Abstract

The high atomic-scale complexity inherent in the aptly named complex concentrated alloys, or high entropy alloys, presents unique challenges in understanding (1) the structure and motion of defects that control mechanical properties and (2) the thermodynamic phase space encompassing stable, metastable, single, and multiphase alloys, possibly with chemical short range ordering. These factors plus the huge range of possible compositions makes computationally guided design of new high-performance alloys difficult but essential. Here, emerging concepts and theoretical frameworks for understanding defect structures, energies, and motion, and thermodynamics are discussed with a focus on yield strength and phase behavior. Pressing directions for future research are suggested to advance toward the predictive capabilities needed for alloy design.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Overview

Two major issues face the design of complex concentrated alloys (CCAs). First, the space of alloy compositions is immense (e.g., more than 10,000,000 alloys in the Ti–Zr–Hf–V–Nb–Ta–Cr–Mo–W family of bcc alloys at 5% composition intervals).1 Second, to satisfy performance requirements, alloys must have a balance of properties such as high strength at low/high homologous temperatures, sufficient ductility at room temperature for processing and application resilience, good fracture toughness, phase stability over the temperature range of applications, and environmental resistance. The combinatorial problem of composition plus properties has a silver lining: from among the millions of possible alloys, we only need to discover a handful that can satisfy multiple requirements. It is impossible to produce and test millions of alloys, and so approaches to navigate through the space by understanding fundamental property/composition relationships are critical. One approach uses available data on properties and thermodynamics combined with simple rules to extrapolate across the composition space.2,3 A second approach uses high-throughput experiments to gain broader insights and data on thermodynamics and some required structural properties4 followed by refined studies. A science, rather than data, approach is to develop theories and reliable simulations that provide understanding of the mechanisms controlling properties and thermodynamics, enabling an informed roadmap through the vast composition/performance space toward an experimentally feasible set of candidate alloys.

Similar to conventional materials, atoms in single phase CCAs have an underlying periodic crystal lattice. This suggests that structural properties are governed by mechanisms found in traditional materials (i.e., the structure, motion, and interaction of defects [solutes, dislocations, precipitates, grain boundaries, twins, and vacancies]) in the crystalline lattice. The unique complication of CCAs is that this lattice is compositionally disordered at the atomic scale. In dilute alloys, one element is a solvent phase and the others are “solutes” that interact with defects in the solvent matrix. In CCAs, there are solutes everywhere, and the defects are embedded within that pervasive solute field.5 The conceptual challenge is thus to understand how defect properties are modified in the presence of atomic-scale randomness. Observed macroscopic and atomic-scale properties of CCAs suggest that new mechanisms are not required to understand many properties. A firm theoretical understanding of CCAs can begin by building on the vast detailed understanding of mechanisms in non-CCAs. Here, we discuss challenges in understanding crystalline defects in CCAs, sample recent progress toward solving these challenges in key performance domains (strength, thermodynamics), and identify critical issues that require new insights and methods.

Prerequisite: Knowledge of alloy phase stability

Physics-based models of properties and performance require detailed understanding of the equilibrium phases of a given alloy composition and temperature. For example, alloy strengthening can result from solid-solution strengthening, precipitate strengthening, and grain size. Calculation of phase diagram (CalPhaD) methods have pivoted to CCAs, and are producing accurate phase boundaries when interpolating between experimental data that include many binary and ternary alloys data in the database.6 CCAs must be treated with caution because Gibbs’ phase rule dictates more possible phases with increasing number of chemical components. The chemical complexity of CCAs thus presents challenges to the construction of these methods. The rapid pace of new experiments is, fortunately, driving automation of updates.7 A permanent, digital, public archive of high-quality experimental thermodynamic data would be beneficial for the community and for evolution of CalPhaD databases. Better approximations of the configurational entropy, beyond the cluster site approximation, are also needed. Finally, mapping uncertainty, training advanced databases to provide error predictions, and providing (Bayesian) feedback for new experimental data are needed to improve predictions.

