Abstract

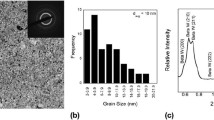

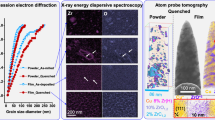

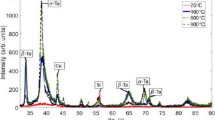

We report the sputter deposition of Cu-7V and Cu-27V (at.%) alloy films in an attempt to yield a “clean” alloy to investigate nanocrystalline stability. Films grown in high vacuum chambers can mitigate processing contaminates which convolute the identification of nanocrystalline stability mechanism(s). The initial films were very clean with carbon and oxygen contents ranging between ~0.01 and 0.38 at.%. Annealing at 400 °C/1 h facilitated the clustering of vanadium at high-angle grain boundary triple junctions. At 800 °C/1 h annealing, the Cu-7V film lost its nanocrystalline grain sizes with the vanadium partitioned to the free surface; the Cu-27V retained its nanocrystalline grains with vanadium clusters in the matrix, but surface solute segregation was present. Though the initial alloy and vacuum annealing retained the low contamination levels sought, the high surface area-to-volume ratio of the film, coupled with high segregation tendencies, enabled this system to phase separate in such a manner that the stability mechanisms that were to be studied were lost at high temperatures. This illustrates obstacles in using thin films to address nanocrystalline stability.

Similar content being viewed by others

References

A. Detor and C. Schuh: Grain boundary segregation, chemical ordering and stability of nanocrystalline alloys: Atomistic computer simulations in the Ni–W system. Acta Mater. 55(12), 4221 (2007).

C. Koch, R. Scattergood, K. Darling, and J. Semones: Stabilization of nanocrystalline grain sizes by solute additions. J. Mater. Sci. 43(23–24), 7264 (2008).

C. Koch, R. Scattergood, M. Saber, and H. Kotan: High temperature stabilization of nanocrystalline grain size: Thermodynamic versus kinetic strategies. J. Mater. Res. 28(13), 1785 (2013).

E. Nes, N. Ryum, and O. Hunderi: On the zener drag. Acta Metall. 33(1), 11 (1985).

K.A. Darling, B.K. VanLeeuwen, C.C. Koch, and R.O. Scattergood: Thermal stability of nanocrystalline Fe–Zr alloys. Mater. Sci. Eng., A 527(15), 3572 (2010).

A. Khalajhedayati and T.J. Rupert: High-temperature stability and grain boundary complexion formation in a nanocrystalline Cu-Zr alloy. JOM 67(12), 2788 (2015).

F. Liu and R. Kirchheim: Nano-scale grain growth inhibited by reducing grain boundary energy through solute segregation. J. Cryst. Growth. 264(1–3), 385 (2004).

J. Weissmuller: Some basic notions on nanostructured solids. Mater. Sci. Eng., A 179, 102 (1994).

Y. Chen, Y. Liu, F. Khatkhatay, C. Sun, H. Wang, and X. Zhang: Significant enhancement in the thermal stability of nanocrystalline metals via immiscible tri-phases. Scr. Mater. 67(2), 177 (2012).

D. Gupta: Diffusion, solute segregations and interfacial energies in some material: An overview. Interface Sci. 11(1), 7 (2003).

T. Chookajorn and C.A. Schuh: Nanoscale segregation behavior and high-temperature stability of nanocrystalline W–20at.% Ti. Acta Mater. 73, 128 (2014).

H.A. Murdoch and C.A. Schuh: Estimation of grain boundary segregation enthalpy and its role in stable nanocrystalline alloy design. J. Mater. Res. 28(16), 2154 (2013).

K.A. Darling, B.K. VanLeeuwen, J.E. Semones, C.C. Koch, R.O. Scattergood, L.J. Kecskes, and S.N. Mathaudhu: Stabilized nanocrystalline iron-based alloys: Guiding efforts in alloy selection. Mater. Sci. Eng., A 528(13–14), 4365 (2011).

H. Peng, Y. Chen, and F. Liu: Effects of alloying on nanoscale grain growth in substitutional binary alloy system: Thermodynamics and kinetics. Metall. Mater. Trans. A 46A(11), 5431 (2015).

A. Detor and C. Schuh: Tailoring and patterning the grain size of nanocrystalline alloys. Acta Mater. 55(1), 371 (2007).

T. Rupert, W. Cai, and C. Schuh: Abrasive wear response of nanocrystalline Ni-W alloys across the Hall-Petch breakdown. Wear 298, 120 (2013).

V. Novikov: Grain growth in nanocrystalline materials. Mater. Lett. 159, 510 (2015).

M. Hillert and B. Sundman: A treatment of the solute drag on moving grain boundaries and phase interfaces in binary alloys. Acta Metall. 24(8), 731 (1976).

