Abstract

57Fe conversion electron Mössbauer (CEM) spectroscopy, SEM and magnetization measurements were used to study the effect of swift heavy ion irradiation on metallic 57Fe (10 nm) thin layer vacuum deposited onto SiO2/Si. About 85% of the total iron content of the surface layer detected by CEM was present as metallic, crystalline alpha iron before the irradiation, while upon irradiation with 160 MeV Xe ions, with a fluence of 5 × 1013 ion cm−2, ~ 21% was converted to amorphous iron and ~ 47% to silicon-containing iron oxide phases. The presence of pure iron in the amorphous state was evidenced by CEM in agreement with magnetization measurements. Temperature dependence of CEM measurements and the FC/ZFC curves of the irradiated deposit indicated superparamagnetic nature of the iron-silicon-oxide phases. The results are discussed in terms of the thermal spike model for the formation of the amorphous iron phase that can be essential for the formation of silicon-iron-oxides.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Amorphous iron thin films and coatings on different substrate surfaces can have different properties, advantageous for technology, depending on their preparation method, composition and structure. Production of amorphous iron and some related phases poses a major challenge for both science and technology, as it requires specific, non-equilibrium techniques, but these materials can be used advantageously in many fields, such as photovoltaic technology [1], amorphous iron motors [2], nanomedicine [3], communication and computer technology [4] as well as catalysis [5, 6].

The coatings which are composed of amorphous iron and nanoparticles of iron oxides may combine the advantages of both random arrangements of atoms in amorphous state as well as those of nano dimension. The difficulties in their successful synthesis can inspire researchers to study this area. In our present work, we aimed at preparing and studying a system of this type, with special attention to the effect of swift heavy ion irradiation on thin metallic iron layer vacuum deposited onto SiO2/Si substrate.

It is well-known that amorphous iron can be produced in a metal form alloyed with certain metals and/or metalloids by rapid quenching at which iron solidifies from the molten state at a cooling rate of more than ~ 105 K s−1 [7]. However, amorphous pure iron, which does not contain any component other than iron, cannot be produced by this method because the cooling rate required for this is not feasible. Some properties of amorphous pure iron have been predicted by extrapolation from measurements on amorphous iron alloys [8, 9]. Amorphous pure iron has been successfully produced by sonochemical means [10] and by swift heavy ion irradiation [11,12,13]. Electrochemical preparation of amorphous pure iron [14], production of amorphous iron hydride by reaction in aqueous solution [15] and production of metallic amorphous iron by thermal decomposition of iron carbonyl in liquid phase [16] were also reported. Crystallization of amorphous iron under specific pressure conditions was followed in situ by electron microscopy [17].

The amorphization of crystalline thin films, multilayers and bulk materials upon heavy ion irradiation is a well-known phenomenon [11, 12, 18, 19]. The formation of amorphous iron by heavy ion irradiation depends not only on the irradiation conditions (ion type, energy and fluence of the ion) but also on the material and method of production of both the coating and the substrate. In the case of SiO2 and Si which are frequently used as substrates for iron deposits, or in their multilayers with iron [20,21,22,23,24,25], different irradiation conditions induced the formation of various nanostructured phases [26,27,28,29,30,31,32,33,34,35,36,37].

The amorphous state of iron was characterized by several methods, including XRD, SEM, TEM [10], magnetic measurements [38], transmission [39] and conversion electron Mössbauer spectroscopy [11,12,13, 40].

Mössbauer spectroscopy is a useful tool for the investigation of amorphous alloys because the electric monopole and quadrupole as well as the magnetic dipole interactions measured by this method offer a unique possibility of providing information about the local environment of a Mössbauer atom [41, 42]. It has already been successfully applied to investigate the effect of heavy ion irradiation in vacuum deposited and electrodeposited iron-bearing thin layers and coatings [11,12,13, 40, 43,44,45].

In our previous works [11, 12, 40] we used a variety of swift heavy ion irradiations (with different energies and fluences) on α-Fe thin layers deposited onto substrates where the thickness of the substrate oxide layer was much smaller than the thickness of the metal deposit. In these experiments, very small, almost negligible amount of iron oxides/oxyhydroxides formed, and we focused on the appearance of pure amorphous Fe phase.

The novelty of the present work is that we performed a temperature dependence study, using conversion electron 57Fe Mössbauer spectroscopy, magnetization and SEM/EDX measurements, elucidating the formation and influence of temperature on the evolution of Fe-containing phases, especially amorphous iron and nanosized iron oxides, occurring under swift heavy ion irradiation with Xe ions of an energy of 160 MeV in a 57Fe thin film deposited onto SiO2/Si, where the thickness of the metallic Fe layer and the thickness of the SiO2 layer on the Si substrate were nearly the same.

Results and discussion

RT 57Fe conversion electron Mössbauer spectrum of the metallic 57Fe thin layer evaporated onto Si substrate before swift heavy ion irradiation is shown in Fig. 1. The spectrum can be satisfactorily evaluated into a sextet and a doublet, the Mössbauer parameters of which are shown in Table 1.

It can be seen from Table 1 that the RT spectrum of the non-irradiated sample, shown in Fig. 1, consists of a dominating sextet with relatively narrow spectral lines and a low intensity doublet. The sextet is the fingerprint of the crystalline α-iron having a bcc structure [46, 47]. This result is consistent with the type of structure expected from the vacuum deposition of iron as has already been demonstrated previously [11]. The doublet can be attributed to FeIII dominantly in oxygen microenvironments, e.g. to an iron oxide or oxy-hydroxide phase based on its characteristic Mössbauer parameters [11]. This phase can be explained by the corrosion of the surface of the α-iron layer in air after the vacuum deposition. It cannot be excluded either that this component may partly be associated with iron atoms having oxygen neighbors at the interface of SiO2 thin layer on Si. Similar components have already been found previously in vacuum deposited thin (70 nm) 57Fe metal layers [11].

Figure 2 shows the conversion electron Mössbauer spectra of the irradiated sample, recorded in the temperature range between 17 and 295 K (at 17 K, 50 K, 70 K, 100 K, 120 K, 150 K and 295 K). Comparing the envelops of CEM spectra of the vacuum deposited 57Fe metallic layer before (Fig. 1) and after (Fig. 2a) the irradiation with 160 MeV energy 132Xe26+ ions with a fluence of 5 × 1013 ion cm−2, it is very striking that considerable spectral changes can be observed. On the other hand, the CEM spectra of the irradiated sample show significant changes with the temperature, too.

Several attempts were made to find the optimal decomposition of the complex CEM spectra shown in Fig. 2. Finally, we decomposed the spectra into 2 (at 295 K) or 3 sextets and 2 doublets. This decomposition was found to be optimal for the spectrum fitting at minimal number of components, which is consistent with those obtained previously on swift heavy ion irradiated thin films and with the temperature dependence of parameters of the occurring phases [11, 12, 40]. The corresponding Mössbauer parameters are shown in Table 2. A detailed description of the Mössbauer parameters listed in Table 2 can be found, for example, in a recently published Mössbauer spectroscopy tutorial book [48].

