Abstract

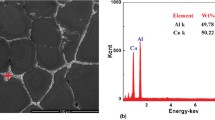

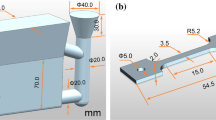

This work was undertaken to investigate the influences of Mg content on the microstructure and mechanical properties of cast Al–2Li–2Cu–0.2Zr alloy. The addition of increasing amounts of Mg led to continuous grain refinement of as-cast base alloy accompanied by the increased volume fraction of secondary phases distributed along grain boundaries or interdendritic regions. The tensile test results showed that Mg addition could greatly enhance the mechanical properties of the base alloy after subjected to the solution treatments and artificial ageing. The precipitation behavior and microstructural evolution were also investigated. The addition of Mg would facilitate the nucleation of δ′ (Al3Li) phases after quenching. The presence of Mg was observed to lower the growth rate of δ′ and δ′-precipitation-free zones (δ′-PFZs) of the base alloy. Precipitation of θ′ (Al2Cu) phase would be almost suppressed, and S′ (Al2CuMg) phase was consequently introduced due to Mg additions. The precipitation of S′ phases was encouraged at the expense of T1 (Al2CuLi) phases as the Mg content increased. The increased amount of S′ phases tended to coalesce to form coarse laths distributed in uneven manner for alloys with relatively high Mg content (≥ 1 wt%). No improvements in mechanical properties were observed in alloys with heterogeneous distribution of coarse S′ laths. The optimal Mg addition in cast Al–2Li–2Cu alloy was 0.5 wt%.

Similar content being viewed by others

References

Starke EA Jr, Sanders TH, Palmer IG (1981) New approaches to alloy development in the Al–Li system. JOM 33:24–33

Rioja RJ, Liu J (2012) The evolution of Al–Li base products for aerospace and space applications. Metall Mater Trans A 43:3325–3337

Abd El-Aty A, Xu Y, Guo X, Zhang S-H, Ma Y, Chen D (2018) Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al–Li alloys: a review. J Adv Res 10:49–67

Gilmore DL, Starke EA Jr (1997) Trace element effects on precipitation processes and mechanical properties in an Al–Cu–Li alloy. Metall Mater Trans A 28:1399–1415

Csontos AA, Starke EA Jr (2000) The effect of processing and microstructure development on the slip and fracture behavior of the 2.1 wt pct Li AF/C-489 and 1.8 wt pct Li AF/C-458 Al–Li–Cu–X alloys. Metall Mater Trans A 31:1965–1976

Gumbmann E, De Geuser F, Sigli C, Deschamps A (2017) Influence of Mg, Ag and Zn minor solute additions on the precipitation kinetics and strengthening of an Al–Cu–Li alloy. Acta Mater 133:172–185

Gable BM, Zhu AW, Csontos AA, Starke EA Jr (2001) The role of plastic deformation on the competitive microstructural evolution and mechanical properties of a novel Al–Li–Cu–X alloy. J Light Metals 1:1–14

Noble B, Thompson GE (1971) Precipitation characteristics of aluminium–lithium alloys. Metal Sci J 5:114–120

Silcock JM (1959–1960) The structural ageing characteristics of Al–Cu–Li alloys. J Inst Metals 88:357–364

Silcock JM, Heal TJ, Hardy HK (1954) Structural ageing characteristics of binary aluminium–copper alloys. J Inst Metals 82:239–248

Huang JC, Ardell AJ (1987) Crystal structure and stability of T1 precipitates in aged Al–Li–Cu alloys. Mater Sci Technol 3:176–188

Ratchev P, Verlinden B, De Smet P, Van Houtte P (1998) Precipitation hardening of an Al–4.2 wt% Mg–0.6 wt% Cu alloy. Acta Mater 46:3523–3533

Gupta AK, Gaunt P, Chaturvedi MC (1987) The crystallography and morphology of the S’-phase precipitate in an Al (CuMg) alloy. Philos Mag A 55:375–387

Srinivasan S, Desch PB, Schwarz RB (1991) Metastable phases in the Al3X (X = Ti, Zr, and Hf) intermetallic system. Scri Metall Mater 25:2513–2516

Kang S, Grant NJ (1987) Rapidly solidified P/M X2020 aluminum alloys. Metall Trans A 18:2037–2046

Ball MD, Lloyd DJ (1985) Particles apparently exhibiting five-fold symmetry in Al–Li–Cu–Mg alloys. Scr Metall 19:1065–1068

Gumbmann E, Lefebvre W, De Geuser F, Sigli C, Deschamps A (2016) The effect of minor solute additions on the precipitation path of an Al–Cu–Li alloy. Acta Mater 115:104–114

Kumar KS, Heubaum FH (1997) The effect of Li content on the natural aging response of Al–Cu–Li–Mg–Ag–Zr alloys. Acta Mater 45:2317–2327

Kim JD, Park JK (1993) Effect of stretching on the precipitation kinetics of an Al–2.0Li–2.8Cu–0.5Mg(–0.13Zr) alloy. Metall Trans A 24:2613–2621

Tsivoulas D, Prangnell PB (2014) The effect of Mn and Zr dispersoid-forming additions on recrystallization resistance in Al–Cu–Li AA2198 sheet. Acta Mater 77:1–16

Chen A, Zhang L, Wu G, Sun M, Liu W (2017) Influences of Mn content on the microstructures and mechanical properties of cast Al–3Li–2Cu–0.2Zr alloy. J Alloys Compd 715:421–431

Chen A, Wu G, Zhang L, Zhang X, Shi C, Li Y (2016) Microstructural characteristics and mechanical properties of cast Al–3Li–xCu–0.2Zr alloy. Mater Sci Eng A 677:29–40

