Abstract

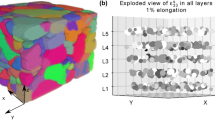

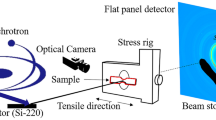

Taking the mesoscale to mean length and time scales at which a material’s behavior is too complex to be understood by construction from the atomistic scale, we focus on three-dimensional characterization and modeling of mesoscale responses of polycrystals to thermal and mechanical loading. Both elastic and plastic internal structural responses are now accessible via high-energy x-ray probes. The combination of diffraction experiments and computed tomography, for example, is yielding new insights into how void formation correlates with microstructural features such as grain boundaries and higher-order junctions. The resulting large, combined data sets allow for validation of micromechanical and thermal simulations. As detectors improve in resolution, quantum efficiency, and speed of readout, data rates and data volumes present computational challenges. Spatial resolutions approach one micrometer, while data sets span a cubic millimeter. Examples are given of applications to tensile deformation of copper, grain growth in nickel and titanium, and fatigue cracks in superalloys.

Similar content being viewed by others

References

Basic Energy Sciences Advisory Committee Subcommittee on Mesoscale Science, “From Quanta to the Continuum: Opportunities for Mesoscale Science,” US Department of Energy (September 2012); http://science.energy.gov/~/media/bes/pdf/reports/files/OFMS_rpt.pdf (accessed December 2014).

J. Li, C.Z. Wang, J.P. Chang, W. Cai, V.V. Bulatov, K.M. Ho, S. Yip, Phys. Rev. B Condens. Matter 10, 104113 (2004).

L. Kubin, B. Devincre, T. Hoc, Mater. Sci. Eng. A 483–484, 19 (2008).

H.J. Bunge, Texture Analysis in Materials Science (Butterworths, London, UK, 1982).

C. Kords, D.D. Tjahjanto, M. Diehl, D. Raabe, F. Roters, P. Eisenlohr, Procedia IUTAM 2, 3 (2012).

P.R. Dawson, D.E. Boyce, R. Rogge, Comput. Model. Eng. Sci. 10, 123 (2005).

S. Subedi, R. Pokharel, A.D. Rollett, Mater. Sci. Eng. A 638, 348 (2015).

R.A. Lebensohn, J.P. Escobedo, J.F. Bingert, Acta Mater. 61, 6918 (2013).

C.A. Stein, A. Cerrone, S.-B. Lee, T. Ozturk, P. Kenesei, H. Tucker, R. Pokharel, C. Hefferan, J. Lind, R.M. Suter, A.R. Ingraffea, A.D. Rollett, Curr. Opin. Solid State Mater. Sci. 18, 244 (2014).

V. Bulatov, W. Cai, Computer Simulations of Dislocations (Oxford University Press, Oxford, UK, 2006).

L.P. Kubin, Dislocations, Mesoscale Simulations, and Plastic Flow (Oxford University Press, Oxford, UK, 2013).

B. Derby, Acta Metall. Mater. 39, 955 (1991).

Z.P. Luo, H.W. Zhang, N. Hansen, K. Lu, Acta Mater. 60, 1322 (2012).

S. Xia, A. El-Azab, Model. Simul. Mater. Sci. Eng. 23, 055009 (2015).

G.S. Liu, S.D. House, J. Kacher, M. Tanaka, K. Higashida, I.M. Robertson, Mater. Charact. 87, 1 (2014).

W. Yang, B.C. Larson, G.M. Pharr, G.E. Ice, J.D. Budai, J.Z. Tischler, W.J. Liu, J. Mater. Res. 19, 66 (2004).

B.C. Larson, W. Yang, G.E. Ice, J.D. Budai, J.Z. Tischler, Nature 415, 887 (2002).

A. Ulvestad, A. Singer, J.N. Clark, H.M. Cho, J.W. Kim, R. Harder, J. Maser, Y.S. Meng, O.G. Shpyrko, Science 348, 1344 (2015).

M de Koning, R.J. Kurtz, V.V. Bulatov, C.H. Henager, R.G. Hoagland, W. Cai, M. Nomura, J. Nucl. Mater. 323, 281 (2003).

H.C. Huang, H. Van Swygenhoven, MRS Bull. 34, 160 (2009).