Based on the Mössbauer parameters characteristic of the individual phases the following assignment of the spectral components can be made:

The sextet indicated by Sextet (1) in Table 2 relates to the crystalline α-iron phase. The isomer shift, δ, effective magnetic induction, B, and their regular temperature dependence agrees excellently with those characteristic of crystalline α-iron phase [46,47,48], which makes the assignment of this component unquestionable. We found that the relative spectral area of crystalline α-iron decreased from about 85% (Table 1) to about 32% (Table 2) upon the applied swift heavy ion irradiation. This clearly shows that the irradiation with 160 MeV energy 132Xe26+ ions with a fluence of 5 × 1013 ion cm−2 resulted in a transformation of crystalline α-iron into other phases.

The sextet denoted by Sextet (2) in Table 2 has very broad non-Lorentzian spectral lines which are typical of amorphous phases. This component can be considered as a superposition of several magnetically split sub-spectra belonging to iron atoms being in a range of slightly different microenvironments. The Mössbauer parameters of Sextet (2) match excellently those of amorphous iron phase [11, 12, 39] and thus Sextet (2) was assigned to amorphous iron [10,11,12,13, 39, 40]. This is the same phase induced by swift heavy ion irradiation as was shown for the first time by Kuzmann et al. [11]. The regular temperature dependence of the Mössbauer parameters of amorphous Fe (Table 2), confirms the correct assignment of this component in the present case. The appearance of Sextet (2) in the spectrum of the irradiated sample evidences the formation of amorphous iron phase from crystalline α-iron. Its occurrence (about 22%, see Table 2) corresponds to the expectation for the partial amorphization of the crystalline α-iron taking into account the conditions of swift heavy ion irradiation [11, 12] and literature data [11, 12, 39, 40].

Doublet (3) in Table 2 can be associated with iron atoms being in high-spin Fe3+ state based on its isomer shift and quadrupole splitting [42, 46,47,48,49,50]. These parameters are slightly different from those belonging to the non-irradiated sample (Table 1). This doublet can be assigned to more than one phase in which the microenvironments of the iron atoms render high-spin Fe3+ state. Doublet (3) may again correspond to iron-oxide or iron-oxy-hydroxide phases which were present in the non-irradiated state. However, the considerable increase of the relative occurrence of this component after irradiation, at the expense of metallic α-iron phase (Table 2), may indicate an irradiation-induced oxidation of iron. The irradiation-induced iron-oxide phases are present dominantly in superparamagnetic state since their relative spectral area gradually decreases with lowering the temperature, while at the same time, a magnetically split spectrum develops, with increasing effective magnetic induction and relative area.

Sextet (5) in Table 2, with very broad lines, can be associated with a transitional relaxation state of the superparamagnetic iron-bearing oxide phases (which may contain Si, too), occurring in the temperature range 100–150 K.

Sextet (6) in Table 2 can be assigned to iron-oxide and/or iron-silicon-oxide phases based on their characteristic Fe3+ isomer shift and high effective magnetic induction [42, 48,49,50].

From our analysis, the phase represented by Sextet (5) must convert into that represented by Sextet (6) as the temperature drops from 100 to 70 K. Most probably they co-exist in a certain temperature range, but the resolution of the Mössbauer spectra could not be essentially improved by further increasing the number of subspectra. This may also be the reason of the anomalous temperature variation of some of the isomer shifts (Table 2). More parameter correlations can be expected with the parameters of Doublet (3) in the lower temperature range of 70–17 K. Let us also note that the presence of Sextet (6) is obvious by visual inspection and this is the main product of the superparamagnetic transition of Doublet (3) as the temperature is decreasing.

Doublet (4) in Table 2 reflects the occurrence of high-spin Fe2+ microenvironments [42, 46,47,48,49,50] formed upon the swift heavy ion irradiation, which can be associated with the formation of FeSiOx and/or FeOx·SiO2 [51, 52]. The occurrence of this Fe2+ component is surprising at first sight since its formation needs a reduction process during the irradiation. However, such reduction can be possible in the presence of CO or H2 which can be input by the swift heavy ion bombardment into the metal SiO2/Si interface. Similar cases have already been reported [34, 43, 44]. In the cases of high-energy Au and Ar ion irradiations of CeO2 films on SiO2/Si substrates, the irradiation caused partial amorphization at the CeO2/SiO2/Si interface, and created oxygen vacancies due to the formation of Ce2O3 at RT. Furthermore, reaction with CO molecules at the ambient pressure caused an additional reduction of cerium promoting the transition of Ce2O3 to a stable silicate compound [34]. On the other hand, when SnO2 films were implanted with 57Fe ions, the implanted Fe ions existed as FeII and FeIII in the SnO2 film, while a part of the Sn ions were also reduced into SnII on the implanted surface layer [44]. The 57Fe Mössbauer spectrum also indicated the presence of FeII phase in Fe implanted SiO2 at a substrate temperature of 500 ºC [43].

If we take into account that no FeII component was present in the non-irradiated state, furthermore, paramagnetic FeII and FeIII components, somewhat similar to ours, were also observed in iron ion-implanted SiO2 [43] as well as several structural changes and phase formation could happen in SiO2/Si due to the heavy ion irradiation [26,27,28,29,30, 32, 34, 35, 37] we may suppose that Doublet (4) can be mainly associated with iron silicon oxides in which Fe occurs in FeII oxidation state. The evaluated average Mössbauer parameters of Doublet (4) (Table 2) are not so far from those characteristic of FeSiO2 [52] and those found for nano fayalite (Fe2SiO4) [51].

Let us emphasize again that the evaluated Mössbauer parameters of Doublet (3), Doublet (4), Sextet (5) and Sextet (6) can be considered as average parameters, since the considerable correlations between the parameters do not allow to distinguish satisfactorily the individual components at the fitting of these very complex spectra. Consequently, both FeII and FeIII doublets can be considered as a superposition of doublet components characteristic of different iron microenvironments. This is also consistent with the anomalous temperature dependence of Mössbauer parameters (Table 2), especially in relation to the isomer shift of Doublet (3).

It can be clearly seen from Table 2 and Fig. 2 that both FeII and FeIII doublets are gradually reduced and converted to magnetic sextets by lowering the temperature and, apart from the small amount of paramagnetic components still present, the iron atoms are in a magnetic state at 17 K. The low intensity (4–5%) paramagnetic doublet components at 17 K can be associated with superparamagnetic phases, which are not yet transformed into magnetic state at this temperature, but it cannot be entirely excluded that they belong to silicon-iron oxide phases of other composition and structure, having large particle size.

Although the large linewidth of the dominant Sextet (6) allows this sextet to be considered a superposition of several sextets, the average Mössbauer parameters correspond well to the Mössbauer spectra of nano-maghemite or substituted nano-magnetite [46, 47, 53]. It is known that, in general, nano-maghemite and nano-magnetite have isostructural spinel structure and it is not easy to distinguish them [53].