Chen A, Peng Y, Zhang L, Wu G, Li Y (2016) Microstructural evolution and mechanical properties of cast Al–3Li–1.5Cu–0.2Zr alloy during heat treatment. Mater Charact 114:234–242

Zhang X, Zhang L, Wu G, Liu W, Shi C, Tao J, Sun J (2017) Microstructural evolution and mechanical properties of cast Al–2Li-2Cu-0.5Mg-0.2Zr alloy during heat treatment. Mater Charact 132:312–319

Mukhopadhyay AK, Zhou DS, Yang QB (1992) Effect of variation in the Cu: Mg ratios on the formation of T2 and C phases in AA 8090 alloys. Scri Metall Mater 26:237–242

Fridlyander IN, Rokhlin LL, Dobatkina TV, Nikitina NI (1993) Investigation of the phase equilibria in aluminum alloys containing lithium. Met Sci Heat Treat 35:567–571

Wang F, Liu Z, Qiu D, Taylor JA, Easton MA, Zhang M-X (2013) Revisiting the role of peritectics in grain refinement of Al alloys. Acta Mater 61:360–370

Liu YL, Hu ZQ, Zhang Y, Shi CX (1993) The solidification behavior of 8090 Al–Li alloy. Metall Trans B 24:857–865

Hekmat-Ardakan A, Elgallad EM, Ajersch F, Chen XG (2012) Microstructural evolution and mechanical properties of as-cast and T6-treated AA2195 DC cast alloy. Mater Sci Eng A 558:76–81

Dorward RC (1988) Solidus and solvus isotherms for quaternary Al–Li–Cu–Mg alloys. Metall Trans A 19:1631–1634

Gayle FW, Vander Sande JB (1984) “Composite” precipitates in an Al–Li–Zr alloy. Scr Metall 18:473–478

Gayle FW, Heubaum FH, Pickens JR (1990) Structure and properties during aging of an ultra-high strength Al–Cu–Li–Ag–Mg alloy. Scr Metall Mater 24:79–84

Gregson PJ, Flower HM, Tite CNJ, Mukhopadhyay AK (1986) Role of vacancies in coprecipitation of δ’- and S-phases in Al–Li–Cu–Mg alloys. Mater Sci Technol 2:349–353

Baumann SF, Williams DB (1985) Experimental observations on the nucleation and growth of δ’ (Al3Li) in dilute Al–Li alloys. Metall Trans A 16:1203–1211

Gleiter H, Hornbogen E (1965) Theorie der Wechselwirkung von Versetzungen mit kohärenten geordneten Zonen (I). Phys Status Solidi 12:235–250

Flower HM, Gregson PJ (1987) Solid state phase transformations in aluminium alloys containing lithium. Mater Sci Technol 3:81–90

Satya Prasad K, Gokhale AA, Mukhopadhyay AK, Banerjee D, Goel DB (1999) On the formation of faceted Al3Zr (β’) precipitates in Al–Li–Cu–Mg–Zr alloys. Acta Mater 47:2581–2592

Tsivoulas D, Robson JD (2015) Heterogeneous Zr solute segregation and Al3Zr dispersoid distributions in Al–Cu–Li alloys. Acta Mater 93:73–86

Gregson PJ, Flower HM (1985) Microstructural control of toughness in aluminium–lithium alloys. Acta Metall 33:527–537

Balducci E, Ceschini L, Messieri S, Wenner S, Holmestad R (2017) Thermal stability of the lightweight 2099 Al–Cu–Li alloy: tensile tests and microstructural investigations after overaging. Mater Des 119:54–64

Tosten MH, VasudÉvan AK, Howell PR (1988) The aging characteristics of an Al-2 Pct Li-3 Pct Cu-0.12 Pct Zr alloy at 190 °C. Metall Trans A 19:51–66

Noble B, Thompson GE (1972) T1 (Al2CuLi) precipitation in aluminium–copper–lithium alloys. Metal Sci J 6:167–174

Lynch SP, Muddle BC, Pasang T (2001) Ductile-to-brittle fracture transitions in 8090 Al–Li alloys. Acta Mater 49:2863–2874

Goswami R, Bernstein N (2015) Effect of interfaces of grain boundary Al2CuLi plates on fracture behavior of Al–3Cu–2Li. Acta Mater 87:399–410

Suresh S, Vasudevan AK, Tosten M, Howell PR (1987) Microscopic and macroscopic aspects of fracture in lithium-containing aluminum alloys. Acta Metall 35:25–46

Jha S, Sanders T, Dayananda M (1987) Grain boundary precipitate free zones in Al–Li alloys. Acta Metall 35:473–482

Beatrice CRS, Garlipp W, Cilense M, Adorno AT (1995) Vacancy-Mg atom binding energy in Al–Mg alloys. Scr Metall Mater 32:23–26

Hirosawa S, Sato T, Kamio A (1998) Effects of Mg addition on the kinetics of low-temperature precipitation in Al–Li–Cu–Ag–Zr alloys. Mater Sci Eng A 242:195–201

Acknowledgements

This work was supported by the National Key R&D Program of China (Grant No. 2016YFB0301003) and the 111 Project (Grant No. B16032).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical standards

This article does not contain any studies with human or animal subjects.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, X., Zhang, L., Wu, G. et al. Influences of Mg content on the microstructures and mechanical properties of cast Al–2Li–2Cu–0.2Zr alloy. J Mater Sci 54, 791–811 (2019). https://doi.org/10.1007/s10853-018-2826-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2826-y