Complementing the semi-empirical/experimentally based CalPhaD, direct first-principles based on density functional theory (DFT) has been applied to study CCAs. Total energies of supercells containing multiple elements in any crystal structure and degree of chemical ordering can be computed. In many systems, the high-temperature random solid-solution state is an important reference structure, especially because many CCAs are annealed at high temperatures and then quenched. The use of special quasi-random structures (SQSs) enables the use of relatively small periodic simulation cells while preserving the random correlations of much larger but computationally unfeasible sizes.8 Total energies of random and chemically ordered systems can also be systematically represented using the cluster expansion method to develop effective Hamiltonians in terms of pair, triplet, and higher structures at various atomic distances.9 Thermodynamics and phase-diagrams can then be constructed, as widely done in traditional alloys, often including vibrational and electronic contributions to the free energy.10 Similar to CalPhaD, guidelines for the thermodynamics of CCAs can be developed by looking at the heats of formation of much simpler binary and ternary alloys.11,12 Although DFT provides good chemical accuracy, it remains costly and imperfect, with issues such as accurate handling of paramagnetic alloys (e.g., Co–Cr–Fe–Mn–Ni Cantor family) and the high cost of computing free energies.

Most modeling to date has focused on random alloys. The role of chemical short range order (CSRO), introduced during standard metallurgical annealing used to homogenize alloys, requires considerably more attention. A random lattice contains regions with high enthalpy that are relieved by the formation of CSRO, as seen by Monte Carlo simulations under equilibrium conditions using with energies from DFT, cluster expansion methods, or atomistic potentials.13,14,15,16,17 However, CSRO should be studied at realistic annealing temperatures to mimic the actual diffusive process, which is computationally challenging for DFT. Experimental observations of CSRO are also very challenging but essential. Progress is being made using advanced methods (scanning transmission electron microscopy (STEM), STEM-high angular dark field, extended energy-loss fine structure),18,19 but validation of simulated CSRO remains undone.

When CSRO exists, it affects defect structures and motion relative to those in the random alloy. A defect usually involves local topological changes away from the crystalline lattice so that defect motion changes the relative positions of atoms. This decreases the CSRO locally, and increases the energy. This energy cost contributes to the barrier for defect motion. For instance, it has long been known that CSRO creates an additional temperature-independent strengthening because dislocation shearing disrupts the CSRO across the glide plane. Recent theory and simulations have revisited this issue,16,17,20,21 but the topic warrants continued study.

Defects in the presence of high chemical disorder

We ultimately need defect energies in complex environments. Accessible by DFT are basic properties and some average defect energies such as the equilibrium lattice constant, elastic constants, surface energies, stable and unstable stacking fault energies (SSFE and USFE), and vacancy formation energies. All require averaging over results on multiple SQS realizations for a given composition. Changes in these quantities with composition, relevant because the composition is spatially fluctuating in real alloys, incurs even more computational cost. DFT is also imperfect; it makes significant underpredictions of the bcc shear modulus C44 and significant overpredictions of the fundamental Peierls stress needed to move screw dislocations in bcc metals. The coherent potential approximation provides a more-efficient but approximate method to circumvent the use of many SQS cells, and to date has been shown to be reasonably accurate for lattice and elastic constants and SSFE in some alloys.22,23 The computational cost of DFT prohibits the study of many important extended defects because the additional CCA feature of compositional fluctuations requires the sampling of much larger sizes than needed in simple metals.21

Conventional DFT is also at T = 0 K, which may be insufficient. For instance, the DFT-computed SSFE of NiCoCr is negative,24,25 indicating stability of hcp over fcc while as-fabricated NiCoCr is fcc. This may be resolved by more advanced free energy calculations,24,25 or be due to issues with magnetism26 or CSRO.14 More-subtle but DFT-accessible quantities are the average misfit volumes of the alloying elements, which are relevant for determining the mechanical interaction between solutes and any defect that creates a stress field. Misfits are obtained as the derivatives of total volume versus composition around a desired composition.27,28 The small errors in DFT volumes can magnify errors in misfits, and again magnetism can be problematic,26 both pointing to the need for more-accurate first-principles methods.

DFT-accessible properties such as the SSFE and USFE do not directly relate to mechanical properties such as strength and ductility, although they are related to, and guide understanding of, the relevant defects (e.g., dislocations, cracks). To directly model volumes of material containing enough atoms to represent such extended defects incorporating a realistic range of chemical fluctuations in complex alloys requires more approximate methods of computations of energies and forces among atoms. Well-calibrated embedded atom method (EAM) potentials are widely available for elemental metals but accurate extensions to just binary alloys are quite limited. Multicomponent CCAs pose an even greater challenge. A useful potential must be (1) qualitatively correct, avoiding unphysical spurious artifacts that can arise when studying important extended defects; and (2) quantitatively reasonable. Identifying artifacts when examining defects in a CCA with intrinsic atomic-scale disorder can be difficult. Potentials introduced by Zhou et al.29,30,31 enable easy creation of multicomponent potentials that are qualitatively and reasonably quantitatively suitable for modeling lattice and elastic properties, and some screw dislocation properties, in bcc CCAs,32,33,34,35 although they can fail in applications to cracks.36 Atomistic-scale studies with qualitatively accurate potentials enables the study of defects in a complex chemical environment where many key quantities are calculable. This provides a critical platform for testing theories and mechanisms of defect structure and motion.