In the present case, however, the assignment of Sextet (6) to nano-magnetite can be supported by the fact that Sextet (6) must also include FeII component, since the FeII paramagnetic components occurring at higher temperatures have already been transformed to magnetic ones at 17 K. Magnetite containing silicon but lacking any other components than ferrous and ferric iron (Si-magnetite or silician magnetite) was shown to form from FeIII hydroxide precipitates in contact with SiO2 under continued dehydration and reduction [54]. In our case, the presence of ferric iron oxide/oxy-hydroxide on the surface in close contact with SiO2 of the as-deposited sample was confirmed by Mössbauer spectroscopy (Fig. 1, Table 1), while evidence for continuous reduction under swift heavy ion irradiation was presented by the appearance of Doublet (4) belonging to ferrous iron in the spectra of the irradiated sample (Fig. 2, Table 2). In the Si-magnetite precipitates, Si replaces Fe3+ at tetrahedral sites of the magnetite structure and vacancies are introduced at the octahedral Fe2+ sites forming a maghemite-like structure with a composition of [□0.5Fe2+0.5]oct[Fe3+]octSitetO4. The Si-magnetite was previously labelled as γ-Fe1.5SiO4 and its structure was explicitly identified by HRTEM and DFT calculations [55]. These showed that γ-Fe1.5SiO4 is more stable than α-Fe1.5SiO4 (laihunite), although both nano-precipitates can occur in their host minerals of magnetite and fayalite. The assignment of Sextet (6) to Si-substituted nano-magnetite, γ-Fe1.5SiO4, may be further supported by the average effective magnetic field B (Table 2), which is somewhat smaller than that expected for pure magnetite, due to the lack of Fe2+ at the octahedral site in γ-Fe1.5SiO4.

The results of the Mössbauer analysis of swift heavy ion irradiated metallic 57Fe layer vacuum deposited onto SiO2/Si can be well supported by the magnetization measurements depicted in Figs. 3 and 4.

The magnetization curves (Figs. 3 and 4) of the irradiated 57Fe layer deposited onto SiO2/Si substrate, apart from the considerable diamagnetic contribution which can be well seen on the hysteresis curves, are typical of the spin-glass materials, including also those having superparamagnetic behavior [56, 57].

In Fig. 3, the strikingly large diamagnetic contribution and the decrease of magnetization with the external field originated from the diamagnetic substrate the occurrence of which in the sample is huge, since the 10 nm metallic 57Fe was evaporated onto a 10 nm SiO2 layer on 0.5 mm thick Si. If the diamagnetic contribution is excluded, the hysteresis curves (Fig. 3) can be considered as a superposition of magnetization from the different phases present in the swift heavy ion irradiated sample. They may reflect the combined contributions from the ferromagnetic crystalline α-Fe phase, the ferromagnetic spin-glass amorphous iron phase [38] as well as the superparamagnetic γ-Fe1.5SiO4 phase which is supposedly ferromagnetic at low temperatures as there is no iron at the tetrahedral sites and all the iron atoms in the octahedral sites have the same spin direction [55]. Accordingly, the magnetization measurements can support the existence of amorphous iron and of the superparamagnetic γ-Fe1.5SiO4 phase reflected by Mössbauer spectra (Fig. 2) in the vacuum deposited metallic 57Fe layer irradiated by 160 MeV Xe ions with a fluence of 5 × 1013 ion cm−2.

Figure 4 shows the temperature dependence of zero-field-cooled (ZFC) and field-cooled (FC) magnetization measured in magnetic fields of 100 and 1000 Oe in the temperature range from 5 to 280 K for the irradiated 57Fe films deposited onto SiO2/Si. As can be seen, the ZFC magnetization initially increased with temperature showing a slight maximum at TB. On the other hand, the field cooled (FC) magnetization continuously decreased with increasing temperature. More importantly, the ZFC and FC curves bifurcated from each other, at temperature Tirr. TB and Tirr depended on the magnetic field applied during the magnetization measurements [57, 58]. Thus, the temperature dependence of the FC and ZFC magnetization indicated irreversible behavior between the FC and ZFC data, with the irreversibility depending on the applied magnetic field. The observed behavior of ZFC and FC curves (Fig. 4) is typical of spin-glass system [57]. Since TB and Tirr have different values, the observed temperature dependence of ZFC and FC reflects that nano-sized superparamagnetic particles should occur in the irradiated sample [59]. ZFC and FC curves found for nano-magnetites are consistent with our observation. This confirms our findings obtained by CEM measurements. The magnetization curves can be considered as the superposition of the magnetization of the different phases, which may reflect the small amount of ferromagnetic crystalline α-Fe phase, the spin-glass amorphous iron phase, and the dominant superparamagnetic γ-Fe1.5SiO4 phase. The ZFC curve measured at the larger magnetic field showed an irreversibility at around 150 K and a blocking temperature around 100 K, which is highly uncertain due to its very flat cusp, suggesting a very broad size distribution for Si-substituted magnetite particles. However, these temperatures are in a good agreement with those obtained from the CEM spectra showing the superparamagnetic transition where the sextets corresponding to the nano-iron-oxides appear in the spectra.

Well below the blocking temperature, the flat nature and small slope of the ZFC curve mainly indicate ferromagnetic interaction, which may also support the presence of the γ-Fe1.5SiO4 phase in which the iron atoms in the crystallographic position B are ferromagnetically coupled [60,61,62].

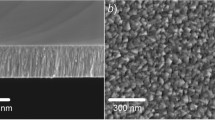

The Mössbauer and magnetic measurements results related to the phase composition occurring in the swift heavy ion irradiated sample are consistent with the EDX elemental analysis results in the sense that no new elements or contaminants are incorporated at the sample surface upon irradiation. Elemental distribution maps and SEM micrograph obtained are shown in Fig. 5.

The elemental composition obtained by EDX analysis confirmed that the sample contains Si, Fe and O. The carbon indicated also by EDX can be detected either due to the organic tape used for ensuring the contact between the deposit and target backing or due to the processing of the sample at the analysis.

The elemental distribution maps of the irradiated sample indicate basically equal distribution of Fe, Si and O on the surface, which is consistent with the method of sample preparation and the uniform swift Xe ion irradiation, reflecting that the phases formed by the irradiation are evenly distributed along the surface of the whole sample.

The SEM micrograph of the irradiated sample shows spherical formations and their aggregates roughly between 15 and 100 nm in size. They may be associated with the radiation-induced formation of silicon-containing nano iron oxide phases which were shown in Mössbauer spectra and supported by magnetization measurements. However, the size of a number of these particles reflected by SEM micrograph is higher than those that could exhibit superparamagnetism in the Mössbauer spectrum at room temperature. At the same time, the room temperature CEM spectrum does not contain any magnetically split subspectrum which hyperfine field could be characteristic of these oxide phases being in non-superparamagnetic state. Resolving the contradiction requires further investigation. Therefore, the above mentioned formations can be associated with aggregates of the superparamagnetic nano iron oxide phases. It cannot be ruled out either that the formations observed by SEM belong to silicon-iron oxide phases of other composition and structure observed in Mössbauer measurements, which are still in paramagnetic state at 17 K.

