Abstract

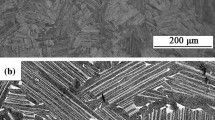

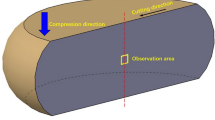

The present study describes the hot deformation behaviour of a novel Ti–6Al–4Mo–1V–0.1Si alloy. The flow characteristics of the alloy were investigated in the strain rate range of 0.01 s−1 to 10 s−1 and at temperatures ranging from 800 to 1050 °C. The increase in deformation temperature and decrease in strain rate results in gradual decrease of flow stress. Flow softening was observed for deformation at lower temperatures (800–900 °C) due to lamellae kinking, whereas flat flow curve characteristics were observed for deformation at higher temperatures (950–1050 °C) due to a balance of dynamic recovery and recrystallization. The flow stress characteristics during hot deformation were predicted using constitutive modelling based on the Arrhenius hyperbolic sine equation. The strain rate sensitivity map was created for 0.69 strain. The optimum hot deformation zone was observed at 0.01 s−1 in the temperature range (925–1050 °C), and at strain rates of 1 s−1 and 5 s−1 from 900 to 975 °C.

Graphical abstract

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

A.K. Nag, K.V.U. Praveen, V. Singh, Effect of heat treatment on tensile behaviour of Ti–6Al–5Zr–0.5Mo–0.25Si alloy. Bull. Mater. Sci. 29, 147–154 (2006)

M. Saood, K.M. Ibrahim, E. El-Kashif, M. Shoeib, A. Elshalakany, M.S. Mohamed, Mechanical behavior and corrosion properties of Ti–7Mo–8Nb alloy for biomedical applications. Mater. Res. Express (2021). https://doi.org/10.1088/2053-1591/ac2346

T. Alloy, Q. Wang, X. Lei, M. Hu, X. Xu, R. Yang, L. Dong, Effect of heat treatment on microstructure and tensile property, 1–12 (2021)

X. Yang, C.R. Hutchinson, Corrosion-wear of β-Ti alloy TMZF (Ti–12Mo–6Zr–2Fe) in simulated body fluid. Acta Biomater. 42, 429–439 (2016). https://doi.org/10.1016/j.actbio.2016.07.008

M. Atapour, A. Pilchak, G.S. Frankel, J.C. Williams, Corrosion behaviour of investment cast and friction stir processed Ti–6Al–4V. Corros. Sci. 52, 3062–3069 (2010). https://doi.org/10.1016/j.corsci.2010.05.026

M. Atapour, A.L. Pilchak, M. Shamanian, M.H. Fathi, Corrosion behavior of Ti–8Al–1Mo–1V alloy compared to Ti–6Al–4V. Mater. Des. 32, 1692–1696 (2011). https://doi.org/10.1016/j.matdes.2010.09.009

A. Gupta, R.K. Khatirkar, A. Kumar, M.S. Parihar, Investigations on the effect of heating temperature and cooling rate on evolution of microstructure in an α + β titanium alloy. J. Mater. Res. 33, 946–957 (2018). https://doi.org/10.1557/jmr.2018.54

Z.X. Zhang, S.J. Qu, A.H. Feng, J. Shen, D.L. Chen, Hot deformation behavior of Ti–6Al–4V alloy: effect of initial microstructure. J. Alloys Compd. 718, 170–181 (2017). https://doi.org/10.1016/j.jallcom.2017.05.097

E.B. Shell, S.L. Semiatin, Effect of initial microstructure on plastic flow and dynamic globularization during hot working of Ti–6Al–4V. Metall. Mater. Trans. A 30, 3219–3229 (1999). https://doi.org/10.1007/s11661-999-0232-4

W.J. Kim, H.T. Jeong, Construction of processing maps combined with deformation mechanism maps using creep deformation equations. J. Mater. Res. Technol. 9, 13434–13449 (2020). https://doi.org/10.1016/j.jmrt.2020.09.023

Y. Kim, Y.-B. Song, S.H. Lee, Y. Kwon, Characterization of the hot deformation behavior and microstructural evolution of Ti–6Al–4V sintered preforms using materials modeling techniques. J. Alloys Compd. 676, 15–25 (2016). https://doi.org/10.1016/j.jallcom.2016.03.146

Y.V.R.K. Prasad, T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, Microstructural modeling and process control during hot working of commercial Ti–6A1–4V: response of lamellar and equiaxed starting microstructures. Mater. Manuf. Process. 15, 581–604 (2000). https://doi.org/10.1080/10426910008913007

F. Waqar, S. Nitesh, R. Jaladurgam, V.A. Kumar, R. Kumar, Hot deformation characteristics and microstructure evolution. Int. J. Adv. Eng. Sci. Appl. Math. 13, 49–62 (2021). https://doi.org/10.1007/s12572-020-00283-5

