Abstract

The rapid design of advanced materials is a topic of great scientific interest. The conventional “forward” paradigm of materials design involves evaluating multiple candidates to determine the best candidate that matches the target properties. However, recent advances in the field of deep learning have given rise to the possibility of an “inverse” design paradigm for advanced materials, wherein a model provided with the target properties is able to find the best candidate. Being a relatively new concept, there remains a need to systematically evaluate how these two paradigms perform in practical applications. Therefore, the objective of this study is to directly, quantitatively compare the forward and inverse design modeling paradigms. We do so by considering two case studies of refractory high-entropy alloy design with different objectives and constraints and comparing the inverse design method to other forward schemes like localized forward search, high-throughput screening, and multi-objective optimization.

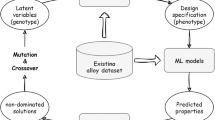

Graphical abstract

Similar content being viewed by others

Data availability

A static snapshot of the code and data used to generate the results in this work are publicly available on https://doi.org/10.5281/zenodo.8061193 [30].

References

A. Debnath, A.M. Krajewski, H. Sun, S. Lin, M. Ahn, W. Li et al., Generative deep learning as a tool for inverse design of high entropy refractory alloys. J. Mater. Inform. (2021). https://doi.org/10.20517/jmi.2021.05

Y. Liu, T. Zhao, W. Ju, S. Shi, Materials discovery and design using machine learning. J. Materiomics 3(3), 159–177 (2017)

A. Agrawal, A. Choudhary, Perspective: materials informatics and big data: realization of the “fourth paradigm’’ of science in materials science. Appl. Mater. 4(5), 053208 (2016)

Z.K. Liu, Ocean of data: integrating first-principles calculations and CALPHAD modeling with machine learning. J. Phase Equilib. Diffus. 39(5), 635–649 (2018)

C. Wen, Y. Zhang, C. Wang, D. Xue, Y. Bai, S. Antonov et al., Machine learning assisted design of high entropy alloys with desired property. Acta Mater. 170, 109–117 (2019)

A. Fischer, C. Igel, An introduction to restricted Boltzmann machines, in Iberoamerican congress on pattern recognition. (Springer, Berlin, 2012), pp.14–36

D.A. Reynolds, Gaussian mixture models, in Encyclopedia of biometrics, vol. 741, (Springer, Boston, 2009), pp.659–663

G.E. Hinton, Deep belief networks. Scholarpedia 4(5), 5947 (2009)

D.P. Kingma, M. Welling et al., An introduction to variational autoencoders. Found. Trends Mach. Learn. 12(4), 307–392 (2019)

I. Goodfellow, Y. Bengio, A. Courville, Deep learning., (MIT Press, 2016). http://www.deeplearningbook.org. Accessed 15 Feb 2023

C. Yeung, R. Tsai, B. Pham, B. King, Y. Kawagoe, Ho D, et al., Global inverse design across multiple photonic structure classes using generative deep learning (2020). arXiv preprint arXiv:2012.15790

Y. Dan, Y. Zhao, X. Li, S. Li, M. Hu, J. Hu, Generative adversarial networks (GAN) based efficient sampling of chemical composition space for inverse design of inorganic materials. NPJ Comput. Mater. 6(1), 1–7 (2020)

Y. Dong, D. Li, C. Zhang, C. Wu, H. Wang, M. Xin et al., Inverse design of two-dimensional graphene/h-BN hybrids by a regressional and conditional GAN. Carbon 169, 9–16 (2020)

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A (2004). https://doi.org/10.1016/j.msea.2003.10.257

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun et al., Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299–303 (2004). https://doi.org/10.1002/ADEM.200300567

O.N. Senkov, D.B. Miracle, K.J. Chaput, J.P. Couzinie, Development and exploration of refractory high entropy alloys-A review. J. Mater. Res. 33(19), 3092–3128 (2018). https://doi.org/10.1557/JMR.2018.153

