug release by simple diffusion of a single drug-loaded nanosheet,[20] drug release can be controlled by combining a release-controlled layer and a drug-loaded layer. We need poly(D, L-lactic acid) (PLA) with a glass transition temperature (Tg) of 52–55°C in the effective range of PTT at the release-controlled layer. PTT and local chemotherapy are expected to be simultaneously achieved for high therapeutic efficacy and reduction of adverse side effects.[21]

Materials and methods

Materials

Poly(vinyl alchol) (PVA, Mw: 13,000–23,000), Copper(II) sulfate (CuSO4・5H2O), hydrogen peroxide (H2O2, 30 w/w%), ethyl acetate, and chloroform were purchased from Kanto Chemical Co., Ltd. (Tokyo, Japan). Poly(D, L-lactic acid) (PLA, Mw: 300,000–600,000) was purchased from Polysciences Inc. (Warrington, PA). Poly(caprolactone)(PCL, Mn: 70,000–90,000), D-PBS, dopamine hydrochloride and hydrochloric acid were purchased from Sigma-Aldrich (Louis, MO). Tris hydroxymethyl aminomethane (Tris) was purchased from Nacalai Tesque Inc. (Kyoto, Japan). Rhodamine B was purchased from Tokyo Chemical Industry Co., Ltd. (Tokyo, Japan). A roll of poly(ethylene terephthalate) (PET) film (Lumirror, 25T60) was purchased from Panac Co., Ltd. (Tokyo, Japan). Poly(urethane) adhesive was purchased from Konishi Co., Ltd. (Osaka, Japan). Dotite was purchased from Fujikura Kasei Co., Ltd. (Tokyo, Japan).

Fabrication of PCL nanosheets and modification of PDA

A PVA (5.0 wt%) solution was prepared in ultrapure water and a PCL (3.0 wt%) solution was prepared in ethyl acetate. A PVA layer was fabricated on a PET film by a roll-to-roll process (Line speed: 1.3 m/min, temperature: 120°C, roll rotation: 30 rpm) with Micro Gravure™ Coater ML-120 (Yasui Seiki Co., Ltd, Kanagawa, Japan). The PVA layer was used as a sacrificial layer for peeling off the nanosheet from the PET film. The PVA/PET film was cut into 5 cm2 and set on a spin coater MS-A100 (Mikasa Co., Ltd., Tokyo, Japan). The PCL solution (1 mL) was dropped onto the film to make a PCL nanosheet by spin-coating (4000 rpm, 20 s). After drying it at room temperature, the PCL/PVA bi-layered PET film framed with four masking tapes was peeled off from the PET film using tweezers. The frame of the PCL/PVA bi-layered PET film was immersed in ultrapure water for 20 min to dissolve and remove the PVA layer, obtaining a frame having a PCL nanosheet.

Next, PDA was modified on the surface of the PCL nanosheet. Tris (50 mM) was dissolved in ultrapure water and then adjusted to pH 8.5 using hydrochloric acid. A dopamine solution was prepared by adding copper sulfate (5.0 mM), dopamine (2.0 mg/mL), and hydrogen peroxide (19.6 mM) to the Tris solution. Copper sulfate and hydrogen peroxide were used as catalysts to enhance the oxidative polymerization of dopamine. The PCL nanosheet was attached to a PVC quadrangle frame and immersed in the dopamine solution at room temperature. The dopamine solution was replaced every 2 h and soaked for a total of 6 h. The PDA-modified PCL sheet (PDA-PCL sheet) was immersed in ultrapure water for 1 week to remove dopamine, hydrogen peroxide, and copper sulfate.

