Abstract

Turbine engine performance, as measured by specific fuel consumption (defined as fuel consumed relative to the thrust produced by the engine), is a key criterion in engine selection. To achieve the specific fuel consumption required of modern engines, engineers combine advanced designs and materials to achieve higher operating temperatures and, therefore, higher engine efficiency. One of the difficulties of using advanced materials is that they exploit scarce, hard-to-replace elements to allow higher operating temperatures. In this article, we describe steps being taken by General Electric Co. and the turbine engine industry to continue to improve engines in a material space constrained by material availability. As a specific example, we focus on the transition metal rhenium.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

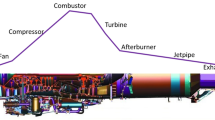

In their drive to increase engine efficiency, materials engineers have developed a wide range of materials. Whereas early engines were made from steel and exhibited relatively simple geometries, today’s engines incorporate many different materials and complex geometries depending on the needs of each specific component. Materials such as polymer-matrix composites, titanium alloys, wrought nickel and cobalt superalloys, and both equiaxed and single-crystal cast superalloys have all found applications in engines. In addition, each of these new material classifications has a range of associated compositions. For example, cast single-crystal nickel-based superalloys are classified into generations depending on the amount of rhenium in the specific alloys. Whereas rhenium is not present in first-generation single-crystal superalloys, it is used in increasing quantities in the second- and third-generation single-crystal superalloys. To continue to improve engine efficiency, it will be necessary to develop even more advanced materials for high-temperature use. In general, the advanced materials being developed are more complex and contain elements that are scarcer than was the case for previous generations of materials.

The challenge of sustainability was addressed at the International Congress on Sustainability Science & Engineering forum in 2009, for which the overview stated: “Sustainability has become a common currency in describing proactive plans and solutions in many scientific, engineering, and social science disciplines with no consensus on what sustainability means.” 1 To some extent, this remains true today, as the general definition of sustainable development (see the introductory article in this issue by Green et al.) is of limited use in assessing the sustainability of a given part or product. For the purposes of this article, we focus on a more specialized aspect of sustainability that strongly affects current and future aviation technology: conserving elements that are critical to producing components that enable efficiency improvements in turbine engines. In this case, the focus on sustainability arises because of the business desire to meet the market demand for more fuel-efficient engines when one of the critical elements for meeting that demand is in short supply.

For sustainable development of advanced engines, it is necessary to have a stable supply chain for each of the materials used. In the past, there have been concerns about the supply and/or cost of various elements. For example, the price of tantalum increased significantly in 2000, from approximately US$34/lb (US$75/kg) to approximately US$220/lb (US$485/kg), based on “overoptimistic forecasts of market growth and an apparent shortage of tantalum source material for processing.” 2 Many materials that are critical for engine manufacture are in short supply because they are present at very low levels in Earth’s crust; have environmental issues associated with their smelting; are from less politically stable parts of the world; or are associated with negative social consequences, such as mining being done to support conflict. Each of these supply-chain issues can change the sustainability of using these materials in manufacturing operations.

In this article, we discuss the procedures used to identify which materials could have an impact on the ability to manufacture engines and some of the developments that might mitigate an imprudent reliance on certain materials. To simplify the discussion, we concentrate on metallic structural materials because they are the predominant materials used in engines and discuss rhenium as a specific example of a critical element.

Identifying critical elements

Quantitative methods have recently been developed to evaluate the relative supply risks posed by raw materials at the element level. The U.S. National Research Council outlined an assessment tool that builds a “criticality matrix” in which risks are quantified element by element in two categories: “supply risk” and “impact of supply restriction.” 3 The U.S. Department of Energy recently used this methodology to determine the criticality of elements to renewable energy technologies.4 Methods are being developed to refine the supply risk category by using well-established indices that quantify element availability, as well as economic and geopolitical factors.5 A recent joint study group of the American Physical Society and the Materials Research Society also evaluated the landscape of energy-critical elements required for large-scale deployment of new technologies for the production, transmission, efficient use, or conservation of energy.6

The process that General Electric Co. (GE) uses to evaluate the risks associated with material shortages is a modification of the method developed by the National Research Council.7 The supply risk category is expanded to “price and supply risk” and includes an assessment of demand and supply dynamics, price volatility, geopolitics, and coproduction with other elements. The assessment of this first category relies on supply data from the U.S. Geological Survey, as well as knowledge of company-specific supply dynamics and current and projected future uses of the element. The second category is focused on the “impact of a restricted supply on GE” and includes an assessment of the company’s volume of usage compared to the world supply, the criticality of the element to products, and the impact on revenue of products containing the element. The results of a 2008 assessment for the element rhenium are shown in Figure 1, where the areas of the circles are proportional to the amount of usage by the company. This analysis thus indicated the need to develop risk-mitigation strategies for rhenium, because of its criticality as a constituent of the superalloys used in aircraft engines.

