Abstract

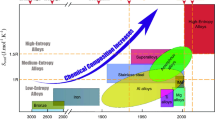

The current review outlines the size-dependent plastic behavior of high-entropy alloys (HEAs) and the underlying deformation mechanisms. Particular focus is laid upon the influence of microstructural design on the small-scale deformation characteristics. The role of defect types as carriers of plasticity is appraised and correlated with the frequently observed mechanical behavior peculiar to the breed of HEAs. Deformation response is classified on the basis of mechanical testing techniques probing intrinsic (nanoindentation techniques) as well as extrinsic size (micro/nanopillar compression) effects. The mechanisms of incipient plasticity and serrated flow behavior in HEAs are discussed. Furthermore, the role of interfaces between crystallographically dissimilar lattices on small-scale deformation behavior in these alloys is assessed. The article provides a clear overview of the existing HEA research in this avenue as well as the critical knowledge gaps that need to be addressed.

Similar content being viewed by others

References

J-W. Yeh, S-K. Chen, S-J. Lin, J-Y. Gan, T-S. Chin, T-T. Shun, C-H. Tsau, and S-Y. Chang: Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299 (2004).

P-K. Huang, J-W. Yeh, T-T. Shun, and S-K. Chen: Multi-principal-element alloys with improved oxidation and wear resistance for thermal spray coating. Adv. Eng. Mater. 6, 74 (2004).

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent: Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng., A 375–377 (Suppl. C), 213 (2004).

S. Praveen and H.S. Kim: High-entropy alloys: Potential candidates for high-temperature applications—An overview. Adv. Eng. Mater. 20, 1700645 (2018).

E.J. Pickering and N.G. Jones: High-entropy alloys: A critical assessment of their founding principles and future prospects. Int. Mater. Rev. 61, 183 (2016).

D.B. Miracle and O.N. Senkov: A critical review of high entropy alloys and related concepts. Acta Mater. 122 (Suppl. C), 448 (2017).

D.B. Miracle: Critical assessment 14: High entropy alloys and their development as structural materials. Mater. Sci. Technol. 31, 1142 (2015).

L.M. Martyushev and V.D. Seleznev: Maximum entropy production principle in physics, chemistry and biology. Phys. Rep. 426, 1 (2006).

M.C. Gao, C. Zhang, P. Gao, F. Zhang, L.Z. Ouyang, M. Widom, and J.A. Hawk: Thermodynamics of concentrated solid solution alloys. Curr. Opin. Solid State Mater. Sci. 21, 238 (2017).

W. Zhang, P.K. Liaw, and Y. Zhang: Science and technology in high-entropy alloys. Sci. China Mater. 61, 2 (2018).

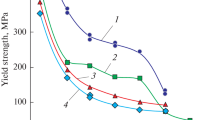

R. Carroll, C. Lee, C-W. Tsai, J-W. Yeh, J. Antonaglia, B.A.W. Brinkman, M. LeBlanc, X. Xie, S. Chen, P.K. Liaw, and K.A. Dahmen: Experiments and model for serration statistics in low-entropy, medium-entropy, and high-entropy alloys. Sci. Rep. 5, 16997 (2015).

J-W. Yeh: Alloy design strategies and future trends in high-entropy alloys. JOM 65, 1759 (2013).

J-W. Yeh: Physical metallurgy of high-entropy alloys. JOM 67, 2254 (2015).

J-W. Yeh, S-J. Lin, T-S. Chin, J-Y. Gan, S-K. Chen, T-T. Shun, C-H. Tsau, and S-Y. Chou: Formation of simple crystal structures in Cu–Co–Ni–Cr–Al–Fe–Ti–V alloys with multiprincipal metallic elements. Metall. Mater. Trans. A 35, 2533 (2004).

M.C. Gao, J-W. Yeh, P.K. Liaw, and Y. Zhang: High-Entropy Alloys: Fundamentals and Applications (Springer, New York, NY, 2016).