Measurements of physical properties of the PDA-PCL sheets

PDA modification was evaluated by measurements of thickness, FT-IR spectrum, and Raman spectrum. Regarding thickness, PCL nanosheets and PDA-PCL sheets were adhered on a silicon wafer with a few drops of water followed by dry. Two parallel scratches were made at the center of the sheet using tweezers to expose the surface of silicon wafer. The height difference between the silicon wafer and the sheet was measured with a stylus profiler (Dektak XT-E, Bruker Co., Ltd., MA), and then the thickness was calculated. For FT-IR measurement (Jasco Co., Ltd., Tokyo, Japan), The PCL nanosheet or the PDA-PCL sheet were attached individually to a PVC frame and conducted FT-IR measurements. The conditions for the measurement were the range of wavenumber from 400 to 4000 cm−1 and 64 scan number. The Raman spectra of the PCL nanosheet or the PDA-PCL sheet were obtained with micro-Raman spectroscopy (Renishaw plc, Wotton-under-Edge, UK). They were set on a sample stand with the measurement conditions of laser wavelength of 532 nm and the range of wavenumber from 800 to 2000 cm−1.

Measurement of photothermal conversion of the PDA-PCL sheets

The PDA-PCL sheets were irradiated with near-infrared light to measure their heat generation performance. Specifically, PCL nanosheets and PDA-PCL sheets (mono-layer, bi-layers, or tri-layers) were attached to the bottom of plastic dish and fixed all four corners of the sheet with poly(urethane) adhesive. For bi- and tri-layer samples, PDA-PCL sheets were collected on a mesh, overlapped to prevent air bubbles in between, and attached to the dish. A thermocouple was fixed in the center of the sheet with Dotite (conductive paste). 24 h after drying, a near-infrared LED (850 nm, 10 W, LED generic Co., Ltd., Yamanashi, Japan) was irradiated from the bottom of the dish for 5 min and the surface temperature of each sheet was measured. The distance of LED and the dish was kept at 1.0 cm. Next, the heat generation performance was evaluated by changing the intensity of LED irradiation. PDA-PCL (tri-layers) were prepared in the same way as described above, and the surface temperature was measured with changing the distance between LED and the dish at 1.0, 1.5, and 2.0 cm to change the LED intensity. Finally, the stability of PDA-PCL sheets was evaluated by repeatedly irradiating with LED. LED irradiation was switched on and off every 5 min, and the surface temperature was measured.

Evaluation of drug release layer

Rhodamine B (RhoB, 1.3 × 10–3 wt%) and PLA (1.7 wt%) were dissolved in chloroform and stirred at room temperature for 24 h. RhoB was used as a model drug in this experiment. PLA (5.0 wt%) was also prepared with ethyl acetate as the solvent. A RhoB-loaded PLA nanosheet or a PLA nanosheet were fabricated by a spin-coating method as described above. After drying at room temperature and framed with masking tapes, the nanosheet was peeled off from the PET film using tweezers and immersed in ultrapure water for 20 min to dissolve the PVA layer. The RhoB-loaded PLA nanosheet and PLA nanosheet were collected on a mesh and cut into 5 and 8 mm2, respectively. The RhoB-loaded PLA nanosheet and PLA nanosheet were attached to a glass substrate (8 mm2) in this order. The four sides were fixed with poly(urethane) adhesive to prevent the leakage of RhoB from the edges. After drying for 24 h, the sample was placed on the bottom of a quartz cuvette and PBS (3 mL, r.t.) was added. The top of the cuvette was sealed with a dura-seal to prevent the evaporation of PBS. To investigate the release rate of RhoB at certain temperatures (37–62°C), the solution temperature was controlled with a constant-temperature water bath (Yamato Scientific Co., Ltd., Tokyo, Japan) and the fluorescence intensity of RhoB in the solution was measured every 15 min with a fluorescence spectrophotometer (RF-5300PC, Shimadzu Co., Ltd., Kyoto, Japan). The solution temperature was measured with a thermocouple.

