Abstract

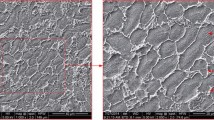

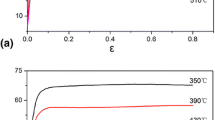

To characterize the TA32 titanium alloy (Ti–5.5Al–3.5Sn–3.0Zr–0.7Mo–0.3Si–0.4Nb–0.4Ta, wt%) hot deformation behavior, the isothermal constant strain rate tensile tests in range of temperature 600–720 ℃ with strain rate 0.0001–0.1 s−1 were performed. Based on strain compensation of Arrhenius constitutive, physically based constitutive and BP neural network constitutive model were used to regress the high-temperature flow stress and the prediction accuracy were evaluated by correlation coefficient and average relative error. A cross-validation approach was used to evaluate the predictability of the three constitutive models. The result show that the tensile strength is more sensitive to strain rate than deformation temperature, according to the fitting results and sixteen cross-validation tests indicate that the BP model can provide the most accurate prediction for TA32 hot flow behavior. As revealed by micrographs, both high temperature and low strain rate are benefited for dynamic recrystallization and spheroidization with β phase.

Graphical abstract

Cross-validation of three models.

Similar content being viewed by others

Data availability statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

W.Y. Li, Z.Y. Chen, J.R. Liu et al., Effect of texture on anisotropy at 600 ℃ in a near-α titanium alloy Ti60 plate. Mater. Sci. Eng. A 688, 322–329 (2017)

N. Li, Z.B. Zhao, S.X. Zhu et al., Analysis of the active slip mode during compression of the near-α titanium alloy in the α+β phase-field: Insights from the results of electron backscattered diffraction. Mater Lett. 288, 129363 (2017)

Y. Li, P. Gao, J. Yu et al., Mesoscale deformation mechanisms in relation with slip and grain boundary sliding in TA15 titanium alloy during tensile deformation. J. Mater. Sci. Technol. 98, 72–86 (2021)

V.A. Kumar, R.K. Gupta, M. Prasad et al., Recent advances in processing of titanium alloys and titanium aluminides for space applications: A review. J. Mater. Res. 36, 689–716 (2021)

C.B. Lan, Y. Wu, L.L. Guo et al., Microstructure, texture evolution and mechanical properties of cold rolled Ti-32.5Nb-6.8Zr-2.7Sn biomedical beta titanium alloy. J. Mater. Sci. Technol. 34, 788–792 (2018)

M.K. Gouda, S.A. Salman, S. Ebied et al., Biocompatibility and corrosion resistance of low-cost Ti–14Mn–Zr alloys. J. Mater. Res. 36, 4883–4893 (2021)

A. Ghosh, A. Singh, N.P. Gurao, Effect of rolling mode and annealing temperature on microstructure and texture of commercially pure-titanium. Mater. Charact. 125, 83–93 (2017)

W.X. Yu, Y.F. Lv, S.K. Li et al., Mechanism of the anisotropy of yield ratio in TA5 titanium alloy plates. Mater. Sci. Eng. A 639, 314–319 (2015)

A. Ghosh, N.P. Gurao, Effect of crystallographic texture on ratcheting response of commercially pure titanium. Mater. Des. 115, 121–132 (2017)

A.O. Mosleh, A.D. Kotov, P. Mestre-Rinn et al., Superplastic forming of Ti-4Al-3Mo-1V alloy: Flow behavior modelling and finite element simulation. Procedia Manuf. 37, 239–246 (2019)

Y. Feng, M. Wu, Q. Gao et al., A Numerical simulation to study the effects of different laser cladding sequences on residual stress and deformation of Ti-6Al-4V/WC. J. Mater. Res. 36, 3214–3225 (2021)

C. Cheng, Y. Feng, Z. Chen et al., Effect of annealing temperature on microstructure, texture and tensile properties of TA32 sheet. Mater. Sci. Eng A 826, 141971 (2021)

T. Sakai, A. Belyakov, R. Kaibyshev, M. Hiromi, J.J. John, Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 60, 130–207 (2014)

L. Lu, W.A. Yu, L.A. Hao et al., Effect of the Zener-Hollomon parameter on the dynamic recrystallization kinetics of Mg–Zn–Zr–Yb magnesium alloy. Comput. Mater. Sci. 166, 221–229 (2019)

Y. Perlovich, M. IsAeNkova, M. Grekhov et al., Features of the structure development and the deformation process in Zr-based alloys under radial forging. Mater. Sci. Forum 584–586, 338–342 (2008)

F.H. Zhu, W. Xiong, X.F. Li et al., A new flow stress model based on Arrhenius equation to track hardening and softening behaviors of Ti6Al4V alloy. Rare Met. 37, 1035–1045 (2018)

S. Long, Y.F. Xia, P. Wang et al., Constitutive modelling, dynamic globularization behavior and processing map for Ti-6Cr-5Mo-5V-4Al alloy during hot deformation. J. Alloys Compd. 796, 65–76 (2019)