Emerging approaches involve machine learning. One approach uses extensive DFT calculations of a defect energy over many compositions and realizations followed by learning of the property trends, as demonstrated37 for the USFE in bcc HEAs that is important for intrinsic ductility.36,37,38 Another approach is to develop a similar DFT database to create a machine-learning interatomic potential, from which defect properties can be studied. Potentials are often aimed at the study one or a few properties, such as thermodynamics in the Cantor alloys,39 the USFE in bcc alloys,40 or dislocations in bcc MoNbTaW.41 The required database size grows exponentially with the number of components, remaining a bottleneck. Comparable successes may also be achievable for some properties using cluster expansions.42 Although ML potentials inherit inaccuracies of DFT, they are rapidly showing impressive successes in traditional multicomponent alloys with complex precipitate phases, pointing toward great promise for CCAs.

Framework for understanding defects in CCAs

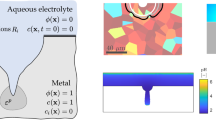

It is straightforward to create an initial defect in a random alloy, especially using interatomic potentials. The energy-minimizing structure that arises is due to the totality of effects of the specific random environment on the defect. Figure 1i–j shows the structures of initial straight screw and edge dislocations relaxed in a random model bcc NbTaV alloy; the dislocation becomes wavy/kinked. In general, a defect structure adapts to the local environment, making it extremely difficult to determine what aspects of the random alloy have (1) caused such structural changes and (2) control the motion and barriers to motion. Thus, although simulations can be executed and reported, the extraction of key underlying energetics and mechanisms is challenging. More nuanced approaches are needed.

(a, b) Screw and edge dislocation cores in a true random model NbTaV alloy; (c, d) the 〈A〉 atom cores and the Nb/dislocation interaction energy at one selected site; (e, f) energy map of interaction energy of Nb at all sites; (g, h) change in energy of an Nb solute at each site when the dislocation glides (one Peierls barrier a for the screw, distance w for the edge); (i, j) dislocation waviness caused by the random composition fluctuations in the true random alloy including cross-kinks along the screw whose motion requires vacancy (V) and self-interstitial formation.

A general atomistic framework for understanding defects in the atomically random alloy is thus essential. One approach uses an analogy to effective-medium theories for alloys.43 Specifically, any random alloy has a mean-field counterpart represented by a single “average atom” 〈A〉. The 〈A〉 atom material discards all local atomic distortions in the true random alloy but preserves all the macroscopic (average) alloy properties. The 〈A〉 atom is thus the underlying homogeneous reference material into which defects can be inserted and studied, computationally or theoretically. A defect in the 〈A〉-atom material is very similar to the same defect found in elemental metals (e.g., Figure 1a–d) of the same crystal structure, but with the average properties of the true alloy. Most importantly, individual elements of the alloy can then be introduced into the defect of the 〈A〉-atom material (e.g., Figure 1c, d), as in classical dilute alloys, to compute the chemical perturbations in local energies or structures. A quantum representation of the 〈A〉 material is achievable using the coherent potential approximation (CPA). But CPA does not permit important local relaxations and so is limited; new approaches are needed. An EAM 〈A〉 potential can be constructed analytically using the underlying EAM potentials for the alloy constituents.28 The accuracy of the EAM 〈A〉 atom material, relative to the true random EAM alloy, has been shown in various publications. For example, Figure 1c, d shows the 〈A〉 atom screw and edge dislocation core structures in a model NbTaV CCA, and Figure 1e, f shows the interaction energy versus position of a single Nb solute in and around these dislocations. Maps of the interaction energy of every solute in the alloy with the defect of interest (e.g., Nb, Ta, and V with the screw dislocation) are the fundamental basis for understanding the energetics of the defect in the true random alloy. In particular, the energy changes upon defect motion (Figure 1g, h) control how the defect relaxes, and the energy barriers for motion in a true random environment due to random compositional fluctuations throughout the alloy can be understood.28,35

Dislocations: A case study

An important defect that illustrates the general points of the previous sections is a dislocation.