R. Kirchheim: Grain coarsening inhibited by solute segregation. Acta Mater. 50(2), 413 (2002).

J.R. Trelewicz and C.A. Schuh: Grain boundary segregation and thermodynamically stable binary nanocrystalline alloys. Phys. Rev. B 79(9), 094112 (2009).

K.A. Darling, M.A. Tschopp, B.K. VanLeeuwen, M.A. Atwater, and Z.K. Liu: Mitigating grain growth in binary nanocrystalline alloys through solute selection based on thermodynamic stability maps. Comput. Mater. Sci. 84, 255 (2014).

M. Saber, C. Koch, and R. Scattergood: Thermodynamic grain size stabilization models: An overview. Mater. Res. Lett. 3(2), 65 (2015).

S. Sooraj, V. Muthaiah, P. Kang, C. Koch, and S. Mula: Microstructural evolution and thermal stability of Fe-Zr metastable alloys developed by mechanical alloying followed by annealing. Philos. Mag. 96(25), 2649 (2016).

T. Chookajorn, H.A. Murdoch, and C.A. Schuh: Design of stable nanocrystalline alloys. Science 337(6097), 951 (2012).

J. Weissmüller: Alloy effects in nanostructures. Nanostruct. Mater. 3, 261 (1993).

R. Kirchheim: Reducing grain boundary, dislocation line and vacancy formation energies by solute segregation. I. Theoretical background. Acta Mater. 55(15), 5129 (2007).

J. Drolet and A. Galibois: Impurity-drag effect on grain growth. Acta Metall. 16(12), 1387 (1968).

F. Abdeljawad and S.M. Foiles: Stabilization of nanocrystalline alloys via grain boundary segregation: A diffuse interface model. Acta Mater. 101, 159 (2015).

C.S. Smith: Introduction to grains, phases, and interfaces: an interpretation of microstructure. Trans. Metall. Soc. AIME 175, 15 (1948).

B. Farber, E. Cadel, A. Menand, G. Schmitz, and R. Kirchheim: Phosphorus segregation in nanocrystalline Ni-3.6 at.% P alloy investigated with the tomographic atom probe (TAP). Acta Mater. 48(3), 789 (2000).

T. Hentschel, D. Isheim, R. Kirchheim, F. Muller, and H. Kreye: Nanocrystalline Ni-3.6 at.% P and its transformation sequence studied by atom-probe field-ion microscopy. Acta Mater. 48(4), 933 (2000).

T. Rojhirunsakool, K.A. Darling, M.A. Tschopp, G.P.P. Pun, Y. Mishin, R. Banerjee, and L.J. Kecskes: Structure and thermal decomposition of a nanocrystalline mechanically alloyed supersaturated Cu-Ta solid solution. MRS Commun. 5(2), 333 (2015).

T. Chookajorn, M. Park, and C.A. Schuh: Duplex nanocrystalline alloys: Entropic nanostructure stabilization and a case study on W-Cr. J. Mater. Res. 30(2), 151 (2015).

J.W. Cahn: The impurity-drag effect in grain boundary motion. Acta Mater. 10, 789 (1962).

A. Detor and C. Schuh: Microstructural evolution during the heat treatment of nanocrystalline alloys. J. Mater. Res. 22(11), 3233 (2007).

H.A. Murdoch and C.A. Schuh: Stability of binary nanocrystalline alloys against grain growth and phase separation. Acta Mater. 61(6), 2121 (2013).

C. O'Brien, C. Barr, P. Price, K. Hattar, and S. Foiles: Grain boundary phase transformations in PtAu and relevance to thermal stabilization of bulk nanocrystalline metals. J. Mater. Sci. 53(4), 2911 (2018).

X. Zhou, X.-x. Yu, T. Kaub, R.L. Martens, and G.B. Thompson: Grain boundary specific segregation in nanocrystalline Fe(Cr). Sci. Rep. 6, 34642 (2016).

M. Kapoor, T. Kaub, K.A. Darling, B.L. Boyce, and G.B. Thompson: An atom probe study on Nb solute partitioning and nanocrystalline grain stabilization in mechanically alloyed Cu-Nb. Acta Mater. 126, 564 (2017).

B. Clark, K. Hattar, M. Marshall, T. Chookajorn, B. Boyce, and C. Schuh: Thermal stability comparison of nanocrystalline Fe-based binary alloy pairs. JOM 68(6), 1625 (2016).

C.J. Marvel, P.R. Cantwell, and M.P. Harmer: The critical influence of carbon on the thermal stability of nanocrystalline Ni-W alloys. Scr. Mater. 96, 45 (2015).

C.J. Marvel, B.C. Hornbuckle, K.A. Darling, and M.P. Harmer: Intentional and unintentional elemental segregation to grain boundaries in a Ni-rich nanocrystalline alloy. J. Mater. Sci. 54(4), 3496 (2019).

J.B. Seol, C.M. Kwak, J.C. Han, K.H. Baek, and Y.K. Jeong: Correlative transmission electron microscopy and atom probe tomography on field evaporation mechanism of a bulk LaAlO3 oxide. Appl. Surf. Sci. 479, 828 (2019).

