Abstract

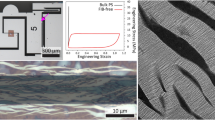

Specimen preparation is a critical aspect in electron microscopy and is particularly challenging for in situ investigations that require specimens to fit onto specific testing devices. We report a modification of a substrate lift-off technique for thin films that enables users to produce specimens for in situ nanomechanical tensile testing. By depositing an electron transparent film, removing it from its substrate, and mounting it to a Cu grid (which serves for preparatory staging), rectangular specimens are focus ion beam (FIB) milled and mounted to push-to-pull or similar MEMS-like devices for nanomechanical testing. Using the FIB, the gauge length is milled into a reduced cross-section yielding the ‘dog-bone’ geometry. This use of this Cu grid-staging significantly reduces mounting and thinning steps for the direct film-to-device preparation as well as allows the testing device to be used multiple times for new specimens. Finally, we reveal ion-induced grain growth with improper milling and solute induced grain boundary embrittlement in the nanocrystalline alloy studied.

Graphic abstract

Similar content being viewed by others

References

J. Kacher, C. Kirchlechner, J. Michler, E. Polatidis, R. Schwaiger, H. Van Swygenhoven, M. Taheri, M. Legros, Impact of in situ nanomechanics on physical metallurgy. Mrs Bull. 44, 465 (2019)

C. Gammer, J. Kacher, C. Czarnik, O. Warren, J. Ciston, A. Minor, Local and transient nanoscale strain mapping during in situ deformation . Appl Phys. Lett. 109, 081906 (2016)

D.C. Bufford, D. Stauffer, W.M. Mook, S. SyedAsif, B.L. Boyce, K. Hattar, High cycle fatigue in the transmission electron microscope. Nano Lett. 16, 4946 (2016)

A. Kobler, C. Kübel, Challenges in quantitative crystallographic characterization of 3D thin films by ACOM-TEM. Ultramicroscopy 173, 84 (2017)

E. Izadi, A. Darbal, R. Sarkar, J. Rajagopalan, Grain rotations in ultrafine-grained aluminum films studied using in situ TEM straining with automated crystal orientation mapping. Mater Des. 113, 186 (2017)

J.R. Greer, J.-Y. Kim, M.J. Burek, The in-situ mechanical testing of nanoscale single-crystalline nanopillars. JOM. 61, 19 (2009)

Q. Yu, M. Legros, A.M. Minor, situ TEM nanomechanics. MRS Bull. 40, 62 (2015)

A. Kobler, C. Brandl, H. Hahn, C. Kübel, In situ observation of deformation processes in nanocrystalline face-centered cubic metals. Beilstein J. Nanotech. 7, 572 (2016)

A. Kobler, A. Kashiwar, H. Hahn, C. Kübel, Combination of in situ straining and ACOM TEM: A novel method for analysis of plastic deformation of nanocrystalline metals. Ultramicroscopy 128, 68 (2013)

D. Kiener, C. Motz, G. Dehm, R. Pippan, Overview on established and novel FIB based miniaturized mechanical testing using in-situ SEM. Int. J. Mat. Res. 100, 1074 (2009)

M. Legros, D. Gianola, C. Motz, Quantitative in situ mechanical testing in electron microscopes. MRS Bull. 35, 354 (2010)

F.R. Brotzen, Mechanical testing of thin films. Int. Mat. Rev. 39, 24 (1994)

J. Kacher, Q. Yu, C. Chisholm, C. Gammer and A.M. Minor: In Situ TEM Nanomechanical Testing, in MEMS and Nanotechnology, Volume 5, (Springer, City, 2016), pp. 9.

