Abstract

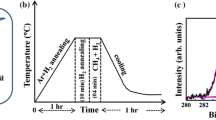

Graphene, with unique electrical, optical and mechanical properties is a promising material in industrial applications, such as batteries, supercapacitors, transistors and semiconductor devices. These potential applications of graphene have motivated the development of large-scale synthesis of graphene on copper substrates by chemical vapor deposition (CVD). To enable practical applications of large-area, high quality graphene layers at the centimeter and wafer scales, process control needs to be implemented for optimizing the morphology and electrical properties and enable repeatable growth-cycle of graphene layers for process-line implementation. Here we investigate the effects of process quartz-tube position on the structural properties of graphene. Furthermore, we describe a procedure for process optimization of the growth parameters. Graphene is grown on copper foils by CVD, and transferred to the SiO2/Si and glass substrates. The detailed characterization of the graphene layers are conducted using Raman spectroscopy, optical microscopy (OM), scanning electron microscopy (SEM) and UV-vis spectroscopy. The experimental results show that the position of copper foil into the quartz tube plays a significant role in the Raman features of the graphene, and influences the optical, morphology and surface properties of graphene layers. We believe that these results will be useful for determining the optimum processing conditions of high quality graphene layers at the centimeter and wafer scales.

Similar content being viewed by others

References

A. K. Geim & K. S Novoselov. Nature Mater. 6, 183 (2006).

K. I. Bolotin et al., Solid State Commun., 146,(2008).

C. Lee et al., Science,321, 385(2008).

A.A. Balandin et al., Nano Lett. 8, 902 (2008).

X.S. Li et al., Science 324, 1312 (2009).

L. Zhao et al., Solid State Commun., 151, 509–513 (2011).

X. Li et al., Science 324, 1312 (2009).

M. Regmi et al., Carbon, Volume 50, Issue 1, 134 (2012).

A. Srivastava et al., Chem. Mater., 22 (11), 3457–3461(2010).

A. Reina, Nano Lett., 9 (1), 30–35 (2009).

A. Srivastava., Chem. Mater., 22 (11), 3457 (2010).

D. I. Fotiadis et al., Journal of Crystal Growth, 100, 577 (1990).

Z.H. Ni et al., Nano Res., 1, 273 (2008).

M. S. Dresselhaus et al., NanoScience and Technology, Part 1,15 (2012).

Y. Kim et al., Appl. Phys. Lett., 98, 263106 (2011).

Z. Ni et al., Nano Res, 1, 273 (2008).

T. Parul et al., Journal of Vacuum Science & Techonolgy, 30 (1), 11401–7 (2012).

B. Y. Zhu et al., Advance Materials, 22 (35), 3906–3924 (2010).

Acknowledgments

We gratefully acknowledge financial support for this work by the Riverside Public Utilities, the CMMI Division of the National Science Foundation (Award: 0800680), the Materials Research Science and Engineering Center (NSF-MRSEC) on Polymers (Award: 0213695), the Winston Chung Global Energy Center at UCR, and the Nanoscale Science and Engineering Center (NSF-NSEC) on hierarchical manufacturing (CHM, Award: 0531171).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mutlu, Z., Penchev, M., Ruiz, I. et al. Effects of Process Tube Position on Properties of Graphene Layers. MRS Online Proceedings Library 1451, 57–62 (2012). https://doi.org/10.1557/opl.2012.1456

Published:

Issue Date:

DOI: https://doi.org/10.1557/opl.2012.1456