Abstract

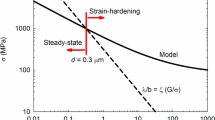

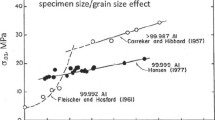

Recent observations on strength and deformation of small metals containing microstructures, including dislocation patterns, grain boundaries, and second-phase precipitates are reviewed. These microstructures impose an internal length scale that may interplay with the extrinsic length scale due to the specimen size to affect strength and deformation in an intricate manner. For micro-crystals containing pre-existing dislocations, Taylor work-hardening may dictate the dependence of strength on specimen size. The presence of grain boundaries in a small specimen may lead to effects far from the conventional Hall–Petch behavior. Precipitate–dislocation interactions in a small specimen may lead to an interesting weakest-size behavior.

Similar content being viewed by others

References

R. Dou and B. Derby: A universal scaling law for the strength of metal micropillars and nanowires. Scr. Mater. 61, 524 (2009).

J.R. Greer and J.T.M. De Hosson: Plasticity in small-sized metallic systems: intrinsic versus extrinsic size effect. Prog. Mater. Sci. 56, 654 (2011).

A.H.W. Ngan, L. Zuo, and P.C. Wo: Size dependence and stochastic nature of yield strength of micron-sized crystals: a case study on Ni3Al. Prof. R. Soc. Lond. A462, 1661 (2006).

L. Zuo and A.H.W. Ngan: Molecular dynamics study on compressive yield strength in Ni3Al micro-pillars. Phil. Mag. Lett. 86, 355 (2006).

J.R. Greer, W.C. Oliver, and W.D. Nix: Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 53, 1821 (2005).

J.R. Greer and W.D. Nix: Nanoscale gold pillars strengthened through dislocation starvation. Phys. Rev. B 73, 245410 (2006).

Z.W. Shan, R.K. Mishra, S.A.S. Asif, O.L. Warren, and A.M. Minor: Mechanical annealing and source-limited deformation in submicrometre-diameter Ni crystals. Nat. Mater. 7, 115 (2008).

T.A. Parthasarathy, S.I. Rao, D.M. Dimiduk, M.D. Uchic, and D.R. Trinkle: Contribution to size effect of yield strength from the stochastics of dislocation source lengths in finite samples. Scr. Mater. 56, 313 (2007).

D.M. Norfleet, D.M. Dimiduk, S.J. Polasik, M.D. Uchic, and M.J. Mills: Dislocation structures and their relationship to strength in deformed nickel microcrystals. Acta Mater. 56, 2988 (2008).

K.S. Ng and A.H.W. Ngan: Stochastic nature of plasticity of aluminum micro-pillars. Acta Mater. 56, 1712 (2008).

Y. Cui, C. Po, and N. Ghoniem: Controlling strain bursts and avalanches at the nano- to micrometer scale. Phys. Rev. Lett. 117, 155502 (2016).

S.I. Rao, D.M. Dimiduk, T.A. Parthasarathy, M.D. Uchic, M. Tang, and C. Woodward: Athermal mechanisms of size-dependent crystal flow gleaned from three-dimensional discrete dislocation simulations. Acta Mater. 56, 3245 (2008).

J.A. El-Awady, M. Wen, and N.M. Ghoniem: The role of the weakest-link mechanism in controlling the plasticity of micropillars. J. Mech. Phys. Solids 57, 32 (2009).

C. Motz, D. Weygand, J. Senger, and P. Gumbsch: Initial dislocation structures in 3-D discrete dislocation dynamics and their influence on microscale plasticity. Acta Mater. 57, 1744 (2009).

S. Akarapu, H.M. Zbib, and D.F. Bahr: Analysis of heterogeneous deformation and dislocation dynamics in single crystal micropillars under compression. Int. J. Plast. 26, 239 (2010).

M. Huang, L. Zhao, and J. Tong: Discrete dislocation dynamics modelling of mechanical deformation of nickel-based single crystal superalloys. Int. J. Plast. 28, 141 (2012).

Y. Cui, P. Lin, Z.L. Liu, and Z. Zhuang: Theoretical and numerical investigations of single arm dislocation source controlled plastic flow in FCC micropillars. Int. J. Plast. 55, 279 (2014).

Q. Yu, M. Legros, and A.M. Minor: In situ TEM nanomechanics. MRS Bull. 40, 62 (2015).

P.J. Imrich, C. Kirchlechner, D. Kiener, and G. Dehm: In situ TEM microcompression of single and bicrystalline samples: insights and limitations. JOM 67, 1704 (2015).