W. Zhang, H. Ding, J. Zhao, B. Yang, W. Yang, Hot deformation behavior and processing maps of Ti–6Al–4V alloy with starting fully lamellar structure. J. Mater. Res. 33, 3677–3688 (2018). https://doi.org/10.1557/jmr.2018.331

P. Gao, M. Fu, M. Zhan, Z. Lei, Y. Li, Deformation behavior and microstructure evolution of titanium alloys with lamellar microstructure in hot working process: a review. J. Mater. Sci. Technol. 39, 56–73 (2020). https://doi.org/10.1016/j.jmst.2019.07.052

J.S. Jha, B. Jayabalan, S.P. Toppo, R. Singh, A. Tewari, S.K. Mishra, Hot deformation behaviour of Ti–6Al–4V alloy with a transformed microstructure: a multimodal characterisation. Philos. Mag. 99, 1429–1459 (2019). https://doi.org/10.1080/14786435.2019.1584409

E.B. Shell, S.L. Semiatin, Effect of initial microstructure on plastic flow and dynamic globularization during hot working of Ti–6AI–4V. Metall. Mater. Trans. A 30, 3219–3229 (1999). https://doi.org/10.1007/s11661-999-0232-4

H.Q. Chen, C.X. Cao, L. Guo, H. Lin, Hot deformation mechanism and microstructure evolution of TC11 titanium alloy in β field. Trans. Nonferr. Met. Soc. China (Engl. Ed.) 18, 1021–1027 (2008). https://doi.org/10.1016/S1003-6326(08)60175-2

A.J. Ardell, Microstructural stability at elevated temperatures. J. Eur. Ceram. Soc. 19, 2217–2231 (1999). https://doi.org/10.1016/S0955-2219(99)00094-1

W. Yang, W. Ji, Z. Zhou, A. Hao, L. Qing, H. Hao, J. Xu, Analysis of deformation behavior and microstructure changes for α/β titanium alloy at elevated temperature. Metals (Basel) 11, 1–16 (2021). https://doi.org/10.3390/met11020303

M. Villa, J.W. Brooks, R.P. Turner, H. Wang, F. Boitout, R.M. Ward, Microstructural modeling of the α + β phase in Ti–6Al–4V: a diffusion-based approach. Metall. Mater. Trans. B 50, 2898–2911 (2019). https://doi.org/10.1007/s11663-019-01675-0

Z. Xiao, Q. Wang, Y. Huang, J. Hu, M. Li, Hot deformation characteristics and processing parameter optimization of Al–6.32Zn–2.10Mg alloy using constitutive equation and processing map. Metals (Basel) 11, 1–18 (2021). https://doi.org/10.3390/met11020360

M. Murugesan, D.W. Jung, Two flow stress models for describing hot deformation behavior of AISI-1045 medium carbon steel at elevated temperatures. Heliyon 5, e01347 (2019). https://doi.org/10.1016/j.heliyon.2019.e01347

R.M. Miller, T.R. Bieler, S.L. Semiatin, Flow softening during hot working of Ti–6Al–4V with a lamellar colony microstructure. Scr. Mater. 40, 1387–1393 (1999). https://doi.org/10.1016/S1359-6462(99)00061-5

S. Ghosh, M.C. Somani, D. Setman, S. Mula, Hot deformation characteristic and strain dependent constitutive flow stress modelling of Ti + Nb stabilized interstitial free steel. Met. Mater. Int. 27, 2481–2498 (2021). https://doi.org/10.1007/s12540-020-00827-1

H. Egner, W. Egner, Modeling of a tempered martensitic hot work tool steel behavior in the presence of thermo-viscoplastic coupling. Int. J. Plast. 57, 77–91 (2014). https://doi.org/10.1016/j.ijplas.2014.03.002

J.A. Rodríguez-Martínez, A. Rusinek, R. Pesci, R. Zaera, Experimental and numerical analysis of the martensitic transformation in AISI 304 steel sheets subjected to perforation by conical and hemispherical projectiles. Int. J. Solids Struct. 50, 339–351 (2013). https://doi.org/10.1016/j.ijsolstr.2012.09.019

I. Papatriantafillou, M. Agoras, N. Aravas, G. Haidemenopoulos, Constitutive modeling and finite element methods for TRIP steels. Comput. Methods Appl. Mech. Eng. 195, 5094–5114 (2006). https://doi.org/10.1016/j.cma.2005.09.026

S.L. Semiatin, J.F. Thomas, P. Dadras, Processing–microstructure relationships for Ti–6Al–2Sn–4Zr–2Mo–0.1Si. Metall. Trans. A 14, 2363–2374 (1983). https://doi.org/10.1007/BF02663312

