Abstract

Germanium nanocrystals embedded in high-k dielectric matrices are of main interest for infrared sensing application, as a role model for Ge-based nanoelectronics passivation or for nonvolatile memory devices. The capability of the size control of those nanocrystals via rapid thermal processing of superlattice structures is shown for the [Ge–TaZrOx/TaZrOx]n, [Ge–TaZrOx/SiO2/TaZrOx]6, and [TaZrOx/Ge–SiO2]n superlattice systems. All superlattices were deposited by radiofrequency magnetron sputtering. Transmission electron microscopy (TEM) imaging confirms the formation of spherically shaped nanocrystals. Raman scattering proved the crystallization of Ge above 700°C. The TaZrOx crystallizes above 770°C, associated with a phase separation of Ta2O5 and ZrO2 as confirmed by x-ray diffraction. For the composite layers having 3 nm and 6 nm thickness, the size of the Ge nanocrystals correlates with the deposited layer thickness. Thicker composite layers (above 9 nm) form two fractions of nanocrystals with different sizes. An additional SiO2 layer in the [Ge–TaZrOx/SiO2/TaZrOx]6 superlattice stacks facilitates the formation of larger and better separated Ge nanocrystals. The deposition of Ge-SiO2 composite layers separated by pure TaZrOx illustrates the barrier effect of TaZrOx against Ge diffusion. All three material systems allow the controlled formation of Ge nanocrystals in amorphous matrices at temperatures above 700 and below 770°C.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Impact statement

The use of germanium nanocrystals for applications, such as floating gate memory cells, is very difficult due to challenges in size and position control. This article presents important steps toward the solution of those challenges in the material system germanium/tantalumzirconiumoxide. Our path allows the formation of electrically isolated nanocrystals between 3 and 6 nm in diameter embedded in an amorphous high-k matrix. In comparison to our previous publication, which mentioned the general possibility of size-controlled germanium nanocrystals in tantalumzirconiumoxide, details and limits of this material system and the influence of an additional SiO2 interlayer are shown here.

Introduction

Semiconductor nanocrystals embedded in dielectric matrices have been widely studied over the last decades. In particular, Si and Ge nanocrystals are considered for applications as absorbers for the third generation of solar cells,1 as sensitizers enhancing the luminescence of rare earth elements,2, 3 as light emitters4 for integrated photonics, and as charge storage nodes for nanocrystal-based nonvolatile memory devices.5, 6

Ge nanocrystals are compatible with current CMOS technologies and offer benefits compared to Si nanocrystals such as a lower crystallization temperature and larger exciton Bohr radius. The synthesis of Ge nanocrystals can be realized by Ge ion implantation into an oxide matrix7 or by deposition of Ge-rich oxide films using chemical vapor deposition (CVD),8 sputtering techniques,9 or evaporation10 followed by thermally triggered phase separation and Ostwald ripening of Ge clusters and their crystallization. The size control is normally realized by adjusting the Ge content in the oxide matrix11 or using tailored annealing temperatures12,13,14 or annealing times.15 However, the broad size distributions resulting from these methods may deteriorate the electronic and optical properties of the final devices.

A more promising way to prepare nanocrystals of controlled size, position, and areal density is a high-temperature treatment of superlattice structures. When annealing alternating composite (semiconductor and matrix material) and pure (matrix material only) layer stacks, the interplay between Gibbs energy and interface energy restricts the formation of the semiconductor nanocrystals to roughly the thickness of the mixed layers.

This approach was initially applied to obtain Si nanocrystals in a SiO2 matrix.16, 17 For Ge, this approach was documented by Zschintzsch et al.,18 who used a periodic arrangement of thin Ge-rich GeOx layers separated by SiO2 layers. In the case of this approach, the prevention of Ge diffusion into the separation layer is one important requirement. Therefore, the choice of the separation layer material is crucial. Only if the material is a good barrier against the Ge diffusion, the position and size of the Ge nanocrystals can be controlled by the location of the Ge-rich layers and by its thicknesses, respectively. Furthermore, the thickness of the separation layers determines the distances between the layers containing Ge nanocrystals and hence the nanocrystal density across the stack.19 There are several studies about embedding Ge nanocrystals in different matrix materials like AlOx,20, 21 SiC,22 or GeOx.23

In this study, ZrO2-based matrix materials are used. ZrO2 shows good barrier properties against Ge diffusion,24 and possesses a high bandgap of 5.1–7.1 eV25, 26 as well as a high permittivity of 20–47 depending on its crystal structure.27 Because of the marginal miscibility of ZrO2 and Ge, the growth of Ge nanocrystals within a ZrO2 matrix is possible via phase segregation of Ge from Ge-rich Ge-ZrOx layers separated by ZrO2 layers. Attempts have been made to use [Ge-ZrOx/ZrO2] superlattices for controlled formation of Ge nanocrystals within a ZrO2 matrix.28,29,30 However, this approach has two drawbacks. It leads to the formation of elongated Ge clusters with insufficiently controlled size, shape and spatial distribution.28 Furthermore, the crystallization of Ge and ZrO2 occurs simultaneously at about 660°C.9, 24

Amorphous matrices provide potentially better passivation of the nanocrystal surface, which is required to observe quantum confinement effects by preventing the instant recombination of an exciton31 and can suppress leakage currents through the stack more efficiently (due to the absence of grain boundaries). The latter effect helps to suppress discharging of the nanocrystals across the blocking oxide, if the Ge nanocrystals are used in nonvolatile memories.32