In the presence of a solute field, dislocations minimize their energy by becoming wavy: they find local energetically favorable solute fluctuations at the cost of longer dislocation line length and elastic energy (line tension) (Figure 1i–j). This basic idea of Labusch was refined and quantified in dilute fcc alloys44 and extended to fcc CCAs45 and edge dislocations in bcc CCAs.28 Starting from the straight dislocation in the average alloy (Figure 1c–d) and the solute/dislocation interaction energies and their changes with glide (e.g., Figure 1e–h), the competing energetic factors (solute, line tension) lead to characteristic waviness scales and a lowering of the total energy. Lying in local energy minimum, the dislocation segments can only move by stress-assisted thermal activation over adjacent unfavorable solute environments, ultimately leading to a stress \({\tau }_{y}(T,\dot{\upvarepsilon })\) required to sustain a strain rate \(\dot{\upvarepsilon }\) at temperature T. Atomistic simulations of fcc and bcc (edge dislocations only) CCAs using model potentials have illustrated the overall behavior. Theory then shows how \({\tau }_{y}(T,\dot{\upvarepsilon })\) depends on the underlying properties (Burgers vector, elastic constants, line tension, solute/dislocation interaction energies, dislocation structure connected to the SSFE and USFE). Taking the elastic solute/dislocation interaction as –p(x)ΔVn for each solute n in the pressure field p(x) of the dislocation further enables analytic models for \({\tau }_{y}(T,\dot{\upvarepsilon })\); many predictions agree well with experiments.26,27,28,45,46,47 Such analytic models can then be used with approximate or computed inputs to guide alloy design/selection,1 achieving a major goal for theory and modeling of CCAs.

Simulations in model fcc CCAs also illustrate how local composition fluctuations can produce large local changes in the SSFE, which dramatically affects the partial dissociation distance of the dislocation. In some local regions along a screw dislocation,5,16,17,48,49,50 the partial dislocations can constrict and enable cross-slip spontaneously or with very low barrier. Cross-slip is usually thermally activated with a high barrier in elemental metals having SSFEs similar to those of the Cantor-family alloys. Hence, the random atomistic environment may significantly change the cross-slip rate, which controls work-hardening behavior of the alloy.

In the bcc CCAs, strengthening at low homologous temperatures is usually controlled by screw dislocations, as in elemental metals and dilute alloys. Although edge dislocations may be significantly strengthened in some bcc alloys (previously discussed) at high temperatures, the screw dislocation always confers high strength and so study of screws is essential. Again, the local solute/dislocation interactions (Figure 1c, e) cause spontaneous changes in the core structure; both waviness via kinking in the glide plane (Figure 1g) and complex changes to the screw core first observed in model bcc CCAs51 and later using first-principles methods in Nb-Ti-Zr alloys (Figure 2).52 Theories have been developed to handle spontaneously kinked screw dislocations.34,35 The strength is controlled by (1) the lateral motion of the kinks through the fluctuating solute environment plus (2) cross-kinks that are formed by the intersection of kinks that form on different screw glide planes (Figure 1i). Cross-kinks can only fail by the formation of high-energy vacancies and self-interstitials, conferring high-temperature strength to the alloy. But a diffusion-controlled failure mechanism of cross-kinks at high temperatures leads to a sharp drop in yield stress.34,53 Theories to determine or experiments to measure the activation energy for solute/vacancy diffusion in these complex alloys are needed.

Left: Spontaneous kink nucleation sites forming along a 1/2 〈111〉 screw dislocation in Nb16Ti33Zr50 calculated using a multi-scale DFT method52 and shown by the differention out-of-plane displacements of neighboring atoms, with the star indicating the center of the core. Right: Three-dimensional representation of dislocation core, filled red triangles show the location of the core, that is, the dislocation line would thread through the centers of the red triangles.