S.J. Fensin, C. Brandl, E.K. Cerreta, G.T. Gray, T.C. Germann, S.M. Valone, JOM 65, 410 (2013).

T.E. Buchheit, C.C. Battaile, C.R. Weinberger, E.A. Holm, JOM 63, 33 (2011).

S.F. Li, J. Lind, C.M. Hefferan, R. Pokharel, U. Lienert, A.D. Rollett, R.M. Suter, J. Appl. Crystallogr. 45, 1098 (2012).

J. Oddershede, S. Schmidt, H.F. Poulsen, H.O. Sorensen, J. Wright, W. Reimers, J. Appl. Crystallogr. 43, 539 (2010).

Y.S. Choi, M.A. Groeber, P.A. Shade, T.J. Turner, J.C. Schuren, D.M. Dimiduk, M.D. Uchic, C. Woodward, A.D. Rollett, T.A. Parthasarathy, Metall. Mater. Trans. A 45, 6352 (2014).

A.J. Beaudoin, M. Obstalecki, R. Storer, W. Tayon, J. Mach, P. Kenesei, U. Lienert, Model. Simul. Mater. Sci. Eng. 20, 024006 (2012).

H. Lim, J.D. Carroll, C.C. Battaile, T.E. Buchheit, B.L. Boyce, C.R. Weinberger, Int. J. Plast. 60, 1 (2014).

R. Pokharel, J. Lind, A.K. Kanjarala, R.A. Lebensohn, S.F. Li, P. Kenesei, R.M. Suter, A.D. Rollett, Annu. Rev. Condens. Matter Phys. 5, 317 (2014).

J. Schuren, J. Lind, S.F. Li, J. Bernier, P. Shade, T.J. Turner, P. Kenesei, J. Almer, B. Blank, R.M. Suter, Curr. Opin. Condens. Matter Mater. Sci. 19, 234 (2015).

R.A. Lebensohn, Acta Mater. 49, 2723 (2001).

B. Jakobsen, H.F. Poulsen, U. Lienert, J. Almer, S.D. Shastri, H.O. Sorensen, C. Gundlach, W. Pantleon, Science 312, 889 (2006).

H. Simons, A. King, W. Ludwig, C. Detlefs, W. Pantleon, S. Schmidt, I. Snigireva, A. Snigirev, H.F. Poulsen, Nat. Commun. 6, 6098 (2015).

W.M. Garrison, A.L. Wojcieszynski, Mater. Sci. Eng. A 464, 321 (2007).

K.S. Choi, W.N. Liu, X. Sun, M.A. Khaleel, Acta Mater. 57, 2592 (2009).

M.D. Uchic, M.A. Groeber, A.D. Rollett, JOM 63, 25 (2011).

S.F. Li, R.M. Suter, J. Appl. Crystallogr. 46, 512 (2013).

W. Ludwig, P. Reischig, A. King, M. Herbig, E.M. Lauridsen, G. Johnson, T.J. Marrow, J.Y. Buffière, Rev. Sci. Instrum. 80, 033905 (2009).

D.M. Saylor, A. Morawiec, G.S. Rohrer, J. Am. Ceram. Soc. 85, 3081 (2002).

Y. Jin, B. Lin, M. Bernacki, G.S. Rohrer, A.D. Rollett, N. Bozzolo, Mater. Sci. Eng. A 597, 295 (2014).

E.A. Holm, G.S. Rohrer, S.M. Foiles, A.D. Rollett, H.M. Miller, D.L. Olmsted, Acta Mater. 59, 5250 (2011).

J. Gruber, D.C. George, A.P. Kuprat, G.S. Rohrer, A.D. Rollett, Scr. Mater. 53, 351 (2005).

C.M. Hefferan, S.F. Li, J. Lind, U. Lienert, A.D. Rollett, P. Wynblatt, R.M. Suter, CMC—Comput. Mater. Con. 14, 209 (2009).

M. Bäurer, M. Syha, D. Weygand, Acta Mater. 61, 5664 (2013).

I.M. McKenna, S.O. Poulsen, E.M. Lauridsen, W. Ludwig, P.W. Voorhees, Acta Mater. 78, 125 (2014).

M.C. Demirel, A.P. Kuprat, D.C. George, A.D. Rollett, Phys. Rev. Lett. 90, 016106 (2003).

