Abstract

To investigate the basic characteristics of multi-component boride in Fe–B alloy, the samples were prepared by directional solidification, and then the microstructural evolution, crystallography, nanomechanical properties and wear-resistance of multi-component M2B have been systematically studied. The results show that the boride grows in the sequence of Mo-rich → Fe-rich → Cr-rich M2B. The Mo-rich M2B has the body centered tetragonal (bct) structure with stoichiometry of Fe0.72Cr0.27Mo0.80(B,C), the Fe-rich M2B possesses the bct structure with stoichiometry of Fe1.59Cr0.38Mo0.08(B,C), while the Cr-rich M2B owns the body centered orthorhombic (bco) structure with stoichiometry of Fe1.48Cr0.50Mo0.02(B,C). Moreover, the Mo addition can facilitate more dislocations in the M2B compared to the Cr addition. Thus, the Mo-rich M2B has the best stiffness and toughness, followed by the Cr-rich M2B and then the Fe-rich M2B. Additionally, the Mo-rich and Cr-rich M2B can possess higher wear-resistance relative to the Fe-rich M2B.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

P. Xiao, Y.M. Gao, C.C. Yang, Z.W. Liu, Y.F. Li, F.X. Xu, Microstructure, mechanical properties and strengthening mechanisms of Mg matrix composites reinforced with in situ nanosized TiB2 particles. Mater. Sci. Eng. A 710, 251–259 (2018)

Z.F. Huang, S.Q. Ma, J.D. Xing, B.Y. Wang, Bulk Fe2B crystal fabricated by mechanical ball milling and plasma activated sintering. J. Alloy. Compd. 582, 196–200 (2014)

G.B. Ying, X.D. He, M.W. Li, S.Y. Du, W.B. Han, F. He, Effect of Cr7C3 on the mechanical, thermal, and electrical properties of Cr2AlC. J. Alloy. Comp. 509, 8022–8027 (2011)

Y. Mitsui, Y. Ikehara, K. Takahashi, S. Kimura, G. Miyamoto, T. Furuhara, K. Watanabe, K. Koyama, Fe-Fe3C binary phase diagram in high magnetic fields. J. Alloy. Compd. 632, 251–255 (2015)

Z. Lv, H.G. Fu, J.D. Xing, Z.F. Huang, S.Q. Ma, Y. Hu, Influence of boron contents on oxidation behavior and the diffusion mechanism of Fe–B based alloys at 1073K in air. Corros. Sci. 108, 185–193 (2016)

Y.L. Yi, J.D. Xing, Y.F. Lu, Y.M. Gao, H.G. Fu, L.L. Yu, M.J. Wan, Q.L. Zheng, Effect of normal load on two-body abrasive wear of an Fe-B-Cr-C based alloy with minor Cu and Ni additions. Wear 408, 160–170 (2018)

S.Q. Ma, J.D. Xing, H.G. Fu, Y.L. He, Y. Bai, Y.F. Li, Y.P. Bai, Interface characteristics and corrosion behaviour of oriented bulk Fe2B alloy in liquid zinc. Corros. Sci. 78, 71–80 (2014)

S.Q. Ma, J.D. Xing, H.G. Fu, Y.M. Gao, J.J. Zhang, Microstructure and crystallography of borides and secondary precipitation in 18 wt.% Cr–4 wt.% Ni–1 wt.% Mo–3.5 wt.% B–0.27 wt.% C steel. Acta. Mater. 60, 831–843 (2012)

S.Q. Ma, J.D. Xing, Y.L. He, H.G. Fu, Y.F. Li, G.Z. Liu, Effect of orientation and lamellar spacing of Fe2B on interfaces and corrosion behavior of Fe-B alloy in hot-dip galvanization. Acta Mater. 115, 392–402 (2016)

X.Y. Ren, H.G. Fu, J.D. Xing, Y.W. Yang, S.L. Tang, Effect of boron concentration on microstructures and properties of Fe–B–C alloy steel. J. Mater. Res. 304, 1–11 (2017)

J.J. Zhang, Y.M. Gao, J.D. Xing, S.Q. Ma, D.W. Yi, J.B. Yan, Effects of chromium addition on microstructure and abrasion resistance of Fe–B cast alloy. Tribol. Lett. 44, 31–39 (2011)