Recently, it has been shown that the crystallization temperature of ZrO2 can be increased by adding tantalum into the ZrO2 layers.33 Based on this result, the work presented here discusses the use of TaZrOx as separation layers in [Ge–TaZrOx/TaZrOx]n superlattices for controlled formation of Ge nanocrystals within an amorphous high-k matrix. For this purpose, [Ge–TaZrOx/TaZrOx]n superlattices with different thicknesses of the periodic motif were deposited and subjected to a rapid thermal annealing process. Furthermore, the effect of additional SiO2 separation layers on the formation of Ge nanocrystals in [Ge–TaZrOx/SiO2/TaZrOx]6 superlattice stacks was studied. For comparison, the formation of separated Ge nanocrystals with controlled size in [Ge–SiO2/TaZrOx] superlattice structures was investigated as well.

Experimental

The [Ge–TaZrOx/TaZrOx]10, [Ge–TaZrOx/SiO2/TaZrOx]6, and [TaZrOx/Ge–SiO2]n stacks were fabricated using an rf magnetron sputtering system, equipped with three plasma sources carrying 3″ Ge, ZrO2/Ta2O5 and SiO2 targets, respectively. In the sputtering chamber, the targets are arranged confocally in a top-down approach above the substrate, which is rotated during the deposition. The sputtering processes were performed by an argon plasma, without substrate heating, at a pressure of 5.2·10−3 mbar. The applied power densities, used for the deposition of the respective layer, are given in Table I. As substrates, 〈100〉 silicon wafers were used, which were subjected to a standard RCA cleaning procedure, dipped in diluted hydrofluoric acid, and immediately transferred to an oxidation chamber to form a 3-nm-thin SiO2 layer by dry oxidation. The Ge–TaZrOx composite layers were co-sputtered using a confocal arrangement of a Ge target and a mixed ZrO2/Ta2O5 target with a Ta content of 17 at.%. Pure TaZrOx and pure SiO2 layers were deposited by sputtering only the ZrO2/Ta2O5 or the SiO2 target, respectively. To avoid the evaporation of volatile GeO and the oxidation of Ge in the layers during annealing, all stacks were covered by a top 10-nm SiO2 capping layer.

Four different superlattice structures were deposited. Superlattice SL1 is a [Ge–TaZrOx/TaZrOx]10 stack consisting of 10 periods of alternating Ge–TaZrOx composite and pure TaZrOx separation layers with a thickness of 5 nm each. In order to reveal the influence of the Ge–TaZrOx composite layer thickness on the nanocrystal size, a [Ge–TaZrOx/TaZrOx]4 stack with four composite layers of varied thickness between 3 and 12 nm and a constant Ge concentration was fabricated (SL2). To show the influence of a SiO2 layer on the phase separation and nucleation processes, a [SiO2/Ge–TaZrOx/TaZrOx]6 stack was fabricated (SL3), comprising an additional SiO2 interlayer beneath each composite layer. For comparison a [Ge–SiO2/TaZrOx]9 superlattice was sputtered (SL4). The detailed sputtering conditions are given in Table I.

The chemical composition of the as-deposited films (SL1, SL2, and SL3) was determined by Rutherford backscattering spectrometry (RBS) using helium ions with an energy of 1.7 MeV (normal incidence, scattering angle 170°). For the RBS experiments, single composite films were deposited on glassy carbon substrates (to enable a background-free oxygen signal) using the same deposition conditions as previously stated. According to RBS, the Ge-rich layers contained 19 at.% Ge, 12 at.% Ta, 9 at.% Zr, and 60 at.% O in the case of SL1 and 36 at.% Ge, 9 at.% Ta, 7 at.% Zr, and 48 at.% O in the case of SL2 and SL3. The chemical composition of the separation layers is always 17 at.% Ta, 12 at.% Zr, and 71 at.% of O. The relative uncertainties of about 5% for the heavy elements Ge, Zr, and Si with well-known cross sections are smaller than the relative uncertainty for O (about 10%).

To trigger the segregation and crystallization processes, the multilayer stacks were annealed for 30 s at temperatures between 650ºC and 800°C in a nitrogen atmosphere using a rapid thermal processing (RTP) tool.

The size, form, and spatial distribution of the Ge nanoclusters were analyzed on cross-section specimens using a JEOL 2200 FS transmission electron microscope (TEM), which is equipped with a corrector for spherical aberration in the illumination system. In order to enhance the visibility of the nanoclusters, the Fresnel defocus mode was employed, which can lead to an overestimation of the crystallite size.

Raman scattering and glancing angle x-ray diffraction (GAXRD) measurements were performed to study the crystallization temperatures of individual phases in this system. All Raman spectra were detected in the 50–600 cm−1 spectral range using a LabRAM HR 800 spectrometer (Horiba Jobin Yvon) with a thermoelectrically cooled CCD detector. The spectrometer was equipped with gratings of 1800 grooves/mm. Raman scattering was excited by a 532-nm (2.33 eV) spectral line of a frequency-doubled Nd:YAG laser. The linearly polarized laser beam was focused on the sample surface using a 100× Olympus microscope objective (numerical aperture 0.80) with a long working distance. In order to avoid laser-induced heating or thermal decomposition of the samples, the applied laser power was adjusted by a filter and kept very low (0.4–0.5 mW).

