Abstract

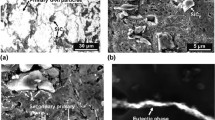

In this work, powder thixoforming technique was utilized to prepare 10 vol% SiC particulate-reinforced 6061 alloy matrix (SiCp/6061Al) composite and artificial aging treatment was conducted to enhance mechanical properties. The results reveal that the aging process of SiCp/6061Al composite at 175 °C can be divided into three stages: under-aged (0.5–10 h) stage, peak-aged (10 h) stage and over-aged (10–48 h) stage, which were dominated by Guinier–Preston zone, β″ and β phase, respectively. Correspondingly, the tensile strengths of this composite exhibited a trend of first rising (0.5–10 h) and then decreasing (10–48 h), while the elongation continuously decreased all the time. Comparing with the as-fabricated composite, optimal aging treatment for 10 h led to maximum ultimate tensile strength of 309 MPa, yield strength of 240 MPa and a moderate elongation of 3.7%, representing remarkable increments of 34.3%, 87.5% and 42.3%, respectively. The aging behaviors of SiCp/6061Al composite and corresponding strengthening as well as toughening mechanisms were discussed.

Graphic abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

I.A. Ibrahim, F.A. Mohamed, E.J. Lavernia, Particulate reinforced metal matrix composites - A review. J. Mater. Sci. 26(5), 1137 (1991)

B. Chen, X.Y. Zhou, B. Zhang, K. Kondoh, J.S. Li, M. Qian, Microstructure, tensile properties and deformation behaviors of aluminium metal matrix composites co-reinforced by ex-situ carbon nanotubes and in-situ alumina nanoparticles. Mater. Sci. Eng. A 795, 139930 (2020)

B.L. Dasari, M. Morshed, J.M. Nouri, D. Brabazon, S. Naher, Mechanical properties of graphene oxide reinforced aluminium matrix composites. Composite B 145, 136 (2018)

J.J. Wang, J.J. Hao, Z.M. Guo, S. Wang, Plasma preparation and low-temperature sintering of spherical TiC–Fe composite powder. Int. J. Miner. Metall. Mater. 22, 1328 (2015)

M.C. Flemings, Behavior of metal alloys in the semisolid state. Metall. Trans. B 22(3), 269 (1991)

T.J. Chen, H. Qin, X.Z. Zhang, Effects of reheating duration on the microstructure and tensile properties of in situ core–shell-structured particle-reinforced A356 composites fabricated via powder thixoforming. J. Mater. Sci. 53(Suppl 2), 2576 (2018)

X.Z. Zhang, T.J. Chen, Solution treatment: A route towards enhancing tensile ductility of SiCp/6061Al composite via powder thixoforming and comparison of micromechanical strength modeling. Mater. Sci. Eng. A 696, 466 (2017)

X.Z. Zhang, T.J. Chen, Y.H. Qin, Effects of solution treatment on tensile properties and strengthening mechanisms of SiCp/6061Al composites fabricated by powder thixoforming. Mater. Des. 99, 182 (2016)

P. Li, T. Chen, H. Qin, Effects of pressure on microstructure and mechanical properties of SiCp/2024 Al-based composites fabricated by powder thixoforming. J. Mater. Sci. 52(4), 2045 (2017)

H. Su, W.L. Gao, C. Mao, H. Zhang, Z. Lu, Microstructures and mechanical properties of SiCp/2024 aluminum matrix composite synthesized by stir casting. Chin. J. Nonferrous Met. 20(2), 217 (2010)

S.-J. Hong, H.-M. Kim, D. Huh, C. Suryanarayana, B.S. Chun, Effect of clustering on the mechanical properties of SiC particulate-reinforced aluminum alloy 2024 metal matrix composites. Mater. Sci. Eng. A 347(1), 198 (2003)

P. Li, T. Chen, Tensile properties and fracture behavior of a powder-thixoformed 2024Al/SiCp composite at elevated temperatures. Metals 7(10), 408 (2017)

X.Z. Zhang, T.J. Chen, Toughening mechanisms of solution-treated SiCp/6061 aluminum matrix composites fabricated via powder thixoforming. J. Mater. Res. 33(18), 2728 (2018)

X.Z. Zhang, T.J. Chen, Bimodal microstructure dispersed with nanosized precipitates makes strong aluminum alloy with large ductility. Mater. Des. 191, 108695 (2020)

G.F. Liu, T.J. Chen, Z.J. Wang, Effects of solid solution treatment on microstructure and mechanical properties of SiCp/2024 Al composite: A comparison with 2024 Al alloy. Mater. Sci. Eng. A 817, 141413 (2021)

R. Dong, W. Yang, Z. Yu, P. Wu, M. Hussain, L. Jiang, G. Wu, Aging behavior of 6061Al matrix composite reinforced with high content SiC nanowires. J. Alloys Compd. 649, 1037 (2015)

N.A. Belov, D.G. Eskin, A.A. Aksenov, Multicomponent Phase Diagrams: Applications for Commercial Aluminum Alloys (Elsevier, Amsterdam, 2005)

