Abstract

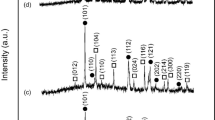

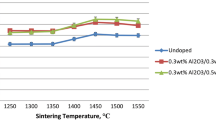

In order to expand the family and improve the bioactivity of oral implant ceramics, the phase structures, mechanical and wetting properties of the hot-pressed yttria-zirconia/multilayer graphene oxide composite (3Y-ZrO2/GO) ceramics were investigated. GO was uniformly distributed in 3Y-ZrO2 powders, forming the C–O–Zr bond during the sintering process. In comparison to raw 3Y-ZrO2 ceramics, the flexural strength and fracture toughness improved up to 200% (1489.96 ± 35.71 MPa) in ZG3 (with 0.15 wt% GO) and 40.9% (8.95 ± 0.59 MPa m1/2) in ZG2 (with 0.1 wt% GO), respectively, while the relative density and Vickers hardness increased slightly. The toughening mechanisms included crack deflection, crack bridging, and GO put-out. Meanwhile, the composite ceramics were transformed into a more hydrophilic direction and indicated a good wetting property. In consideration of mechanical and wetting properties, the ZG3 would be a favorable alternative to the yttria-zirconia ceramic (Y-TZP) in dental implant applications. The results are expected to serve as a technical guidance for the fabrication and evaluation of dental implants.

Similar content being viewed by others

References

G.-R. Fan, H.-J. Su, J. Zhang, M. Guo, H. Yang, H.-F. Liu, E.-Y. Wang, L. Liu, and H.-Z. Fu: Microstructure and cytotoxicity of Al2O3-ZrO2 eutectic bioceramics with high mechanical properties prepared by laser floating zone melting. Ceram. Int. 44, 17978–17985 (2018).

L. Bao, J.-X. Liu, F. Shi, Y.-Y. Jiang, and G.-S. Liu: Preparation and characterization of TiO2 and Si-doped octacalcium phosphate composite coatings on zirconia ceramics (Y-TZP) for dental implant applications. Appl. Surf. Sci. 290, 48–52 (2014).

A. Carvalho, L. Grenho, M.-H. Fernandes, A. Daskalova, A. Trifonov, I. Buchvarov, and F.-J. Monteiro: Femtosecond laser microstructuring of alumina toughened zirconia for surface functionalization of dental implants. Ceram. Int. 46, 1383–1389 (2020).

I. Sailer, N.-A. Makarov, D.-S. Thoma, M. Zwahlen, and B.-E. Pjetursson: All-ceramic or metal-ceramic tooth-supported fixed dental prostheses (FDPs)? A systematic review of the survival and complication rates. Part I: Single crowns (SCs). Dent. Mater. 31, 603–623 (2015).

C.-L. Coadou, N. Karst, F. Emieux, O. Sicardy, A. Montani, G. Bernard-Granger, J. Chevalier, L. Gremillard, and J.-P. Simonato: Assessment of ultrathin yttria-stabilized zirconia foils for biomedical applications. J. Mater. Sci. 50, 1–11 (2017).

O.-S.-A. El-Ghany and A.-H. Sherief: Zirconia based ceramics, some clinical and biological aspects: Review. Fut. Dent. J. 2, 55–64 (2016).

M.-S. Chaar, N. Passia, and M. Kern: Ten-year clinical outcome of three-unit posterior FDPs made from a glass-infiltrated zirconia reinforced alumina ceramic (in-ceram zirconia). J. Dent. 43, 512–517 (2015).

M.-E. Roy, L.-A. Whiteside, B.-J. Katerberg, and J.-A. Steiger: Phase transformation, roughness, and microhardness of artificially aged yttria- and magnesia-stabilized zirconia femoral heads. J. Biomed. Mater. Res. A 83A, 1096–1102 (2007).

R.-C. Garvie, C. Urbani, D.-R. Kennedy, and J.-C. McNeuer: Biocompatibility of magnesia-partially stabilized zirconia (Mg-PSZ) ceramics. J. Mater. Sci. 19, 3224–3228 (1984).