R. Maaß, L. Meza, B. Gan, S. Tin, and J.R. Greer: Ultrahigh strength of dislocation-free Ni3Al nanocubes. Small 8, 1869 (2012).

L.Y. Chen, M.-R. He, J. Shin, G. Richter, and D.S. Gianola: Measuring surface dislocation nucleation in defect-scarce nanostructures. Nature Mater. 14, 707 (2015).

H. Bei, S. Shim, G.M. Pharr, and E.P. George: Effects of pre-strain on the compressive stress-strain response of Mo-alloy single-crystal micropillars. Acta Mater. 56, 4762 (2008).

C.R. Weinberger and W. Cai: Surface-controlled dislocaiton multiplication in metal micropillars. Proc. Nat. Acad. Sci. USA 105, 14304 (2008).

T.T. Zhu, A.J. Bushby, and D.J. Dunstan: Materials mechanical size effects: a review. Mater. Technol. 23, 193 (2008).

A.H.W. Ngan: An explanation for the power-law scaling of size effect on strength in micro-specimens. Scr. Mater. 65, 978 (2011).

R. Gu and A.H.W. Ngan: Dislocation arrangement in small crystal volumes determines power-law size dependence of yield strength. J. Mech. Phys. Solids 61, 1531 (2013).

A.S. Schneider, D. Kiener, C.M. Yakacki, H.J. Maier, P.A. Gruber, N. Tamura, M. Kunz, A.M. Minor, and C.P. Frick: Influence of bulk pre-straining on the size effect in nickel compression pillars. Mater. Sci. Eng. A 559, 147 (2013).

J.A. El-Awady, M.D. Uchic, P.A. Shade, S.-L. Kim, S.I. Rao, D.M. Dimiduk, and C. Woodward: Pre-straining effects on the power-law scaling of size-dependent strengthening in Ni single crystals. Scr. Mater. 68, 207 (2013).

P.S. Phani, K.E. Johanns, E.P. George, and G.M. Pharr: A simple stochastic model for yielding in specimens with limited number of dislocations. Acta Mater. 61, 2489 (2013).

J.A. El-Awady: Unravelling the physics of size-dependent dislocation-mediated plasticity. Nat. Commun. 6, 5926 (2015).

R. Gu and A.H.W. Ngan: Effects of pre-straining and coating on plastic deformation of aluminum micropillars. Acta Mater. 60, 6102 (2012).

B. Ehrler, X.D. Hou, T.T. Zhu, K.M.Y. Png, C.J. Walker, A.J. Bushby, and D.J. Dunstan: Grain size and sample size interact to determine strength in a soft metal. Phil. Mag. 88, 3043 (2008).

X.X. Chen and A.H.W. Ngan: Specimen size and grain size effects on tensile strength of Ag microwires. Scr. Mater. 64, 717 (2011).

C. Keller, E. Hug, and X. Feaugas: Microstructural size effects on mechanical properties of high purity nickel. Int. J. Plast. 27, 635 (2011).

X.X. Chen and A.H.W. Ngan: Tensile deformation of silver micro-wires of small thickness-to-grain-size ratios. Mater. Sci. Eng. A 539, 74 (2012).

P.S.S. Leung and A.H.W. Ngan: Size effect on the strength of micron-sized polycrystals—a dislocation dynamics simulation study. Scr. Mater. 69, 235 (2013).

R. Gu and A.H.W. Ngan: Size effect on the deformation behavior of duralumin micropillars. Scr. Mater. 68, 861 (2013).

K. Gan, R. Gu, and A.H.W. Ngan: The weakest size of precipitated alloys in the micro regime: the case of duralumin. Submitted to J. Mater. Res.

R. Gu, P.S.S. Leung, and A.H.W. Ngan: Size effect on deformation of duralumin micropillars—a dislocation dynamics study. Scr. Mater. 76, 73 (2014).

C. Zhou, I.J. Beyerlein, and R. LeSar: Plastic deformation mechanisms of fcc single crystals at small scales. Acta Mater. 59, 7673 (2011).

Acknowledgment

Financial support by the Kingboard Professorship Endowment is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ngan, A.H.W., Chen, X.X., Leung, P.S.S. et al. Size effects of micrometer-scaled metals—the search continues for materials containing real microstructures. MRS Communications 7, 131–140 (2017). https://doi.org/10.1557/mrc.2017.23

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2017.23