Z. Wang, J. Tan, B.A. Sun, S. Scudino, K.G. Prashanth, W.W. Zhang, Y.Y. Li, J. Eckert, Fabrication and mechanical properties of Al-based metal matrix composites reinforced with Mg65Cu20Zn5Y10 metallic glass particles. Mater. Sci. Eng. A 600(4), 53 (2014)

S. Min, C.Q. Xie, H.E. Yue-Hui, Model of effects of particle failure on yield stress of SiC reinforced aluminum alloy composites. Chin. J. Nonferrous Met. 20(2), 244 (2010)

S. Pogatscher, H. Antrekowitsch, H. Leitner, D. Pöschmann, Z.L. Zhang, P.J. Uggowitzer, Influence of interrupted quenching on artificial aging of Al-Mg-Si alloys. Acta Mater. 60(11), 4496 (2012)

M.H. Jacobs, The structure of the metastable precipitates formed during ageing of an Al–Mg–Si alloy. Philos. Magn. 26(1), 13 (1972)

K. Ma, H. Wen, T. Hu, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, J.M. Schoenung, Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 62(5), 141 (2014)

K.A. Unocic, D. Shin, X. Sang, E. Cakmak, P.F. Tortorelli, Single-step aging treatment for a precipitation-strengthened Ni-based alloy and its influence on high-temperature mechanical behavior. Scripta Mater. 162, 416 (2019)

Z. Zhang, J. Fan, Z. Wu, D. Zhao, Q. Gao, Q. Wang, Z. Chen, B. Tang, H. Kou, J. Li, Precipitation behavior and strengthening-toughening mechanism of hot rolled sheet of Ti65 titanium alloy during aging process. J. Alloys Compd. 831, 154786 (2020)

S. Jin, T. Ngai, G. Zhang, T. Zhai, S. Jia, L. Li, Precipitation strengthening mechanisms during natural ageing and subsequent artificial aging in an Al–Mg–Si–Cu alloy. Mater. Sci. Eng. A 724, 53 (2018)

X. Liu, J. Li, E. Liu, C. He, C. Shi, N. Zhao, Towards strength-ductility synergy with favorable strengthening effect through the formation of a quasi-continuous graphene nanosheets coated Ni structure in aluminum matrix composite. Mater. Sci. Eng. 748, 52 (2019)

J. Woźniak, M. Kostecki, K. Broniszewski, W. Bochniak, A. Olszyna, Aging behaviour of AA6061/SiCp composites produced by direct extrusion with a reversibly rotating die method. Arch. Metall. Mater. 60(3), 1755 (2015)

X. Cen, Influence of heat treatment on mechanical behavior and microstructure of SiCp/6061Al composites. Foundry Technol. 38(5), 1051 (2017)

D.E. Vg, G. Shaikshavali, M. Muralimohan, Mechanical properties of Al6061 based metal matrix composites reinforced with ceramic particulates and effect of age hardening on its tensile characteristics. Int. J. Eng. Res. Gen. Sci. 4(2), 726 (2016)

A.M. El-Sabbagh, M. Soliman, M.A. Taha, H. Palkowski, Effect of rolling and heat treatment on tensile behaviour of wrought Al–SiCp composites prepared by stir-casting. J. Mater. Process. Technol. 213(10), 1669 (2013)

T. Das, P.R. Munroe, S. Bandyopadhyay, The effect of Al2O3 particulates on the precipitation behaviour of 6061 aluminium-matrix composites. J. Mater. Sci. 31(20), 5351 (1996)

Y.L. Li, W.X. Wang, H.S. Chen, J.C. Zhao, B.D. Wang, Effect of heat treatment on microstructure and properties of 30%B4C/6061Al composites. Trans. Mater. Heat Treat. 37(4), 22 (2016)

C.M. Friend, S.D. Luxton, The effect of δ alumina fibre arrays on the age-hardening characteristics of an Al–Mg–Si alloy. J. Mater. Sci. 23(9), 3173 (1988)

X. Zhang, Effects of Heat Treatment on the Microstructures and Mechanical Properties of Sicp/6061al Composite Fabricated by Powder Thixoforming and Research on the Corresponding Strengthening and Toughening Mechanisms (Lanzhou University of Technology, Lanzhou, 2019)

Z. Wu, R. Ahmad, B. Yin, S. Sandlöbes, W.A. Curtin, Mechanistic origin and prediction of enhanced ductility in magnesium alloys. Science 359(6374), 447 (2018)

X. Li, L. Lu, J. Li, X. Zhang, H. Gao, Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys. Nat. Rev. Mater. 5(9), 706 (2020)

W. Yu, S.L. Sing, C.K. Chua, C. Kuo, X. Tian, Particle-reinforced metal matrix nanocomposites fabricated by selective laser melting: A state of the art review. Prog. Mater. Sci. 104, 330 (2019)