E.-T. Thostenson, Z.-F. Ren, and T.-W. Chou: Advances in the science and technology of carbon nanotubes and their composites: A review. Compos. Sci. Technol. 61, 1899–1912 (2001).

S. Iijima: Helical microtubules of graphitic carbon. Nature 354, 56–58 (1991).

V. Castranova, P.-A. Schulte, and R.-D. Zumwalde: Occupational nanosafety considerations for carbon nanotubes and carbon nanofibers. Acc. Chem. Res. 46, 642–649 (2012).

N. Aoki, T. Akasaka, F. Watari, and A. Yokoyama: Carbon nanotubes as scaffolds for cell culture and effect on cellular functions. Dent. Mater. J. 26, 178–185 (2007).

N. Ogihara, Y. Usui, K. Aoki, M. Shimizu, N. Narita, K. Hara, K. Nakamura, N. Ishigaki, S. Takanashi, M. Okamoto, H. Kato, H. Haniu, N. Ogiwara, N. Nakayama, S. Taruta, and N. Saito: Biocompatibility and bone tissue compatibility of alumina ceramics reinforced with carbon nanotubes. Nanomedicine 7, 981–993 (2012).

A.-A. Khan, A.-A. Al Kheraif, J. Syed, D.-D. Divakar, and J.-P. Matinlinna: Enhanced resin zirconia adhesion with carbon nanotubes-infused silanes: A pilot study. J. Adhes. 94, 167–180 (2016).

C. Lee, X.-D. Wei, J.-W. Kysar, and J. Hone: Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321, 385–388 (2008).

H.-Y. He, J. Klinowski, M. Forster, and A. Lerf: A new structural model for graphite oxide. Chem. Phys. Lett. 287, 53–56 (1998).

J.-W. Liu, Q. Zhang, X.-W. Chen, and J.-H. Wang: Surface assembly of graphene oxide nanosheets on SiO2 particles for the selective isolation of hemoglobin. Chemistry 17, 4864–4870 (2011).

L. Kou and C. Gao: Making silica nanoparticle-covered graphene oxide nanohybrids as general building blocks for large-area superhydrophilic coatings. Nanoscale 3, 519–528 (2011).

J.-H. Shin and S.-H. Hong: Fabrication and properties of reduced graphene oxide reinforced yttria-stabilized zirconia composite ceramics. J. Eur. Ceram. Soc. 34, 1297–1302 (2014).

S. Ramesh, M.-M. Khan, H.-C. Alexander Chee, Y.-H. Wong, P. Ganesan, M.-G. Kutty, U. Sutharsini, W.-J. Kelvin Chew, and A. Niakan: Sintering behavior and properties of graphene oxide-doped Y-TZP ceramics. Ceram. Int. 42, 17620–17625 (2016).

Z.-Y.-B. Zeng, Y.-Z. Liu, W.-P. Chen, X.-Q. Li, Q.-F. Zheng, K.-L. Li, and R.-R. Guo: Fabrication and properties of in situ reduced graphene oxide-toughened zirconia composite ceramics. J. Am. Ceram. Soc. 101, 3498-3507 (2018).

X. Huang, X.-Y. Qi, F. Boey, and H. Zhang: Graphene-based composites. Chem. Soc. Rev. 41, 666–686 (2012).

G.-K.-R. Pereira, A.-B. Venturini, T. Silvestri, K.-S. Dapieve, A.-F. Montagner, F.-Z.-M. Soares, and L.-F. Valandro: Low-temperature degradation of Y-TZP ceramics: A systematic review and meta-analysis. J. Mech. Behav. Biomed. 55, 151–163 (2016).

A.-C. Ferrari, J.-C. Meyer, V. Scardaci, C. Casiraghi, M. Lazzeri, F. Mauri, S. Piscanec, D. Jiang, K.-S. Novoselov, S. Roth, and A.-K. Geim: Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 97, 187401.1–187401.4 (2006).

