Abstract

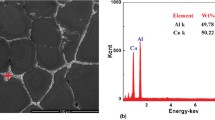

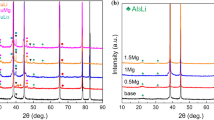

In this research, microstructure characterization, phase analysis and tensile tests were performed to investigate the influence of Zn content upon permanent mold cast Al–3Li–2Mg–0.1Zr alloy. Results showed that the most significant grain refinement was caused by 1 wt% Zn as constitutional undercooling was increased with Zn addition and decreased with the formation of (Al, Zn)49Mg32 phases. To dissolve second phases in as-cast alloys, including Al3Li, Al12Mg17, Al2MgLi, AlLi and (Al, Zn)49Mg32, three-stage solution treatment (500 °C/10 h + 535 °C/10 h + 560 °C/20 h) was designed. After quenching and artificial aging for 8 h at 175 °C, Al–3Li–2Mg–1Zn–0.1Zr alloy presented the optimum comprehensive mechanical properties. The elongation, yield strength and ultimate tensile strength reached 6.9%, 221 MPa and 351 MPa, respectively. The performance improvement with Zn addition was mainly attributed to grain refinement and solution strengthening, while the composition of precipitates was almost unaffected.

Graphic abstract

Similar content being viewed by others

Data availability

Data will be made available at reasonable request.

References

K. Lv, C. Zhu, J. Zheng, X. Wang, B. Chen, Precipitation of T1 phase in 2198 Al–Li alloy studied by atomic-resolution HAADF-STEM. J. Mater. Res. 34(20), 3535–3544 (2019). https://doi.org/10.1557/jmr.2019.136

Y. Zou, X. Chen, B. Chen, Corrosion behavior of 2198 Al–Cu–Li alloy in different aging stages in 3.5 wt% NaCl aqueous solution. J. Mater. Res. 33, 1011–1022 (2018). https://doi.org/10.1557/jmr.2018.33

L. Zhong, W. Gao, Z. Feng, Z. Lu, G. Mao, Microstructure characteristics and constitutive modeling for elevated temperature flow behavior of Al–Cu–Li X2A66 alloy. J. Mater. Res. 33(8), 912–922 (2018). https://doi.org/10.1557/jmr.2017.466

Y. Guo, Z. Huang, G. Jin, Research status of corrosion Al-Li alloy in acid medium. IOP Conf. Ser. (2019). https://doi.org/10.1088/1757-899x/612/2/022031

A. Chen, G. Wu, L. Zhang, X. Zhang, C. Shi, Y. Li, Microstructural characteristics and mechanical properties of cast Al-3Li-xCu-0.2Zr alloy. Mater. Sci. Eng. A 677, 29–40 (2016). https://doi.org/10.1016/j.msea.2016.09.040

P. Zhang, M. Chen, Progress in characterization methods for thermoplastic deforming constitutive models of Al–Li alloys: a review. J. Mater. Sci. 55(23), 9828–9847 (2020). https://doi.org/10.1007/s10853-020-04682-8

A. Medjahed, A. Henniche, M. Derradji, T. Yu, Y. Wang, R. Wu, L. Hou, J. Zhang, X. Li, M. Zhang, Effects of Cu/Mg ratio on the microstructure, mechanical and corrosion properties of Al–Li–Cu-Mg-X alloys. Mater. Sci. Eng. A 718, 241–249 (2018). https://doi.org/10.1016/j.msea.2018.01.118

Y. Peng, A. Chen, L. Zhang, W. Liu, G. Wu, Effect of solution treatment on microstructure and mechanical properties of cast Al–3Li–1.5Cu–0.2Zr alloy. J. Mater. Res. 31, 1124–1132 (2016). https://doi.org/10.1557/jmr.2016.103

C. Shi, G. Wu, L. Zhang, X. Zhang, J. Sun, J. Zhang, Microstructures and mechanical properties of ultralight cast Al-3Li-XMg-0.1Zr alloys. Mater. Charact. (2020). https://doi.org/10.1016/j.matchar.2020.110698

H. Ning, J. Li, P. Ma, Y. Chen, X. Zhang, K. Zhang, R. Zhang, Evolution of aging precipitates in an Al–Li alloy with 15 wt% Li concentration. Vacuum (2020). https://doi.org/10.1016/j.vacuum.2020.109677

Y. Ma, J. Li, R. Zhang, J. Tang, C. Huang, H. Li, Z. Zheng, Strength and structure variation of 2195 Al-Li alloy caused by different deformation processes of hot extrusion and cold-rolling. Trans. Nonferrous Met. Soc. China 30(4), 835–849 (2020). https://doi.org/10.1016/s1003-6326(20)65258-x

J. Zhang, G. Wu, L. Zhang, X. Zhang, C. Shi, J. Sun, Effect of Zn on precipitation evolution and mechanical properties of a high strength cast Al–Li–Cu alloy. Mater. Charact. (2020). https://doi.org/10.1016/j.matchar.2019.110089

D. Liu, Y. Ma, J. Li, R. Zhang, H. Iwaoka, S. Hirosawa, Precipitate microstructures, mechanical properties and corrosion resistance of Al-1.0 wt%Cu-2.5 wt%Li alloys with different micro-alloyed elements addition. Mater. Charact. (2020). https://doi.org/10.1016/j.matchar.2020.110528

D.H. StJohn, M. Qian, M.A. Easton, P. Cao, Z. Hildebrand, Grain refinement of magnesium alloys. Metall. Mater. Trans. A 36(7), 1669–1679 (2005). https://doi.org/10.1007/s11661-005-0030-6

