Abstract

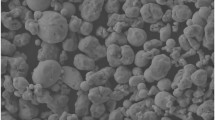

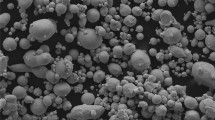

In this paper, the microstructure and the shear property of Cu/In–45Cu/Ni solder joints by transient liquid phase were studied, and the intermetallic compounds (IMCs) growth mechanism was investigated. The results showed that the IMCs volume ratio of solder joints was increased firstly and then decreased with increasing bonding time, and the IMCs volume ratio reached its maximum value of 95.8% at 60 min. The Cu interfacial IMC of the solder joint with dense microstructure was Cu2In phase at 60 min, and the Ni interfacial IMC was Ni3In7. The maximum shear strength of solder joints was obtained at 60 min, which is 15.21 MPa. The shear fracture appeared honeycomb structure, and the fracture occurred at the phase interface of Ni3In7/Cu11In9. The thickness of the interfacial IMCs and the white IMCs around the Cu particles (Cu@IMC) was increased continuously with increasing bonding time, and thus, the interconnection of Cu–Ni substrates was realized ultimately.

Similar content being viewed by others

References

F. Roccaforte, F. Giannazzo, F. Iucolano, J. Eriksson, M.H. Weng, and V. Raineri: Surface and interface issues in wide band gap semiconductor electronics. Appl. Surf. Sci. 256, 5727–5735 (2010).

D. Wang, D. Li, M. Zhao, Y. Xu, and Q.F. Wei: Multifunctional wearable smart device based on conductive reduced graphene oxide/polyester fabric. Appl. Surf. Sci. 454, 218–226 (2018).

F. Roccaforte, P. Fiorenza, G. Greco, R.L. Nigro, F. Giannazzo, F. Iucolano, and M. Saggio: Emerging trends in wide band gap semiconductors (SiC and GaN) technology for power devices. Microelectron. Eng. 187, 66–77 (2017).

L.M. Yin, S. Wei, Z.L. Xu, and Y.F. Geng: The effect of joint size on the creep properties of microscale lead-free solder joints at elevated temperatures. J. Mater. Sci.: Mater. Electron 24, 1369–1374 (2013).

S. Stoyanov, C. Bailey, and M. Desmulliez: Optimisation modelling for thermal fatigue reliability of lead-free interconnects in fine-pitch flip-chip packaging. Solder. Surf. Mt. Technol. 21, 11–24 (2009).

E.H. Amalu, N.N. Ekere, R.S. Bhatti, S. Mallik, G. Takyi, and A.O.A. Ibhadode: Numerical investigation of thermo-mechanical behaviour of ball grid array solder joint at high temperature excursion. Adv. Mater. Res. 367, 287–292 (2011).

H.Y. Zhao, J.H. Liu, Z.L. Li, Y.X. Zhao, H.W. Niu, X.G. Song, and H.J. Dong: Non-interfacial growth of Cu3Sn in Cu/Sn/Cu joints during ultrasonic-assisted transient liquid phase soldering process. Mater. Lett. 186, 283–288 (2017).

W. Chen and J. Duh: Suppression of Cu3Sn layer and formation of multi-orientation IMCs during thermal aging in Cu/Sn–3.5Ag/Cu–15Zn transient liquid-phase bonding in novel 3D-IC Technologies. Mater. Lett. 186, 279–282 (2017).

X.D. Liu, S.L. He, and H. Nishikawa: Thermally stable Cu3Sn/Cu composite joint for high-temperature power device. Scr. Mater. 110, 101–104 (2016).

R.H. Zhang, F. Guo, J.P. Liu, H. Shen, and F. Tai: Morphology and growth of intermetallics at the interface of Sn-based solders and Cu with different surface finishes. J. Electron. Mater. 38, 241–251 (2009).

F.C. Tai, K.J. Wang, and J.D. Duh: Application of electroless Ni–Zn–P film for under-bump metallization on solder joint. Scr. Mater. 61, 748–751 (2009).

T. Kadoguchi, N. Take, K. Yamanaka, S. Nagao, and K. Suganuma: Highly thermostable joint of a Cu/Ni–P plating/Sn–0.7Cu solder added with Cu balls. J. Mater. Sci. 52, 3244–3254 (2017).

