Abstract

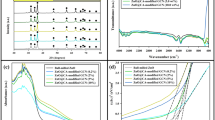

Metallic thin-film composite membranes are produced by sputtering metal films onto commercial polymer membranes. The separations capability of the membrane substrate is enhanced with the addition of a 10 nm Ta film. The addition of a tantalum layer decreases the molecular weight cutoff of the membrane from 70 kDa dextran (19 nm) to below 5 kDa (6 nm). Water flux drops from 168 LMH/bar (LMH: liters/meters2/hour) (polymer support) to 8.8 LMH/bar (Ta composite). A nanoporous layer is also added to the surface through Mg/Pd film deposition and dealloying. The resulting nanoporous Pd is a promising catalyst with a ligament size of 4.1 ± 0.9 nm. The composite membrane's ability to treat water contaminated with chlorinated organic compounds (COCs) is determined. When pressurized with hydrogen gas, the nanoporous Pd composite removes over 70% of PCB-1, a model COC, with one pass. These nanostructured films can be incorporated onto membrane supports enabling diverse reactions and separations.

Similar content being viewed by others

References

W.J. Lau, A.F. Ismail, N. Misdan, and M.A. Kassim: A recent progress in thin film composite membrane: A review. Desalination 287, 190 (2012).

J. Schwinge, P.R. Neal, D.E. Wiley, D.F. Fletcher, and A.G. Fane: Spiral wound modules and spacers: Review and analysis. J. Membr. Sci. 242, 129 (2004).

A.G. Fane, R. Wang, and M.X. Hu: Synthetic membranes for water purification: Status and future. Angew. Chem. Int. Ed. 54, 3368 (2015).

J.R. Werber, C.O. Osuji, and M. Elimelech: Materials for next-generation desalination and water purification membranes. Nat. Rev. Mater. 1, 16018 (2016).

B.S. Lalia, V. Kochkodan, R. Hashaikeh, and N. Hilal: A review on membrane fabrication: Structure, properties and performance relationship. Desalination 326, 77 (2013).

J.E. Cadotte: Interfacially synthesized reverse osmosis membrane. USA patent 4,277,344 (1981)

D.M. Warsinger, S. Chakraborty, E.W. Tow, M.H. Plumlee, C. Bellona, S. Loutatidou, L. Karimi, A.M. Mikelonis, A. Achilli, A. Ghassemi, L.P. Padhye, S.A. Snyder, S. Curcio, C.D. Vecitis, H.A. Arafat, and J.H. Lienhard: A review of polymeric membranes and processes for potable water reuse. Prog. Polym. Sci. 81, 209 (2018).

P. Marchetti, M.F. Jimenez Solomon, G. Szekely, and A.G. Livingston: Molecular separation with organic solvent nanofiltration: A critical review. Chem. Rev. 114, 10735 (2014).

B. Zhu, M. Duke, L. Dumée, A. Merenda, E. Des Ligneris, L. Kong, P. Hodgson, and S. Gray: Short review on porous metal membranes–fabrication, commercial products, and applications. Membranes 8, 83 (2018).

J.-O. Kim, J.-T. Jung, and J. Chung: Treatment performance of metal membrane microfiltration and electrodialysis integrated system for wastewater reclamation. Desalination 202, 343 (2007).

L.F. Dumee, L. He, B. Lin, F.-M. Ailloux, J.-B. Lemoine, L. Velleman, F. She, M.C. Duke, J.D. Orbell, G. Erskine, P.D. Hodgson, S. Gray, and L. Kong: The fabrication and surface functionalization of porous metal frameworks–a review. J. Mater. Chem. A 1, 15185 (2013).

H. Wang, X. Hu, Z. Ke, C.Z. Du, L. Zheng, C. Wang, and Z. Yuan: Review: Porous metal filters and membranes for oil–water separation. Nanoscale Res. Lett. 13, 284 (2018).

J.E. Greene: Review article: Tracing the recorded history of thin-film sputter deposition: From the 1800s to 2017. J. Vac. Sci. Technol., A 35, 05C204 (2017).

R. Kukla: Magnetron sputtering on large scale substrates: An overview on the state of the art. Surf. Coat. Technol. 93, 1 (1997).

R. Ludwig, R. Kukla, and E. Josephson: Vacuum web coating–state of the art and potential for electronics. Proc. IEEE 93, 1483 (2005).

W. Kittler and I. Ritchie: Continuous coating of indium tin oxide onto large area flexible substrates. Proc. SPIE 325, 61 (1982).

M.J. Detisch, T.J. Balk, and D. Bhattacharyya: Synthesis of catalytic nanoporous metallic thin films on polymer membranes. Ind. Eng. Chem. Res. 57, 4420 (2018).