W-R. Wang, W-L. Wang, S-C. Wang, Y-C. Tsai, C-H. Lai, and J-W. Yeh: Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 26 (Suppl. C), 44 (2012).

Z.J. Zhang, M.M. Mao, J. Wang, B. Gludovatz, Z. Zhang, S.X. Mao, E.P. George, Q. Yu, and R.O. Ritchie: Nanoscale origins of the damage tolerance of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 6, 10143 (2015).

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw: Refractory high-entropy alloys. Intermetallics 18, 1758 (2010).

J.C. Rao, H.Y. Diao, V. Ocelík, D. Vainchtein, C. Zhang, C. Kuo, Z. Tang, W. Guo, J.D. Poplawsky, Y. Zhou, P.K. Liaw, and J.T.M. De Hosson: Secondary phases in AlxCoCrFeNi high-entropy alloys: An in situ TEM heating study and thermodynamic appraisal. Acta Mater. 131 (Suppl. C), 206 (2017).

H.Y. Diao, R. Feng, K.A. Dahmen, and P.K. Liaw: Fundamental deformation behavior in high-entropy alloys: An overview. Curr. Opin. Solid State Mater. Sci. 21, 252 (2017).

Z. Tang, O.N. Senkov, C.M. Parish, C. Zhang, F. Zhang, L.J. Santodonato, G. Wang, G. Zhao, F. Yang, and P.K. Liaw: Tensile ductility of an AlCoCrFeNi multi-phase high-entropy alloy through hot isostatic pressing (HIP) and homogenization. Mater. Sci. Eng., A 647 (Suppl. C), 229 (2015).

O.N. Senkov, J.D. Miller, D.B. Miracle, and C. Woodward: Accelerated exploration of multi-principal element alloys for structural applications. Calphad 50 (Suppl. C), 32 (2015).

O.N. Senkov, J.D. Miller, D.B. Miracle, and C. Woodward: Accelerated exploration of multi-principal element alloys with solid solution phases. Nat. Commun. 6, 6529 (2015).

A. Gali and E.P. George: Tensile properties of high- and medium-entropy alloys. Intermetallics 39, 74 (2013).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu: Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61 (Suppl. C), 1 (2014).

S. Gorsse, D.B. Miracle, and O.N. Senkov: Mapping the world of complex concentrated alloys. Acta Mater. 135, 177 (2017).

M-H. Tsai and J-W. Yeh: High-entropy alloys: A critical review. Mater. Res. Lett. 2, 107 (2014).

B.S. Murty, J-W. Yeh, and S. Ranganathan: High-Entropy Alloys (Butterworth-Heinemann, Amsterdam, Netherlands, 2014).

J.W. Yeh, Y.L. Chen, S.J. Lin, and S.K. Chen: High-entropy alloys—A new era of exploitation. Mater. Sci. Forum 560, 1 (2007).

F. Otto, Y. Yang, H. Bei, and E.P. George: Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 61, 2628 (2013).

N.G. Jones, K.A. Christofidou, and H.J. Stone: Rapid precipitation in an Al0.5CrFeCoNiCu high entropy alloy. Mater. Sci. Technol. 31, 1171 (2015).

N.G. Jones, J.W. Aveson, A. Bhowmik, B.D. Conduit, and H.J. Stone: On the entropic stabilisation of an Al0.5CrFeCoNiCu high entropy alloy. Intermetallics 54, 148 (2014).

N.G. Jones, A. Frezza, and H.J. Stone: Phase equilibria of an Al0.5CrFeCoNiCu high entropy alloy. Mater. Sci. Eng., A 615, 214 (2014).

D. Ma, B. Grabowski, F. Körmann, J. Neugebauer, and D. Raabe: Ab initio thermodynamics of the CoCrFeMnNi high entropy alloy: Importance of entropy contributions beyond the configurational one. Acta Mater. 100 (Suppl. C), 90 (2015).

K.G. Pradeep, N. Wanderka, P. Choi, J. Banhart, B.S. Murty, and D. Raabe: Atomic-scale compositional characterization of a nanocrystalline AlCrCuFeNiZn high-entropy alloy using atom probe tomography. Acta Mater. 61, 4696 (2013).