S. Bhowmick, H. Espinosa, K. Jungjohann, T. Pardoen, O. Pierron, Advanced microelectromechanical systems-based nanomechanical testing: Beyond stress and strain measurements. MRS Bull. 44, 487 (2019)

Q. Guo, G.B. Thompson, In-situ Indentation and Correlated Precession Electron Diffraction Analysis of a Polycrystalline Cu Thin Film. JOM. 70, 1081 (2018)

Q. Guo, Y. Gu, C.M. Barr, T. Koenig, K. Hattar, L. Li, G.B. Thompson, In situ indentation and high cycle tapping deformation responses in a nanolaminate crystalline/amorphous metal composite. Mater. Sci. Eng. A 798, 140074 (2020)

M.-R. He, S.K. Samudrala, G. Kim, P.J. Felfer, A.J. Breen, J.M. Cairney, D.S. Gianola, Linking stress-driven microstructural evolution in nanocrystalline aluminium with grain boundary doping of oxygen. Nat Commun. 7, 11225 (2016)

J. Kacher, T. Zhu, O. Pierron, D.E. Spearot, Integrating in situ TEM experiments and atomistic simulations for defect mechanics. Cur. Op. Sol. St. Mat. Sci. 23, 117 (2019)

S. Gupta, S. Stangebye, K. Jungjohann, B. Boyce, T. Zhu, J. Kacher, O.N. Pierron, In situ TEM measurement of activation volume in ultrafine grained gold. Nanoscale 12, 7146 (2020)

H. Van Swygenhoven, M. Spaczer, A. Caro, D. Farkas, Competing plastic deformation mechanisms in nanophase metals. Phys. Rev. B 60, 22 (1999)

H. Vehoff, D. Lemaire, K. Schüler, T. Waschkies, B. Yang, The effect of grain size on strain rate sensitivity and activation volume–from nano to UFG nickel. Int. J. Mater. Res. 98, 259 (2007)

J. Stinville, E.R. Yao, P.G. Callahan, J. Shin, F. Wang, M.P. Echlin, T.M. Pollock, D.S. Gianola, Dislocation dynamics in a nickel-based superalloy via in-situ transmission scanning electron microscopy. Acta Mater. 168, 152 (2019)

D. Chang and W. Sharpe Jr: Mechanical analysis and properties of MEMS materials. Microeng. Aerospace Syst. 73 (1999).

D.S. Gianola, C. Eberl, Micro-and nanoscale tensile testing of materials. JOM. 61, 24 (2009)

Y. Zhu, T.-H. Chang, A review of microelectromechanical systems for nanoscale mechanical characterization. J. Micromech. Microeng. 25, 093001 (2015)

R.A. Bernal, R. Ramachandramoorthy, H.D. Espinosa, Double-tilt in situ TEM holder with multiple electrical contacts and its application in MEMS-based mechanical testing of nanomaterials. Ultramicroscopy 156, 23 (2015)

Y. Yang, Z. Fu, X. Zhang, Y. Cui, F. Xu, T. Li, Y. Wang, Situ TEM mechanical characterization of one-dimensional nanostructures via a standard double-tilt holder compatible MEMS device. Ultramicroscopy 198, 43 (2019)

H.J. Qu, K.H. Yano, P.V. Patki, M.J. Swenson, J.P. Wharry, Understanding plasticity in irradiated alloys through TEM in situ compression pillar tests. J. Mater. Res. 35, 1037 (2020)

S. Bhowmick, E. Hintsala, D. Stauffer, S.A.S. Asif, In situ TEM study of friction and wear of olivine. Microsc. Microanal. 25, 1898 (2019)

V. Samaeeaghmiyoni, H. Idrissi, J. Groten, R. Schwaiger, D. Schryvers, Quantitative in-situ TEM nanotensile testing of single crystal Ni facilitated by a new sample preparation approach. Micron 94, 66 (2017)

P.H. Warren, G. Warren, M. Dubey, J. Burns, Y.Q. Wu, J.P. Wharry, Method for fabricating depth-specific TEM in situ tensile bars. JOM. 72, 2057 (2020)

