Abstract

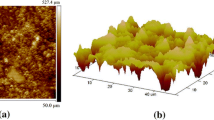

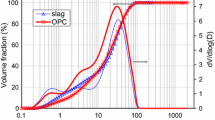

Regarding the significance of cement paste in construction materials, the present paper aims to use nanoindentation to measure and map mechanical properties of hardened cement pastes. The mechanical properties of involved phases were extracted from grid nanoindentation on the cement paste. The results suggested that nanoindentation can be used as a tool to measure and map mechanical properties of hardened cement pastes, and can identify the phases, including outer product, inner product, calcium hydroxide (or interface of residual cement clinker), and residual cement clinker.

Similar content being viewed by others

References

G. Constantinides and F.J. Ulm: The effect of two types of C–S–H on the elasticity of cement-based materials: results from nanoindentation and micromechanical modeling. Cem. Concrete Res. 34, 67 (2004).

W. Zhu, J.J. Hughes, N. Bicanic and C.J. Pearce: Nanoindentation mapping of mechanical properties of cement paste and natural rocks. Mater. Charact. 58, 1189 (2007).

H.M. Jennings, J.J. Thomas, J.S. Gevrenov, G. Constantinides and F.J. Ulm: A multi-technique investigation of the nanoporosity of cement paste. Cem. Concrete Res. 37, 329 (2007).

G. Constantinides and F.J. Ulm: The nanogranular nature of C–S–H. J. Mech. Phys. Solids 55, 64 (2007).

P. Mondal, S.P. Shah and L. Marks: A reliable technique to determine the local mechanical properties at the nanoscale for cementitious materials. Cem. Concrete Res. 37, 1440 (2007).

F.J. Ulm, M. Vandamme, C. Bobko and J.A. Ortega: Statistical indentation techniques for hydrated nanocomposites: concrete, bone, and shale. J. Am. Ceram. Soc. 90, 2677 (2007).

M. Vandamme and F.J. Ulm: Nanogranular origin of concrete creep. Proc. Natl. Acad. Sci. U. S. A. 106, 10552 (2009).

T. Howind, J.J. Hughes, W. Zhu, F. Puertas, S. Goñi, M.S. Hernández, A. Guerrero, M. Palacios and J.S. Dolado: Mapping of mechanical properties of cement paste microstructures. In 13th Int. Congress on the Chemistry of Cement, Á. Palomo; A. Zaragoza and J.C.L. Agüí; (Madrid, 2011).

D. Davydov, M. Jirasek and L. Kopecky: Critical aspects of nano-indentation technique in application to hardened cement paste. Cem. Concrete Res. 41, 20 (2011).

M. Vandamme, F.J. Ulm and P. Fonollosa: Nanogranular packing of C–S–H at substochiometric conditions. Cem. Concrete Res. 40, 14 (2010).

C.L. Hu, Z.J. Li, Y.Y. Gao and Y.M. Zhang: Investigation on microstructures of cementitious composites incorporating slag. Adv. Cem. Res. 26, 222 (2014).

J.J. Chen, L. Sorelli, M. Vandamme, F.J. Ulm and G. Chanvillard: A coupled nanoindentation/sem-eds study on low water/cement ratio portland cement paste: evidence for C–S–H/Ca(OH)(2) nanocomposites. J. Am. Ceram. Soc. 93, 1484 (2010).

C.L. Hu, Y.G. Han, Y.Y. Gao, Y.M. Zhang and Z.J. Li: Property investigation of calcium–silicate–hydrate (C–S–H) gel in cementitious composites. Mater. Charact. 95, 129 (2014).

G.M. Pharr and A. Bolshakov: Understanding nanoindentation unloading curves. J. Mater. Res. 17, 2660 (2002).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

Y.T. Cheng and C.M. Cheng: Scaling, dimensional analysis, and indentation measurements. Mater. Sci. Eng. R - Rep. 44, 91 (2004).

D. Tabor: A simple theory of static and dynamic hardness. Proc. R. Soc. A 192, 247 (1948).

S. Cariou, F.J. Ulm and L. Dormieux: Hardness-packing density scaling relations for cohesive-frictional porous materials. J. Mech. Phys. Solids 56, 924 (2008).

A.P. Dempster, N.M. Laird and D.B. Rubin: Maximum likelihood from incomplete data via the em algorithm. J. R. Stat. Soc. Ser. B Stat. Methodol. 39, 1 (1977).

G. Schwarz: Estimating the dimension of a model. Ann. Stat. 6, 461 (1978).

L. Jiang, Y.M. Zhang, C.L. Hu and Z.J. Li: Calculation of elastic modulus of early-age cement paste. Adv. Cem. Res. 24, 193 (2012).

K. Velez, S. Maximilien, D. Damidot, F. Fantozzi and F. Sorrentino: Determination by nanoindentation of elastic modulus and hardness of pure constituents of Portland cement clinker. Cem. Concr. Res. 31, 555 (2001).

Acknowledgments

The financial supports from Hong Kong Research Grant Council under Grant 615412 and China Ministry of Science and Technology under Grant 2015CB655100 are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, C. Nanoindentation as a tool to measure and map mechanical properties of hardened cement pastes. MRS Communications 5, 83–87 (2015). https://doi.org/10.1557/mrc.2015.3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2015.3