L. Nana, F. Yuanjing, L. Qingchen, and X. Changfa: Microstructure and performance of a porous polymer membrane with a copper nano-layer using vapor-induced phase separation combined with magnetron sputtering. Polymers 9, 524 (2017).

J.-E. Lim, S. Yoon, B.-U. Hwang, N.-E. Lee, and H.-K. Kim: Self-connected Ag nanoporous sponge embedded in sputtered polytetrafluoroethylene for highly stretchable and semi-transparent electrodes. Adv. Mater. Interfaces 6, 1801936 (2019).

J. Erlebacher: An atomistic description of dealloying porosity evolution, the critical potential, and rate-limiting behavior. J. Electrochem. Soc 151, 10 (2004).

J. Erlebacher, M.J. Aziz, A. Karma, N. Dimitrov, and K. Sieradzki: Evolution of nanoporosity in dealloying. Nature 410, 450 (2001).

Y. Ding, Y.J. Kim, and J. Erlebacher: Nanoporous gold leaf: “Ancient technology”/Advanced material. Adv. Mater. 16, 1897 (2004).

L. Wang, N. Briot, P. Swartzentruber, and T.J. Balk: Magnesium alloy precursor thin films for efficient, practical fabrication of nanoporous metals. Metall. Mater. Trans. A 45, 1 (2014).

I. McCue, E. Benn, B. Gaskey, and J. Erlebacher: Dealloying and dealloyed materials. Annu. Rev. Mater. Res. 46, 263 (2016).

J.B. Cook, E. Detsi, Y. Liu, Y.-L. Liang, H.-S. Kim, X. Petrissans, B. Dunn, and S.H. Tolbert: Nanoporous tin with a granular hierarchical ligament morphology as a highly stable Li-Ion battery anode. ACS Appl. Mater. Interfaces 9, 293 (2017).

Z. Zhang, Y. Wang, Z. Qi, W. Zhang, J. Qin, and J. Frenzel: Generalized fabrication of nanoporous metals (Au, Pd, Pt, Ag, and Cu) through chemical dealloying. J. Phys. Chem. C 113, 12629 (2009).

E. Şeker, W.-C. Shih, and K.J. Stine: Nanoporous metals by alloy corrosion: Bioanalytical and biomedical applications. MRS Bull. 43, 49 (2018).

C.K. Hwang, J.M. Kim, S. Hwang, J.H. Kim, C.H. Sung, B.M. Moon, K.H. Chae, J.P. Singh, S.H. Kim, S.S. Jang, S.W. Lee, H.C. Ham, S. Han, and J.Y. Kim: Porous strained Pt nanostructured thin-film electrocatalysts via dealloying for PEM fuel cells. Adv. Mater. Interfaces 7, 1901326 (2019).

J. Wang, Z. Wang, D. Zhao, and C. Xu: Facile fabrication of nanoporous PdFe alloy for nonenzymatic electrochemical sensing of hydrogen peroxide and glucose. Anal. Chim. Acta 832, 34 (2014).

W.-C. Li and T.J. Balk: Preparation and hydrogen absorption/desorption of nanoporous palladium thin films. Materials 2, 2496 (2009).

T. Fujita, P. Guan, K. McKenna, X. Lang, A. Hirata, L. Zhang, T. Tokunaga, S. Arai, Y. Yamamoto, N. Tanaka, Y. Ishikawa, N. Asao, Y. Yamamoto, J. Erlebacher, and M. Chen: Atomic origins of the high catalytic activity of nanoporous gold. Nat. Mater. 11, 775 (2012).

T. Fujita, K. Higuchi, Y. Yamamoto, T. Tokunaga, S. Arai, and H. Abe: In-situ TEM study of a nanoporous Ni–Co catalyst used for the dry reforming of methane. Metals 7, 406 (2017).

Y. Ding and M. Chen: Nanoporous metals for catalytic and optical applications. MRS Bull. 34, 569 (2009).

B.Z. Wu, H.Y. Chen, S.F.J. Wang, C.M. Wai, W.S. Liao, and K.H. Chiu: Reductive dechlorination for remediation of polychlorinated biphenyls. Chemosphere 88, 757 (2012).

C. Schüth and M. Reinhard: Hydrodechlorination and hydrogenation of aromatic compounds over palladium on alumina in hydrogen-saturated water. Appl. Catal. B 18, 215 (1998).

B.P. Chaplin, M. Reinhard, W.F. Schneider, C. Schüth, J.R. Shapley, T.J. Strathmann, and C.J. Werth: Critical review of Pd-based catalytic treatment of priority contaminants in water. Environ. Sci. Technol. 46, 3655 (2012).

C. Schüth, S. Disser, F. Schüth, and M. Reinhard: Tailoring catalysts for hydrodechlorinating chlorinated hydrocarbon contaminants in groundwater. Appl. Catal., B 28, 147 (2000).