S. Praveen, B.S. Murty, and R.S. Kottada: Alloying behavior in multi-component AlCoCrCuFe and NiCoCrCuFe high entropy alloys. Mater. Sci. Eng., A 534 (Suppl. C), 83 (2012).

F. Otto, A. Dlouhý, K.G. Pradeep, M. Kuběnová, D. Raabe, G. Eggeler, and E.P. George: Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures. Acta Mater. 112 (Suppl. C), 40 (2016).

E.J. Pickering, H.J. Stone, and N.G. Jones: Fine-scale precipitation in the high-entropy alloy Al0.5CrFeCoNiCu. Mater. Sci. Eng., A 645 (Suppl. C), 65 (2015).

E.J. Pickering, R. Muñoz-Moreno, H.J. Stone, and N.G. Jones: Precipitation in the equiatomic high-entropy alloy CrMnFeCoNi. Scr. Mater. 113 (Suppl. C), 106 (2016).

I. Basu, V. Ocelík, and J.T.M. De Hosson: Size dependent plasticity and damage response in multiphase body centered cubic high entropy alloys. Acta Mater. 150, 104 (2018).

L.J. Santodonato, Y. Zhang, M. Feygenson, C.M. Parish, M.C. Gao, R.J.K. Weber, J.C. Neuefeind, Z. Tang, and P.K. Liaw: Deviation from high-entropy configurations in the atomic distributions of a multi-principal-element alloy. Nat. Commun. 6, 5964 (2015).

Y. Deng, C.C. Tasan, K.G. Pradeep, H. Springer, A. Kostka, and D. Raabe: Design of a twinning-induced plasticity high entropy alloy. Acta Mater. 94, 124 (2015).

Z. Li, C.C. Tasan, K.G. Pradeep, and D. Raabe: A TRIP-assisted dual-phase high-entropy alloy: Grain size and phase fraction effects on deformation behavior. Acta Mater. 131 (Suppl. C), 323 (2017).

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, and C.C. Tasan: Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 534, 227 (2016).

S.S. Nene, K. Liu, M. Frank, R.S. Mishra, R.E. Brennan, K.C. Cho, Z. Li, and D. Raabe: Enhanced strength and ductility in a friction stir processing engineered dual phase high entropy alloy. Sci. Rep. 7, 16167 (2017).

M. Wang, Z. Li, and D. Raabe: In situ SEM observation of phase transformation and twinning mechanisms in an interstitial high-entropy alloy. Acta Mater. 147, 236 (2018).

Y. Ma, Q. Wang, B.B. Jiang, C.L. Li, J.M. Hao, X.N. Li, C. Dong, and T.G. Nieh: Controlled formation of coherent cuboidal nanoprecipitates in body-centered cubic high-entropy alloys based on Al2(Ni,Co,Fe,Cr)14 compositions. Acta Mater. 147, 213 (2018).

Y.L. Zhao, T. Yang, J.H. Zhu, D. Chen, Y. Yang, A. Hu, C.T. Liu, and J-J. Kai: Development of high-strength Co-free high-entropy alloys hardened by nanosized precipitates. Scr. Mater. 148, 51 (2018).

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, and Z.P. Lu: A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 102, 187 (2016).

J.C. Rao, V. Ocelík, D. Vainchtein, Z. Tang, P.K. Liaw, and J.T.M. De Hosson: The fcc-bcc crystallographic orientation relationship in AlxCoCrFeNi high-entropy alloys. Mater. Lett. 176 (Suppl. C), 29 (2016).

J.C. Rao, V. Ocelík, D. Vainchtein, Z. Tang, P.K. Liaw, and J.T.M. De Hosson: On the onset of nano-ordered phase distributions in high-entropy alloys. Rev. Adv. Mater. Sci. 48, 105 (2017).

