Abstract

Using a combination of dimensional analysis and large deformation finite element simulations of indentations of power-law hardening model materials, a framework for capturing the hardness characteristics of transversely isotropic materials is developed. By considering 4800 combinations of material properties, relationships that predict the hardness of transversely isotropic materials are formulated for both longitudinal and transverse indentations. It is found that hardness tends to be higher for materials with plastic anisotropy than those that exhibit equivalent elastic anisotropy. For perfectly plastic materials, the hardness to the yield stress ratio (R0) can vary from 2.5 to 3.5, while for materials with strain hardening, R0 can be as high as 10. A tighter relationship between the hardness and the Tabor’s representative stress is observed with the ratio of the hardness to the Tabor’s representative stress (Rt) ranging from 2.2 to 4, depending on the elastic and plastic properties and the degree of anisotropy.

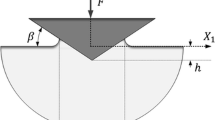

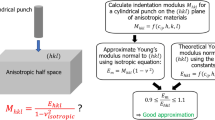

Graphical abstract

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings are available upon request.

Code availability

N/A.

References

B. Backes, K. Durst, M. Goken, Determination of plastic properties of polycrystalline metallic materials by nanoindentation: Experiments and finite element simulations. Philos. Mag. 86, 5541–5551 (2006)

Y.W. Bao, W. Wang, Y.C. Zhou, Investigation of the relationship between elastic modulus and hardness based on depth-sensing indentation measurements. Acta Mater. 52, 5397–5404 (2004)

J.L. Bucaille, S. Stauss, E. Felder, J. Michler, Determination of plastic properties of metals by instrumented indentation using different sharp indenters. Acta Mater. 51, 1663–1678 (2003)

J.L. Bucaille, S. Stauss, P. Schwaller, J. Michler, A new technique to determine the elastoplastic properties of thin metallic films using sharp indenter. Thin Solid Films 447, 239–245 (2004)

K.S. Chen, T.C. Chen, K.S. Ou, Development of semi-empirical formulation for extracting materials properties from nanoindentation measurements: Residual stresses, substrate effect, and creep. Thin Solid Films 516, 1931–1940 (2008)

W.M. Chen, M. Li, T. Zhang, Y.T. Chen, C.M. Cheng, Influence of indenter tip roundness on hardness behavior in nanoindentation. Mater. Sci. Eng. A Struct. 445, 323–327 (2007)

Y.T. Cheng, C.M. Cheng, Scaling, dimensional analysis, and indentation measurements. Mater. Sci. Eng. R. 44, 91–149 (2004)

N. Chollacoop, M. Dao, S. Suresh, Depth-sensing instrumented indentation with dual sharp indenters. Acta Mater. 51, 3713–3729 (2003)

M. Tian, T.A. Venkatesh, Indentation of shape memory polymers: Characterization of thermomechanical and shape memory properties. Polymer 54, 1405–1414 (2013)

G. Cheng, T.A. Venkatesh, Dominant factors influencing the nanoindentation response of piezoelectric materials: A case study in relaxor ferroelectrics. Philos. Mag. Lett. 93, 116–128 (2013)

A.E. Giannakopoulos, P.L. Larsson, R. Vestergaard, Analysis of Vickers indentation. Int. J. Solids Struct. 31, 2679–2708 (1994)

K. Kese, Z.C. Li, Semi-ellipse method for accounting for the pile-up contact area during nanoindentation with the Berkovich indenter. Scr. Mater. 55, 699–702 (2006)

H. Lan, T.A. Venkatesh, On the uniqueness and sensitivity issues in determining the elastic and plastic properties of power-law hardening materials through sharp and spherical indentation. Philos. Mag. 87, 4671–4729 (2007)

H. Lan, T.A. Venkatesh, On the sensitivity characteristics in the determination of the elastic and plastic properties of materials through multiple indentation. J. Mater. Res. 22, 1043–1063 (2007)

H. Lan, T.A. Venkatesh, Determination of the elastic and plastic properties of materials through instrumented indentation with reduced sensitivity. Acta Mater. 55, 2025–2041 (2007)

P.L. Larsson, On the mechanical behavior of global parameters in the material characterization by sharp indentation testing. J. Test Eval. 32, 310–321 (2004)

P.L. Larsson, A.E. Giannakopoulos, E. Soderlund, D.J. Rowcliffe, R. Vestergaard, Analysis of Berkovich indentation. Int. J. Solids Struct. 33, 221–248 (1996)