The GAXRD patterns were measured with a thin-film diffractometer (X'Pert from PANalytical), which was equipped with a 0.4° equatorial Soller collimator and with a planar Ge monochromator, both located in the diffracted beam. CuKα radiation (λ1 = 0.15406 nm and λ2 = 0.15444 nm) was used. The GAXRD patterns were collected in a 2θ range between 10° and 90° at a fixed glancing angle of incidence of 1°. The small incidence angle reduces the penetration depth of x-rays into the sample and increases the scattering power of the thin films. In order to avoid the substrate reflection 311, all samples were mounted with a 45° rotation between the [001] direction of the (100)-oriented Si wafer and the diffraction plane. The instrumental broadening of the diffractometer was determined using a LaB6 standard from NIST. To interpret the GAXRD pattern Rietveld analysis, performed with the MAUD software were used.34, 35

Results and discussion

Formation of Ge nanocrystals in Ge–TaZrOx/TaZrOx superlattices [SL1]

Rapid thermal annealing triggers the segregation of Ge from originally intermixed continuous Ge–TaZrOx layers and stimulates the desired nucleation, growth, and crystallization of Ge nanoclusters, but also the undesirable crystallization of the TaZrOx matrix. Therefore, the temperature of the rapid thermal annealing must be adjusted between the crystallization temperatures of Ge and TaZrOx.

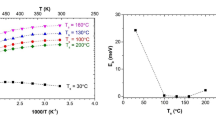

The crystallization temperature of the Ge nanoparticles was determined using Raman spectroscopy on the superlattice stack SL1, having 19 at.% Ge in the Ge-rich layers. Individual samples were annealed at temperatures between 650ºC and 800°C (Figure 1). The Raman spectra of the as-deposited sample and the sample annealed at 650°C show a broad band at about 275 cm−1, which is a feature of the amorphous contributions of Ge and matrix.24 The weak signal at around 300 cm−1 is the second order transverse acoustic (2TA) phonon mode of the silicon substrate.36 The transition from amorphous Ge (or from Ge dissolved in Ge–TaZrOx) to crystalline Ge is observable between 650ºC and 700°C, as indicated by the steep increase of the intensity of the signal at about 300 cm−1, which belongs to the Γ25’ optical phonon at the Γ-point in the Brillouin-zone.37 Annealing at higher temperatures further reduces the full width at half maximum of the phonon mode and leads to a more symmetric shape of this mode. This indicates a continuous improvement of the grade of crystallinity in the Ge clusters.

Raman scattering spectra of the periodic [Ge–TaZrOx/TaZrOx]10 superlattice (SL1) in the as-deposited state and after annealing at temperatures between 650ºC and 800°C. For better comparison, all spectra are normalized to their highest intensity. The dashed line at about 300 cm−1 marks the position of the crystalline Ge phonon mode.

The crystallization temperature of the amorphous TaZrOx matrix was determined using glancing angle x-ray diffraction. Figure 2 depicts GAXRD patterns of superlattice SL1 annealed at 750°C, 770°C, and 800°C. The sample annealed at 750°C revealed three broad reflections at 2θ ≈ 27°, 2θ ≈ 45°, and 2θ ≈ 55°, which originate from nanocrystalline Ge, and two broad peaks at 2θ ≈ 30° and 2θ ≈ 52° that can be attributed to the amorphous matrix. The crystallization of the matrix starts at 770°C annealing temperature, demonstrated by the sharp reflection at 2θ ≈ 30° originated by an orthorhombic phase of TaZrOx.33 According to the Raman measurement (Figure 1), the temperature window to synthesize Ge nanocrystals within an amorphous matrix is thus between 700°C and 770°C. After annealing at 800°C, three crystalline phases were identified in the sample: cubic Ge with the space group \(Fd\overline{3 }m\), orthorhombic (Zr,Ta)O2 with the space group \(Pbc{2}_{1}\), and orthorhombic (Ta,Zr)2O5 with the space group \(C2mm\).33

Glancing angle x-ray diffraction (GAXRD) patterns of the [Ge–TaZrOx/TaZrOx]10 superlattice (SL1) after annealing at 750°C, 770°C, and 800°C. Black dots mark the measured intensities. The red line represents the result of the Rietveld refinement that was performed for the sample annealed at 800°C with cubic Ge (space group \(Fd\overline{3 }m\)), orthorhombic ZrO2 (space group Pbc21), and orthorhombic Ta2O5 (space group C2mm). Positions of diffraction lines of individual phases are shown by bars at the bottom of the figure. For the sake of clarity, only the low-angle parts of the GAXRD patterns are displayed.

The presence of Ge nanocrystals in the annealed Ge–TaZrOx/TaZrOx multilayers (SL1) was confirmed by HRTEM (Figure 3). The formation of Ge nanoclusters is triggered by the interplay between the Gibbs energy of the metastable Ge–TaZrOx solid solution and the interface energy of the Ge/TaZrOx interfaces. A horizontal arrangement of the nanocrystals is supported by the presence of TaZrOx separation layers. The volume density of Ge nanocrystals depends on the Ge concentration and thickness of the Ge–TaZrOx layers, and on the Ge–TaZrOx/TaZrOx thickness ratio.