Our results can be understood in terms of the interaction between the deposit and the irradiating swift heavy ions. It is known, that in solids, macroscopic changes caused by high-energy heavy ion irradiation can result from three types of elemental interactions between radiation and matter atoms of the matrix: elastic collisions, electron excitation and nuclear reactions [63, 64]. In ion-atom collisions, if the energy, transferred during the collision, exceeds the threshold energy Td ≈ 25 eV required to remove the atom from its lattice location, the atom leaves its original location, creating a Frenkel pair defect. If the transferred energy is large enough, the first ejected atom may again cause lattice defects during further collisions. Ejected atoms cause more and more defects as long as their energy does not fall below the threshold, creating defect cascades that can lead to various changes in the structure and properties of the material. In the region of electron braking, changes in the structure and properties of matter under the influence of radiation can originate from two mechanisms, the excitation of electrons and the ionization of atoms. The excitation of the electrons can lead to the release of large amounts of heat in a rather small volume, which can result in large-scale heating and even melting of the crystal lattice, creating so-called thermal spikes [65, 66]. This process is most common in metals, where due to good thermal conductivity, the spikes cool extremely quickly, which can also lead to the formation of large amounts of lattice defects or to the amorphization of the material. Observing the events on a time scale, the process of forming such a thermal spike proceeds as follows (Fig. 6). The collision of the ion and the electrons in its path leads to rapid heating of the electron subsystem. During the deceleration of the ion in this way, it transfers some of its energy to the electron gas in 10–17 s, creating a zone of tilted thermodynamic equilibrium with hot electrons and a cold lattice. The excited electrons reach thermodynamic equilibrium with each other through electron–electron interactions in 10–15 s, and they transfer their excess energy to the lattice in 10–13 s through electron–phonon interactions, leading to large-scale heating of the lattice. Thus, the temperature of the material along the ion path can significantly exceed the melting temperature, resulting in a cylinder of a few nanometers in diameter containing molten material (thermal spike), a latent track which solidifies in 10–11 s seconds, resulting in a cooling rate of nearly 1014 K s−1 [67, 68]. Since our target is metal, it is not reasonable to take into account another mechanism, so-called Coulomb explosion [66, 69]. We also exclude any possible contribution of inelastic processes, like nuclear reactions, in view of projectile mass and energy [63, 64].

Therefore, the observed structural changes in the material are mainly due to the thermal spike mechanism.

In our present case the stopping power values, calculated using the SRIM-2013 code [70], for Fe irradiated with 160 MeV Xe ions are (dE/dx)e = 35.45 keV nm−1 for electron stopping and (dE/dx)n = 17.81 × 10–2 keV nm−1 for nuclear stopping. The penetration depth of these ions in Fe is 8.07 μm. The threshold value of electronic stopping power for formation of thermal spikes reported for bulk iron is 40 keV nm−1 [71]. Although our value is somewhat lower than this threshold, we should take into consideration that our case is a thin deposit film surface when in contrast to bulk samples an enhanced electronic scattering from grain boundaries, surface and interfaces may cause substantial decrease in electron mobility and an increase in electron–phonon coupling. This would result in a decreased value of the threshold electronic stopping power [72,73,74,75] required for the formation of thermal spikes able to induce significant atomic rearrangements. This is supported by the result of a previous work [12] when amorphous iron phase was observed in swift heavy ion irradiated electrodeposited iron thin films due to 246 MeV Kr irradiation when the value of (dE/dx)e = 24.1 keV nm−1 was sufficient to produce enough thermal spikes. Based on the data above, one can conclude that in our case, the main mechanism responsible for the formation of the amorphous iron phase is the thermal spike. This mechanism explaining the formation of the irradiation-induced amorphous iron phase is the same as that given in previous works [12, 13, 40, 45].

The formation of the considerable amount of the silicon-iron-oxides due to 160 MeV Xe ion irradiation can be explained by the accelerated diffusion of ions via the molten tracks and ion beam mixing at the interfaces similarly as reported in other works [26, 76]. Namely, significant atomic transport occurs, by interdiffusion, from one layer to the other when the ion track passes through the interface of a layered system and the electronic stopping power exceeds the energy needed to melt the components along the trajectory of the ion [76]. The oxide formation processes depend on the electronic energy loss of the incident ions. Diffusion controlled dissolution of oxygen in iron takes place when the electronic energy loss is below the track formation threshold. In iron, chemical reaction and homogeneous oxide phase formation take place in a surface layer.

If the track formation threshold in iron is exceeded, the swift heavy ion will generate a molten track inside this layer, which allows the oxygen to diffuse from the oxide-iron interface to the deep layers and thereby to extend the oxide phase area to larger depths [26]. The effective diffusion constant estimated for swift heavy ion-induced oxygen diffusion in iron is larger by a factor of about 1000 than that of thermally induced one. If the electronic stopping power exceeds the track formation thresholds of both interface forming materials, the swift heavy ion irradiation will cause strong intermixing effects, which can lead to the formation of new oxide phases. It was found that the mixing rate varies with the square of the electronic energy deposition above the threshold [76]. The values of the electronic energy deposition Se obtained for our present 160 MeV energy Xe irradiation case are 418 eV (atoms nm−2)−1 for iron, 274.5 eV (atoms nm−2)−1 for Fe2O3, 266.6 eV (atoms nm−2)−1 for Si and 208.1 eV (atoms nm−2)−1 for SiO2. These values are much higher than the corresponding interface mixing threshold energies Sec of 216 and 113 eV (atoms nm−2)−1 for Fe/SiO2, 53 and 41 eV (atoms nm−2)−1 for Fe2O3/SiO2, for the top layer and backing layer, respectively, and of 149 eV (atoms nm−2)−1 for Si as well as 15–30 eV (atoms nm−2)−1 for SiO2 [76]. The formation of radiation-induced silicon-iron-oxide phases we obtained at present can be understood by the explanation above. It is consistent with the above consideration, why we found only a small amount of oxide phase in Fe films in previous studies when the effects of high-energy heavy ion irradiation were investigated. Namely, the electron energy losses were either below the threshold energy in the case of Cu substrate [12] or were much lower than those in the present case. This latter scenario may apply when Fe films deposited onto SiO2/Si were irradiated with 209 MeV energy Kr ions [11]. However, it cannot be ruled out entirely that for thicker iron films studied earlier, CEMS was not sensitive enough to give information on what is happening at the interface and in the substrate.

One may think that the incorporation of Xe can also occur in the irradiation-induced iron oxide phases since xenon iron oxides were predicted [77] forming under very high pressure in Earth’s lower mantle. Such a phase formation which ought to happen more intensely near the penetration depth of ions, which is ~ 8 µm in our case, would not be observable using conversion electron Mössbauer spectroscopy.

Comparing our results with those of previous relevant works, it could be concluded that they are basically in line with each other. The partial transformation of α-iron into other phases has already been observed in different iron films vacuum or electrodeposited onto SiO2/Si and other substrates, irradiated by swift heavy ions [11, 12, 26, 40, 76] as well as with low energy heavy ion implantation [13, 43]. The amorphous iron phase shown at present is consistent with those reported earlier [11,12,13, 39, 40, 45]. The formation of a small amount of FeII oxide phase has already been also indicated upon 180 MeV Kr ion irradiation [26]. However, due to the fact that, in the present case, an Fe layer was evaporated with a thickness comparable to the thickness of the SiO2 layer and we used swift heavy ion irradiation with electron energy deposition much more above the threshold energy than applied in the previous works it was possible to observe that the majority of the metallic α-iron film was converted dominantly to silicon-iron-oxides and, to a less extent, to amorphous iron. Furthermore, the temperature-dependent conversion electron Mössbauer spectroscopy gave a possibility for more accurate phase analysis as earlier.