S. Semiatin, V. Seetharaman, I. Weiss, Flow behavior and globularization kinetics during hot working of Ti–6Al–4V with a colony alpha microstructure. Mater. Sci. Eng. A 263, 257–271 (1999). https://doi.org/10.1016/S0921-5093(98)01156-3

D. Mahadule, R.K. Khatirkar, A. Gupta, R. Kumar, Effect of heating temperature and cooling rate on the microstructure and mechanical properties of a Mo-rich two phase α + β titanium alloy. J. Mater. Res. 36, 751–763 (2021). https://doi.org/10.1557/s43578-020-00100-6

D. Mahadule, R.K. Khatirkar, S.K. Gupta, A. Gupta, T.R. Dandekar, Microstructure evolution and corrosion behaviour of a high Mo containing α + β titanium alloy for biomedical applications. J. Alloys Compd. 912, 165240 (2022). https://doi.org/10.1016/j.jallcom.2022.165240

F.W. Syed, V. Anil Kumar, R.K. Gupta, A.K. Kanjarla, Role of microstructure on the tension/compression asymmetry in a two-phase Ti–5Al–3Mo–1.5V titanium alloy. J. Alloys Compd. 795, 151–162 (2019). https://doi.org/10.1016/j.jallcom.2019.04.272

T.R. Dandekar, R.K. Khatirkar, A. Gupta, N. Bibhanshu, A. Bhadauria, S. Suwas, Strain rate sensitivity behaviour of Fe–21Cr–1.5Ni–5Mn alloy and its constitutive modelling. Mater. Chem. Phys. 271, 124948 (2021). https://doi.org/10.1016/j.matchemphys.2021.124948

I. Weiss, S.L. Semiatin, Thermomechanical processing of alpha titanium alloys—an overview. Mater. Sci. Eng. A 263, 243–256 (1999)

R. Yu, P. Wang, G. Li, M. Fang, G. Xu, M. Zhang, Correction and modeling of flow stress during hot deformation of 7055 aluminum alloy. J. Mater. Eng. Perform. (2022). https://doi.org/10.1007/s11665-022-06699-3

Q. Fu, W. Yuan, W. Xiang, Constitutive relationship for hot deformation of TB18 titanium alloy. Adv. Mater. Sci. Eng. (2020). https://doi.org/10.1155/2020/5716548

Z. Yang, W. Yu, S. Lang, J. Wei, G. Wang, P. Ding, Hot deformation behavior and processing maps of a new Ti–6Al–2Nb–2Zr–0.4B titanium alloy. Materials (Basel) 3, 1 (2021). https://doi.org/10.3390/ma14092456

A. Momeni, S. Kazemi, A. Bahrani, Hot deformation behavior of microstructural constituents in a duplex stainless steel during high-temperature straining. Int. J. Miner. Metall. Mater. 20, 953–960 (2013). https://doi.org/10.1007/s12613-013-0820-6

S. Kingklang, V. Uthaisangsuk, Investigation of hot deformation behavior of duplex stainless steel grade 2507. Metall. Mater. Trans. A 48, 95–108 (2017). https://doi.org/10.1007/s11661-016-3829-4

H. Mirzadeh, A. Najafizadeh, Hot deformation and dynamic recrystallization of 17–4 PH stainless steel. ISIJ Int. 53, 680–689 (2013). https://doi.org/10.2355/isijinternational.53.680

J. Zhang, H. Di, H. Wang, K. Mao, T. Ma, Y. Cao, Hot deformation behavior of Ti-15-3 titanium alloy: a study using processing maps, activation energy map, and Zener–Hollomon parameter map. J. Mater. Sci. 47, 4000–4011 (2012). https://doi.org/10.1007/s10853-012-6253-1

G. Shi, Y. Zhang, H. Liu, X. Li, G. Wang, Z. Li, L. Yan, K. Wen, B. Xiong, Constructing processing maps for hot deformation and microstructural evolution of Al–Zn–Mg–Cu alloys. Mater. Res. Express 6, 096566 (2019). https://doi.org/10.1088/2053-1591/ab2fb4

Y.V.R.K. Prasad, T. Seshacharyulu, Processing maps for hot working of titanium alloys. Mater. Sci. Eng. A 243, 82–88 (1998). https://doi.org/10.1016/s0921-5093(97)00782-x

F. Wu, W. Xu, X. Jin, X. Zhong, X. Wan, D. Shan, B. Guo, Study on hot deformation behavior and microstructure evolution of Ti55 high-temperature titanium alloy. Metals (Basel) (2017). https://doi.org/10.3390/met7080319