Defocused transmission electron microscope (TEM) micrographs of a [Ge–TaZrOx/TaZrOx]10 superlattice stack (SL1) after annealing at 725°C. The marked areas in the defocused micrograph (left) are shown in high-resolution (HRTEM) micrographs on the right-hand side of the figure in order to confirm the crystallinity of the Ge clusters and the amorphous nature of the TaZrOx separation layers.

Rietveld analysis of the GAXRD patterns of the superlattice SL1 annealed at 800°C (Figure 3) revealed crystallite sizes and lattice parameters of individual phases that are summarized in Table I. Cubic Ge was refined in the space group \(Fd\overline{3 }m\),38 orthorhombic (Zr,Ta)O2 in the space group Pbc21,40 and orthorhombic Ta2O5 in the space group C2mm.39 The used TaZrOx sputtering target with the same amount of Ta and Zr leads to an interaction of both orthorhombic phases and changes the lattice parameters.6 Crystallite sizes were determined using the Williamson–Hall approach.41

After annealing at 800°C, the size of the Ge nanocrystals in superlattice SL1 determined using XRD was (8.0 ± 1.0) nm. These nanocrystals are significantly larger than the Ge nanocrystals annealed at 725°C, which size was (3.1 ± 1.3) nm as revealed by the HRTEM micrograph (Figure 3). The larger size of Ge nanocrystals in the superlattice annealed at a higher temperature is a consequence of Ostwald ripening of Ge nanoclusters. However, the Ge nanocrystals in superlattice SL1 annealed at 800°C, determined by XRD, are even larger than the thickness of the original Ge–TaZrOx composite layers (5 nm). This phenomenon can be explained by a decreasing of the barrier effect of TaZrOx against Ge at higher temperatures. Note that the different techniques of size determination can lead to different results, but the difference in the size is too significant to be caused by the method only. The average sizes, also identified by XRD, of the Ta2O5 and (Zr,Ta)O2 crystallites are (20 ± 1) nm and (24 ± 1) nm, respectively. Both sizes are also significantly larger than the original thickness of the TaZrOx separation layers. Obviously, the crystallites of the oxide matrix grow coherently not only through the original separation layers, but also through the original Ge–TaZrOx composite layers. A similar effect was already reported for annealed Fe/Au multilayers.42

From the difference between the measured lattice parameters of Ge and Ta2O5 and the corresponding reference values (Table II) it follows that the phase segregation (Ge, ZrO2, Ta2O5) is not fully complete at the annealing temperature of 800°C and the annealing time of 30 s. ZrO2 contains Ta that acts as a stabilizer of the metastable orthorhombic crystal structure of zirconia.33 Vice versa, Ta2O5 contains possibly a small amount of Zr. From the thermodynamic point of view, Ge can accommodate less than 4.5 × 10–3 tantalum43 and much less than 5 × 10–5 oxygen.44 The expected maximum concentration of Zr in Ge is even lower. Presence of the impurities in the Ge nanocrystals can only be assumed from the deviation of its lattice parameter from the intrinsic value (Table II). As several foreign elements can be involved, it is not possible to determine their concentrations solely from a single lattice parameter.

The main reason for the presence of impurities in Ge is the intermixing of the elements during the deposition process. During the annealing, Ge segregates from the other elements and the Ge nanocrystals are "purified." As the out-diffusion that accompanies this process is facilitated by the temperature and time of the annealing process, a strategy to reduce the amount of impurities further is the increase of the thermal budget. Higher temperatures lead to the crystallization of the matrix material (see Table II), so that a longer annealing time might be preferable.

Pure oxygen interstitials are not problematic due to their electric inactivity.45 The effects of high-k cations like Zr in Ge induced by high-k oxide/Ge interfaces were investigated by DFT calculations, which revealed that Zr is able to form clusters either with vacancies or with oxygen interstitials, both reducing the charge carrier mobility, which is not a relevant parameter in nanocrystals. However, the formation of high-k-Ge–O clusters should occur at the Ge-matrix interface in this process.45 Other effects (e.g., on the optical properties) cannot be excluded, but have not yet been reported in the literature to the best of our knowledge.

Effect of the Ge–TaZrOx layer thickness and Ge concentration on the formation of Ge nanocrystals [SL2]

The influence of the Ge–TaZrOx composite layer thickness on the phase segregation and Ge nucleation was studied with the superlattice structure SL2, which contains composite layers with a constant Ge concentration of 36 at.% and successively increasing thickness. The thickness of the separation layers was kept constant at 7 nm. As the Ge concentration in this sample series is higher than in superlattice SL1 (19 at.%), also the effect of the Ge concentration on the formation of Ge nanocrystals is illustrated by this experiment.

HRTEM micrographs of the superlattice SL2 (Figure 4) prove that the originally continuous Ge–TaZrOx layers become fragmented after annealing for 30 s at 725°C. As described for SL1, this fragmentation is driven by phase segregation and accompanied by the nucleation, growth and crystallization of Ge nanoclusters. However, the comparison with the superlattice SL1 (Figure 3) shows that a higher Ge concentration in the Ge–TaZrOx layers facilitates the formation of separated Ge nanoclusters. This phenomenon is a consequence of the concentration dependence of the Gibbs energy in immiscible or metastable systems. As the Gibbs energy of the GeTaZrOx solid solution increases with increasing Ge content (up to 50 mol% Ge), the driving force for the phase decomposition increases with increasing Ge content as well. Furthermore, a higher Ge concentration in Ge–TaZrOx leads to the formation of Ge nanoclusters with a larger volume.