Drug release control with the PDA-PCL sheets

Samples were prepared by attaching the PDA-PCL sheets (tri-layers, 7 mm2), a RhoB-loaded nanosheet (5 mm2), and a PLA nanosheet (3.0 wt%, 8 mm2) to a glass substrate (8 mm2) in this order. After drying it at room temperature for 1 h, the four sides of the glass substrate were fixed with poly(urethane) adhesive and dried for 24 h. The samples were placed in the bottom of a quartz cuvette and then PBS (3 mL, r.t.) was added to it. The top of the cuvette was sealed with a dura-seal to prevent the evaporation of PBS. The fluorescence intensity of RhoB was measured every 30 min with the fluorescence spectrophotometer. The near-infrared LED was kept with a distance of 1.0 cm from the bottom of the cuvette and irradiated for 30 min every 1 week. After LED irradiation was stopped, the cuvette was left at room temperature, so the temperature gradually returned to room temperature.

Results and discussion

Measurements of physical properties of the PDA-PCL sheets

Photographs of the sheets before and after PDA modification are shown in Fig. 1(a). Compared with the PCL nanosheet, the color of the PDA-PCL sheet became black. The thicknesses of the PCL nanosheets and PDA-PCL sheets were 192 ± 5 nm and 954 ± 58 nm, respectively (n = 5). The thickness of the PDA layer is estimated to be 762 ± 58 nm based on the increase in the sheet thickness with the PDA modification. However, the high transparency was still maintained. PCL nanosheets have low mechanical stiffness and high extensibility due to the linear structure of PCL (Mn: 70,000–90,000), while PDA is a mixture of oligomers (trimer and tetramer) resulting in low extensibility.[22] Therefore, compared to PCL nanosheets, the properties of PDA-PCL sheets are expected to be influenced by PDA, resulting in higher mechanical stiffness.[18]

IR measurement was conducted to identify the surface functional groups [Fig. 1(b)]. PCL-derived peaks were identified as C–H stretching vibration: 2862 cm−1, 2936 cm−1, C=O stretching vibration: 1724 cm−1 before and after PDA modification. After PDA modification, absorption bands derived from hydroxyl groups: 3100–3600 cm−1 and aromatic rings: 1500–1650 cm−1 were additionally observed.

Raman spectra are shown in Fig. 1(c). The PCL-derived peaks were identified as C=O stretching vibration: 1723 cm−1, CH2 bending: 1441 cm−1 and 1417 cm−1, CH2 twisting vibration: 1305 cm−1, C–C stretching vibration: 1108 cm−1 and 1064 cm−1. On the other hand, after PDA modification, only G- and D-bands derived from aromatic rings were observed. In comparison with the previous data[23] of PDA, similar Raman spectra were obtained, confirming that a thick PDA layer was constructed on the surface of the PCL nanosheet.

Measurement of photothermal conversion of the PDA-PCL sheets

For each sample of PCL nanosheets and PDA-PCL sheets (mono-layer, bi-layers, tri-layers), the surface temperatures during LED irradiation were measured for 10 min [Fig. 2(a)]. The surface temperature of the sheets became stable after LED irradiation for approximately 3 min. The thickness of the PDA on a mono-layer of PDA-PCL sheet is about 762 nm, and the average surface temperature immediately after LED irradiation for 5 min is 55.8°C. Also, the surface temperatures were 58.8 and 61.9°C for bi- and tri-layers of PDA-PCL sheets, respectively. The melting point of PCL is around 60°C and the temperature slightly exceeded 60°C in the sample with tri-layers of PDA-PLC sheets. However, there was no significant change in them after LED irradiation. The exothermic temperature increased with the layering of PDA-PCL sheets, in other words, increasing the total amount of PDA. The amount of PDA was calculated in the area in contact with Dotite and the exothermic intensity Δt is the value obtained by subtracting the surface temperature of the PCL nanosheets from that of the PDA-PCL sheets after 5 min of LED irradiation.[24] The exothermic intensity Δt for the amount of modified PDA was 20.2 μg: 14.2 °C, 40.4 μg: 17.2°C, 60.6 μg: 20.3°C. There was no proportional relationship between the amount of PDA and exothermic intensity. Namely, suggesting that the photothermal conversion efficiency of PDA gradually decreased. This is hypothesized to be due to the fact that the PDA-PCL sheets are black in color as shown in Fig. 1(a), so the overlapping them reduces the transmittance of near-infrared light and reduces the light intensity at the surface of the sheet, where the temperature was measured.