Conclusions

Irradiation-induced transformation upon swift heavy ion irradiation applying 160 MeV 132Xe26+ ions with a fluence of 5 × 1013 ion cm−2 was found in the as-deposited, dominantly metallic, crystalline α-Fe (~ 85%) and minor FeIII oxide/oxyhydroxide (~ 15%) thin layer produced by vacuum deposition of 57Fe metal onto SiO2/Si substrate. The formation of amorphous pure iron (~ 21%), i.e., metallic iron without alloying elements in amorphous state, and silicon-iron-oxides (~ 47%), which latter can be associated with Si-substituted magnetite γ-Fe1.5SiO4, develops upon swift heavy ion irradiation, while ~ 32% of the total iron retains the crystalline α-Fe state. The irradiation-induced silicon-iron-oxide phases, of which ~ 19% is in FeII state, show superparamagnetic behavior with a transition in a wide temperature range starting from 150 K. The swift heavy ion irradiation-induced formation of amorphous iron and Fe-Si oxide phases in the metallic 57Fe layer vacuum deposited onto SiO2/Si can be interpreted in terms of the thermal spike model of the energy deposition of heavy ions involving irradiation accelerated diffusion and atomic mixing. Additional swift heavy ion irradiation experiments to further promote the irradiation-induced transformation of the as-deposited crystalline α-Fe phase are in progress.

Methods

Iron metal enriched in 57Fe (95 wt.%) was vapor-deposited, at a pressure of 2 × 10–5 Pa, onto thermally oxidized Si wafers, with approximately 10 nm thick SiO2 layer present on the Si surface. The thickness of the evaporated iron layer was 10 nm. The deposition process was monitored by a calibrated quartz crystal. The surface dimension of the deposited samples was 14 × 14 mm2.

The swift heavy ion irradiation of this metallic 57Fe layer was carried out with 160 MeV energy 132Xe26+ ions with a fluence of 5 × 1013 ion cm−2 at room temperature, at a current density of 0.01 μA cm−2 and a pressure of about 10–3 Pa, at the IC-100 cyclotron of the Flerov Laboratory of Nuclear Reactions, JINR, Dubna, Russia. The Si substrate sides of the samples were mounted onto a Cu target backing using a double-sided carbon tape. The plane of samples was oriented perpendicular to the ion beam direction. The temperature of target backing was controlled during the irradiation.

Conversion electron Mössbauer measurements on the metallic 57Fe thin layers before and after the swift heavy ion irradiation were performed by conventional Mössbauer spectrometers (WISSEL) with flowing gas (96% He, 4% CH4) proportional counters and 57Co(Rh) sources of 1.85 GBq activity, at room temperature (RT). CEM measurements of the irradiated sample were also performed in a wide temperature range between 17 and 295 K (at 17 K, 50 K, 70 K, 100 K, 120 K, 150 K and 295 K) using a CEM apparatus with a cryostat (Iwatani Cryo Mini D310). The low temperature CEM spectra were recorded using a proportional counter filled with a counter gas of 1 bar pressure at RT. Hydrogen was used as counter gas for the measurements at 17 K and 50 K, while 98%He-2%CH4 gas mixture was applied for the measurements at temperatures higher than 70 K. The CEM apparatus with the proportional counter was described in detail elsewhere [78, 79]. The major part of the information with this method can be obtained mainly from sample depths less than 100 nm [80,81,82]. Isomer shifts were given relative to α-iron. The evaluation of Mössbauer spectra was performed by least-square fitting of the lines using the MOSSWINN code [83].

The magnetization measurements were performed using a Quantum Design Physical Properties Measurement System (PPMS Dynacool system) with the vibrating sample magnetometer (VSM) option. The temperature dependence of the magnetization was recorded in a sweep mode of 1 K min−1 in the zero-field-cooled (ZFC) and field-cooled (FC) measuring regimes. The hysteresis loops were recorded at temperatures of 280 K and 5 K, in external magnetic fields ranging from − 5 to + 5 T.

The surface morphology of the material was characterized by a JSM6490LV scanning electron microscope (SEM, JEOL). The samples were coated with carbon for this purpose.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

L. Antwis, L. Wong, A. Smith, K. Homewood, C. Jeynes, R. Gwilliam, Optimization and characterization of amorphous iron disilicide formed by ion beam mixing of Fe/Si multilayer structures for photovoltaic applications. AIP Conf. Proc. 1321, 278–281 (2011). https://doi.org/10.1063/1.3548379

A. Hirzel, The basics of amorphous-iron motors. Mach. Des. 86, 38–42 (2014)

J. Shi, Amorphous iron nanoparticles: special structural and physicochemical features enable chemical dynamic therapy for tumors. Nanomedicine 11, 1189–1191 (2016). https://doi.org/10.2217/nnm-2016-0039

D. Yuting, M. Guofeng, Research progress of Fe-based amorphous/nanocrystalline alloys. IOP Conf. Ser.: Earth Environ. Sci. 565, 012048 (2020). https://doi.org/10.1088/1755-1315/565/1/012048

E.A. Campos, D.V.B.S. Pinto, J.I.S. de Oliveira, E.C. Mattos, R.C.L. Dutra, Synthesis, characterization and applications of iron oxide nanoparticles – a short review. J. Aerosp. Technol. Manag. 7, 267–276 (2015). https://doi.org/10.5028/jatm.v7i3.471

Z. Jia, J. Kang, W.C. Zhang, W.M. Wang, C. Yang, H. Sun, D. Habibi, L.C. Zhang, Surface aging behaviour of Fe-based amorphous alloys as catalysts during heterogeneous photo Fenton-like process for water treatment. Appl. Catal. B: Environ. 204, 537–547 (2017). https://doi.org/10.1016/j.apcatb.2016.12.001

H.J. Güntherodt, H. Beck (eds.), Glassy Metals I: Ionic Structure, Electronic Transport, and Crystallization (Springer, Berlin, 1981). https://doi.org/10.1007/3-540-10440-2

G. Xiao, C.L. Chien, Nonuniqueness of the state of amorphous pure iron. Phys. Rev. B 35, 8763–8766 (1987). https://doi.org/10.1103/PhysRevB.35.8763

M.N. Magomedov, On the properties of the amorphous state of a single-component substance. J. Non-Cryst. Solids 546, 120263 (2020). https://doi.org/10.1016/j.jnoncrysol.2020.120263

K.S. Suslick, S.B. Choe, A.A. Cichowlas, M.W. Grinstaff, Sonochemical synthesis of amorphous iron. Nature 353, 414–416 (1991). https://doi.org/10.1038/353414a0

E. Kuzmann, K. Havancsák, C. Tosello, G. Principi, G. Dóra, C. Daróczi, A. Vértes, Energetic heavy ion irradiation effect in Fe layers studied by Mössbauer spectroscopy. Radiat. Eff. Defects Solids 147, 255–263 (1999). https://doi.org/10.1080/10420159908226993