The size and size distribution of the Ge nanocrystals depends strongly on the composite layer thickness (Figures 4 and 5). The quantity and the size of the nanocrystals were determined by visual inspection. Ge nanocrystals formed from the first composite layer having the thickness of 3 nm exhibit an average size of (4.7 ± 0.8) nm (Figure 5a), which is slightly larger than the thickness of the original composite layer. Nanocrystals formed in the second layer (thickness 6 nm) have an average size of (6.2 ± 1.3) nm (Figure 5b). In the third layer having the thickness of 9 nm, the size distribution of the Ge nanocrystals had to be fitted with a bimodal size distribution leading to average nanocrystal sizes of (4.4 ± 1.5) nm and (8.2 ± 1.6) nm (see Figure 5c). A bimodal size distribution was also observed for the Ge nanocrystals in the fourth composite layer having the thickness of 12 nm. The fitted average sizes of the nanocrystals are (5.4 ± 1.3) nm and (9.1 ± 1.9) nm (Figure 5d).

Size and size distribution of the Ge nanocrystals formed from Ge–TaZrOx composite layers of different thicknesses (SL2): (a) 3 nm, (b) 6 nm, (c) 9 nm, and (d) 12 nm after annealing at 725°C. The size distribution was fitted with one or two normal distributions. The center position (dNP) and the full width at half maximum (FWHM) are given in the respective figure.

In the Ge–TaZrOx layers, which contain 36 at.% Ge and which are thicker than 6 nm, several Ge nuclei form at different vertical positions, because the wavelength of the composition modulations46, 47 is shorter than the composite layer thickness. However, as the wavelength of the composition modulations is not necessarily commensurable with the composite layer thickness, the Ge nanocrystals located at different vertical positions have different size and different volume, as seen in Figure 5. If the composite layers are much thicker than the wavelength of the composition modulations, the Ge nanocrystals show a single normal size distribution with a center. This expectation was confirmed by our previous experiments with 500-nm-thick Ge–TaZrOx composite layers, in which Ge nanocrystals with unimodal size distribution of about 4 nm are formed after annealing. The bigger sizes in the bimodal size distributions may be caused by the limited diffusion geometry in the superlattice structure.

In particular, in the Ge–TaZrOx composite layers, in which Ge nanocrystals having a multimodal size distribution are formed after annealing, Ostwald ripening is an important issue, because it can contribute to the growth of large Ge nanocrystals and to the disappearance of the small ones. Nevertheless, the above-mentioned results document that the size control of the Ge nanocrystals via adjustment of the Ge–TaZrOx layer thickness works reliably only up to a certain Ge–TaZrOx layer thickness, which is smaller than 9 nm for 36 at.% Ge.

Effect of a SiO2 layer underneath the GeTaZrOx composite layer on the growth of Ge nanocrystals [SL3]

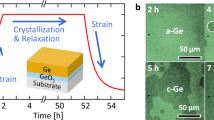

The HRTEM micrograph of SL2 (Figure 4) suggests that Ge nanocrystals penetrate into the silicon dioxide, if they grow in contact with a SiO2 layer. In order to elucidate the influence of neighboring SiO2 on the formation of Ge nanocrystals within the Ge–TaZrOx composite layers, the sample series SL3 was fabricated. In SL3, the composite layers have a Ge concentration of 36 at.% (the same as in SL2). However, SL3 uses additional SiO2 layers, which are located beneath the Ge–TaZrOx composite layers. After annealing for 30 s at 725°C, two types of Ge nanocrystals formed in SL3: larger nanocrystals with a direct contact to SiO2 (Type I) and smaller nanocrystals without contact to SiO2 (Type II). Even keeping in mind that TEM images in the defocus mode overestimate the nanocrystal size, we can state that the Type I nanocrystals appear to be better separated and more spherical shaped than the Type II nanocrystals.

The size and size distribution of nanocrystals in SL3 depends again strongly on the thickness of the composite layers (see Figures 6 and 7). In the first two layers having a thickness of 3 nm and 6 nm, the Ge nanocrystals have a unimodal size distribution. The mean diameter of the Ge nanocrystals is (6.3 ± 2.6) nm and (9.4 ± 3.3) nm for the initially 3- and 6-nm-thick composite layer, respectively. Hence, at the same composite layer thickness, the nanocrystals of the first two layers are significantly larger in SL3 than in SL2. In addition, the distribution of the crystallite size is much broader if the Ge nanocrystals grow on SiO2 (SL3) than if they grow in the TaZrOx matrix (SL2). With increasing thickness of the Ge–TaZrOx layers, the size distribution of Ge nanocrystals becomes progressively larger. For the third and fourth layer having an initial thickness of 9 nm and 12 nm, respectively, the size distributions were approximated by three normal distribution functions. Besides the Type I nanocrystals, composite layers thicker than 6 nm contain several Type II nanocrystals at different vertical positions and with a bimodal size distribution like in SL2. This can again be explained with the wavelength of the composition modulations,46, 47 which is shorter than the composite layer thickness.

Defocused transmission electron microscope (TEM) micrographs of a [Ge–TaZrOx/SiO2/TaZrOx]6 stack with successively increasing Ge–TaZrOx composite layer thicknesses and additional SiO2 layers beneath the composite layers (SL3): (a) in the as-deposited state and (b) after annealing at 725°C. The insets in the top right corner show high-resolution TEM images without defocus affirming the crystallinity of the Ge clusters and the amorphous nature of the SiO2 layers.