V. Ocelík, N. Janssen, S.N. Smith, and J.T.M.D. Hosson: Additive manufacturing of high-entropy alloys by laser processing. JOM 68, 1810 (2016).

A. Manzoni, H. Daoud, R. Völkl, U. Glatzel, and N. Wanderka: Phase separation in equiatomic AlCoCrFeNi high-entropy alloy. Ultramicroscopy 132 (Suppl. C), 212 (2013).

A. Munitz, S. Salhov, S. Hayun, and N. Frage: Heat treatment impacts the micro-structure and mechanical properties of AlCoCrFeNi high entropy alloy. J. Alloy. Comp. 683 (Suppl. C), 221 (2016).

Y. Ma, B. Jiang, C. Li, Q. Wang, C. Dong, P.K. Liaw, F. Xu, and L. Sun: The BCC/B2 morphologies in AlxNiCoFeCr high-entropy alloys. Metals 7, 57 (2017).

J.R. Greer and J.T.M. De Hosson: Plasticity in small-sized metallic systems: Intrinsic versus extrinsic size effect. Prog. Mater. Sci. 56, 654 (2011).

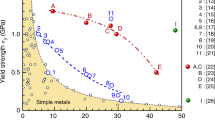

Y. Zou, H. Ma, and R. Spolenak: Ultrastrong ductile and stable high-entropy alloys at small scales. Nat. Commun. 6, 7748 (2015).

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, and R.O. Ritchie: A fracture-resistant high-entropy alloy for cryogenic applications. Science 345, 1153 (2014).

B. Gludovatz, A. Hohenwarter, K.V.S. Thurston, H. Bei, Z. Wu, E.P. George, and R.O. Ritchie: Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 7, 10602 (2016).

M. Feuerbacher, M. Heidelmann, and C. Thomas: Hexagonal high-entropy alloys. Mater. Res. Lett. 3, 1 (2015).

C.L. Tracy, S. Park, D.R. Rittman, S.J. Zinkle, H. Bei, M. Lang, R.C. Ewing, and W.L. Mao: High pressure synthesis of a hexagonal close-packed phase of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 8, 15634 (2017).

M.C. Gao, B. Zhang, S.M. Guo, J.W. Qiao, and J.A. Hawk: High-entropy alloys in hexagonal close-packed structure. Metall. Mater. Trans. A 47, 3322 (2016).

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, and E.P. George: The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 61, 5743 (2013).

G. Laplanche, A. Kostka, O.M. Horst, G. Eggeler, and E.P. George: Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 118 (Suppl. C), 152 (2016).

Y.H. Zhang, Y. Zhuang, A. Hu, J.J. Kai, and C.T. Liu: The origin of negative stacking fault energies and nano-twin formation in face-centered cubic high entropy alloys. Scr. Mater. 130, 96 (2017).

I. Basu, H. Fidder, V. Ocelík, and J.T.M. de Hosson: Local stress states and microstructural damage response associated with deformation twins in hexagonal close packed metals. Crystals 8, 1 (2017).

I. Basu and T. Al-Samman: Twin recrystallization mechanisms in magnesium-rare earth alloys. Acta Mater. 96, 111 (2015).

I. Basu, G. Gottstein, and B.D. Zander: Recrystallization mechanisms in wrought magnesium alloys containing rare-earth elements. Dissertation, RWTH Aachen University, Aachen, Germany, 2016, 2017.

Z. Zhang, H. Sheng, Z. Wang, B. Gludovatz, Z. Zhang, E.P. George, Q. Yu, S.X. Mao, and R.O. Ritchie: Dislocation mechanisms and 3D twin architectures generate exceptional strength-ductility-toughness combination in CrCoNi medium-entropy alloy. Nat. Commun. 8, 14390 (2017).

C. Haase and L.A. Barrales-Mora: Influence of deformation and annealing twinning on the microstructure and texture evolution of face-centered cubic high-entropy alloys. Acta Mater. 150, 88 (2018).

B. Schuh, F. Mendez-Martin, B. Völker, E.P. George, H. Clemens, R. Pippan, and A. Hohenwarter: Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 96, 258 (2015).