E. Kuzmann, S. Stichleutner, K. Havancsák, M.R. El-Sharif, C.U. Chisholm, O. Doyle, V. Skuratov, K. Kellner, G. Dóra, Z. Homonnay, A. Vértes, Amorphous iron phase formation in swift heavy ion irradiated electrodeposited iron thin films. Radiat. Phys. Chem. 75, 741–746 (2006). https://doi.org/10.1016/j.radphyschem.2006.01.006

E. Kuzmann, S. Stichleutner, Z. Homonnay, A. Vértes, A. Paszternák, F. Nagy, I. Felhősi, G. Pető, J. Telegdi, E. Kálmán, Amorphous iron formation due to low energy heavy ion implantation in evaporated 57Fe thin films. J. Radioanal. Nucl. Ch. 277, 699–702 (2008). https://doi.org/10.1007/s10967-007-7117-z

M. Saitou, Formation of amorphous iron thin films during electrodeposition. Int. J. Electrochem. Sci. 15, 434–441 (2020). https://doi.org/10.20964/2020.01.72

K. Taguchi, K. Shinozaki, H. Okumura, C. Michioka, K. Yoshimura, K.N. Ishihara, Discovery of amorphous iron hydrides via novel quiescent reaction in aqueous solution. Sci. Rep. 10, 6199 (2020). https://doi.org/10.1038/s41598-020-63124-2

K. Nomura, J. Tanaka, Y. Ujihira, T. Takahashi, Y. Uchida, Mössbauer and EXAFS studies of amorphous iron produced by thermal decomposition of carbonyl iron in liquid phase. Hyp. Int. 56, 1711–1716 (1990). https://doi.org/10.1007/BF02405500

A. Falqui, D. Loche, A. Casu, In situ TEM crystallization of amorphous iron particles. Curr. Comput.-Aided Drug Des. 10, 41 (2020). https://doi.org/10.3390/cryst10010041

F.V. Nolfi (ed.), Phase Transformations During Irradiation (Applied Science Publishers, New York, 1983)

H. Bernas (ed.), Materials Science with Ion Beams (Springer, Berlin, 2010). https://doi.org/10.1007/978-3-540-88789-8

F. Stromberg, S. Bedanta, C. Antoniak, W. Keune, H. Wende, FeSi diffusion barriers in Fe/FeSi/Si/FeSi/Fe multilayers and oscillatory antiferromagnetic exchange coupling. J. Phys.: Condens. Matter 20, 425205 (2008). https://doi.org/10.1088/0953-8984/20/42/425205

B. Guo, H. Yim, A. Khasanov, J. Stevens, Formation of magnetic FexOy/silica core-shell particles in a one-step flame aerosol process. Aerosol Sci. Technol. 44, 281–291 (2010). https://doi.org/10.1080/02786821003586950

X. Bi, W. Lan, Sh. Ou, Sh. Gong, H. Xu, Magnetic and electrical properties of FeSi/FeSi-ZrO2 multilayers prepared by EB-PVD. J. Magn. Magn. Mater. 261, 166–171 (2003). https://doi.org/10.1016/S0304-8853(02)01469-5

J. Dekoster, A. Vantomme, S. Degroote, R. Moons, G. Langouche, Magnetic phase transition in the CsCI FeSi spacer in Fe/FeSi multilayers. Mater. Res. Soc. Symp. Proc. 382, 253–258 (1995). https://doi.org/10.1557/PROC-382-253

I. Vavra, J. Bydzovsky, P. Svec, J. Derer, V. Kambersky, Z. Frait, R. Lopusnik, P. Sturc, G. Hilscher, Low-temperature studies of magnetic Fe/FeSi multilayers. Physica B 284–288, 1241–1242 (2000). https://doi.org/10.1016/S0921-4526(99)02490-4

E. Greenberg, L.S. Dubrovinsky, C. McCammon, J. Rouquette, I. Kantor, V. Prakapenka, GKh. Rozenberg, M.P. Pasternak, Pressure-induced structural phase transition of the iron end-member of ringwoodite (g-Fe2SiO4) investigated by X-ray diffraction and Mössbauer spectroscopy. Am. Miner. 96, 833–840 (2011). https://doi.org/10.2138/am.2011.3647

T. Roller, W. Bolse, Oxygen diffusion and oxide phase formation in iron under swift heavy ion irradiation. Phys. Rev. B 75, 054107 (2007). https://doi.org/10.1103/PhysRevB.75.054107

P. Dimitrakis, P. Normand, E. Vontitseva, K.H. Stegemann, K.H. Heinig, B. Schmidt, Memory devices obtained by Si+ irradiation through poly-Si/SiO2 gate stack. J. Phys.: Conf. Ser. 10, 002 (2005). https://doi.org/10.1088/1742-6596/10/1/002

S.B. Kaschieva, S.N. Dmitriev, MeV electron irradiation of ion-implanted Si-SiO2 structures, in Ion Implantation: Research and Application. ed. by I. Ahmad (IntechOpen, London, 2017), pp.47–65. https://doi.org/10.5772/67761

P.D. Edmondson, N.P. Young, C.M. Parish, S. Moll, F. Namavar, W.J. Weber, Y. Zhang, Ion-beam-induced chemical mixing at a nanocrystalline CeO2-Si interface. J. Am. Ceram. Soc. 96, 1666–1672 (2013). https://doi.org/10.1111/jace.12214

A.M.J.F. Carvalho, A.D. Touboul, M. Marinoni, J.F. Carlotti, C. Guasch, M. Ramonda, H. Lebius, F. Saigne, J. Bonnet, SiO2-Si under swift heavy ion irradiation: a comparison between normal and grazing incidence features. Nucl. Instrum. Meth. B 266, 2981–2985 (2008). https://doi.org/10.1016/j.nimb.2008.03.206

A. Tiwari, R. Gupta, F. Singh, M. Gupta, V.R. Reddy, G. Sharma, A. Gupta, Size dependence of interfacial intermixing in Fe/Si multilayer. Vacuum 180, 109546 (2020). https://doi.org/10.1016/j.vacuum.2020.109546

L.A. Vlasukova, F.F. Komarov, V.N. Yuvchenko, V.A. Skuratov, “Etchability” of ion tracks in SiO2/Si and Si3N4/Si thin layers, in Nanomaterials: Applications and Properties 1th NAP Proceedings. ed. by A. Pogrebnjak, T. Lyutyy, S. Protsenko (SumDU Publishing, Sumy, 2011), pp.393–399

F. Porrati, R. Sachser, G.C. Gazzadi, S. Frabboni, M. Huth, Fabrication of FeSi and Fe3Si compounds by electron beam induced mixing of [Fe/Si]2 and [Fe3/Si]2 multilayers grown by focused electron beam induced deposition. J. Appl. Phys. 119, 234306 (2016). https://doi.org/10.1063/1.4954067

P. Sapkota, A. Aprahamian, K.Y. Chan, B. Frentz, K.T. Macon, S. Ptasinska, D. Robertson, K. Manukyan, Irradiation-induced reactions at the CeO2/SiO2/Si interface. J. Chem. Phys. 152, 104704 (2020). https://doi.org/10.1063/1.5142619