J.H. Lee, H. Lee, D.H. Kim, A numerical approach to evaluation of elastic modulus using conical indenter with finite tip radius. J. Mater. Res. 23, 2528–2537 (2008)

M. Lichinchi, C. Lenardi, J. Haupt, R. Vitali, Simulation of Berkovich nanoindentation experiments on thin films using finite element method. Thin Solids Films. 333, 278–286 (1998)

Y.Y. Lim, M.M. Chaudhri, The effect of the indenter load on the nanohardness of ductile metals: An experimental study on polycrystalline work-hardened and annealed oxygen-free copper. Philos. Mag. A. 79, 2979–3000 (1999)

M. Dao, N. Challocoop, K.J. Van Vliet, T.A. Venkatesh, S. Suresh, Computational modeling of forward and reverse problems in instrumented sharp indentation. Acta Mater. 49, 3899–3918 (2001)

N. Ogasawara, N. Chiba, X. Chen, Measuring the plastic properties of bulk materials by single indentation test. Scr. Mater. 54, 65–70 (2006)

W.C. Oliver, Alternative technique for analyzing instrumented indentation data. J. Mater. Res. 16, 3202–3206 (2001)

W.C. Oliver, G.M. Pharr, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992)

W.C. Oliver, G.M. Pharr, Nanoindentation in materials research: Past, present, and future. MRS Bull. 35, 897–907 (2010)

G.M. Pharr, A. Bolshakov, Understanding nanoindentation unloading curves. J. Mater. Res. 17, 2660–2671 (2002)

T.A. Venkatesh, K.J. Van Vliet, A.E. Giannakopoulos, S. Suresh, Determination of elasto-plastic properties by instrumented sharp indentation: Guidelines for property extraction. Scr. Mater. 42, 833–839 (2000)

J.T. Wang, P.D. Hodgson, C.H. Yang, Effects of mechanical properties on the contact profile in Berkovich nanoindentation of elastoplastic materials. J. Mater. Res. 27, 313–319 (2012)

Z.H. Xu, D. Rowcliffe, Method to determine the plastic properties of bulk materials by nanoindentation. Philos. Mag. A. 82, 1893–1901 (2002)

H. Lan, T.A. Venkatesh, On the relationships between hardness and the elastic and the plastic properties of isotropic power-law hardening materials. Philos. Mag. A. 93, 35–55 (2014)

X.Z. Xiao, L. Yu, Nano-indentation of ion-irradiated nuclear structural materials: A review. Nuclear Mater. Energy 22, 100721 (2020)

M.M. Chaudhri, Indentation hardness of diamond single crystals, nanopolycrystal, and nanotwinned diamonds: A critical review. Diamond Mater. 109, 108076 (2020)

M.M. Islam, S.I. Shaki, N.M. Shaheen, P. Bayati, M. Haghshenas, An overview of microscale indentation fatigue: Composites, thin films, coatings, and ceramics. Micron 148, 103110 (2021)

A. Gouldstone, N. Chollacoop, M. Dao, J. Li, A.M. Minor, Y.-L. Shen, Indentation across size scales and disciplinesrecent developments in experimentation and modeling. Acta Mater. 55, 4015–4039 (2007)

T. Rouxel, J.I. Jang, U. Ramamurty, Prog. Mater. Sci. 121, 1 (2021)

A.C. Fischer-Cripps, S.J. Bull, N. Schwarzer, Critical review of claims for ultra-hardness in nanocomposite coatings. Philos. Mag. 92(1601), 1630 (2012)

C.A. Schuh, Nanoindentation studies of materials. Mater. Today 9, 32–40 (2006)

Q. Wang, F. Long, Z. Wang, N. Guo, M.R. Daymond, Orientation dependent evolution of plasticity of irradiated Zr-25.Nb pressure tube alloy studied by nanoindentation and finite element modeling. J. Nucl. Mater. 512, 371–384 (2018)

S.M. Kalkhoran, W.B. Choi, A. Gouldstone, Estimation of plastic anisotropy in Ni–5% Al coatings via spherical indentation. Acta Mater. 60, 803–810 (2012)

G. Cheng, X. Sun, Y. Wang, S.L. Tay, W. Gao, Nanoindentation study of electrodeposited Ag thin coating: An inverse calculation of anisotropic elastic-plastic properties. Surf. Coat. Technol. 310, 43–50 (2017)