Edge strengthening is favored in bcc alloys with large solute misfit volumes and large shear modulus whereas screw dislocation strengthening is favored in alloys with large solute-screw dislocation interaction energies and large vacancy and self-interstitial formation energies. The main challenge in applying the screw theories lies in determining the interaction energies in real alloys. The Zhou et al. EAM potentials28,29 provide some guidance, but comparisons with direct DFT in dilute alloys vary considerable (good34 and poor [e.g., Ta in Mo.54]) Direct DFT simulations over the range of statistical variations are computationally unfeasible,52 but sampling this variation using short dislocation segments has recently been done for MoNbTaW,23 yielding the variance in the solute-screw dislocation interaction energies that enters theoretical models.31,32 Further work along these lines is needed, as are efforts to develop simple accurate first-principles methods for solute/defect interaction energies.55 Another challenge for screws is that there is no theory for motion of screws having complex local core structures (Figure 2) varying along the screw line. This issue remains entirely open. Nonetheless, application of the above theories that neglect this complication have shown reasonable agreement with experiments. Finally, we emphasize that detailed TEM studies of the dislocation microstructures of alloys after low and, especially, high-temperature deformation,56,57 are strongly recommended for bcc CCAs to ascertain the screw versus edge competition.

The dislocation is just one example of the broader importance of solute/defect interactions in CCAs. The same concepts apply to grain boundaries and crack tips, for instance. The direct computation of any of these interaction energies in DFT is challenging, as noted earlier, because the defect/dislocation adapts to the specific local environment (e.g., Figure 1i–j; Figure 2) and there is no 〈A〉 atom reference to which single solutes can be added (e.g., Figure 1c–d), as in EAM-based modeling.

Summary

CCAs present a rich landscape of opportunities for the discovering new alloys, and innovative approaches are needed to accelerate down-selection from the huge composition/property space to identify candidate alloys for experimental investigation. Current theory and modeling are well-positioned to guide this process. Precise quantitative results are perhaps less important than conceptual understanding and mechanistic models that are sufficiently accurate to provide the necessary guidance. However, many challenges remain due to the wide range of important defects (dislocations, grain boundaries, cracks,….) and phase behaviors that require investigation but push existing limitations of computational methods.

Data availability

Data sharing not applicable to this article as no data sets were generated or analyzed during the current study.

References

C. Lee, F. Maresci, R. Feng, Y. Chou, T. Ungar, M. Widom, K. An, J.D. Poplawsky, Y.-C. Chou, P.K. Liaw, W.A. Curtin, Nat. Commun. (2021). https://doi.org/10.1038/s41467-021-25807

O.N. Senkov, J.W. Miller, D.B. Miracle, C. Woodward, Nat. Commun. (2015). https://doi.org/10.1038/ncomms7529

N. Islam, W. Huang, H. Zhuang, Comput. Mater. Sci. (2018). https://doi.org/10.1016/j.commatsci/2018.04.003

D.B. Miracle, M. Li, Z. Zhang, R. Mishra, K.M. Flores, Ann. Rev. Mater. Res. 51, 131 (2021). https://doi.org/10.1146/annurev-matsci-080619-022100

W.G. Noehring, W.A. Curtin, Scripta Mater. (2019). https://doi.org/10.1016/j.scriptamat.2020.06.012

K. Wertz, J. Miller, O. Senkov, J. Mater. Res. (2018). https://doi.org/10.1557/jmr.2018.61

F. Zhang, “Rapid Deployment of Thermodynamic Capability for Integrated Computational Materials Engineering” (STTR study, FA8650-16-C-5021).

A. van de Walle, P. Tiwary, M.M. de Jong, D.L. Olmsted, M.D. Asta, A. Dick, D. Shin, Y. Wang, L.-Q. Chen, Z.-K. Liu, Calphad (2013). https://doi.org/10.1016/j.calphad.2013.06.006

F. Körmann, A.V. Ruban, M.H.F. Sluiter, Mater. Res. Lett. (2017). https://doi.org/10.1080/21663831.2016.1198837

R. Feng, P.K. Liaw, M.C. Gao, M. Widom, NPJ Comput. Mater. (2017). https://doi.org/10.1038/s41524-017-0049-4

M.C. Troparevsky, J.R. Morris, M. Daene, Y. Wang, A.R. Lupini, G.M. Stocks, JOM (2015). https://doi.org/10.1007/s11837-015-1594-2

A. Natarajan, P. Dolin, A. Van der Ven, Acta Mater. (2020). https://doi.org/10.1016/j.actamat.2020.08.034

A. Tamm, A. Aabloo, M. Klintenberg, M. Stocks, A. Caro, Acta Mater. (2015). https://doi.org/10.1016/j.actamat.2015.08.015

