Abstract

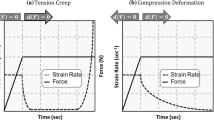

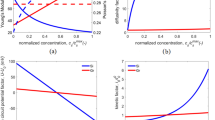

Next-generation batteries owe their energy increases to lithium anodes, whose mechanical properties, such as flow stress, are poorly understood and yet critical to the design of long life, stable electrodes. The purpose of this study was to determine the main sensitivities of lithium metal’s compression flow stress as a function of aspect ratio (AR), strain rate (SR), and temperature. The flow stress at room temperature increased with a decreasing AR (1.86 MPa at the AR of 0.045 and the SR of 1 × 10–3) and increasing SR (1.39 MPa at 1.0 s−1 SR and a base AR of 2). The impact of geometric size (AR) and SR was shown to be cumulative with a peak flow stress of 1.91 MPa at the AR of 0.23 and 1.0 s−1 SR at room temperature. Additionally, as temperature increased, the flow stress significantly decreased (i.e., 0.21 MPa at 132 °C, TH = 0.90 and base SR and AR) across all ARs.

Graphic Abstract

Similar content being viewed by others

References

A. Masias, Lithium ion battery design for transportation, in Behavior of lithium-ion batteries in electric vehicles: battery health, performance, safety, and cost. ed. by G. Pistoia, B. Liaw (Springer, Cham, 2018), pp. 1–34

P. Albertus, S. Babinec, S. Litzelman, A. Newman, Status and challenges in enabling the lithium metal electrode for high-energy and low-cost rechargeable batteries. Nat. Energy 3, 16–21 (2018)

B.D. McCloskey, Status and challenges in enabling the lithium metal electrode for high-energy and low-cost rechargeable batteries. J. Phys. Chem. Lett. 6(22), 4581–4588 (2015)

United States Advanced Battery Consortium (2018). USABC goals for advanced batteries for EVS—CY 2020 commercialization. https://www.uscar.org/commands/files_download.php?files_id=364. Accessed 23 July 2018

A. Masias, N. Felten, R. Garcia-Mendez, J. Wolfenstine, J. Sakamoto, Elastic, plastic and creep mechanical properties of lithium metal. J. Mater. Sci. 54(3), 2585–2600 (2019)

E.G. Herbert, S.A. Hackney, N.J. Dudney, P.S. Phani, Nanoindentation of high-purity vapor deposited lithium films: the elastic modulus. J. Mater. Res. 33(10), 1335–1346 (2018)

S. Yu, R.D. Schmidt, R. Garcia-Mendez, R. Herbert, N.J. Dudney, J.B. Wolfenstine, J. Sakamoto, D.J. Siegel, Elastic properties of the solid electrolyte Li7La3Zr2O12 (LLZO). Chem. Mater. 28, 197–206 (2016)

E.J. Cheng, A. Sharafi, J. Sakamoto, Intragranular Li metal propagation through polycrystalline Li6.25Al0.25La3Zr2O12 ceramic electrolyte. Electrochim. Acta 223, 85–91 (2017)

A. Sakuda, A. Hayashi, Y. Takigawa, K. Higashi, M. Tatsumisago, Evaluation of elastic modulus of Li2S–P2S5 glassy solid electrolyte by ultrasonic sound velocity measurement and compression test. J. Ceram. Soc. Jpn. 121, 946–949 (2013)

C. Xu, Z. Ahmad, A. Aryanfar, V. Viswanathan, J.R. Greer, Enhanced strength and temperature dependence of mechanical properties of Li at small scales and its implications for Li metal anodes. Proc. Nat. Acad. Sci. 114, 57–61 (2017)

M. Aubin, Direct mesaurement measurement of nanosized li dendrite growth stress by in situ TEM Abstract # EN05.08.12, Materials Research Society 2019 Fall Conference, Boston, MA (2019)

E.G. Herbert, S.A. Hackney, V. Thole, Nanoindentation of high-purity vapor deposited lithium films: a mechanistic rationalization of diffusion-mediated flow. J. Mater. Res. 33(10), 1347–1360 (2018)

R. Schultz, Lithium: measurement of young’s modulus and yield strength. Fermilab Tech. Memo 2191, 1–6 (2002)

W.S. LePage, Y. Chen, E. Kazyak, K. Chen, A.J. Sanchez, A. Poli, E. Arruda, M.D. Thouless, N.P. Dasgupta, Lithium mechanics: roles of strain rate and temperature and implications for lithium metal batteries. J. Electrochem. Soc. 166(166), A89–A97 (2019)

S. Tariq, K. Ammigan, P. Hurh, R. Schultz, Li material testing- fermilab antiproton source lithium collection lens, in Proceedings 2003 particle accelerator conference. (IEEE, Piscataway, 2003), pp. 1452–1454. https://doi.org/10.1109/PAC.2003.1288558