H.-L. Lien and W.-X. Zhang: Nanoscale Pd/Fe bimetallic particles: Catalytic effects of palladium on hydrodechlorination. Appl. Catal., B 77, 110 (2007).

B.-W. Zhu and T.-T. Lim: Catalytic reduction of chlorobenzenes with Pd/Fe nanoparticles: Reactive sites, catalyst stability, particle aging, and regeneration. Environ. Sci. Technol. 41, 7523 (2007).

C. Grittini, M. Malcomson, Q. Fernando, and N. Korte: Rapid dechlorination of polychlorinated biphenyls on the surface of a Pd/Fe bimetallic system. Environ. Sci. Technol. 29, 2898 (1995).

G.V. Lowry and M. Reinhard: Pd-catalyzed TCE dechlorination in groundwater: Solute effects, biological control, and oxidative catalyst regeneration. Environ. Sci. Technol. 34, 3217 (2000).

M. Ohring: Chapter 5 - Plasma and ion beam processing of thin films. In Materials Science of Thin Films, 2nd ed. M. Ohring, ed. (Academic Press, San Diego, 2002); p. 203.

C.M. Chan, T.M. Ko, and H. Hiraoka: Polymer surface modification by plasmas and photons. Surf. Sci. Rep. 24, 3 (1996).

M.S. Mauter, Y. Wang, K.C. Okemgbo, C.O. Osuji, E.P. Giannelis, and M. Elimelech: Antifouling ultrafiltration membranes via post-fabrication grafting of biocidal nanomaterials. ACS Appl. Mater. Interfaces 3, 2861 (2011).

J. Wang, X. Chen, R. Reis, Z. Chen, N. Milne, B. Winther-Jensen, L. Kong, and L. Dumée: Plasma modification and synthesis of membrane materials–a mechanistic review. Membranes 8, 56 (2018).

J.C. Wataha and C.T. Hanks: Biological effects of palladium and risk of using palladium in dental casting alloys. J. Oral. Rehabil. 23, 309 (1996).

L. Joska, M. Marek, and J. Leitner: The mechanism of corrosion of palladium–silver binary alloys in artificial saliva. Biomaterials 26, 1605 (2005).

V. Smuleac, L. Bachas, and D. Bhattacharyya: Aqueous phase synthesis of PAA in PVDF membrane pores for nanoparticle synthesis and dichlorobiphenyl degradation. J. Membr. Sci. 346, 310 (2010).

L. Leandro, R. Malureanu, N. Rozlosnik, and A. Lavrinenko: Ultrasmooth gold layer on dielectrics without the use of additional metallic adhesion layers. ACS Appl. Mater. Interfaces 7, 5797 (2015).

V. Devaraj, J. Lee, J. Baek, and D. Lee: Fabrication of ultra-smooth 10 nm silver films without wetting layer. Appl. Sci. Converg. Technol. 25, 32 (2016).

J. Yun: Ultrathin metal films for transparent electrodes of flexible optoelectronic devices. Adv. Funct. Mater. 27, 21 (2017).

W. Ho and K. Sirkar: Membrane Handbook, Vol. 2 (Springer Science + Business Media, LLC, New York, 1992), pp. 953.

S.R. Wickramasinghe, S.E. Bower, Z. Chen, A. Mukherjee, and S.M. Husson: Relating the pore size distribution of ultrafiltration membranes to dextran rejection. J. Membr. Sci. 340, 1 (2009).

S.G. Schultz and A.K. Solomon: Determination of the effective hydrodynamic radii of small molecules by viscometry. J. Gen. Physiol. 44, 1189 (1961).

R. Sander: Compilation of Henry's law constants (version 4.0) for water as solvent. Atmos. Chem. Phys. 15, 4399 (2015).

L.A. Giannuzzi and F.A. Stevie: A review of focused ion beam milling techniques for TEM specimen preparation. Micron 30, 197 (1999).

Acknowledgments

This research was supported by NSF KY EPSCoR grant (Grant 1355438) and NIH-NIEHS-SRC (Award No. P42ES007380). The authors thank Nicolas J. Briot at the UK Electron Microscopy Center, as well as John May and Megan Combs at the UK Environmental Training and Research Lab for help with FIB/SEM and GC/MS work, respectively. The authors also thank Solecta Inc., Oceanside, CA, for providing a flat sheet membrane for testing.

Author information

Authors and Affiliations

Corresponding author

Supplementary material

Supplementary material

To view supplementary material for this article, please visit https://doi.org/10.1557/jmr.2020.176.

Rights and permissions

About this article

Cite this article

Detisch, M.J., John Balk, T., Bezold, M. et al. Nanoporous metal–polymer composite membranes for organics separations and catalysis. Journal of Materials Research 35, 2629–2642 (2020). https://doi.org/10.1557/jmr.2020.176

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.176