Y.L. Yi, Q. Li, J.D. Xing, H.G. Fu, D.W. Yi, Y.Z. Liu, B.C. Zheng, Effects of cooling rate on microstructure, mechanical properties, and residual stress of Fe-2.1B (wt%) alloy. Mater. Sci. Eng. A 754, 129–139 (2019)

H.G. Fu, New development of high boron wear-resistant alloy. Foundry Technol. 55, 292–295 (2006)

J.J. Zhang, X.W. Wei, J. Wang, Q.F. Tang, Research progress of wear resistant Fe-B alloy. Foundry 63, 669–674 (2014)

O. Ozdemir, M. Usta, C. Bindal, A.H. Ucisik, Hard iron boride (Fe2B) on 99.97 wt% pure iron. Vacuum 80, 1391–1395 (2006)

M.S. Li, X.L. Fu, W.D. Xu, R.L. Zhang, R.H. Yu, Valence electron structure of Fe2B phase and its eigen-brittleness. Acta Metall. Sin. 31, 201–208 (1995)

Y.X. Jian, Z.F. Huang, J.D. Xing, B.C. Zheng, L. Sun, Y.Z. Liu, Y.M. Liu, Effect of improving Fe2B toughness by chromium addition on the two-body abrasive wear behavior of Fe-3.0 wt% B cast alloy. Tribol. Int. 101, 331–339 (2016)

Y.L. Yi, J.D. Xing, X.Y. Ren, H.G. Fu, Q. Li, D.W. Yi, Investigation on abrasive wear behavior of Fe-B alloys containing various molybdenum contents. Tribol. Int. 135, 237–245 (2019)

C. Zhou, J. Xing, B. Xiao, J. Feng, X. Xie, Y. Chen, First principles study on the structural properties and electronic structure of X2B (X=Cr, Mn, Fe Co, Ni, Mo and W) compounds. Comput. Mater. Sci. 44, 1056–1064 (2009)

B. Xiao, J. Feng, C. Zhou, J. Xing, X. Xie, Y. Cheng, R. Zhou, The elasticity, bond hardness and thermodynamic properties of X2B (X=Cr, Mn, Fe Co, Ni, Mo, W) investigated by DFT theory. Phys. B: Condens. Mater. 405, 1274–1278 (2010)

B. Xiao, J.D. Xing, S.F. Ding, W. Su, Stability, electronic and mechanical properties of Fe2B. Phys. B: Condens. Mater. 403, 1723–1730 (2008)

S.Q. Ma, W.J. Pan, J.D. Xing, S.Q. Guo, H.G. Fu, P. Lyu, Microstructure and hardening behavior of Al-modified Fe-1.5 wt%B-0.4 wt %C high-speed steel during heat treatment. Mater. Charact. 132, 1–9 (2017)

Y.W. Yang, H.G. Fu, Y.P. Lei, K.M. Wang, L.L. Zhu, L. Jiang, Phase diagram calculation and analyze on cast high-boron high-speed steel. J. Mater. Eng. Perform. 25, 409–420 (2016)

Z. Lv, H.G. Fu, J.D. Xing, S.Q. Ma, Y. Hu, Microstructure and crystallography of borides and mechanical properties of Fe-B-C-Cr-Al alloys. J. Alloy. Compd. 662, 54–62 (2016)

H.G. Fu, Q. Xiao, J.C. Kuang, Z.Q. Jiang, J.D. Xing, Effect of rare earth and titanium additions on the microstructures and properties of low carbon Fe–B cast steel. Mater. Sci. Eng. A 466, 160–165 (2007)

Y.L. Yi, J.D. Xing, M.J. Wan, L.L. Yu, Y.F. Lu, Y.X. Jian, Effect of Cu on microstructure, crystallography and mechanical properties in Fe-B-C-Cu alloys. Mater. Sci. Eng. A 708, 274–284 (2017)

W.R. Thorpe, B. Chicco, Fe-rich corner of the metastable C-Cr-Fe liquidus surface. Metall. Trans. A 16, 1541–1549 (1985)

Y.H. Liu, Y.Q. Wu, T. Shan, Z.K. Wang, G.C. Jiang, Molecular dynamics simulation of phase transformation of δ-Fe→γ-Fe→liquid in continuos temperature-rise process. Acta. Metall. Sin. 46, 172–178 (2010)