S. Gurbán, P. Petrik, M. Serényi, A. Sulyok, M. Menyhárd, E. Baradács, B. Parditka, C. Cserháti, G.A. Langer, Z. Erdélyi, Electron irradiation induced amorphous SiO2 formation at metal oxide/Si interface at room temperature; electron beam writing on interfaces. Sci. Rep. 8, 2124 (2018). https://doi.org/10.1038/s41598-018-20537-4

K. Bharuth-Ram, T.B. Doyle, K. Zhang, H. Masenda, H. Hofsass, Instability of ferromagnetic nanoclusters in Fe implanted amorphous SiO2. Phys. Procedia 75, 565–571 (2015). https://doi.org/10.1016/j.phpro.2015.12.072

B. Satpati, P.V. Satyam, T. Som, B.N. Dev, Ion irradiation induced effects in metal nanostructures, arXiv:cond-mat/0503030. https://arxiv.org/abs/cond-mat/0503030

M.W. Grinstaff, M.B. Salamon, K.S. Suslick, Magnetic properties of amorphous iron. Phys. Rev. B 48, 269–273 (1993). https://doi.org/10.1103/PhysRevB.48.269

G.J. Long, D. Hautot, Q.A. Pankhurst, D. Vandormael, F. Grandjean, J.P. Gaspard, V. Briois, T. Hyeon, K.S. Suslick, Mössbauer-effect and x-ray-absorption spectral study of sonochemically prepared amorphous iron. Phys. Rev. B 57, 10716–10722 (1998). https://doi.org/10.1103/PhysRevB.57.10716

E. Kuzmann, S. Stichleutner, Z. Homonnay, K. Havancsák, C.U. Chisholm, M. El-Sharif, V.A. Skuratov, A. Nakanishi, K. Nomura, Generation of superparamagnetism in metallic α-iron by swift heavy ion irradiation. Radiat. Phys. Chem. 127, 165–168 (2016). https://doi.org/10.1016/j.radphyschem.2016.06.032

E. Kuzmann, Z. Homonnay, S. Nagy, K. Nomura, Mössbauer Spectroscopy, in Handbook of Nuclear Chemistry, 2nd edn., ed. by A. Vértes, S. Nagy, Z. Klencsár, R.G. Lovas, F. Rösch (Springer, Boston, 2011), pp.1379–1446. https://doi.org/10.1007/978-1-4419-0720-2_25

E. Kuzmann, S. Nagy, A. Vértes, Critical review of analytical applications of Mössbauer spectroscopy illustrated by mineralogical and geological examples. Pure Appl. Chem. 75, 801–858 (2003). https://doi.org/10.1351/pac200375060801

K. Nomura, H. Reuther, Nano particles of iron oxides in SiO2 glass prepared by ion implantation. J. Radioanal. Nucl. Chem. 287, 341–346 (2011). https://doi.org/10.1007/s10967-010-0858-0

K. Nomura, H. Reuther, Nano-structure analysis of Fe implanted SnO2 films by 57Fe and 119Sn CEMS. Hyp. Int. 191, 159–165 (2009). https://doi.org/10.1007/s10751-009-9966-z

S. Stichleutner, E. Kuzmann, K. Havancsák, A. Huhn, M.R. El-Sharif, C.U. Chisholm, O. Doyle, V. Skuratov, Z. Homonnay, A. Vértes, Fluence and ion dependence of amorphous iron-phase-formation due to swift heavy ion irradiation in electrodeposited iron thin films. Radiat. Phys. Chem. 80, 471–474 (2011). https://doi.org/10.1016/j.radphyschem.2010.11.010

J.G. Stevens, V.E. Stevens (eds.), Mössbauer Effect Data Index, Adam Hilger, London, 1968–1973

J.G. Stevens (ed.), Mössbauer Effect Data Journal, Mössbauer Effect Data Center, Asheville, 1975–2006.

Y. Yoshida, G. Langouche (eds.), Mössbauer Spectroscopy: Tutorial Book (Springer, Berlin, 2013). https://doi.org/10.1007/978-3-642-32220-4

A. Vértes, L. Korecz, K. Burger, Mössbauer Spectroscopy (Akadémiai Kiadó, Budapest, 1979)

E. Murad, J. Cashion, Mössbauer Spectroscopy of Environmental Materials and Their Industrial Utilization (Springer, Boston, 2004). https://doi.org/10.1007/978-1-4419-9040-2

B. Kobzi, K. Nomura, K. Sinkó, Visible light-activated photo-Fenton dye degradation ability of different FeOx·SiO2 composite systems measured by 57Fe Mössbauer spectroscopy. J. Radioanal. Nucl. Chem. 318, 1307–1315 (2018). https://doi.org/10.1007/s10967-018-6160-2

R.R. Langeslay, H. Sohn, B. Hu, J.S. Mohar, M. Ferrandon, C. Liu, H. Kim, A.J. Kropf, C. Yang, J. Niklas, O.G. Poluektov, E. Alp, P.I. de Leon, A.P. Sattelberger, A.S. Hock, M. Delferro, Nuclearity effects in supported, single-site Fe(II) hydrogenation pre-catalysts. Dalton Trans. 47, 10842–10846 (2018). https://doi.org/10.1039/C8DT02720J

Z. Klencsár, A. Ábrahám, L. Szabó, E.G. Szabó, S. Stichleutner, E. Kuzmann, Z. Homonnay, G. Tolnai, The effect of preparation conditions on magnetite nanoparticles obtained via chemical co-precipitation. Mater. Chem. Phys. 223, 122–132 (2019). https://doi.org/10.1016/j.matchemphys.2018.10.049

H. Shimazaki, On the occurrence of silician magnetites. Resour. Geol. 48, 23–29 (1998). https://doi.org/10.1111/j.1751-3928.1998.tb00004.x

H. Xu, Z. Shen, H. Konishi, Si-magnetite nano-precipitates in silician magnetite from banded iron formation: Z-contrast imaging and ab initio study. Am. Mineral. 99, 2196–2202 (2014). https://doi.org/10.2138/am-2014-4964

M. Knobel, W.C. Nunes, L.M. Socolovsky, E. De Biasi, J.M. Vargas, J.C. Denardin, Superparamagnetism and other magnetic features in granular materials: a review on ideal and real systems. J. Nanosci. Nanotechno. 8, 2836–2857 (2008). https://doi.org/10.1166/jnn.2008.15348

A.P. Guimaraes, Principles of Nanomagnetism, 2nd edn. (Springer, Cham, 2017). https://doi.org/10.1007/978-3-319-59409-5

K. Kukli, M. Kemell, H. Castan, S. Duenas, J. Link, R. Stern, M.J. Heikkila, T. Jogiaas, J. Kozlova, M. Rahn, K. Mizohata, M. Ritala, M. Leskela, Magnetic properties and resistive switching in mixture films and nanolaminates consisting of iron and silicon oxides grown by atomic layer deposition. J. Vac. Sci. Technol. A 38, 042405 (2020). https://doi.org/10.1116/6.0000212

