Abstract

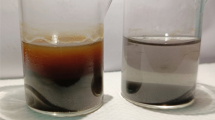

Iron foams are potential materials for the production, purification, and recuperation of hydrogen through redox systems. They are inexpensive, recyclable, and environmentally friendly. Nevertheless, iron foams cannot be employed repeatedly for redox cycling at high temperatures because the structure suffers morphological changes and a decrease in the effective porosity. In this work, two different pore structures of Fe-foams fabricated by freeze-casting have been produced: constant (CP) and gradient (GP) pore size. CP Fe-foams were obtained by employing a double-sided cooling technique to minimize gradients in pore width that result when using one-sided, constant cooling solidification techniques. GP Fe-foams were manufactured using a fixed-temperature cold plate. Optical microscopy and X-ray tomography were employed to characterize the pore structure and, for GP Fe-foams, to investigate the effect of redox cycling. After redox cycling, GP Fe-foams exhibited significant pore degradation.

Similar content being viewed by others

References

W.L. Li, K. Lu, and J.Y. Walz: Freeze casting of porous materials: Review of critical factors in microstructure evolution. Int. Mater. Rev. 57, 37 (2012).

S.M. Miller, X. Xiao, and K.T. Faber: Freeze-cast alumina pore networks: Effects of freezing conditions and dispersion medium. J. Eur. Ceram. Soc. 35, 3595 (2015).

K.L. Scotti and D.C. Dunand: Freeze casting–A review of processing, microstructure and properties via the open data repository, FreezeCasting.net. Prog. Mater. Sci. 94, 243 (2018).

T. Fukasawa, Z.-Y. Deng, M. Ando, T. Ohji, and Y. Goto: Pore structure of porous ceramics synthesized from water-based slurry by freeze-dry process. J. Mater. Sci. 36, 2523 (2001).

D. Rozmanov and P.G. Kusalik: Anisotropy in the crystal growth of hexagonal ice, I h. J. Chem. Phys. 137, 094702 (2012).

K. Araki and J.W.J.W. Halloran: New freeze-casting technique for ceramics with sublimable vehicles. J. Am. Ceram. Soc. 87, 1859 (2004).

D.R. Stull: Vapor pressure of pure substances: Organic and inorganic compounds. Ind. Eng. Chem. 39, 517 (1947).

R. Sepúlveda, A.A. Plunk, and D.C. Dunand: Microstructure of Fe2O3 scaffolds created by freeze-casting and sintering. Mater. Lett. 142, 56 (2015).

Y. Chino and D.C. Dunand: Directionally freeze-cast titanium foam with aligned, elongated pores. Acta Mater. 56, 105 (2008).

H. Zhang, P. D'Angelo Nunes, M. Wilhelm, and K. Rezwan: Hierarchically ordered micro/meso/macroporous polymer-derived ceramic monoliths fabricated by freeze-casting. J. Eur. Ceram. Soc. 36, 51 (2016).

C.M. Pekor, P. Kisa, and I. Nettleship: Effect of polyethylene glycol on the microstructure of freeze-cast alumina. J. Am. Ceram. Soc. 91, 3185 (2008).

T. Waschkies, R. Oberacker, and M.J. Hoffmann: Investigation of structure formation during freeze-casting from very slow to very fast solidification velocities. Acta Mater. 59, 5135 (2011).

A. Preiss, B. Su, S. Collins, and D. Simpson: Tailored graded pore structure in zirconia toughened alumina ceramics using double-side cooling freeze casting. J. Eur. Ceram. Soc. 32, 1575 (2012).

C. Stolze, T. Janoschka, U.S. Schubert, F.A. Müller, and S. Flauder: Directional solidification with constant ice front velocity in the ice-templating process. Adv. Eng. Mater. 18, 111 (2016).

P. Durán, J. Lachén, J. Plou, R. Sepúlveda, J. Herguido, and J.A. Peña: Behaviour of freeze-casting iron oxide for purifying hydrogen streams by steam-iron process. Int. J. Hydrogen Energy 41, 19518 (2016).

X. Wang, K. Li, L. Jia, Q. Zhang, S.P. Jiang, B. Chi, J. Pu, L. Jian, and D. Yan: Porous Ni–Fe alloys as anode support for intermediate temperature solid oxide fuel cells: I. Fabrication, redox and thermal behaviors. J. Power Sources 277, 474 (2015).

S.K. Wilke and D.C. Dunand: Structural evolution of directionally freeze-cast iron foams during oxidation/reduction cycles. Acta Mater. 162, 90 (2019).