(a) PDA amount and surface temperature of each sheets (round: PCL, triangle: mono-layer of PDA-PCL sheet, square: bi-layers of PDA-PCL sheets, diamond: tri-layers of PDA-PCL sheets, n = 3). (b) LED intensity and the surface temperature of each sheet (LED irradiation: 5 min, tri-layers of PDA-PCL sheets, n = 3). (c) The stability of the temperature rise and fall during repeated LED irradiation (gray area: LED on, white area: LED off).

The next experiment was conducted by changing the LED intensity which was controlled by changing the distance from the light source. The average surface temperatures immediately after LED irradiation for 5 min at the distance of 1.0 cm, 1.5 cm, and 2.0 cm were 61.9, 43.7, and 37.7°C, respectively [Fig. 2(b)]. It was suggested that the average surface temperature was inversely proportional to the square of the distance between the light source and the sheet. This may be due to the fact that the light intensity is inversely proportional to the square of the distance. In previous studies, it was demonstrated that heating at around 45°C kills cancer cells in 15–60 min, and heating at 50–60°C kills cancer cells in a few min.[25] In this study, by controlling the amount of PDA and light source intensity, a temperature range from 37.7 to 61.9°C can be achieved within 5 min by near-infrared light irradiation, suggesting that the PDA-PCL sheet has an effective photothermal conversion performance for PTT which is able to kill cancer cells.

Next, we evaluated the stability of the temperature rise and fall of the surface of the PDA-PCL sheet during repeated LED irradiation [Fig. 2(c)]. The LED irradiation was repeated every 5 min, and a mono-layer of PDA-PCL sheet showed the same heat generation repeatedly. After 10 cycles of LED irradiation, there was no visible fragmentation or discoloration of the sample and the PDA remained supported on the PCL nanosheets. In the previous study in which the films of PCL and polyurethane containing with PDA nanoparticles were irradiated with near-infrared light at a wavelength of 808 nm, there was no change in photothermal conversion performance after five times of LED irradiations.[26] This means that PDA seems not to be degraded by near-infrared light absorption. Gold-based photothermal reagents are difficult to use in the second and subsequent PTT because of the significant loss of absorbance after the first LED irradiation due to the deformation and fragmentation.[27,28] In this study, we showed that PDA is capable for 10 times heating cycle of photothermal conversion at least.

Evaluation of drug release layer

The thicknesses of the PLA nanosheets and RhoB-loaded PLA nanosheets were 492 ± 4 nm and 205 ± 17 nm, respectively (n = 5). The prepared samples were placed in cuvettes as shown in Fig. 3(a) and RhoB release behavior at each solution temperature was measured for 3 h [Fig. 3(b)]. The RhoB release rate was found to be enhanced with increasing temperature. A remarkable enhancement of RhoB release rate was observed above the glass transition temperature of PLA (52–55°C) [Fig. 3(c)]. In the sample with the solution temperature set at 55°C, the RhoB release rate remained to be slow until 15 min and became to be enhanced after 15 min. Since the solution temperature immediately after the start of the measurement was around room temperature (23.5°C), it is suggested that the temperature of PLA would be below Tg until 15 min pass, and after 15 min pass it would exceed above Tg. Specifically, it is considered that the micro-Brownian motion of the polymer chains above Tg would promote the permeation of RhoB molecules through spaces opened among the polymer chains. Therefore, the bi-layered drug release sheet fabricated in this experiment successfully constructed a system in which drug release can be suppressed at body temperature (37°C) and enhanced when the Tg of PLA is exceeded by heat generated from the PDA-PCL sheets by near-infrared light irradiation.

