Abstract

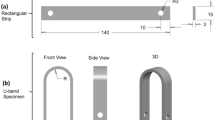

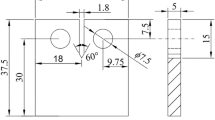

The stress corrosion cracking (SCC) of the commercial austenitic stainless steel type 304 was investigated as function of test temperature, microstructure and mechanical properties in acidic chloride solution (25 wt.%-MgCl2) using slow strain rate tests (SSRT). Susceptibility and mechanism of SCC was investigated using SSRT performed at strain rate of 1 x 10-6 in/s in a glass autoclave containing a magnesium chloride solution at 20, 50 and 80°C. The SCC assessment was carried out in function of the results of time to failure ratio (TFR), elongation ratio (ELR), ultimate tensile strength ratio (UTS-R), strain ratio(eR), yielding strength ratio (YSR) and stress rupture ratio (SR-R). This assessment was complemented by some scanning electron microscopy (SEM) observations, in order to determine the type of fracture and its features. SSRT results indicate that 304 stainless steel was susceptible to SCC at 50 and 80°C. SCC susceptibility increases as the temperature increase. By the contrary, the mechanical properties decreases with temperature increase. SEM observations showed a ductile type of fracture, indicating that cracks appear to be originated from the pits, increasing the number of cracks as the temperature increases. Corrosion pits are one of the main potential sites for surface crack initiation. The stress concentration in the pits will be the nucleation site for cracks.

Similar content being viewed by others

References

R. Jones, Stress Corrosion Cracking, Edited by Russell H. Jones, ASM International, Ohio, U.S.A. (1992), p.1–40, 91-130.

H. L. Logan, The stress corrosion of metals, Ed. John Wiley and Sons, Inc. N.Y. (1966), p. 107, 116.

ASTM G36-2006 Evaluating stress-corrosion cracking resistance of metals and alloys in a boiling magnesium chloride solution, (2006), p. 1–3.

R. Nishimura, Corrosion Science, 49, 81–91 (2007).

R. Nishimura, Y. Maeda, Corrosion Science, 46, 769–785 (2004).

N. A. Mariano, D. Spinelli, Materials Science and Engineering A, 385, 212–219 (2004).

G. M. Ugiansky, J.H. Payer (Eds.), Stress Corrosion Cracking—The Slow Strain Rate Technique, American Society for Testing and Materials, Philadelphia, (1979).

R. D. Kane, C.J.B.M. Joia, A.L.L.T. Small and J.A.C. Ponciano, Materials Performance, 36(9), 71–74 (1997).

O. E. Vega, A. Villagomez, J.M. Hallen and A. Contreras, Corrosion Engineering Science & Technology, 44(4), 289–296 (2009).

P. R. Rhodes, Corrosion, 57, 923–965 (2001).

M. Salazar, M. A. Espinosa P. Hernández and A. Contreras, Corrosion Engineering Science & Technology, 46(4), 464–470 (2011).

NACE TM-0198-2004. Slow Strain Rate Test Method for Screening Corrosion Resistant Alloys (CRAs) for Stress Corrosion Cracking in Sour Oilfield Service, (2004), p.1–17.

ASTM G-129-2006. Slow strain rate testing to evaluate the susceptibility of metallic materials to environmentally assisted cracking, (2006), p.1–7.

Z. Velazquez, E. Guzman, M. A. Espinosa-Medina and A. Contreras, Stress corrosion cracking behavior of X60 pipe steel in soil environment, Materials Research Society, Symposium Proceedings Vol. 1242, Edited by R. Pérez, A. Contreras and R. Esparza, (2010), p. 69–78.

M. Takano, Corrosion, 30(12), 441–446 (1974).

M. Takano and N. Totsuka, Corrosion, 36(1), 36–41 (1980).

R. Nishimura and Y. Maed, Corrosion Science, 46(3), 769–785 (2004).

H. F. López, M. M. Cisneros, H. Mancha, O. García, M. J. Pérez, Corrosion Science, 48, 913–924 (2006).

M. Al-Mansour, A. M. Alfantazi, M. El-boujdaini, Materials and Design, 30, 4088–4094. (2009).

P. Liang, X. Li, C. Du, and X. Chen, Materials & Design, 30, 1712–1717 (2009).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Contreras, A., Hernández, S.L., Terres, E. et al. Effect of Microstructure and Mechanical Properties on the Stress Corrosion Cracking Assessment of Type 304 Stainless Steel Using Slow Strain Rate Tests. MRS Online Proceedings Library 1372, 31–39 (2011). https://doi.org/10.1557/opl.2012.116

Published:

Issue Date:

DOI: https://doi.org/10.1557/opl.2012.116