J. Ding, Q. Yu, M. Asta, R.O. Ritchie, Proc. Natl. Acad. Sci. U.S.A. (2018). https://doi.org/10.1073/pnas.1808660115

Q.J. Li, H. Sheng, E. Ma, Nat. Commun. (2019). https://doi.org/10.1038/s41467-019-11464-7

E. Antillon, C. Woodward, S.I. Rao, B. Akdim, T.A. Parthasarathy, Acta Mater. (2020). https://doi.org/10.1016/j.actamat.2020.02.041

E. Antillon, C. Woodward, S.I. Rao, B. Akdim, Acta Mater. (2021). https://doi.org/10.1016/j.actamat.2021.117012

J.L. Hart, A.C. Lang, R.B. Cummings, I. MacLaren, M.L. Taheri, Microsc. Microanal. (2019). https://doi.org/10.1017/S1431927619003659

R. Zhang, S. Zhao, J. Ding, Y. Chong, T. Jia, C. Ophus, M. Asta, R.O. Ritchie, Nature (2020). https://doi.org/10.1038/s41586-020-2275-z

S. Nag, Concurrent Multiscale Modeling and Theory of Solute-Strengthening for Dilute and Complex Concentrated Alloys, PhD thesis, EPFL (2020)

S. Yin, J. Ding, M. Asta, R.O. Ritchie, NPJ Comput. Mater. (2020). https://doi.org/10.1038/s41524-020-00377-5

X. Sun, H. Zhang, W. Li, X. Ding, Y. Wang, L. Vitos, Nanomaterials (2019). https://doi.org/10.3390/nano10010059

Z. Yang, S. Lu, Y. Tian, Z. Gu, H. Mao, J. Sun, L. Vitos, J. Mater. Sci. Technol. (2021). https://doi.org/10.1016/j.jmst.2020.10.078

S. Zhao, G.M. Stocks, Y. Zhang, Acta Mater. (2017). https://doi.org/10.1016/j.actamat.2017.05.001

C. Niu, C. LaRosa, J. Miao, M.J. Mills, M. Ghazisaeidi, Nat. Commun. (2018). https://doi.org/10.1038/s41467-018-03846-0

B. Yin, S. Yoshida, N. Tsuji, W.A. Curtin, Nat. Commun. (2020). https://doi.org/10.1038/s41467-020-16083-1

B. Yin, W.A. Curtin, NPJ Comput. Mater. (2019). https://doi.org/10.1038/s41524-019-0151-x

F. Maresca, W.A. Curtin, Acta Mater. (2020). https://doi.org/10.1016/j.actamat.2019.10.015

X.W. Zhou, H.N.G. Wadley, R.A. Johnson, D.J. Larson, N. Tabat, A. Cerezo, A.K. Petford-Long, G.D.W. Smith, P.H. Clifton, R.L. Martens, T.F. Kelly, Acta Mater. 49, 4005 (2001). https://doi.org/10.1016/S1359-6454(01)00287-7

D.-Y. Lin, S.S. Wang, D.L. Peng, M. Li, D. Hui, J. Phys. Condens. Matter. (2013). https://doi.org/10.1088/0953-8984/25/20/209501

Z. Lin, R.A. Johnson, L.V. Zhigilei, Phys. Rev. B (2008). https://doi.org/10.1103/PhysRevB.77.214108

S.I. Rao, B. Akdim, E. Antillon, C. Woodward, T.A. Parthasarathy, O.N. Senkov, Acta Mater. (2019). https://doi.org/10.1016/j.actamat.2019.02.013

S.I. Rao, E. Antillon, C. Woodward, B. Akdim, T.A. Parthasarathy, O.N. Senkov, Scripta Mater. (2019). https://doi.org/10.1016/j.scriptamat.2019.02.012

S.I. Rao, C. Woodward, B. Akdim, O.N. Senkov, D. Miracle, Acta Mater. (2021). https://doi.org/10.1016/j.actamat.2021.116758

F. Maresca, W.A. Curtin, Acta Mater. (2020). https://doi.org/10.1016/j.actamat.2019.10.007

E. Mak, B. Yin, W.A. Curtin, J. Mech. Phys. Solids (2021). https://doi.org/10.1016/j.jmps.2021.104389

Y.J. Hu, A. Sundar, S. Ogata, L. Qi, Acta Mater. (2021). https://doi.org/10.1016/j.actamat.2021.116800