Size and size distribution of the Ge nanocrystals formed from Ge–TaZrOx composite layers of different thicknesses (a) 3 nm, (b) 6 nm, (c) 9 nm, and (d) 12 nm above SiO2 layers (SL3). The stack was annealed for 30 s at 725°C. The size distribution was fitted with one or three normal distributions. The center position (dNP) and the full width at half maximum (FWHM) are given in the respective figure. Only the first four layers of SL3 were analyzed.

It has been shown that there is no diffusion of Ge atoms into SiO2 at 725°C.18 Thus, we explain the growth of the Type I Ge nanocrystals into the SiO2 layer (Figure 6) by a lower surface energy at the interface SiO2/Ge than at the Ge/TaZrOx interface, leading to a preferred nucleation process of the nanocrystals at the interface between the composite Ge/TaZrOx and the pure SiO2 layer. The growing Ge nanocrystal displaces SiO2, which gives the impression of growth into the SiO2 layer. However, this effect does not affect the spatial positioning significantly, due the stop of the growth at the underlying TaZrOx/SiO2 interface. To prove this hypothesis, sample SL4 with Ge–SiO2 composite layers was grown and investigated.

[TaZrOx/Ge–SiO2]n superlattice structure [SL4]

For comparison, the behavior of the mixed Ge–SiO2 system in contrast to the Ge–TaZrOx material system was investigated on superlattice structure SL4. In this case, no penetration of the Ge nanocrystals into the TaZrOx separation layers can be detected by TEM imaging. This supports the assumption that the surface energy at the Ge/SiO2 interface does not reinforce a crystal growth of the Ge clusters into the TaZrOx separation layers. The good barrier characteristics of the TaZrOx leads to a high positioning accuracy, as discussed earlier. However, the Ge segregation and hence the nanocrystal formation are much less developed than in the comparable Ge–TaZrOx layers for the same thermal budget (Figure 8a). A possible explanation of this phenomenon could be the mentioned smaller interface energy of Ge nanocrystals in SiO2 compared to TaZrOx leading to a weaker driving force for Ge segregation. The formation of well-defined nanocrystals in an amorphous SiO2 matrix may need a higher thermal budget (e.g., a deposition at increased temperatures).48 An increase of the annealing temperature above 800°C, however, would lead to undesirable crystallization of the TaZrOx barrier layers.

(a): Focused transmission electron microscope micrograph of a [Ge–SiO2/TaZrOx]9 superlattice structure (SL4) after thermal treatment at 725°C for 30 s. (b) Normalized Raman spectra of SL4 (red) in comparison to completely amorphous (blue) and crystalline (black) Ge in amorphous SiO2 matrices. The maximum intensities of the signals belonging to the Ge are normalized for better comparison of the shape of the signal. The absolute intensity shows no relation to the amount of Ge in the samples.

Conclusions

Superlattices of Ge-containing composite layers and TaZrOx separation layers with the structures [Ge–TaZrOx/TaZrOx]n, [Ge–TaZrOx/SiO2/TaZrOx]6, and [TaZrOx/Ge–SiO2]n were fabricated by confocal rf magnetron sputtering. Size-controlled crystalline Ge nanoclusters were successfully grown in an amorphous high-k matrix by appropriate choice of matrix material and annealing procedure. By introducing Ta2O5 into the ZrO2, the amorphous phase of the matrix has been stabilized up to 770°C, whereas the Ge nanoclusters start to crystallize at 700°C for 30 s RTP annealing. Hence, the simultaneous crystallization of the Ge and the ZrO2, which was reported several times for the system Ge/ZrO2,6, 24, 29 has been successfully avoided. In this work, the superlattices deposited with an amorphous TaZrOx matrix contain spherical shaped Ge nanocrystals with very good control over size and spatial distribution. This enables the use of this material system for applications such as nonvolatile memories. The formation of separated Ge nanoclusters can further be facilitated by increasing the Ge concentration in the Ge–TaZrOx layers up to 50 at.%.

Nevertheless, there are minor drawbacks. Mainly, the nanocrystal size control is less efficient for mixed layers exceeding 6-nm thickness. Ge–TaZrOx composite layers of 9 and 12 nm thickness form a bimodal nanocrystal size distribution, which is likely due to short-range composition modulations being smaller than the layer thickness. The lattice parameter of the Ge nanocrystals is found to deviate from the bulk value, which indicates the incorporation of foreign atoms (presumably Ta, Zr, O) and an incomplete phase separation into Ge and Ta and Zr based oxides. These impurities could influence the physical properties of the Ge nanocrystals.

The addition of a SiO2 layer underneath the composite layer ([Ge–TaZrOx/SiO2/TaZrOx]6 superlattice stacks) leads to the formation of well-shaped and separated nanocrystals that penetrate into the SiO2 layer and in difference to SiO2-free superlattices to larger crystals. This is most likely due to the Ge/SiO2 interface, which is energetically favorable compared to the Ge/TaZrOx interface. However, the distribution of the crystallite sizes is much broader here than for Ge nanocrystals grown in the TaZrOx matrix only. At least the segregation of Ge from the Ge–TaZrOx composition layer leads to better results than the segregation from the Ge–SiO2 compound layer.