D. Klimenko, N. Stepanov, J. Li, Q. Fang, S. Zherebtsov, Machine learning-based strength prediction for refractory high-entropy alloys of the Al-Cr-Nb-Ti-V-Zr system. Materials 14(23), 7213 (2021)

Y. Jung, K. Lee, S.J. Hong, J.K. Lee, J. Han, K.B. Kim et al., Investigation of phase-transformation path in TiZrHf(VNbTa)x refractory high-entropy alloys and its effect on mechanical property. J. Alloys Compd. 12(886), 161187 (2021). https://doi.org/10.1016/J.JALLCOM.2021.161187

A. Radford, L. Metz, S. Chintala, Unsupervised representation learning with deep convolutional generative adversarial networks (2015). arXiv preprint arXiv:1511.06434

F. Pedregosa, G. Varoquaux, A. Gramfort, V. Michel, B. Thirion, O. Grisel et al., Scikit-learn: machine learning in python. J. Mach. Learn. Res. 12, 2825–2830 (2011)

D. Whitley, A genetic algorithm tutorial. Stat. Comput. 4(2), 65–85 (1994)

P.I. Frazier, A tutorial on Bayesian optimization (2018). arXiv preprint arXiv:1807.02811

J. Bao, D. Chen, F. Wen, H. Li, G. Hua, CVAE-GAN: fine-grained image generation through asymmetric training, in Proceedings of the IEEE international conference on computer vision. (2017), pp.2745–2754

K. Aggarwal, M. Kirchmeyer, P. Yadav, S.S. Keerthi, P. Gallinari, Regression with conditional GAN (2019). arXiv preprint arXiv:1905.12868

A. Debnath, W.F. Reinhart, Investigating representation schemes for surrogate modeling of high entropy alloys (2022). arXiv preprint arXiv:2301.00179

A. Paszke, S. Gross, F. Massa, A. Lerer, J. Bradbury, G. Chanan et al., PyTorch: an imperative style, high-performance deep learning library, in Advances in neural information processing systems 32. ed. by H. Wallach, H. Larochelle, A. Beygelzimer, F. d’Alché-Buc, E. Fox, R. Garnett (Curran Associates Inc, Red Hook, 2019), pp.8024–8035. http://papers.neurips.cc/paper/9015-pytorch-an-imperative-style-high-performance-deep-learning-library.pdf

X. Chong, S.L. Shang, A.M. Krajewski, J.D. Shimanek, W. Du, Y. Wang et al., Correlation analysis of materials properties by machine learning: illustrated with stacking fault energy from first-principles calculations in dilute fcc-based alloys. J. Phys.: Condens. Matter. 33(29), 295702 (2021). https://doi.org/10.1088/1361-648x/ac0195

A.M. Krajewski, A. Debnath, S. Lin, M. Ahn, H. Sun, W. Reinhart. et al., ULtrahigh TEmperature Refractory Alloys (ULTERA) Database of High Entropy Alloys. Zenodo. Described in: https://phaseslab.com/ultera. Available from: https://doi.org/10.5281/zenodo.7566416

J. Blank, K. Deb, Pymoo: multi-objective optimization in python. IEEE Access 8, 89497–89509 (2020)

A. Debnath, W. Reinhart, Code and data for ‘comparing forward and inverse design paradigms: a case study on refractory high-entropy alloys’. Zenodo. https://doi.org/10.5281/zenodo.8061193

Acknowledgments

The present work is based upon work supported by the Department of Energy/Advanced Research Projects Agency—Energy (ARPA-E) under award No DE-AR0001435. The authors would also like to thank John Shimanek, Christopher DeSalle, and Douglas Wolfe for helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Debnath, A., Raman, L., Li, W. et al. Comparing forward and inverse design paradigms: A case study on refractory high-entropy alloys. Journal of Materials Research 38, 4107–4117 (2023). https://doi.org/10.1557/s43578-023-01122-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-023-01122-6