Y. Jiang, Y.C. Lin, G. Wang, G. Pang, M. Chen, Z. Huang, Microstructure evolution and a unified constitutive model for a Ti-55511 alloy deformed in β region. J. Alloys Compd. 870, 159534 (2021). https://doi.org/10.1016/j.jallcom.2021.159534

Y. Jiang, Y.C. Lin, X. Jiang, D. He, X. Zhang, Hot tensile properties, microstructure evolution and fracture mechanisms of Ti–6Al–4V alloy with initial coarse equiaxed phases. Mater. Charact. 163, 110272 (2020). https://doi.org/10.1016/j.matchar.2020.110272

Y.C. Lin, Y. Xiao, Y. Jiang, G. Pang, H. Li, Spheroidization and dynamic recrystallization mechanisms of Ti-55511 alloy with bimodal microstructures during hot compression in α + β region. Mater. Sci. Eng. A 782, 139282 (2020). https://doi.org/10.1016/j.msea.2020.139282

G. Su, Z. Yun, Y. Lin, D. He, S. Zhang, Z. Chen, Microstructure Evolution and a Unified Constitutive Model of Ti-55511 Alloy Compressed at Stepped Strain Rates. Materials 14(22), 1–20 (2021)

S. Ebied, A. Hamada, W. Borek, M. Gepreel, A. Chiba, High-temperature deformation behavior and microstructural characterization of high-Mn bearing titanium-based alloy. Mater. Charact. 139, 176–185 (2018). https://doi.org/10.1016/j.matchar.2018.03.004

Y.F. Xia, S. Long, Y.T. Zhou, J. Zhao, T.Y. Wang, J. Zhou, Identification for the optimal working parameters of Ti–6Al–4V–0.1Ru alloy in a wide deformation condition range by processing maps based on DMM. Mater. Res. 19, 1449–1460 (2016). https://doi.org/10.1590/1980-5373-MR-2016-0448

R. Ding, Z.X. Guo, A. Wilson, Microstructural evolution of a Ti–6Al–4V alloy during thermomechanical processing. Mater. Sci. Eng. A 327, 233–245 (2002). https://doi.org/10.1016/S0921-5093(01)01531-3

I. Weiss, T. Sakai, J.J. Jonas, Effect of test method on transition from multiple to single peak dynamic recrystallization. Met. Sci. 18, 77–84 (1984). https://doi.org/10.1179/030634584790420249

B. Liu, H. Matsumoto, Y.P. Li, Y. Koizumi, Y. Liu, A. Chiba, Dynamic phase transformation during hot-forging process of a powder metallurgy α + β titanium alloy. Mater. Trans. 53, 1007–1010 (2012). https://doi.org/10.2320/matertrans.M2012042

L. He, A. Dehghan-Manshadi, R.J. Dippenaar, The evolution of microstructure of Ti–6Al–4V alloy during concurrent hot deformation and phase transformation. Mater. Sci. Eng. A 549, 163–167 (2012). https://doi.org/10.1016/j.msea.2012.04.025

A. Dehghan-Manshadi, R.J. Dippenaar, Strain-induced phase transformation during thermo-mechanical processing of titanium alloys. Mater. Sci. Eng. A 552, 451–456 (2012). https://doi.org/10.1016/j.msea.2012.05.069

Z. Guo, S. Malinov, W. Sha, Modelling beta transus temperature of titanium alloys using artificial neural network. Comput. Mater. Sci. 32, 1–12 (2005). https://doi.org/10.1016/j.commatsci.2004.05.004

A. Kumar, A. Gupta, R.K. Khatirkar, N. Bibhanshu, S. Suwas, Strain rate sensitivity behaviour of a chrome–nickel austenitic–ferritic stainless steel and its constitutive modelling. ISIJ Int. 58, 1840–1849 (2018). https://doi.org/10.2355/isijinternational.ISIJINT-2018-051

W. Baldwin, Metallography and microstructures. Metallogr. Microstruct. (2018). https://doi.org/10.31399/asm.hb.v09.9781627081771

Acknowledgments

The authors are thankful to Director, VNIT Nagpur for providing the necessary facilities and constant encouragement to publish this paper.

Author information

Authors and Affiliations

Contributions

DM: Conceptualization, Methodology, Visualization, Investigation, Writing—Original Draft. DK: Methodology, Visualization, Writing—Review and Editing. TRD: Methodology, Visualization, Investigation. RKK: Conceptualization, Supervision, Writing—Review and Editing, Resources. SS: Supervision, Resources, Writing—Review and Editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mahadule, D., Kumar, D., Dandekar, T.R. et al. Modelling of flow stresses during hot deformation of Ti–6Al–4Mo–1V–0.1Si alloy. Journal of Materials Research 38, 3750–3763 (2023). https://doi.org/10.1557/s43578-023-01097-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-023-01097-4