H.J. Dong, Z.L. Li, X.G. Song, H.Y. Zhao, H. Tian, J.H. Liu, and J.C. Yan: Grain morphology evolution and mechanical strength change of intermetallic joints formed in Ni/Sn/Cu system with variety of transient liquid phase soldering temperatures. Mater. Sci. Eng. A 705, 1026–1031 (2017).

L.P. Mo, C.W. Guo, Z. Zhou, F.S. Wu, and C.Q. Liu: Microstructural evolution of Cu–Sn–Ni compounds in full intermetallic micro-joint and in situ micro-bending test. J. Mater. Sci.: Mater. Electron 29, 11920–11929 (2018).

Y. Zhong, M. Huang, H. Ma, W. Dong, Y.P. Wang, and N. Zhao: In situ study on Cu–Ni cross-interaction in Cu/Sn/Ni solder joints under temperature gradient. J. Mater. Res. 31, 609–617 (2016).

H.J. Ji, Y.F. Qiao, and M.Y. Li: Rapid formation of intermetallic joints through ultrasonic-assisted die bonding with Sn–0.7Cu solder for high temperature packaging application. Scr. Mater. 110, 19–23 (2016).

Y.S. Huang, H.Y. Hsiao, C. Chen, and K.N. Tu: The effect of a concentration gradient on interfacial reactions in microbumps of Ni/SnAg/Cu during liquid-state soldering. Scr. Mater. 66, 741–744 (2012).

N. Zhao, M.Y. Wang, Y. Zhong, H.T. Ma, Y.P. Wang, and C.P. Wong: Effect of Zn content on Cu–Ni cross-interaction in Cu/Sn–xZn/Ni micro solder joints. J. Mater. Sci.: Mater. Electron 29, 5064–5073 (2018).

J.W. Yoon and B.S. Lee: Sequential interfacial reactions of Au/In/Au transient liquid phase-bonded joints for power electronics applications. Thin Solid Films 660, 618–624 (2018).

Y.H. Tian, C.J. Hang, X. Zhao, B.L. Liu, N. Wang, and C.Q. Wang: Phase transformation and fracture behavior of Cu/In/Cu joints formed by solid–liquid interdiffusion bonding. J. Mater. Sci.: Mater. Electron 25, 4170–4178 (2014).

S.K. Lin, Y.H. Wang, and H.C. Kuo: Strong coupling effects during Cu/In/Ni interfacial reactions at 280 °C. Intermetallics 58, 91–97 (2015).

T.T. Dorini and L.T.F. Eleno: Thermodynamic reassessment of the Ni–In system using ab-initio data for end-member compound energies. Calphad 62, 42–48 (2018).

L. Noren, R.L. Withers, and Y. Tabira: New B8-B8 phases in the Ni–In system. J. Alloys Compd 309, 179–187 (2000).

P.J. Shang, Z.Q. Liu, D.X. Li, and J.K. Shang: Intermetallic compound identification and Kirkendall void formation in eutectic SnIn/Cu solder joint during solid-state aging. Philos. Mag. Lett. 91, 410–417 (2011).

V.A. Baheti, S. Kashyap, K. Praveen, K. Chattopadhyay, and A. Paul: Bifurcation of the Kirkendall marker plane and the role of Ni and other impurities on the growth of Kirkendall voids in the Cu–Sn system. Acta Mater. 131, 260–270 (2017).

C. Yu, Y. Yang, Y.K. Wang, J.J. Xu, J.M. Chen, and H. Lu: Relation between Kirkendall voids and intermetallic compound layers in the SnAg/Cu solder joints. J. Mater. Sci.: Mater. Electron 23, 124–129 (2012).

H. Liu, K. Wang, K.E. Aasmundtveit, and N. Hoivik: Intermetallic compound formation mechanisms for Cu–Sn solid–liquid interdiffusion bonding. J. Electron. Mater. 41, 2453–2462 (2012).