P. Christodoulou, N. Calos, A step towards designing Fe-Cr-B-C cast alloys. Mater. Sci. Eng. A 301, 103–117 (2001)

C.Q. Guo, P.M. Kelly, Modeling of spatial distribution of the eutectic M2B borides in Fe-Cr-B cast irons. J. Mater. Sci. 39, 1109–1111 (2004)

Y.B. Wang, X.Z. Liao, Y.H. Zhao, E.J. Lavernia, S.P. Ringer, Z. Horita, T.G. Langdon, Y.T. Zhu, The role of stacking faults and twin boundaries in grain refinement of a Cu–Zn alloy processed by high-pressure torsion. Mater. Sci. Eng. A 527, 4959–4966 (2010)

Y. Li, Z. Zhang, R. Vogt, J.M. Schoenung, E.J. Lavernia, Boundaries and interfaces in ultrafine grain composites. Acta Mater. 59, 7206–7218 (2011)

H. Attar, S. Ehtemam-Haghighi, D. Kent, I.V. Okulov, H. Wendrock, M. Bonisch, A.S. Volegov, M. Calin, J. Eckert, M.S. Dargusch, Nanoindentation and wear properties of Ti and Ti-TiB composite materials produced by selective laser melting. Mater. Sci. Eng. A 688, 20–26 (2017)

P. Majumdar, S.B. Singh, M. Chakraborty, Elastic modulus of biomedical titanium alloys by nano-indentation and ultrasonic techniques—a comparative study. Mater. Sci. Eng. A 489, 419–425 (2008)

A. Hynowska, E. Pellicer, J. Fornell, S. González, N.V. Steenberge, S. Suriñach, A. Gebert, M. Calin, J. Eckert, M.D. Baró, Substructured β-phase Ti–31.0 Fe–9.0 Sn and sub-μm structured Ti–39.3 Nb–13.3 Zr–10.7 Ta alloys for biomedical applications: microstructure benefits on the mechanical and corrosion performances. Mater. Sci. Eng. C 32, 2418–2425 (2012)

Y.Z. Wang, H.S. Ding, H.Z. Zhang, R.R. Chen, J.J. Guo, H.Z. Fu, Microstructures and fracture toughness of Ti–(43–48) Al–2Cr–2Nb prepared by electromagnetic cold crucible directional solidification. Mater. Des. 64, 153–159 (2014)

X.F. Ding, J.P. Lin, H. Qi, L.Q. Zhang, X.P. Song, G.L. Chen, Microstructure formation in γ–γ′ Co–Al–W–Ti alloys during directional solidification. J. Alloys Compd. 509, 4041–4046 (2011)

T. Liu, L.S. Luo, L. Wang, N.N. Guo, X.Z. Li, R.R. Chen, Y.Q. Su, J.J. Guo, H.Z. Fu, Influence of thermal stabilization treatment on microstructure evolution of the mushy zone and subsequent directional solidification in Ti-43Al-3Si alloy. Mater. Des. 97, 392–399 (2016)

Y. Gu, P. Tian, W. Xu, X.L. Han, B. Liao, F.R. Xiao, Non-isothermal prior austenite grain growth of a high-Nb X100 pipeline steel during a simulated welding heat cycle process. Mater. Des. 89, 589–596 (2016)

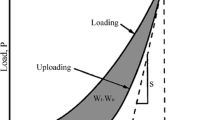

W.C. Oliver, G.M. Pharr, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992)

Y.V. Milman, B.A. Galanov, S.I. Chugunova, Plasticity characteristic obtained through hardness measurement. Acta. Metall. et Mater. 41, 2523–2532 (1993)

Acknowledgments

This work was financially supported by National Natural Science Foundation of China (No. 52005217), Basic and Applied Basic Research Fund Project of Guangdong Province in China (No. 2021A1515010523 and No. 2020A1515110020) and Basic Scientific Research Projects of Central Universities (No. 21620344).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Rights and permissions

About this article

Cite this article

Song, S., Yi, Y., Xing, J. et al. Microstructure evolution, crystallography, nanomechanical properties and wear-resistance of multi-component M2B in Fe–B alloy. Journal of Materials Research 37, 1429–1439 (2022). https://doi.org/10.1557/s43578-022-00543-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00543-z