Z. Zareian, M. Emamy, M. Malekan, H. Mirzadeh, W.J. Kim, A. Bahmani, Tailoring the mechanical properties of Mg–Zn magnesium alloy by calcium addition and hot extrusion process. Mater. Sci. Eng. A (2020). https://doi.org/10.1016/j.msea.2020.138929

R. Mahjoub, K.J. Laws, N. Stanford, M. Ferry, General trends between solute segregation tendency and grain boundary character in aluminium: an ab inito study. Acta Mater. 158, 257–268 (2018). https://doi.org/10.1016/j.actamat.2018.07.069

D. Zhao, O.M. Løvvik, K. Marthinsen, Y. Li, Segregation of Mg, Cu and their effects on the strength of Al Σ5 (210)[001] symmetrical tilt grain boundary. Acta Mater. 145, 235–246 (2018). https://doi.org/10.1016/j.actamat.2017.12.023

S. Zhang, O.Y. Kontsevoi, A.J. Freeman, G.B. Olson, First principles investigation of zinc-induced embrittlement in an aluminum grain boundary. Acta Mater. 59(15), 6155–6167 (2011). https://doi.org/10.1016/j.actamat.2011.06.028

J. Sun, L. Zhang, G. Wu, X. Zhang, M. Rong, C. Wang, Microstructural characteristics and mechanical properties of extruded Al-4Cu-1Li-0.4Mg-0.1Zr-xZn alloy. Mater. Sci. Eng. A 743, 223–232 (2019). https://doi.org/10.1016/j.msea.2018.11.050

Y. Wang, R. Wu, N. Turakhodjaev, M. Liu, Microstructural evolution, precipitation behavior and mechanical properties of a novel Al–Zn–Mg–Cu–Li–Sc–Zr alloy. J. Mater. Res. (2021). https://doi.org/10.1557/s43578-020-00005-4

L. Chen, Y. Li, J. Tang, G. Zhao, C. Zhang, Investigation on microstructure and mechanical properties of Al–5.50Zn–2.35Mg–1.36Cu alloy fabricated by hot extrusion process. J. Mater. Res. 34(18), 3151–3162 (2019). https://doi.org/10.1557/jmr.2019.268

Z.W. Huang, M.H. Loretto, J. White, Influence of lithium additions on precipitation and age hardening of 7075 alloy. Mater. Sci. Technol. 9(11), 967–980 (1993). https://doi.org/10.1179/mst.1993.9.11.967

J. Sun, Y. Ma, C. Gao, H. Luo, Comprehensive tensile properties improved by deep cryogenic treatment prior to aging in friction-stir-welded 2198 Al–Li alloy. Rare Met. (2019). https://doi.org/10.1007/s12598-019-01214-5

S. Wang, C. Zhang, X. Li, J. Wang, Uncovering the influence of Cu on the thickening and strength of the δ′/θ′/δ′ nano-composite precipitate in Al–Cu–Li alloys. J. Mater. Sci. (2021). https://doi.org/10.1007/s10853-021-05894-2

F. Wang, N. Wang, F. Yu, X. Wang, J. Cui, Study on micro-structure, solid solubility and tensile properties of 5A90 Al–Li alloy cast by low-frequency electromagnetic casting processing. J. Alloys Compd. (2020). https://doi.org/10.1016/j.jallcom.2019.153318

H. Sidhar, N.Y. Martinez, R.S. Mishra, J. Silvanus, Friction stir welding of Al–Mg–Li 1424 alloy. Mater. Des. 106, 146–152 (2016). https://doi.org/10.1016/j.matdes.2016.05.111

K.H. Lee, Y.J. Lee, K. Hiraga, Precipitation behavior in the early stage of aging in an Al–Li°Cu–Mg–Zr–Ag (Weldalite 049) alloy. J. Mater. Res. 14(2), 384–389 (1999). https://doi.org/10.1557/JMR.1999.0056

L. Mao, H. Jin, F. Ye, F. Wang, G. Zheng, S. Wu, Effect of thermal cycles on the laser beam welded joint of AA2060 alloys. J. Mater. Res. 33(20), 3439–3448 (2018). https://doi.org/10.1557/jmr.2018.229

J.W. Martin, Aluminum-lithium alloys. Annu. Rev. Mater. Sci. 18(1), 101–119 (1988). https://doi.org/10.1146/annurev.ms.18.080188.000533

C. Shi, G. Wu, L. Zhang, X. Zhang, Al–5.5Mg–1.5Li–0.5Zn–0.07Sc–0.07Zr alloy produced by gravity casting and heat treatment processing. Mater. Manuf. Processes 33(8), 891–897 (2017). https://doi.org/10.1080/10426914.2017.1401725

R.K. Gupta, N. Nayan, G. Nagasireesha, S.C. Sharma, Development and characterization of Al–Li alloys. Mater. Sci. Eng. A 420(1–2), 228–234 (2006). https://doi.org/10.1016/j.msea.2006.01.045

I.N. Fridlyander, V.S. Sandler, Alloy 1420 of the system Al-Mg-Li. Met. Sci. Heat Treat. 30(8), 594–602 (1988). https://doi.org/10.1007/BF00778264

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Nos. 51871148 and 51821001) and the United Fund of National Department of Education and Equipment Development (No. 6141A02033245). The authors are also grateful for the funding support by the National Key R&D Program of China (No. 2016YFB0301003).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Shi, C., Wu, G., Zhang, L. et al. Variation in the microstructure and mechanical properties of permanent mold cast Al–3Li–2Mg–0.1Zr alloy with Zn addition. Journal of Materials Research 36, 2071–2082 (2021). https://doi.org/10.1557/s43578-021-00236-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00236-z