A. Yonezu, K. Yoneda, H. Hirakata, M. Sakihara, K. Minoshima, A simple method to evaluate anisotropic plastic properties based on dimensionless function of single spherical indentation-application to SiC whisker-reinforced aluminum alloy. Mater. Sci. Eng. A 527, 7646–7657 (2010)

Z. Fan, J.Y. Rho, Three-dimensional finite element analysis of the effects of anisotropy on bone mechanical properties measured by nanoindentation. J. Mater. Res. 19, 114–123 (2004)

Z.J. Cheng, X.M. Wang, J. Ge, J.X. Yan, N. Ji, L.L. Tian, F.Z. Cui, The mechanical anisotropy on a longitudinal section of human enamel studied by nanoindentation. J. Mater. Sci.: Mater. Med. 21, 1811–1816 (2010)

A. Jäger, Th. Bader, K. Hofstetter, J. Eberhardsteiner, The relation between indentation modulus, microfibril angle, and elastic properties of wood cell walls. Compos. A 42, 677–685 (2011)

T.S. Bhat, T.A. Venkatesh, Indentation of transversely isotropic power-law hardening materials: Computational modelling of the forward and reverse problems. Philos. Mag. A. 93, 4488–4518 (2013)

ASM Handbook: Properties and Selection Vol. I, II ASM International, Materials Park, OH (1990).

ASM.Matweb.com

J.J. Vlassak, M. Ciavarella, J.R. Barber, X. Wang, The indentation modulus of elastically anisotropic materials for indenters of arbitrary shape. J. Mech. Phys. Sol. 51, 1701–1721 (2003)

Y.F. Gao, G.M. Pharr, Multidimensional contact moduli of elastically anisotropic solids. Scr. Mater. 57, 13–16 (2007)

C. Jin, Numerical investigation of indentation tests on a transversely isotropic elastic material by power-law shaped axisymmetric indenters. J. Adhesion. Sci. Tech. 30, 1223–1242 (2016)

F.M. Borodich, B.A. Galanov, L.M. Keer, M.M. Suarez-Alvarez, The JKR-type adhesive contact problems for transversely isotropic elastic solids. Mech. Mater. 75, 34–44 (2014)

T.L. Li, J.H. Lee, Y.F. Gao, An approximate formulation of the effective indentation modulus of elastically anisotropic film-on-substrate systems. Int. J. Appl. Mech. 1, 515–525 (2009)

M. Wang, J. Wu, X. Zhan, R. Guo, Y. Hui, H. Fan, On the determination of the anisotropic plasticity of metal materials by using instrumented indentation. Mater. Des. 111, 98–107 (2016)

J. Wu, M. Wang, Y. Hui, Z. Zhang, H. Fan, Identification of anisotropic plasticity properties of materials using spherical indentation imprint mapping. Mater. Sci. Eng. A 723, 269–278 (2018)

T. Nakamura, Y. Gu, Identification of elastic-plastic anisotropic parameters using instrumented indentation and inverse analysis. Mech. Mater. 39, 340–356 (2007)

A. Yonezu, M. Tanaka, R. Kusano, X. Chen, Probing out-of-plane anisotropic plasticity using spherical indentation: A numerical approach. Comput. Mater. Sci. 79, 336–344 (2013)

D. Tabor, An improved equation relating hardness to ultimate strength. J. I Met. 79, 1–18 (1951)

Funding

The present study was supported in part by a National Science Foundation Grant DMR-2004944.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix A

Appendix A

As described in “Computational modeling” section, the entire material property database was divided into six domains. For each of the material domains, dimensionless functions that capture the relationships between true projected contact area (Am), the indentation hardness (Hm) and the five elastic and plastic properties of transversely isotropic materials (E0, σ0, EL/ET, σL/σT, n) are identified. Here, of the 24 equations, a list of 6 dimensionless functions for longitudinal indentation hardness is provided. The equations are listed as Пjkl. Here, j varies from 1 to 2 and signifies the indenter orientation—1 for longitudinal, and 2 for parallel indentation; k varies from 4 to 5, and conveys the type of dimensionless function—4 for Am and 5 for Hm; and l represents the part number and varies from 1 to 6. X, Y, and Z represent the properties E0, EL/ET, and σL/σT, respectively.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bhat, T.S., Venkatesh, T.A. On the relationships between hardness and the elastic and plastic properties of transversely isotropic power-law hardening materials. Journal of Materials Research 37, 3599–3616 (2022). https://doi.org/10.1557/s43578-022-00730-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00730-y