Material conservation

Once critical elements have been identified using the quantification method discussed in the preceding section, it is necessary to identify all of the sources and sinks for the critical elements throughout the production process. Thus, for each critical element, each step of the component manufacturing process and the component life cycle is audited to determine the amount of the critical element that is either added or discarded at that step. After the audit, it is necessary to develop the technologies and business plans to ensure that as little as possible of the critical element escapes from the life-cycle loop.

A schematic of such a life-cycle loop for a part made by casting is shown in Figure 2. The loop starts with melting of the primary alloy, which has a composition designed to provide a certain set of properties in the finished part. It is possible to reduce the amount of the critical element used at this point if an alternate composition, containing smaller amounts of the element, can be found that also produces the required final properties. Once the master alloy has been produced and castings have been made, it is common foundry practice to use the scrap from the casting process, such as gates or runners, as feedstock for the next master alloy. This process is called revert. As the castings move through the manufacturing process, they are machined and ground to produce the finished part geometry. These manufacturing processes generate chips, filings, or turnings, which are collectively called swarf. If the chips are large enough, they can go into the revert stream, similarly to gates and runners. Other technologies, usually chemical reduction to the elemental state, have been developed to recover the critical elements from the smaller swarf, such as filings.8 At the end of its useful life, a part can be recycled back to the alloy melting stage for recasting, usually through some sort of business arrangement to return used parts to the manufacturer.

In each step of the life-cycle loop, it is necessary to determine the most cost-efficient method of working with the material. In many cases, it is better to work with the material as an alloy. For example, it does not make economic sense to extract specific elements from alloys in larger pieces such as casting gates or runners; it is much easier to revert the alloy. However, in the case of the fine chips or swarf, it is usually easier to remove the alloying element chemically. This difference arises partly because of the difficulty of melting very fine metallic swarf.

Technologies for preventing loss of critical elements

The overall goal of materials for sustainable development is to have a closed-loop material stream. Any material that is injected into the closed-loop stream would ideally stay in the stream indefinitely. To prevent loss of the critical elements, various technologies are used to return the element back to the start of the loop. These technologies are discussed here using the specific example of rhenium in superalloys.

Rhenium is a scarce element in Earth’s crust, estimated at 0.4 parts per billion.9 Rhenium is recovered as a byproduct of molybdenite concentrates that are, in turn, recovered as a byproduct from copper ores.10 Thus, if the demand for copper decreases, there will also be a reduction in the supply of rhenium, because it is not economically viable to produce copper and molybdenum just to obtain the rhenium byproduct. There are two major uses for rhenium: as a constituent of platinum– rhenium catalysts and as an alloy addition to high-temperature superalloys.10 Approximately three-quarters of the rhenium is used as a strengthener in nickel-based superalloys, where it improves their ability to withstand high temperatures in turbine engines. All of the major producers of turbine engines, including GE, Pratt & Whitney, and Rolls Royce, use rhenium-containing alloys in their engines.10

Reduce

Motivated by concerns about potential supply restrictions, GE recently undertook a program to reduce the usage of rhenium. 7,8 In particular, the production supply of this strategic element was forecast to be less than the demand from the catalyst and superalloy markets described above. In response, alloy development was initiated to reduce the amount of rhenium in the superalloys while still maintaining the properties required for the finished parts. One aspect of this program involves developing alloys for specific applications. In the past, when supply problems were not an issue, it was common practice to develop a single alloy that could cover multiple applications. With the advent of element shortages, however, it has become necessary to tailor each alloy to meet the precise criteria for specific applications.