H. Idrissi, A. Kobler, B. Amin-Ahmadi, M. Coulombier, M. Galceran, J.-P. Raskin, S. Godet, C. Kübel, T. Pardoen, D. Schryvers, Plasticity mechanisms in ultrafine grained freestanding aluminum thin films revealed by in-situ transmission electron microscopy nanomechanical testing. Appl. Phys. Lett. 104, 101903 (2014)

S.H. Oh, M. Legros, D. Kiener, G. Dehm, Situ observation of dislocation nucleation and escape in a submicrometre aluminium single crystal. Nat. Mat. 8, 95 (2009)

M. Mačković, T. Przybilla, C. Dieker, P. Herre, S. Romeis, H. Stara, N. Schrenker, W. Peukert, E. Spiecker, A novel approach for preparation and in situ tensile testing of silica glass membranes in the transmission electron microscope. Front. Mater. 4, 24–26 (2017)

S. Bhowmick, D. Stauffer, H. Guo, S. Kaps, Y.K. Mishra, V. Hrkac, O. Warren, R. Adelung, A. Minor, L. Kienle, In situ electromechanical study of ZnO nanowires. Microsc. Microanal. 19, 434 (2013)

S. Kaps, S. Bhowmick, J. Gröttrup, V. Hrkac, D. Stauffer, H. Guo, O. Warren, J. Adam, L. Kienle, A. Minor, R. Adelung, Y. Mishra, Piezoresistive response of quasi-one-dimensional ZnO nanowires using an in situ electromechanical device. ACS Omega 2, 2985 (2017)

K. Kim, J.C. Yoon, J. Kim, J.H. Kim, S.W. Lee, A. Yoon, Z. Lee, Dedicated preparation for in situ transmission electron microscope tensile testing of exfoliated graphene. Appl. Microsc. 49, 3 (2019)

C. Cao, J.Y. Howe, D. Perovic, T. Filleter, Y. Sun, In situ TEM tensile testing of carbon-linked graphene oxide nanosheets using a MEMS device. Nanotech. 27, 28 (2016)

H. Idrissi, C. Bollinger, F. Boioli, D. Schryvers, P. Cordier, Low-temperature plasticity of olivine revisited with in situ TEM nanomechanical testing. Sci. Adv. 2, 64 (2016)

H. Idrissi, V. Samaee, G. Lumbeeck, T. van der Werf, T. Pardoen, D. Schryvers, P. Cordier, In situ quantitative tensile testing of antigorite in a transmission electron microscope. J. Geophys. Res. 125, 89 (2020)

E.D. Hintsala, D.D. Stauffer, Y. Oh, S.S. Asif, In situ TEM scratch testing of perpendicular magnetic recording multilayers with a novel MEMS tribometer. JOM. 69, 51 (2017)

J. Ye, R.K. Mishra, A.K. Sachdev, A.M. Minor, In situ TEM compression testing of Mg and Mg–02wt% Ce single crystals. Scr. Mater. 64, 292 (2011)

J. Mayer, L.A. Giannuzzi, T. Kamino, J. Michael, TEM sample preparation and FIB-induced damage. MRS Bull. 32, 400 (2007)

X. Li, A.M. Minor, Precise measurement of activation parameters for individual dislocation nucleation during in situ TEM tensile testing of single crystal nickel. Scr Mater. 197, 113764 (2021)

G. Sáfrán, P. Panine, A novel method for the cross-sectional TEM preparation of thin films deposited onto water-soluble substrates. Microsc. Res. Tech. 25, 346 (1993)

K. Peng, Y. Liu, I. Lin, C. Lin, S. Huang and C. Ting: The Development of Low-Temperature Atomic Layer Deposition of HfO2 for TEM Sample Preparation on Soft Photo-Resist Substrate, in 2018 IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits (IPFA), (City, 2018), pp. 1.