X. Li, W. Li, D.L. Irving, L.K. Varga, L. Vitos, S. Schonecker, Acta Mater. (2020). https://doi.org/10.1016/j.actamat.2020.03.004

T. Kostiuchenko, F. Kormann, J. Neugebauer, A. Shapeev, J. Comput. Mater. (2019). https://doi.org/10.1038/s41524-019-0195-y

M. Hodapp, A. Shapeev, arXiv.2107.05620v1 (2021)

S. Yin, Y. Zuo, A. Abu-Odeh, H. Zheng, Z.-G. Li, J. Ding, S.P. Ong, M. Asta, R.O. Ritchie, Nat. Commun. (2021). https://doi.org/10.1038/s41467-021-25134-0

A.R. Natarajan, A. Van der Ven, NPJ Comput. Mater (2020). https://doi.org/10.1038/s41524-020-0348-z

C. Varvenne, A. Luque, W.G. Noehring, W.A. Curtin, Phys. Rev. B (2016). https://doi.org/10.1103/PhysRevB.93.104201

G.P.M. Leyson, L.G. Hector Jr., W.A. Curtin, Acta Mater. (2012). https://doi.org/10.1016/j.actamat.2012.03.037

C. Varvenne, A. Luque, W.A. Curtin, Acta Mater. (2016). https://doi.org/10.1016/j.actamat.2016.07.040

B. Yin, F. Maresca, W.A. Curtin, Acta Mater. (2020). https://doi.org/10.1016/j.actamat.2020.01.062

B. Yin, W.A. Curtin, Mater. Res. Lett. (2020). https://doi.org/10.1080/21663831.2020.1739156

S.I. Rao, C. Woodward, T.A. Parthasarathy, O.N. Senkov, Acta Mater. (2017). https://doi.org/10.1016/j.actamat.2017.05.071

W.G. Nohring, W.A. Curtin, Acta Mater. (2017). https://doi.org/10.1016/j.actamat.2017.02.027

W.G. Nohring, W.A. Curtin, Acta Mater. (2018). https://doi.org/10.1016/j.actamat.2018.05.027

S.I. Rao, C. Varvenne, C. Woodward, T.A. Parthasarathy, D. Miracle, O.N. Senkov, W.A. Curtin, Acta Mater. (2017). https://doi.org/10.1016/j.actamat.2016.12.011

B. Akdim, C. Woodward, S.I. Rao, E. Antillon, Scripta Mater. (2021). https://doi.org/10.1016/j.scriptamat.2021.113834

S.I. Rao, C. Woodward, B. Akdim, E. Antillon, T.A. Parthasarathy, O.N. Senkov, Scripta Mater. (2019). https://doi.org/10.1016/j.scriptamat.2019.07.025

D.R. Trinkle, C. Woodward, Science 310, 1665 (2005)

Y.J. Hu, G. Zhao, B. Zhang, C. Yang, M. Zhang, Z.-K. Liu, X. Qian, L. Qi, Nat. Commun. (2019). https://doi.org/10.1038/s41467-019-12452-7

J.-Ph. Couzinié, L. Lilensten, Y. Champion, G. Dirras, L. Perrière, I. Guillot, Mater. Sci. Eng. A (2015). https://doi.org/10.1016/j.msea.2015.08.024

J.-P. Couzinié, G. Dirras, Mater. Charact. (2018). https://doi.org/10.1016/j.matchar.2018.07.015

Acknowledgments

W.A.C. acknowledges funding from the Swiss National Science Foundation through both the NCCR MARVEL and Project 200021_18198/1. C.W. acknowledges support from the US Air Force Research Laboratory and S.I.R. acknowledges support from an Air Force on-site Contract No. FA8650-21-D-5270 managed by MRL Materials Resources LLC at Wright-Patterson Air Force Base Materials Laboratory.

Conflict of interest

The authors declare no conflicts of interest.

Funding

Open access funding provided by EPFL Lausanne. Funding was supported by National Center of Competence in Research Materials’ Revolution: Computational Design and Discovery of Novel Materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Curtin, W.A., Rao, S.I. & Woodward, C. Progress and challenges in the theory and modeling of complex concentrated alloys. MRS Bulletin 47, 151–157 (2022). https://doi.org/10.1557/s43577-022-00306-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43577-022-00306-5