M. Luo, Y. Yi, S. Wang, Z. Wang, M. Du, J. Pan, and Q. Wang: Review of hydrogen production using chemical-looping technology. Renew. Sustain. Energy Rev. 81, 3186 (2018).

N. Xu, X. Li, X. Zhao, J.B. Goodenough, and K. Huang: A novel solid oxide redox flow battery for grid energy storage. Energy Environ. Sci. 4, 4942 (2011).

A. Leonide, W. Drenckhahn, H. Greiner, and H. Landes: Long term operation of rechargeable high temperature solid oxide batteries. J. Electrochem. Soc. 161, 9, A1297–A1301 (2014).

S. Trocino, S.C. Zignani, M. Lo Faro, V. Antonucci, and A.S. Aricò: Iron–air battery operating at high temperature. Energy Technol. 5, 670 (2017).

A. Inoishi, T. Sakai, Y.W. Ju, S. Ida, and T. Ishihara: Improved cycle stability of Fe-air solid state oxide rechargeable battery using LaGaO3-based oxide ion conductor. J. Power Sources 262, 310 (2014).

T. Um, S.K. Wilke, H. Choe, and D.C. Dunand: Effects of pore morphology on the cyclical oxidation/reduction of iron foams created via camphene-based freeze casting. J. Alloy. Compd. (2020). Available at: https://doi.org/10.1016/j.jallcom.2020.156278 (accessed July 5th, 2020).

H. Park, T. Um, K. Hong, J.S. Kang, H.-S. Nam, K. Kwon, Y.-E. Sung, and H. Choe: Effects of powder carrier on the morphology and compressive strength of iron foams: Water vs camphene. Metall. Mater. Trans. B 49, 2182 (2018).

R. Trivedi: Interdendritic spacing: Part II. A comparison of theory and experiment. Metall. Trans. A Phys. Metall. Mater. Sci. 15A, 977 (1984).

W. Kurz and D.J. Fisher: Dendrite growth at the limit of stability: Tip radius and spacing. Acta Metall. 29, 11 (1981).

E. Çadirli, N. Marasli, B. Bayender, and M. Gündüz: Dependency of the microstructure parameters on the solidification parameters for camphene. Mater. Res. Bull. 35, 985 (2000).

P.J. Lloreda-Jurado, E.M. Pérez-Soriano, A. Paúl, J. Herguido, J.A. Peña, and R. Sepúlveda: Doped iron oxide scaffolds with gradient porosity fabricated by freeze casting: pore morphology prediction and processing parameters. Mater. Sci. Technol. 36 (11), 1227–1237 (2020).

N.O. Shanti, K. Araki, and J.W. Halloran: Particle redistribution during dendritic solidification of particle suspensions. J. Am. Ceram. Soc. 89, 2444 (2006).

S. Deville, E. Saiz, and A.P. Tomsia: Ice-templated porous alumina structures. Acta Mater. 55, 1965 (2007).

S.K. Wilke and D.C. Dunand: In operando tomography reveals degradation mechanisms in lamellar iron foams during redox cycling at 800°C. J. Power Sources 448, 227463 (2020).

T. Hildebrand and P. Rüegsegger: A new method for the model-independent assessment of thickness in three-dimensional images. J. Microsc. 185, 67 (1997).

Acknowledgments

Financial support for this work has been provided by the Spanish Ministerio de Economía, Industria y Competitividad (MINECO), through the project MAT2016-76713-P, and by the U.S. National Science Foundation (NSF CMMI-1562941). P.J. also thanks the Universidad de Sevilla for financial support (Grant PIF II.2A, through VI Plan Propio de Investigación). This work made use of the MatCI Facility at Northwestern University, which receives support from the MRSEC Program (NSF DMR-1720139). Tomography experiments were performed at the DuPont-Northwestern-Dow Collaborative Access Team (DND-CAT), Sector 5 of the Advanced Photon Source, operated by Argonne National Laboratory (DOE DE-AC02-06CH11357). The authors gratefully acknowledge Dr. William Guise (DND-CAT) for assistance in collecting and processing the tomography data.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lloreda-Jurado, P., Wilke, S., Scotti, K. et al. Structure–processing relationships of freeze-cast iron foams fabricated with various solidification rates and post-casting heat treatment. Journal of Materials Research 35, 2587–2596 (2020). https://doi.org/10.1557/jmr.2020.175

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.175