Data availability

Raw data were generated at the institutions of the authors. Derived data supporting the findings of this study are available from the corresponding author upon request.

Code availability

Not applicable.

References

G. Conibeer, M. Green, R. Corkish, Y. Cho, E.-C. Cho, C.-W. Jiang, T. Fangsuwannarak, E. Pink, Y. Huang, T. Puzzer, T. Trupke, B. Richards, A. Shalav, K.-L. Lin, Thin Solid Films 511–512, 654 (2006). https://doi.org/10.1016/j.tsf.2005.12.119

M. Fujii, M. Yoshida, S. Hayashi, K. Yamamoto, J. Appl. Phys. 84(8), 4525 (1998). https://doi.org/10.1063/1.368678

V.Y. Timoshenko, M.G. Lisachenko, O. Shalygina, B.V. Kamenev, D.M. Zhigunov, S.A. Teterukov, P. Kashkarov, J. Heitmann, M. Schmidt, M. Zacharias, J. Appl. Phys. 96(4), 2254 (2004). https://doi.org/10.1063/1.1773383

L. Pavesi, L.D. Negro, C. Mazzoleni, G. Franzò, F. Priolo, Nature 408(6811), 440 (2000)

S. Tiwari, F. Rana, H. Hanafi, A. Hartstein, E.F. Crabbé, K. Chan, Appl. Phys. Lett. 68(10), 1377 (1996). https://doi.org/10.1063/1.116085

D. Lehninger, P. Seidel, M. Geyer, F. Schneider, V. Klemm, D. Rafaja, J. von Borany, J. Heitmann, Appl. Phys. Lett. 106(2), 23116 (2015). https://doi.org/10.1063/1.4905933

K.S. Min, K.V. Shcheglov, C.M. Yang, H.A. Atwater, M.L. Brongersma, A. Polman, Appl. Phys. Lett. 68(18), 2511 (1996). https://doi.org/10.1063/1.115838

S. Cosentino, E.S. Ozen, R. Raciti, A.M. Mio, G. Nicotra, F. Simone, I. Crupi, R. Turan, A. Terrasi, A. Aydinli, S. Mirabella, J. Appl. Phys. 115(4), 43103 (2014). https://doi.org/10.1063/1.4863124

L. Khomenkova, D. Lehninger, O. Kondratenko, S. Ponomaryov, O. Gudymenko, Z. Tsybrii, V. Yukhymchuk, V. Kladko, J. von Borany, J. Heitmann, Nanoscale Res. Lett. 12(1), 196 (2017). https://doi.org/10.1186/s11671-017-1960-9

P. Basa, G. Molnár, L. Dobos, B. Pécz, L. Tóth, A.L. Tóth, A.A. Koós, L. Dózsa, Á. Nemcsics, Zs. J. Horváth, J. Nanosci. Nanotechnol. 8(2), 818 (2008). https://doi.org/10.1166/jnn.2008.A122

S. Takeoka, M. Fujii, S. Hayashi, K. Yamamoto, Phys. Rev. B 58(12), 7921 (1998). https://doi.org/10.1103/PhysRevB.58.7921

U. Serincan, G. Kartopu, A. Guenes, T.G. Finstad, R. Turan, Y. Ekinci, S.C. Bayliss, Semicond. Sci. Technol. 19(2), 247 (2004). https://doi.org/10.1088/0268-1242/19/2/021

J. Aldana, Y.A. Wang, X. Peng, J. Am. Chem. Soc. 123(36), 8844 (2001). https://doi.org/10.1021/ja016424q

A. Dana, S. Ağan, S. Tokay, A. Aydınlı, T.G. Finstad, Phys. Status Solidi C 4(2), 288 (2007). https://doi.org/10.1002/pssc.200673233

S. Foss, T.G. Finstad, A. Dana, A. Aydinli, Thin Solid Films 515(16), 6381 (2007). https://doi.org/10.1016/j.tsf.2006.11.094

M. Zacharias, J. Bläsing, P. Veit, L. Tsybeskov, K. Hirschman, P.M. Fauchet, Appl. Phys. Lett. 74(18), 2614 (1999). https://doi.org/10.1063/1.123914

F. Gourbilleau, X. Portier, C. Ternon, P. Voivenel, R. Madelon, R. Rizk, Appl. Phys. Lett. 78(20), 3058 (2001). https://doi.org/10.1063/1.1371794

M. Zschintzsch, N.M. Jeutter, J. von Borany, M. Krause, A. Mücklich, J. Appl. Phys. 107(3), 34306 (2010). https://doi.org/10.1063/1.3276184

D. Lehninger, J. Beyer, J. Heitmann, Phys. Status Solidi A 155, 1701028 (2018). https://doi.org/10.1002/pssa.201701028

J.D. Budai, C.W. White, S.P. Withrow, M.F. Chisholm, J. Zhu, R.A. Zuhr, Nature 390(6658), 384 (1997). https://doi.org/10.1038/37079

I.D. Sharp, Q. Xu, D.O. Yi, C.W. Yuan, J.W. Beeman, K.M. Yu, J.W. Ager III, D.C. Chrzan, E.E. Haller, J. Appl. Phys. 100(11), 114317 (2006). https://doi.org/10.1063/1.2398727

C. Schubert, U. Kaiser, A. Hedler, W. Wesch, T. Gorelik, U. Glatzel, J. Kräuβlich, B. Wunderlich, G. Heβ, K. Goetz, J. Appl. Phys. 91(3), 1520 (2002). https://doi.org/10.1063/1.1430539