H. Heidari, G. Rivero, H. Idrissi, D. Ramachandran, S. Cakir, R. Egoavil, M. Kurttepeli, A.C. Crabbé, T. Hauffman, H. Terryn, F. Du Prez, D. Schryvers, Melamine-formaldehyde microcapsules: micro- and nanostructural characterization with electron microscopy. Microsc. Microanal. 22, 1222 (2016)

Y.F. Shen, W.Y. Xue, Y.D. Wang, Z.Y. Liu, L. Zuo, Mechanical properties of nanocrystalline nickel films deposited by pulse plating. Surf. Coat. Tech. 202, 5140 (2008)

Y. Wang, A. Hamza, E. Ma, Temperature-dependent strain rate sensitivity and activation volume of nanocrystalline Ni. Acta Mater. 54, 2715 (2006)

R. Schwaiger, B. Moser, M. Dao, N. Chollacoop, S. Suresh, Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Mater. 51, 5159 (2003)

Y. Greenzweig, Y. Drezner, S. Tan, R.H. Livengood, A. Raveh, Current density profile characterization and analysis method for focused ion beam. Microelect. Eng. 155, 19 (2016)

Y. Drezner, Y. Greenzweig, S. Tan, R.H. Livengood, A. Raveh, High resolution TEM analysis of focused ion beam amorphized regions in single crystal silicon: a complementary materials analysis of the teardrop method. J. Vac. Sci. Tech. B 35, 011801 (2016)

D. Kiener, C. Motz, M. Rester, M. Jenko, G. Dehm, FIB damage of Cu and possible consequences for miniaturized mechanical tests. Mat. Sci. Eng. A 459, 262 (2007)

K. Thompson, B. Gorman, D. Larson, B.V. Leer, L. Hong, Minimization of Ga induced FIB damage using low energy clean-up. Microsc. Microanal. 12, 1736 (2006)

S. Srinivasan, C. Kale, B.C. Hornbuckle, K.A. Darling, M.R. Chancey, E. Hernández-Rivera, Y. Chen, T.R. Koenig, Y.Q. Wang, G.B. Thompson, K.N. Solanki, Radiation tolerance and microstructural changes of nanocrystalline Cu-Ta alloy to high dose self-ion irradiation. Acta Mater. 195, 621 (2020)

J. Gupta, J.M.E. Harper, J.L.M. Iv, P.G. Blauner, D.A. Smith, Focused ion beam imaging of grain growth in copper thin films. Appl. Phy. Lett. 61, 663 (1992)

D. Kaoumi, A.T. Motta, R. Birtcher, Grain growth in nanocrystalline metal thin films under in situ ion-beam irradiation. J. ASTM Int. 4, 1 (2007)

A. Gupta, X. Zhou, G.B. Thompson, G.J. Tucker, Role of grain boundary character and its evolution on interfacial solute segregation behavior in nanocrystalline Ni-P. Acta Mater. 190, 113 (2020)

W.T. Geng, A.J. Freeman, R. Wu, C.B. Geller, J.E. Raynolds, Embrittling and strengthening effects of hydrogen, boron, and phosphorus on a Sigma5 nickel grain boundary. Phys. Rev. B. 60, 7149 (1999)

M. Yamaguchi, M. Shiga, H. Kaburaki, Grain boundary decohesion by impurity segregation in a nickel-sulfur. Sys. Sci. 307, 393 (2005)

D. Lee, E. Barrera, J. Stark, H. Marcus, The influence of alloying elements on impurity induced grain boundary embrittlement. Metall. Trans. A 15, 1415 (1984)

M.P. Seah, A. Kelly, Segregation and the strength of grain boundaries. Proc. R Soc. Lond. A 349, 535 (1976)

Acknowledgments

The authors gratefully acknowledge support from the Army Research Office, grant ARO-W911NF-17-1-0528, Dr. Michael Bakas program manager. Alabama Analytical Research Center (ARC) at the University of Alabama is also acknowledged for the use of the SEM/FIB and TEM instruments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bikmukhametov, I., Koenig, T.R., Tucker, G.J. et al. A rapid preparation method for in situ nanomechanical TEM tensile specimens. Journal of Materials Research 36, 2315–2324 (2021). https://doi.org/10.1557/s43578-021-00167-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00167-9