J.M. Cabrera, A.A. Omar, J.M. Prado et al., Modeling the flow behavior of a medium carbon microalloyed steel under hot working conditions. Met. Mater. Trans. A 28, 2233–2244 (1997)

S. Wang, J.R. Luo, L.G. Hou et al., Physically based constitutive analysis and microstructural evolution of AA7050 aluminum alloy during hot compression. Mater. Des. 107, 277–289 (2016)

H.L. Wei, G.Q. Liu, M.H. Zhang, Physically based constitutive analysis to predict flow stress of medium carbon and vanadium microalloyed steels. Mater. Sci. Eng. A Struct. 602, 127–133 (2014)

C. Lu, J. Shi, J. Wang, Physically based constitutive modeling for Ti17 alloy with original basketweave microstructure in β forging: A comparison of three approaches. Mater. Charact. 181, 111455 (2021)

R. Luo, Y. Cao, S. Cui et al., An improved constitutive model based on BP artificial neural network and 3D processing maps of a spray-formed Al–Cu–Li alloy. Trans. Indian Inst. Met. 104, 1809–1817 (2021)

Z. Zhou, H. Gong, J. You et al., Research on compression deformation behavior of aging AA6082 aluminum alloy based on strain compensation constitutive equation and PSO-BP network model. Mater. Today Commun. 28, 102507 (2021)

X.Y. Shu, S.Q. Lu, K.L. Wang et al., A comparative study on constitutive equations and artificial neural network model to predict high-temperature deformation behavior in Nitinol 60 shape memory alloy. J. Mater. Res. 30, 1988–1998 (2015)

O. Yakovtseva, M. Sitkina, A.O. Mosleh et al., High strain rate superplasticity in Al-Zn-Mg-based alloy: Microstructural design, deformation behavior, and modeling. Materials 9, 2098 (2020)

Z. Shen, R. Wu, C. Yuan et al., Comparative study of metamodeling methods for modeling the constitutive relationships of the TC6 titanium alloy. J. Mater. Res. Technol. 10, 188–204 (2020)

Y.Q. Jiang, Y.C. Lin, G.Q. Wang et al., Microstructure evolution and a unified constitutive model for a Ti-55511 alloy deformed in β region. J. Alloys Compd. 870, 159534 (2021)

R. Yu, X. Li, W. Li et al., Application of four different models for predicting the high-temperature flow behavior of TG6 titanium alloy. Mater. Today Commun. 26, 102004 (2021)

N. Bibhanshu, G. Shankar, S. Suwas, Hot deformation and softening response in boron-modified two-phase titanium aluminide Ti-48Al-2V-0.2B. J. Mater. Res. 36, 311–321 (2021)

A.K. Maheshwari, Prediction of flow stress for hot deformation processing. Comput. Mater. Sci. 69, 350–358 (2013)

A. Hajari, M. Morakabati, S.M. Abbasi et al., Constitutive modeling for high-temperature flow behavior of Ti-6242S alloy. Mater. Sci. Eng. A 681, 103–113 (2016)

W. Zhang, H. Ding, J. Zhao et al., Hot deformation behavior and processing maps of Ti–6Al–4V alloy with starting fully lamellar structure. J. Mater. Res. 33, 1–12 (2018)

C.M. Sellars, W.J. Mctegart, On the mechanism of hot deformation. Acta Metall. 14, 1136–1138 (1966)

Y.C. Lin, M.S. Chen, J. Zhong, Constitutive modeling for elevated temperature flow behavior of 42CrMo Steel. Comput. Mater. Sci. 42, 470–477 (2008)

C. Zener, J.H. Hollomon, Effort of strain rate upon plastic flow of steel. J Appl. Phys. 15, 22–32 (1944)

H. Mirzadeh, J.M. Cabrera, A. Najafizadeh, Constitutive relationships for hot deformation of austenite. Acta Mater. 59, 6441–6448 (2011)

H.J. Frost, M.F. Ashby, Deformation-Mechanism Maps: The Plasticity and Creep of Metals and Ceramics (Pergamon Press, Oxford, 1982)

A.O. Mosleh, P. Mestre-Rinn, A.M. Khalil et al., Modelling approach for predicting the superplastic deformation behaviour of titanium alloys with strain hardening/softening characterizations. Mater. Res. Express 7, 016504 (2019)

A.O. Mosleh, A.D. Kotov, A.A. Kishchik et al., Characterization of superplastic deformation behavior for a novel Al-Mg-Fe-Ni-Zr-Sc alloy: Arrhenius-based modeling and artificial neural network approach. Appl. Sci. 11, 2208 (2021)

F. Ozturk, R.E. Ece, N. Polat et al., Application of electric resistance heating method on titanium hot forming at industrial scale. Arab. J. Sci. Eng. 41, 4441–4448 (2016)

Acknowledgments

The study was supported by the project of Test processing of titanium alloy engine exhaust device.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Feng, R., Bao, Y., Ding, Y. et al. Three different mathematical models to predict the hot deformation behavior of TA32 titanium alloy. Journal of Materials Research 37, 1309–1322 (2022). https://doi.org/10.1557/s43578-022-00532-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00532-2