R.L. Rebodos, P.J. Vikesland, Effects of oxidation on the magnetization of nanoparticulate magnetite. Langmuir 26, 16745–16753 (2010). https://doi.org/10.1021/la102461z

J.M.D. Coey, Magnetism and Magnetic Materials (Cambridge University Press, Cambridge, 2010). https://doi.org/10.1017/CBO9780511845000

K. Chesnel, M. Trevino, Y. Cai, J.M. Hancock, S.J. Smith, R.G. Harrison, Particle size effects on the magnetic behaviour of 5 to 11 nm Fe3O4 nanoparticles coated with oleic acid. J. Phys.: Conf. Ser. 521, 012004 (2014). https://doi.org/10.1088/1742-6596/521/1/012004

A. Bourlinos, A. Simopoulos, D. Petridis, H. Okumura, G. Hadjipanayis, Silica maghemite nanocomposites. Adv. Mater. 13, 289–291 (2001)

W. Schilling, H. Ullmaier, Physics of radiation damage in metals, in Materials Science and Technology: A Comprehensive Treatment, vol. 10B, ed. by R.W. Cahn, P. Haasen, E.J. Kramer (Wiley-VCH, Weinheim, 1994), pp.179–241

G.S. Was, Fundamentals of Radiation Materials Science, 2nd edn. (Springer, New York, 2017). https://doi.org/10.1007/978-1-4939-3438-6

F. Seitz, J.S. Koehler, Displacement of atoms during irradiation, in Solid State Physics: Advances in Research and Applications, vol. 2, ed. by F. Seitz, D. Turnbull (Academic Press, New York, 1956), pp.305–448

W. Wesch, E. Wendler (eds.), Ion Beam Modification of Solids: Ion-Solid Interaction and Radiation Damage (Springer, Cham, 2016). https://doi.org/10.1007/978-3-319-33561-2

M. Toulemonde, C. Dufour, E. Paumier, Transient thermal process after a high-energy heavy-ion irradiation of amorphous metals and semiconductors. Phys. Rev. B 46, 14362–14369 (1992). https://doi.org/10.1103/PhysRevB.46.14362

M. Toulemonde, E. Paumier, Ch. Dufour, Thermal spike model in the electronic stopping power regime. Radiat. Eff. Defects Solids 126, 201–206 (1993). https://doi.org/10.1080/10420159308219709

R.L. Fleischer, P.B. Price, R.M. Walker, Ion explosion spike mechanism for formation of charged-particle tracks in solids. J. Appl. Phys. 36, 3645–3652 (1965). https://doi.org/10.1063/1.1703059

J.F. Ziegler, J.P. Biersack, U. Littmark, The Stopping Range of Ions in Solids (Pergamon Press, New York, 1985)

A. Dunlop, D. Lesueur, P. Legrand, H. Dammak, Effects induced by high electronic excitations in pure metals: a detailed study in iron. Nucl. Instrum. Methods B 90, 330–338 (1994). https://doi.org/10.1016/0168-583X(94)95566-2

A. Gupta, Swift heavy ion-induced modification of metallic thin films and multilayers. Vacuum 58, 16–32 (2000). https://doi.org/10.1016/S0042-207X(99)00192-X

A. Gupta, D.K. Avasthi, Large electronically mediated sputtering in gold films. Phys. Rev. B 64, 155407 (2001). https://doi.org/10.1103/PhysRevB.64.155407

Z.G. Wang, C. Dufour, S. Euphrasie, M. Toulemonde, Electronic thermal spike effects in intermixing of bilayers induced by swift heavy ions. Nucl. Instrum. Methods B 209, 194–199 (2003). https://doi.org/10.1016/S0168-583X(02)02028-1

M. Kac, M. Toulemonde, J. Jaworski, J. Juraszek, R. Kruk, S. Protsenko, V. Tokman, M. Marszalek, Swift heavy-ion modification of the interface structure in Fe/Cr multilayers. Vacuum 78, 661–665 (2005). https://doi.org/10.1016/j.vacuum.2005.01.103

B. Schattat, W. Bolse, Fast heavy ion induced interface mixing in thin-film systems. Nucl. Instrum. Methods B 225, 105–110 (2004). https://doi.org/10.1016/j.nimb.2004.04.183

F. Peng, X. Song, Ch. Liu, Q. Li, M. Miao, Ch. Chen, Y. Ma, Xenon iron oxides predicted as potential Xe hosts in Earth’s lower mantle. Nat. Commun. 11, 5227 (2020). https://doi.org/10.1038/s41467-020-19107-y

K. Fukumura, R. Katano, T. Kobayashi, A. Nakanishi, Y. Isozumi, Helium-filled proportional counter operated at low temperatures higher than 13 K. Nucl. Instrum. Methods A 301, 482–484 (1991). https://doi.org/10.1016/0168-9002(91)90014-H

K. Fukumura, A. Nakanishi, T. Kobayashi, Hydrogen-filled proportional counter operated at low temperatures and its application to CEMS. Nucl. Instrum. Methods B 86, 387–389 (1994). https://doi.org/10.1016/0168-583X(94)95305-8

T. Kobayashi, K. Fukumura, A. Nakanishi, Depth selectivity at low temperatures with a proportional counter. Nucl. Instrum. Methods B 76, 204–206 (1993). https://doi.org/10.1016/0168-583X(93)95181-4

Y. Yonekura, T. Toriyama, J. Itoh, K. Hisatake, Depth selective conversion electron Mössbauer spectroscopy by use of a proportional counter. Hyp. Int. 16, 1005–1008 (1983). https://doi.org/10.1007/BF02147407

F. Nagy, Z. Klencsár, New program to estimate layer thicknesses from CEMS spectra. Nucl. Instrum. Methods B 245, 528–538 (2006). https://doi.org/10.1016/j.nimb.2005.11.049

Z. Klencsár, E. Kuzmann, A. Vértes, User-friendly software for Mössbauer spectrum analysis. J. Radioanal. Nucl. Ch. 210, 105–118 (1996). https://doi.org/10.1007/BF02055410

Acknowledgments

The research was supported by grants of the Hungarian National Research, Development and Innovation Office (OTKA projects No K43687, K68135, K100424, K115913, K115784) and by the Czech-Hungarian Intergovernmental Fund, Grant No. CZ-11/2007 (MEB040806). Authors acknowledge the support of the project “Swift heavy ions in research of iron-bearing nanomaterials” No. of theme 04-5-1131-2017/2021 solved in cooperation of the Czech Republic with the JINR (3+3 projects). The authors want to thank the project CZ.02.1.01/0.0/0.0/17_049/0008408 of the Ministry of Education, Youth & Sports of the Czech Republic. Authors thank to internal IGA grant of Palacký University (IGA_PrF_2022_003).

Funding

Open access funding provided by Eötvös Loránd University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that no conflict of interest exists related to the present paper.

Additional information

Z. Homonnay was a guest editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kuzmann, E., Nomura, K., Stichleutner, S. et al. S wift heavy ion irradiation-induced amorphous iron and Fe–Si oxide phases in metallic 57 Fe layer vacuum deposited on surface of SiO 2 /Si . Journal of Materials Research 38, 1061–1073 (2023). https://doi.org/10.1557/s43578-022-00767-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00767-z