Drug release control with the PDA-PCL sheets

A sample that combined a photothermal layer and a drug release layer as shown in Fig. 4(a) was prepared, and the release behavior of RhoB was measured [Fig. 4(b)]. The thicknesses of the PLA nanosheets and RhoB-loaded PLA nanosheets were 197 ± 8 nm and 205 ± 17 nm, respectively (n = 5). Based on the previous experimental results, the distance between the sample and the LED was set at 1.0 cm so that the temperature generated by LED irradiation exceeded the Tg of PLA. After 30 min of LED irradiation, the temperature of PBS was approximately 46°C and the cuvette was gradually cooled to room temperature in about 15 min. Switch-on of RhoB release was observed by LED irradiation, and switch-off was observed when LED irradiation was stopped. However, a gradual leakage of RhoB was observed even after the stop of LED irradiation. It was not due to in the high solution temperature after LED irradiation. Before LED irradiation, the temperature of PLA nanosheet is below Tg and the PLA polymer chains are in a glass state with low mobility. On the other hand, when the temperature is above Tg by LED irradiation, the entanglement of polymer chains becomes loose by micro-Brownian motion, leading to the release of RhoB through the spaces of polymer chains. Such change of the polymer chains by temperature change was reversible because the release of RhoB was suppressed after the stop of LED irradiation. However, plasticization by RhoB would occur for PLA when RhoB molecules were entered, explaining the leakage of RhoB even after the stop of LED irradiation.

In the first LED irradiation, the release rate of RhoB was about 7%, so the sample temperature is estimated to have been around 50°C from the results in Fig. 3(b). The difference in the exothermic temperature of tri-layers of PDA-PCL sheets in this experiment and Fig. 2(a) can be due to the different experimental conditions. While the experiment in Fig. 2(a) measured the temperature of PDA-PCL sheets in air, the sample used in Fig. 4(b) was attached to the bottom of a cuvette filled with PBS, so the temperature would not be as high as in Fig. 2(a).

In the experiment in which LED irradiation was repeated every 24 h (Fig. S1), the amount of RhoB released gradually decreased as the number of LED irradiation increased. This is assumed that the diffusion layer due to the concentration gradient of RhoB inside the drug release layer gradually became thicker. Since RhoB diffusion inside the PLA nanosheets would be slow when the temperature is below Tg, RhoB leakage from the bottom of the RhoB-loaded PLA nanosheet hardly occurred and the concentration gradient of RhoB did not become constant during the 24 h interval. This is supported by the fact that more than 70% of the initial amount of RhoB remained in the nanosheet after four times of LED irradiations. In the experiment in which the LED irradiation interval was 1 week, the amount of RhoB released by LED irradiation was stable (1st: 7.6%, 2nd: 5.9%, 3rd: 6.6%, 4th: 6.2%). It is supposed that by a sufficient interval, the release always occurred in the same state and the released RhoB amount was constant because the concentration gradient of RhoB returned to its initial state before LED irradiation was started due to a sufficient supply of RhoB from the RhoB-loaded PLA nanosheet.