Extensive effort is expended during the development of these new alloys to ensure that they meet all of the property requirements for the specific applications. Also, manufacturing trials must be performed to show that the manufacturing process is not changed significantly. Finally, engine testing must be performed to demonstrate that the alloys have no detrimental effects on the other parts of the engine system

Revert

Revert involves collecting various pieces of scrap, cleaning them to remove any unwanted surface debris, and melting the scrap to produce the next master alloy for casting. The sources of this scrap could include portions of a casting that were not used in the final part or parts that have been retired from service. The main task for rhenium-containing revert is to make sure that as much of it as possible is collected and kept separate from other scrap. These scrap pieces are used as alloy and are not reduced to elements. The strategies around material revert are well-established. One of the main challenges is determining the composition of all of the input materials. In particular, supply-chain practices must be established to prevent mixing of chips with different compositions.11 Mixed-input stock can cause a whole ingot to have the wrong chemistry, which would exclude it from further use in the closed-loop stream for an advanced material.

One area of development is the reduction of revert generated by the casting process. Reducing the amount of scrap generated during casting reduces the possibility of losing the critical element. Techniques such as computer modeling of the casting process can be used to optimize the runners and gates and thus minimize the material sent to revert.

Recover

One of the more commonly overlooked leakage paths from the closed-loop stream is material that is converted into very fine pieces, such as the fine chips that result from grinding. When superalloys are ground, the resulting very fine shavings can be collected. Grinding medium is included with this swarf and must be removed as much as possible to concentrate the alloy. At this point, a decision must be made whether to continue to recover the material as an alloy or to remove the rhenium only. In the specific example mentioned previously, the choice was made to remove the rhenium from the alloy through a proprietary chemical process.8 The rhenium was removed from the alloy and concentrated to produce pure rhenium, which was then used as input stock for producing new alloy.

Recycle

Once a manufactured part has reached the end of its usable life, it becomes a candidate for recycling. Previously, this was one of the major leakages from the closed-loop stream because scrap parts were added to the general metal recycling stream and used as input for other alloys. For example, some superalloy was recycled as input stock for stainless steels because of the high nickel and chromium contents of the superalloy. In this way, the strategic elements from the superalloys were lost to future superalloys and instead became impurities in the steel rather than vital elements in new superalloy. To prevent this loss of rhenium from the closed-loop system, a specific recycling stream was developed within GE for rhenium-containing superalloys.

The process of recycling consists of identifying the material, removing the coatings, and cleaning the metal. In the case of recycling of superalloys from turbine engine components, the identification of material is greatly facilitated because each of the parts has a part number that can be correlated back to an alloy composition, thus reducing the amount of mixed scrap, as discussed in the Revert section. Most engine components have a coating of some kind, and any residual coating must be removed prior to remelting of the alloy, to prevent contamination. The material cleaning is similar to the cleaning done for revert. Once all of these process steps are completed, the material can be used in the revert stream.

It should be noted that, during the coating removal and cleaning stages, the cleaning solution might remove small amounts of the rhenium-containing superalloy, which must also be taken into account in the closed-loop process. The cleaning solution thus becomes another candidate for further recovery.

Reduced material usage: Additive manufacturing

As mentioned in the Revert section, one way to reduce the leakage of rhenium is to reduce the amount of material generated as scrap during the casting process. An alternative to the casting process for producing components that can help in reaching this goal is additive manufacturing. 12,13 In additive manufacturing, a computer is used to represent a three-dimensional shape as a large number of two-dimensional shapes in a computer. These two-dimensional shapes are then built up layer by layer using a computer-controlled melting or sintering process. The result of additive manufacturing is that very little waste material is produced, so that the revert and recover processes become negligible. Additive manufacturing also has the ability to eliminate manufacturing steps by producing a single component for parts that would otherwise require the production and joining of several smaller components.

Airbus has formed an Additive Layer Manufacturing Center,14 and the other aerospace manufacturers have various developmental programs in the United States and globally. These efforts aim to reduce the “buy-to-fly” ratio between the amounts of material in the original rough component shape and in the final product. For many parts in gas turbines, this ratio is around 2:1, meaning that one-half of the raw material remains as swarf generated during machining. For some parts, however, the buy-to-fly ratio is over 10:1, corresponding to 90% material loss.

Clearly, additive manufacturing poses an attractive alternative for the fabrication of parts, as it could reduce the amounts of waste material being produced and the potential loss of critical elements such as rhenium. In practice, additive manufacturing has been used exclusively to produce parts that are relatively small. The time needed to produce large parts by additive manufacturing would be prohibitive with today’s technology. However, accelerating the additive manufacturing process is an area of active development.