M. Herbig, D. Raabe, Y.J. Li, P. Choi, S. Zaefferer, and S. Goto: Atomic-scale quantification of grain boundary segregation in nanocrystalline material. Phys. Rev. Lett. 112(12), 126103 (2014).

X. Zhou, and G.B. Thompson: Charge-state field evaporation behavior in Cu(V) nanocrystalline alloys. Microsc. Microanal. 25, 501 (2019).

P. Stender, Z. Balogh, and G. Schmitz: Triple junction segregation in nanocrystalline multilayers. Phys. Rev. B. 83(12), 121407 (2011).

M.R. Chellali, Z. Balogh, and G. Schmitz: Nano-analysis of grain boundary and triple junction transport in nanocrystalline Ni/Cu. Ultramicroscopy 132, 164 (2013).

R.D. Doherty: Grain coarsening–Insights from curvature modeling Cyril Stanley Smith Lecture. Mater. Sci. Forum 715–716, 1 (2012).

P.P. Shetty, M.G. Emigh, and J.A. Krogstad: Coupled oxidation resistance and thermal stability in sputter deposited nanograined alloys. J. Mater. Res. 34(1), 48 (2019).

X. Zhou and G.B. Thompson: In situ TEM observations of initial oxidation behavior in Fe-rich Fe-Cr alloys. Surf. Coat. Technol. 357, 332 (2019).

Y.F. Qin and S.Q. Wang: Ab-initio study of surface segregation in aluminum alloys. Appl. Surf. Sci. 399, 351 (2017).

Y.H. Chang, W.J. Lu, J. Guenole, L.T. Stephenson, A. Szczpaniak, P. Kontis, A.K. Ackerman, F.F. Dear, I. Mouton, X.K. Zhong, S.Y. Zhang, D. Dye, C.H. Liebscher, D. Ponge, S. Korte-Kerzel, D. Raabe, and B. Gault: Ti and its alloys as examples of cryogenic focused ion beam milling of environmentally-sensitive materials. Nat. Commun. 10, 942 (2019).

K. Hoshino, Y. Iijima, and K.I. Hirano: Diffusion of vanadium, chromium, and manganese in copper. Metall. Trans. A 8(3), 469 (1977).

B. Sadigh, P. Erhart, A. Stukowski, A. Caro, E. Martinez, and L. Zepeda-Ruiz: Scalable parallel Monte Carlo algorithm for atomistic simulations of precipitation in alloys. Phys. Rev. B. 85(18), 184203 (2012).

L.A. Giannuzzi and F.A. Stevie: A review of focused ion beam milling techniques for TEM specimen preparation. Micron 30(3), 197 (1999).

X. Zhou and G.B. Thompson: The influence of alloying interactions on thin film growth stresses. Appl. Surf. Sci. 463, 545 (2019).

O.C. Hellman, J.A. Vandenbroucke, J. Rüsing, D. Isheim, and D.N. Seidman: Analysis of three-dimensional atom-probe data by the proximity histogram. Microsc. Microanal. 6(5), 437 (2000).

D.J. Barton, B.C. Hornbuckle, K.A. Darling, and G.B. Thompson: The influence of isoconcentration surface selection in quantitative outputs from proximity histograms. Microsc. Microanal. 25, 401 (2019).

Y.M. Chen, P.H. Chou, and E.A. Marquis: Quantitative atom probe tomography characterization of microstructures in a proton irradiated 304 stainless steel. J. Nucl. Mater. 451(1-3), 130 (2014).

L.T. Stephenson, M.P. Moody, P.V. Liddicoat, and S.P. Ringer: New techniques for the analysis of fine-scaled clustering phenomena within atom probe tomography (APT) data. Microsc. Microanal. 13(6), 448 (2007).

E. Marquis and J. Hyde: Applications of atom-probe tomography to the characterisation of solute behaviours. Mater. Sci. Eng., Rep. 69(4–5), 37 (2010).

J. Li: AtomEye: an efficient atomistic configuration viewer. Modell. Simul. Mater. Sci. Eng. 11(2), 173 (2003).

S. Alexander: Visualization and analysis of atomistic simulation data with OVITO: The Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 18(1), 015012 (2010).

S. Plimpton: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1 (1995).

Acknowledgment

The authors gratefully acknowledge NSF-DMR-1709803 for support of this work.

Author information

Authors and Affiliations

Corresponding author

Supplementary material

Supplementary material

To view supplementary material for this article, please visit https://doi.org/10.1557/jmr.2020.174.

Rights and permissions

About this article

Cite this article

Zhou, X., Kaub, T., Vogel, F. et al. Complications of using thin film geometries for nanocrystalline thermal stability investigations. Journal of Materials Research 35, 2087–2097 (2020). https://doi.org/10.1557/jmr.2020.174

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2020.174