M.J. Wang, R. Choudhury, J. Sakamoto, Characterizing the Li-solid-electrolyte interface dynamics as a function of stack pressure and current density. Joule 3, 1–14 (2019)

T. Krauskopf, H. Hartmann, W.G. Zeier, J. Janek, Toward a fundamental understanding of the lithium metal anode in solid-state batteries—an electrochemo-mechanical study on the garnet-type solid electrolyte Li6.25Al0.25La3Zr2O12. ACS Appl. Mater. Interfaces 11, 14463–14477 (2019)

J. Kasemchainan, S. Zekoll, D. Spencer Jolly, Z. Ning, G.O. Hartley, J. Marrow, P.G. Bruce, Critical stripping current leads to dendrite formation on plating in lithium anode solid electrolyte cells. Nat. Mater. 18, 1105–1111 (2019)

J. Sakamoto, More pressure needed. Nat. Energy 4, 827–828 (2019)

M. Cook, E.C. Larke, Resistance of copper and copper alloys to homogenous deformation in compression. J. Inst. Metals 71(12), 371–390 (1945)

W.F. Hosford, R.M. Caddell, Metal Forming: Mechanics and Metallurgy (Cambridge University Press, Cambridge, 1993).

C. Zener, H. Hollomon, Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 1944(15), 22–32 (1944)

S. Arrhenius, Über die Reaktionsgeschwindigkeit bei der Inversion von Rohrzucker durch Säuren. Zeitschrift für Physikalische Chemie 4, 226–248 (1889)

J.H. Holloman, Tensile deformation. Transit. Metal. Soc. AIME 12, 268–290 (1945)

K. Huang, R.E. Loge, A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 111, 548–574 (2016)

D. Hull, H. Rosenberg, The deformation of lithium, sodium and potassium at low temperatures: tensile and resistivity experiments. Phil. Mag. 4(39), 303–315 (1959)

C.D. Fincher, D. Ojeda, Y. Zhang, G.M. Pharr, M. Pharr, Mechanical properties of metallic lithium: from nano to bulk scales. Acta Mater. 186, 215–222 (2020)

ASTM E9–09, Standard test methods of compression testing of metallic materials at room temperature (2018). Retrieved from https://www.astm.org/DATABASE.CART/HISTORICAL/E9-09R18.htm. Accessed 10 July 2020

W.F. Hosford, Mechanical Behavior of Materials, 2nd edn. (Cambridge University Press, Cambridge, 2010).

R.M. Brick, Structure and Properties of Engineering Materials, 4th edn. (McGraw-Hill, New York, 1977).

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, J.J. Jonas, Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater Sci. 60, 130–207 (2014)

F.W. Boulger, DMIC Report 226 (Battelle Memorial Institute, Columbus, 1966), pp. 13–37

ASTM E8/E8M-16a, Standard test methods for tension testing of metallic materials (2015). Retrieved from https://www.astm.org/DATABASE.CART/HISTORICAL/E8E8M-16A.htm. Accessed 10 July 2020

C. Monroe, J. Newman, The impact of elastic deformation on deposition kinetics at lithium/polymer interfaces. J. Electrochem. Soc. 152(2), A396–A404 (2005)

A. Ferrese, J. Newman, Mechanical deformation of a lithium-metal anode due to a very stiff separator. J. Electrochem. Soc. 161(9), A1350–A1359 (2014)

J.E. Ni, E.D. Case, J.S. Sakamoto, E. Rangasamy, J.B. Wolfenstine, Room temperature elastic moduli and Vickers hardness of hot-pressed LLZO cubic garnet. J. Mater. Sci. 47, 7978–7985 (2012)

S. Harris, X. Zhang, J.Q. Wang, K. Harrison, S. Roberts, Time-dependent multi-scale theory and simulation for contact between Li metal Abstract # EN05.04.07, Materials Research Society 2019 Fall Conference, Boston, MA (2019)

United States Advanced Battery Consortium (2019). Development of lithium electrode based cell and manufacturing for automotive traction applications. http://www.uscar.org/commands/files_download.php?files_id=504. Accessed 17 Dec 2019

J. Frenkel, The theory of the elastic limit and the solidity of crystal bodies. Z. Angew. Phys. 37, 572–609 (1926)

Instron 5940 Series Single Column Tabletop Product Description. Retrieved from https://www.instron.us/-/media/literaturelibrary/manuals/5940-single-column-table-frames.pdf?la=en. Accessed 10 July 2020

Acknowledgments

The Ford-University Michigan Alliance program (Grant # UM0163) funding support is acknowledged. Thanks are given to Jeff Wolfenstine and Kent Snyder for helpful conversations.

Author information

Authors and Affiliations

Corresponding author

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Masias, A., Felten, N. & Sakamoto, J. Characterizing the mechanical behavior of lithium in compression. Journal of Materials Research 36, 729–739 (2021). https://doi.org/10.1557/s43578-020-00028-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-020-00028-x