V.A. Volodin, E.B. Gorokhov, M.D. Efremov, D.V. Marin, D.A. Orekhov, JETP Lett. 77(8), 411 (2003). https://doi.org/10.1134/1.1587174

S. Haas, F. Schneider, C. Himcinschi, V. Klemm, G. Schreiber, J. von Borany, J. Heitmann, J. Appl. Phys. 113, 044303 (2013). https://doi.org/10.1063/1.4780033

J. Robertson, J. Vac. Sci. Technol. B 18(3), 1785 (2000). https://doi.org/10.1116/1.591472

D. Panda, T.-Y. Tseng, Thin Solid Films 531, 1 (2013). https://doi.org/10.1016/j.tsf.2013.01.004

X. Zhao, D. Vanderbilt, Phys. Rev. B (2002). https://doi.org/10.1103/PhysRevB.65.075105

P. Seidel, M. Geyer, D. Lehninger, F. Schneider, V. Klemm, J. Heitmann, ECS Trans. 53(1), 237 (2013). https://doi.org/10.1149/05301.0237ecst

D. Lehninger, L. Khomenkova, C. Röder, G. Gärtner, B. Abdenroth, J. Beyer, F. Schneider, D.C. Meyer, J. Heitmann, ECS Trans. 66(4), 203 (2015). https://doi.org/10.1149/06604.0203ecst

E. Agocs, Z. Zolnai, A.K. Rossall, J.A. van den Berg, B. Fodor, D. Lehninger, L. Khomenkova, S. Ponomaryov, O. Gudymenko, V. Yukhymchuk, B. Kalas, J. Heitmann, P. Petrik, Appl. Surf. Sci. 421, 283(2017). https://doi.org/10.1016/j.apsusc.2017.03.153

T.-W. Kim, C.-H. Cho, B.-H. Kim, S.-J. Park, Appl. Phys. Lett. 88(12), 123102 (2006). https://doi.org/10.1063/1.2187434

A. Krause, W.M. Weber, U. Schröder, D. Pohl, B. Rellinghaus, J. Heitmann, T. Mikolajick, Appl. Phys. Lett. 99, 222905 (2011). https://doi.org/10.1063/1.3664395

D. Lehninger, D. Rafaja, J. Wünsche, F. Schneider, J. von Borany, J. Heitmann, Appl. Phys. Lett. 110(26), 262903 (2017). https://doi.org/10.1063/1.4990529

M. Ferrari, L. Lutterotti, S. Matthies, P. Polonioli, H.R. Wenk, Mater. Sci. Forum 228–231, 83 (1996). https://doi.org/10.4028/www.scientific.net/MSF.228-231.83

L. Lutterotti, S. Matthies, H.-R. Wenk, ICOTOM-12 21, 14 (1999)

Z. Iqbal, S. Veprek, J. Phys. C 15(2), 377 (1982). https://doi.org/10.1088/0022-3719/15/2/019

H. Fukuda, T. Kobayashi, T. Endoh, S. Nomura, A. Sakai, Y. Ueda, Appl. Surf. Sci. 130–132, 776 (1998). https://doi.org/10.1016/S0169-4332(98)00153-6

A.S. Cooper, Acta Crystallogr. 15(6), 578 (1962). https://doi.org/10.1107/S0365110X62001474

K. Lehovec, J. Less-Common Met. 7(6), 397 (1964). https://doi.org/10.1016/0022-5088(64)90036-0

E.H. Kisi, C.J. Howard, R.J. Hill, J. Am. Ceram. Soc. 72(9), 1757 (1989). https://doi.org/10.1111/j.1151-2916.1989.tb06322.x

G.K. Williamson, W.H. Hall, Acta Metall. 1(1), 22 (1953)

D. Rafaja, H. Fuess, D. Šimek, L. Zdeborová, V. Valvoda, J. Phys. 14(43), 10021 (2002). https://doi.org/10.1088/0953-8984/14/43/301

S.P. Garg, N. Krishnamurthy, M. Venkatraman, S. Raju, J. Phase Equilib. 12(6), 661 (1991). https://doi.org/10.1007/BF02645166

W. Kaiser, C.D. Thurmond, J. Appl. Phys. 32(1), 115 (1961). https://doi.org/10.1063/1.1735936

A. Chroneos, A. Dimoulas, J. Appl. Phys. 111(2), 23714 (2012). https://doi.org/10.1063/1.3679089

J.W. Cahn, Acta Metall. 9(9), 795 (1961). https://doi.org/10.1016/0001-6160(61)90182-1

J.W. Cahn, J. Chem. Phys. 42(1), 93 (1965). https://doi.org/10.1063/1.1695731

B. Zhang, S. Shrestha, M.A. Green, G. Conibeer, Appl. Phys. Lett. 96(26), 261901 (2010). https://doi.org/10.1063/1.3457864

Funding

Open Access funding enabled and organized by Projekt DEAL. For this work, no funding sources have to be acknowledged.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

No conflicts of interest have to be declared.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lehninger, D., Honeit, F., Rafaja, D. et al. Size- and position-controlled Ge nanocrystals separated by high-k dielectrics. MRS Bulletin 47, 773–782 (2022). https://doi.org/10.1557/s43577-022-00311-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43577-022-00311-8