K. Chu, Y. Sohn, and C. Moon: A comparative study of Cn/Sn/Cu and Ni/Sn/Ni solder joints for low temperature stable transient liquid phase bonding. Scr. Mater. 109, 113–117 (2015).

L.D. Chen, M.L. Huang, and S.M. Zhou: Effect of electromigration on intermetallic compound formation in line-type Cu/Sn/Cu and Cu/Sn/Ni interconnects. In 60th Electronic Components and Technology Conference (ECTC) (IEEE: Las Vegas, NV, USA, 2010).

M.J. Rizvi, Y.C. Chan, C. Bailey, H. Lu, M.N. Islam, and B.Y. Wu: Wetting and reaction of Sn–2.8Ag–0.5Cu–1.0Bi solder with Cu and Ni substrates. J. Electron. Mater. 34, 1115–1122 (2005).

S.Y. Piao and S. Lidin: A new compound in the Cu–In system—the synthesis and structure of Cu10In7. Z. Anorg. Allg. Chem. 634, 2589–2593 (2008).

L. Sun, M.H. Chen, and L. Zhang: Microstructure evolution and grain orientation of IMC in Cu–Sn TLP bonding solder joints. J. Alloys Compd. 786, 677–687 (2019).

H. Pao, J.Y. Huang, H.J. Ji, and M.Y. Li: Enhancing the solid/liquid interfacial metallurgical reaction of Sn + Cu composite solder by ultrasonic-assisted chip attachment. J. Alloys Compd. 784, 603–610 (2019).

J.B. Lee, H.Y. Hwang, and M.W. Rhee: Reliability investigation of Cu/In TLP bonding. J. Electron. Mater. 44, 435–441 (2015).

H.L. Li, A. Rong, C.Q. Wang, and Z. Jiang: In situ quantitative study of microstructural evolution at the interface of Sn3.0Ag0.5Cu/Cu solder joint during solid state aging. J. Alloys Compd. 634, 94–98 (2015).

A.A. El-Daly, A. Fawzy, S.F. Mansour, and M.J. Younis: Thermal analysis and mechanical properties of Sn–1.0Ag–0.5Cu solder alloy after modification with SiC nano-sized particles. J. Mater. Sci.: Mater. Electron 24, 2976–2988 (2013).

F.S. Wu, B. Wang, B. Du, B. An, and Y.P. Wu: Effect of stand-off height on microstructure and tensile strength of the Cu/Sn9Zn/Cu solder joint. J. Electron. Mater. 38, 860–865 (2009).

C.M. Liu, D.J. Yu, and X. Chen: Simulation implementation on the direction prediction of crack propagation based on the first principal stress. Key Eng. Mater. 795, 361–366 (2019).

T.R. Bieler, P. Eisenlohr, F. Roters, D. Kumar, D.E. Mason, M.A. Crimp, and D. Raabe: The role of heterogeneous deformation on damage nucleation at grain boundaries in single phase metals. Int. J. Plast. 25, 1655–1683 (2009).

D.Y. Lee, E.V. Barrera, J.P. Stark, and H.L. Marcus: The influence of alloying elements on impurity induced grain boundary embrittlement. Metall. Mater. Trans. A 15, 1415–1430 (1984).

C.L. Briant: On the chemistry of grain boundary segregation and grain boundary fracture. Metall. Mater. Trans. A 21, 2339–2354 (1990).

F.F. Tian, Z.Q. Liu, and J.D. Guo: Phase transformation between Cu(In,Sn)2 and Cu2(In,Sn) compounds formed on single crystalline Cu substrate during solid state aging. J. Appl. Phys. 115, 1335 (2014).

Acknowledgment

This research was financially supported by the National Natural Science Foundation of China (Grant No. 51865006).

Author information

Authors and Affiliations

Corresponding authors

Supplementary Material

Supplementary Material

To view supplementary material for this article, please visit https://doi.org/10.1557/jmr.2020.194.

Rights and permissions

About this article

Cite this article

Yang, L., Zhou, S., Zhang, Y. et al. Microstructure and mechanical property of Cu/In–45Cu/Ni solder joints formed by transient liquid phase bonding. Journal of Materials Research 35, 2848–2858 (2020). https://doi.org/10.1557/jmr.2020.194

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.194