D.L. Olmsted, E.A. Holm, S.M. Foiles, Acta Mater. 57, 3704 (2009).

E.R. Homer, E.A. Holm, S.M Foiles, D.L. Olmsted, JOM 66, 114 (2014).

M. Herbig, A. King, P. Reischig, H. Proudhon, E.M. Lauridsen, J. Marrow J.Y. Buffiere, W. Ludwig, Acta Mater. 59, 590 (2011).

A.D. Spear, S.F. Li, J.F. Lind, R.M. Suter, A.R. Ingraffea, Acta Mater. 76, 413 (2014).

J.C. Newman Jr., E.P. Phillips, R.A. Everett, Fatigue Analysis under Constant- and Variable-Amplitude Loading Using Small-Crack Theory (NASA, TM-1999–209329, 1999).

H. Mughrabi, Mater. Sci. Eng. 33, 207 (1978).

C. Déprés, M. Fivel, L. Tabourot, Scr. Mater. 58, 1086 (2008).

C. Déprés, C.F. Robertson, M.C. Fivel, Philos. Mag. 86, 79 (2006).

C. Déprés, G.V. Prasad Reddy, C.F. Robertson, M.C. Fivel, Philos. Mag. 94, 4115 (2014).

W. Heinz, R. Pippan, G. Dehm, Mater. Sci. Eng. A 527, 7757 (2010).

J.E. Bozek, J.D. Hochhalter, M.G. Veilleux, M. Liu, G. Heber, S.D. Sintay, A.D. Rollett, D.J. Littlewood, A.M. Maniatty, H. Weiland, R.J. Christ, J. Payne, G. Welsh, D.G. Harlow, P.A. Wawrzynek, A.R. Ingraffea, Model. Simul. Mater. Sci. Eng. 16, 065007 (2008).

J.S. Miao, T.M. Pollock, J.W. Jones, Acta Mater. 57, 5964 (2009).

C.S. Shin, C.F. Robertson, M.C. Fivel, Philos. Mag. 87, 3657 (2007).

Y. Ro, S.R. Agnew, R.P. Gangloff, Metall. Mater. Trans. A 39A, 1449 (2008).

X. Tan, “A New Method for Fracture Surface Studies: Combined HEDM Orientation Mapping and Absorption Tomography Applied to a Nickel Superalloy,” PhD thesis, Department of Physics, Carnegie Mellon University, Pittsburgh (2014).

A. Cerrone III, C.A. Stein, R. Pokharel, C. Hefferan, J. Lind, H. Tucker, R.M. Suter, A.D. Rollett, A.R. Ingraffea, Model. Simul. Mater. Sci. Eng. 23 035006 (2015).

B. Lin, Y. Jin, C.M. Hefferan, S.F. Li, J. Lind, R.M. Suter, M. Bernacki, N. Bozzolo, A.D. Rollett, G.S. Rohrer, Acta Mater. 99, pp. 63–68 (2015).

S. Van Boxel, S. Schmidt, W. Ludwig, Y. Zhang, D.J. Jensen, W. Pantleon Mater. Trans. 55, 1, pp. 128–136 (2014).

Acknowledgments

The authors gratefully acknowledge many conversations about mesoscale science as it pertains to microstructure and mechanical properties, and especially, with members of the Basic Energy Sciences Advisory Committee. The nf-HEDM experimental capabilities illustrated here were developed at the Advanced Photon Source in collaboration with U. Lienert and P. Kenesei; analysis procedures and codes were developed at CMU by S.F. Li, J. Lind, C.M. Hefferan, and R.M.S. This work was supported, in part, by an AFOSR Discovery Challenge Thrust Grant #FA9550–10–1-0213 (characterization of fatigue cracks in super-alloys); in part by the US Department of Energy, Office of Basic Energy Sciences, Division of Materials Sciences and Engineering, under Award DESC0002001 (copper deformation); and in part by National Science Foundation Award DMR-1105173 (microstructural evolution in nickel during annealing).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rollett, A.D., Rohrer, G.S. & Suter, R.M. Understanding materials microstructure and behavior at the mesoscale. MRS Bulletin 40, 951–960 (2015). https://doi.org/10.1557/mrs.2015.262

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrs.2015.262