Although a variety of mechanisms have been developed for drug release from polymer nanoparticles used as drug carriers, the typical drug release behavior is an initial burst, followed by a slow secondary release.[29,30] Sheet-type devices also exhibit the release behavior similar to that of polymer nanoparticles.[20] Regarding the switching of drug release, one of the challenges is the suppression of drug leakage during non-stimulation condition. The device shown in this research suppressed the initial burst of RhoB by overlaying a release control layer. In addition, the use of PLA, which has a Tg higher than body temperature, successfully suppressed the leakage of RhoB during non-irradiation state. After resection of colorectal cancer tumors, adjuvant chemotherapy is generally applied every 1–2 weeks for 3–6 months to prevent recurrence. Since approximately 70% of RhoB remained in the sample after four times of LED irradiations, it is assumed that this device can continuously release RhoB even after the fifth and subsequent LED irradiations. This suggests the possibility of minimally invasive treatment of residual or metastasized cancer cells over a long period of several months once implanted in vivo. Furthermore, it is also suggested that a stable amount of drug in the therapeutic range can be supplied at all times since there is no initial burst of RhoB. In this study, we referred only to the release rate of RhoB and not to the amount of RhoB released, it is supposed that the amount of RhoB released can be controlled depending on some factors. Indeed, the effect of the thickness of the release-controlled layer was investigated, and it was confirmed that the release rate of RhoB could be controlled by the thickness of the release-controlled layer as shown in Fig. S2. PLA sheets with thicknesses ranging from 99 to 2337 nm were fabricated and used as release-controlled layers. It was confirmed that 0.3–10.6% of RhoB was released by 30 min of LED irradiation. This suggests that the degree of drug release can be widely controlled by changing the thickness of the release-controlled layer and the time of LED irradiation.

Conclusions

We constructed a novel multi-layered sheet-like device with photothermal switching for achievement of both hyperthermia and local chemotherapy. The PDA-PCL sheets converted near-infrared light to heat and showed effective heat generation capability for PTT. Moreover, combined the PLA nanosheet with the PDA-PCL sheet, a mechanism was established in which the drug release can be controlled repeatedly on/off by the Tg of PLA. RhoB release timing can be controlled by near-infrared light irradiation and several percent of the total RhoB loaded can be released at any time over multiple times. These results indicate that the basic device design for minimally invasive long-term treatment once implanted for colorectal cancer in postoperative therapy appears to have been achieved.

References

H. Sung, J. Ferlay, R.L. Siegel, M. Laversanne, I. Soerjomataram, A. Jemal, F.C.A. Bray, Cancer J. Clin. (2021). https://doi.org/10.3322/caac.21660

K.D. Miller, L. Nogueira, T. Devasia, A.B. Mariotto, K.R. Yabroff, A. Jemal, J. Kramer, R.L.C.A. Siegel, Cancer J. Clin. (2022). https://doi.org/10.3322/caac.21731

X. Li, J.F. Lovell, J. Yoon, X. Chen, Nat. Rev. Clin. Oncol. (2020). https://doi.org/10.1038/s41571-020-0410-2

M.R.K. Ali et al., Proc. Natl. Acad. Sci. USA (2017). https://doi.org/10.1073/pnas.1619302114

J.W. Fisher, S. Sarkar, C.F. Buchanan, C.S. Szot, J. Whitney, H.C. Hatcher, S.V. Torti, C.G. Rylander, M.N. Rylander, Can. Res. (2010). https://doi.org/10.1158/0008-5472.CAN-10-0250

M. Zhou, J. Li, S. Liang, A.K. Sood, D. Liang, C. Li, ACS Nano (2015). https://doi.org/10.1021/acsnano.5b02635

W. Choi, J.Y. Kim, C. Kang, C.C. Byeon, Y.H. Kim, G. Tae, ACS Nano (2011). https://doi.org/10.1021/nn103047r

G.Z. Jia, W.K. Lou, F. Cheng, X.L. Wang, J.H. Yao, N. Dai, H.Q. Lin, K. Chang, Nano Res. (2015). https://doi.org/10.1007/s12274-014-0629-2

S. Link, C. Burda, M.B. Mohamed, B. Nikoobakht, M.A. El-Sayed, J. Phys. Chem. A (1999). https://doi.org/10.1021/jp983141k

Y. Liu, K. Ai, L. Lu, Chem. Rev. (2014). https://doi.org/10.1021/cr400407a

H. Lee, S.M. Dellatore, W.M. Miller, P.B. Messersmith, Science (2007). https://doi.org/10.1126/science.1147241

Y.H. Ding, M. Floren, W. Tan, Biosurf. Biotribol. (2016). https://doi.org/10.1016/j.bsbt.2016.11.001