An example of a monolithic component that was formed using additive manufacturing is shown in Figure 3: a fuel circuit from a combustion module. This part would conventionally consist of 12–20 piece parts, brazed together. In this case, the process is simplified by using additive manufacturing technology to fabricate a single-piece fuel circuit. The process simplification results in a reduction in the amount of energy used in the process through elimination of high-temperature braze cycles. In addition, reduced machining is required, which results in additional energy reduction and reduced opportunity for loss of critical elements.

There is much to learn to exploit these emerging additive manufacturing processes. Figure 4 shows the evolution of the fuel circuit in Figure 3 from initial design to final configuration. The original design (Figure 4a) was built based on a computer model of the conventionally produced fuel circuit components. When this geometry was first produced by additive manufacturing and tested, several problems were identified, so the part geometry was reconfigured to that shown in Figure 4b to mitigate these problems. An advantage of the additive manufacturing process is that changing from the geometry in Figure 4a to that in Figure 4b required only a modification of the geometry in the computer model. No hard tooling, such as of fixtures or gauges, was required. Thus, the redesigned part could be fabricated within one week. As additional quantities of fuel circuits were built and productivity/ throughput was sought, it was realized that various additional changes in the part geometry could eliminate 10% of the cycle time from the fabrication cycle, resulting in the configuration shown in Figure 4c.

Summary

This article has described several of the steps that General Electric Co. and the turbine engine industry have taken and continue to pursue to address the sustainable development of aviation technology. Of specific concern is the need to conserve scarce elements that are critical to producing components that drive efficiency improvements in turbine engines. In this article, the scarce element rhenium was used as an example. Methods have been developed to first identify critical elements and then take actions to reduce the reliance on those critical elements. The actions include both the evaluation of processes and the development of new technologies. Future developments in casting modeling and additive manufacturing to reduce the amounts of material entering the revert and recover streams will be beneficial in reducing the loss of scarce elements. In turn, reducing the loss of elements that are required to meet societal market demands will allow companies to meet their business goals while sustaining the development of future engine advances.

References

First International Congress on Sustainability Science and Engineering, Cincinnati, OH, 9–12 April 2009, http://www.aiche.org/IFS/Conferences/ICOSSE09.aspx (accessed January 2012).

M.J. Magyar, in 2004 Minerals Yearbook (U.S. Geological Survey, Reston, VA, 2004).

Minerals, Critical Minerals, and the U.S. Economy (National Academies Press, Washington, DC, 2008).

Critical Materials Strategy (U.S. Department of Energy, Washington, DC, 2010).

T.E. Graedel, R. Barr, C. Chandler, T. Chase, J. Choi, L. Christofferson, E. Friedlander, C. Henly, C. Jun, N.T. Nassar, D. Schechner, S. Warren, M.-y. Yang, C. Zhu, Environ. Sci. Technol. 46, 1063 (2012).

R. Jaffe, J. Price, Energy Critical Elements: Securing Materials for Emerging Technologies (American Physical Society, Washington, DC, 2011).

S.J. Duclos, J.P. Otto, D.G. Konitzer, Mech. Eng. 132 (9), 36 (2010).

P.J. Fink, J.L. Miller, D.G. Konitzer, JOM 62 (1), 55 (2010).

“Re - Rhenium” (Minor Metals Trade Association, London, UK, 2008), www.mmta.co.uk/metals/Re/ (accessed January 2012).

D.E. Polyak, in 2009 Minerals Yearbook (U.S. Geological Survey, Reston, VA, 2011).

S. Sikkenga, INCAST Mag. 10 (May 1998).

D. Abbott, paper presented at the International Conference on Additive Manufacturing, Leicestershire, UK, 12–13 July 2011.

“Print me a Stradivarius: How a new manufacturing technology will change the world,” The Economist (10 February 2011).

“EADS, GKN Aerospace Launch Additive Layer Manufacturing Collaboration” (EADS, Munich, Germany, 2011), www.eads.com/eads/int/en/our-innovation/latest-news/EADS--GKN-AEROSPACE-LAUNCH-ADDITIVE-LAYER-MANUFACTURING-COLLABORATION-.html (accessed January 2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Konitzer, D., Duclos, S. & Rockstroh, T. Materials for sustainable turbine engine development. MRS Bulletin 37, 383–387 (2012). https://doi.org/10.1557/mrs.2012.35

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrs.2012.35