M. Whelan, On the kinetics of particle dissolution. Metals Sci. J. 3, 95 (1969)

G.K. Williamson, W.H. Hall, X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1(1), 22 (1953)

H.S. Chu, K.S. Liu, J.W. Yeh, Aging behavior and tensile properties of 6061Al-0.3 μm Al2O3p particle composites produced by reciprocating extrusion. Scripta Mater. 45(5), 541 (2001)

M. Zhao, G. Wu, L. Jiang, Aging behavior and precipitation kinetics of SiCp/6061AI composites. J. Mater. Sci. 39(5), 1759 (2004)

I. Dutta, S.M. Allen, J.L. Hafley, Effect of reinforcement on the aging response of cast 6061 Al-Al2O3 particulate composites. Metall. Trans. A 22(11), 2553 (1991)

M. Song, L.I. Xia, K.H. Chen, Modeling the age-hardening behavior of sic/al metal matrix composites. Metall. Mater. Trans. A 38(3), 638 (2007)

H.M. Guo, X.J. Yang, Preparation of semi-solid slurry containing fine and globular particles for wrought aluminum alloy 2024. Trans. Nonferrous. Met. Soc. China. 17, 799 (2007)

G. Esteban-Manzanares, E. Martínez, J. Segurado, L. Capolungo, J. Llorca, An atomistic investigation of the interaction of dislocations with Guinier–Preston zones in Al–Cu alloys. Acta Mater. 162, 189 (2019)

M. Song, Modeling the hardness and yield strength evolutions of aluminum alloy with rod/needle-shaped precipitates. Mater. Sci. Eng. A 443(1–2), 172 (2007)

H. Wen, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, Strengthening mechanisms in a high-strength bulk nanostructured Cu–Zn–Al alloy processed via cryomilling and spark plasma sintering ☆. Acta Mater. 61(8), 2769 (2013)

A.J. Ardell, Precipitation hardening. Metall. Trans. A 16(12), 2131 (1985)

G.H. Li, J.P. Li, F. Xia, J. Zhao, Reinforcing mechanism ofAl3Ti–TiB2–SiC/Al–13Si composite. J. Xi’an Inst. Technol. 25(5), 449 (2005)

S. Amirkhanlou, M. Rahimian, M. Ketabchi, N. Parvin, P. Yaghinali, F. Carreño, Strengthening mechanisms in nanostructured Al/SiCp composite manufactured by accumulative press bonding. Metall. Mater. Trans. A 47(10), 5136 (2016)

V.C. Nardone, K.M. Prewo, On the strength of discontinuous silicon carbide reinforced aluminum composites. Scripta Metall. 20(1), 43 (1986)

C.A. Lewis, P.J. Withers, Weibull modelling of particle cracking in metal matrix composites. Acta Metall. 43(10), 3685 (1995)

L. Sun, G. Wu, Q. Wang, J. Lu, Nanostructural metallic materials: Structures and mechanical properties. Mater. Today. 38, 114 (2020)

E. Ma, T. Zhu, Towards strength–ductility synergy through the design of heterogeneous nanostructures in metals. Mater. Today. 20(6), 323 (2017)

W. Yinmin, C. Mingwei, Z. Fenghua, M. En, High tensile ductility in a nanostructured metal. Nature 419(6910), 912 (2002)

B. Guo, M. Song, X. Zhang, Y. Liu, X. Cen, B. Chen, W. Li, Exploiting the synergic strengthening effects of stacking faults in carbon nanotubes reinforced aluminum matrix composites for enhanced mechanical properties. Composites B 211, 108646 (2021)

X. Zhang, T. Chen, S. Ma, H. Qin, J. Ma, Overcoming the strength-ductility trade-off of an aluminum matrix composite by novel core-shell structured reinforcing particulates. Composite B 206, 108541 (2021)

V.M. Sglavo, F. Marino, B.R. Zhang, S. Gialanella, Ni3Al intermetallic compound as second phase in Al2O3 ceramic composites. Mater. Sci. Eng. A 239–240, 665 (1997)

Y. Yue, Y. Gao, W. Hu, B. Xu, J. Wang, X. Zhang, Q. Zhang, Y. Wang, B. Ge, Z. Yang, Z. Li, P. Ying, X. Liu, D. Yu, B. Wei, Z. Wang, X.-F. Zhou, L. Guo, Y. Tian, Hierarchically structured diamond composite with exceptional toughness. Nature 582(7812), 370 (2020)

Acknowledgments

The authors acknowledge the financial support from the Basic Scientific Fund of Gansu Universities (Grant No. G2014-07), the Program for New Century Excellent Talents in University of China (Grant No. NCET-10-0023) and the Program for Hongliu Outstanding Talents of Lanzhou University of Technology (Grant No. 2012-03).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, X., Chen, T. Simultaneously enhancing the strength and ductility of particulate-reinforced aluminum matrix composite by aging treatment. Journal of Materials Research 36, 3445–3459 (2021). https://doi.org/10.1557/s43578-021-00389-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00389-x