H. Liu, Y. Yang, Y. Liu, J. Pan, J. Wang, F. Man, W. Zhang, G. Liu, Adv. Sci. (2020). https://doi.org/10.1002/advs.201903129

Y. Liu, K. Ai, J. Liu, M. Deng, Y. He, L. Lu, Adv. Mater. (2013). https://doi.org/10.1002/adma.201204683

T. Fujie, N. Matsutani, M. Kinoshita, Y. Okamura, A. Saito, S. Takeoka, Adv. Func. Mater. (2009). https://doi.org/10.1002/adfm.200900103

D. Niwa, M. Koide, T. Fujie, N. Goda, S. Takeoka, J. Biomed. Mater. Res. Part B (2013). https://doi.org/10.1002/jbm.b.32937

K. Yamagishi, T. Nakanishi, S. Mihara, M. Azuma, S. Takeoka, K. Kanosue, T. Nagami, T. Fujie, NPG Asia Mater. (2019). https://doi.org/10.1038/s41427-019-0183-1

K. Yamagishi, I. Kirino, I. Takahashi, H. Amano, S. Takeoka, Y. Morimoto, T. Fujie, Nature Biomed. Eng. (2019). https://doi.org/10.1038/s41551-018-0261-7

C. Xuan et al., Biomaterials (2020). https://doi.org/10.1016/j.biomaterials.2020.120018

K. Ito, A. Saito, T. Fujie, K. Nishiwaki, H. Miyazaki, M. Kinoshita, D. Saitoh, S. Ohtsubo, S. Takeoka, Acta Biomater. (2015). https://doi.org/10.1016/j.actbio.2015.05.035

X. Zheng, S. Zhou, X. Li, J. Weng, Biomaterials (2006). https://doi.org/10.1016/j.biomaterials.2006.03.043

J. Liebscher, Eur. J. Org. Chem. (2019). https://doi.org/10.1002/ejoc.201900445

M.T. Cortés, C. Vargas, D.A. Blanco, I.D. Quinchanegua, C. Cortés, A.M. Jaramillo, J. Chem. Educ. (2019). https://doi.org/10.1021/acs.jchemed.8b00432

V. Ball, Biointerphases (2014). https://doi.org/10.1116/1.4875115

D. Jaque, L. Martínez Maestro, B. Del Rosal, P. Haro-Gonzalez, A. Benayas, J.L. Plaza, E. Martín Rodríguez, J. García Solé, Nanoscale (2014). https://doi.org/10.1039/c4nr00708e

S. Dai, S. Yue, Z. Ning, N. Jiang, Z. Gan, ACS Appl. Mater. Interfaces. (2022). https://doi.org/10.1021/acsami.2c03172

H. Petrova, J.P. Juste, I. Pastoriza-Santos, G.V. Hartland, L.M. Liz-Marzán, P. Mulvaney, Phys. Chem. Chem. Phys. (2006). https://doi.org/10.1039/b514644e

Y.-S. Chen, W. Frey, S. Kim, K. Homan, P. Kruizinga, K. Sokolov, S. Emelianov, Opt. Express (2010). https://doi.org/10.1364/oe.18.008867

S. Fredenberg, M. Wahlgren, M. Reslow, A. Axelsson, Int. J. Pharm. (2011). https://doi.org/10.1016/j.ijpharm.2011.05.049

X. Bai, Z.L. Smith, Y. Wang, S. Butterworth, A. Tirella, Micromachines (2022). https://doi.org/10.3390/mi13101623

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Shinji Takeoka was an editor of this journal during the review and decision stage. For the MRS Communications policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shimizu, K., Takeoka, S. Photothermal switch of drug release from polydopamine-modified nanosheets. MRS Communications 13, 818–824 (2023). https://doi.org/10.1557/s43579-023-00357-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43579-023-00357-y