J.-W. Sha, N.-Q. Zhao, E. Liu, C.-S. Shi, C.-N. He, and J.-J. Li: In situ synthesis of ultrathin 2-D TiO2 with high energy facets on graphene oxide for enhancing photocatalytic activity. Carbon 68, 352–359 (2014).

L. Zhang, W.-W. Liu, C.-G. Yue, T.-H. Zhang, P. Li, Z.-W. Xing, and Y. Chen: A tough graphene nanosheet/hydroxyapatite composite with improved in vitro biocompatibility. Carbon 61, 105–115 (2013).

Q. Zhou, J.-X. Huang, J.-Q. Wang, Z.-G. Yang, S. Liu, Z.-F. Wang, and S.-R. Yang: Preparation of a reduced graphene oxide/zirconia nanocomposite and its application as a novel lubricant oil additive. RSC Adv. 5, 91802–91812 (2015).

D. Li, J. Yao, B. Liu, H. Sun, S. Agtmaal, and C.-H. Feng: Preparation and characterization of surface grafting polymer of ZrO2 membrane and ZrO2 powder. Appl. Surf. Sci. 471, 394–402 (2019).

X. Zhang, Y.-Y. Wu, S.-Y. He, and D.-Z. Yang: Structural characterization of sol-gel composites using TEOS/MEMO as precursors. Surf. Coat. Technol. 201, 6051–6058 (2007).

C.-Q. Liu, K.-Z. Li, H.-J. Li, S.-Y. Zhang, Y.-L. Zhang, and B. Wang: Synthesis, characterization and ceramization of a carbon-rich zirconium-containing precursor for ZrC ceramic. Ceram. Int. 40, 7285–7292 (2014).

S. Fabris, A.-T. Paxton, and M.-W. Finnis: A stabilization mechanism of zirconia based on oxygen vacancies only. Acta Mater. 50, 5171–5178 (2002).

J. Liu, H.-X. Yan, M.-J. Reece, and K. Jiang: Toughening of zirconia/alumina composites by the addition of graphene platelets. J. Eur. Ceram. Soc. 32, 4185–4193 (2012).

M. Kurumada, H. Hara, and E. Iguchi: Oxygen vacancies contributing to intragranular electrical conduction of yttria-stabilized zirconia (YSZ) ceramics. Acta Mater. 53, 4839–4846 (2005).

B.-S. Yilbas: Laser treatment of zirconia surface for improved surface hydrophobicity. J. Alloys Compd. 625, 208–215 (2015).

J.-R. Rani, J. Lim, J. Oh, J.-W. Kim, H.-S. Shin, J.-H. Kim, S. Lee, and S.-C. Jun: Epoxy to carbonyl group conversion in graphene oxide thin films: Effect on structural and luminescent characteristics. J. Phys. Chem. C 116, 19010–19017 (2012).

C. Burmeister and A. Kwade: Process engineering with planetary ball mills. Chem. Soc. Rev. 42, 7660 (2013).

R.-W. Rice, C.-C. Wu, and F. Boichelt: Hardness–grain-size relations in ceramics. J. Am. Ceram. Soc. 77, 2539–2553 (1994).

S.-C. Zhang, W.-G. Fahrenholtz, G.-E. Hilmas, and E.-J. Yadlowsky: Pressureless sintering of carbon nanotube Al2O3 composites. J. Eur. Ceram. Soc. 30, 1373–1380 (2010).

Acknowledgment

This project was supported by the National Natural Science Foundation of China (Grant No. 51175304) and the Shandong Provincial Natural Science Foundation, China (Grant Nos ZR2017MEE052 and ZR2018ZB0105). The authors thank all the former researches contributed to this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, C., Jiang, Z., Zhao, L. et al. Synthesis and characterization of multilayer graphene oxide on yttria-zirconia ceramics for dental implant. Journal of Materials Research 35, 2466–2477 (2020). https://doi.org/10.1557/jmr.2020.199

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.199