J-P. Couzinié, L. Lilensten, Y. Champion, G. Dirras, L. Perrière, and I. Guillot: On the room temperature deformation mechanisms of a TiZrHfNbTa refractory high-entropy alloy. Mater. Sci. Eng., A 645, 255 (2015).

G. Dirras, J. Gubicza, A. Heczel, L. Lilensten, J-P. Couzinié, L. Perrière, I. Guillot, and A. Hocini: Microstructural investigation of plastically deformed Ti20Zr20Hf20Nb20Ta20 high entropy alloy by X-ray diffraction and transmission electron microscopy. Mater. Charact. 108, 1 (2015).

G. Dirras, L. Lilensten, P. Djemia, M. Laurent-Brocq, D. Tingaud, J-P. Couzinié, L. Perrière, T. Chauveau, and I. Guillot: Elastic and plastic properties of as-cast equimolar TiHfZrTaNb high-entropy alloy. Mater. Sci. Eng., A 654, 30 (2016).

M. Feuerbacher: Dislocations and deformation microstructure in a B2-ordered Al28Co20Cr11Fe15Ni26 high-entropy alloy. Sci. Rep. 6, 29700 (2016).

O.N. Senkov, J.M. Scott, S.V. Senkova, F. Meisenkothen, D.B. Miracle, and C.F. Woodward: Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy. J. Mater. Sci. 47, 4062 (2012).

L. Lilensten, J-P. Couzinié, J. Bourgon, L. Perrière, G. Dirras, F. Prima, and I. Guillot: Design and tensile properties of a bcc Ti-rich high-entropy alloy with transformation-induced plasticity. Mater. Res. Lett. 5, 110 (2017).

J. Joseph, N. Stanford, P. Hodgson, and D.M. Fabijanic: Understanding the mechanical behaviour and the large strength/ductility differences between FCC and BCC AlxCoCrFeNi high entropy alloys. J. Alloy. Comp. 726, 885 (2017).

A.M. Giwa, P.K. Liaw, K.A. Dahmen, and J.R. Greer: Microstructure and small-scale size effects in plasticity of individual phases of Al0.7CoCrFeNi high entropy alloy. Extreme Mech. Lett. 8 (Suppl. C), 220 (2016).

R. Raghavan, C. Kirchlechner, B.N. Jaya, M. Feuerbacher, and G. Dehm: Mechanical size effects in a single crystalline equiatomic FeCrCoMnNi high entropy alloy. Scr. Mater. 129, 52 (2017).

Y. Zou, S. Maiti, W. Steurer, and R. Spolenak: Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy. Acta Mater. 65, 85 (2014).

N.L. Okamoto, S. Fujimoto, Y. Kambara, M. Kawamura, Z.M.T. Chen, H. Matsunoshita, K. Tanaka, H. Inui, and E.P. George: Size effect, critical resolved shear stress, stacking fault energy, and solid solution strengthening in the CrMnFeCoNi high-entropy alloy. Sci. Rep. 6, 35863 (2016).

Q. Jiao, G-D. Sim, M. Komarasamy, R.S. Mishra, P.K. Liaw, and J.A. El-Awady: Thermo-mechanical response of single-phase face-centered-cubic AlxCoCrFeNi high-entropy alloy microcrystals. Mater. Res. Lett. 6, 300 (2018).

Q.F. He, J.F. Zeng, S. Wang, Y.F. Ye, C. Zhu, T.G. Nieh, Z.P. Lu, and Y. Yang: Delayed plasticity during nanoindentation of single-phase CoCrFeMnNi high-entropy alloy. Mater. Res. Lett. 5, 300 (2017).

L. Wang, H. Bei, T.L. Li, Y.F. Gao, E.P. George, and T.G. Nieh: Determining the activation energies and slip systems for dislocation nucleation in body-centered cubic Mo and face-centered cubic Ni single crystals. Scr. Mater. 65, 179 (2011).

D. Wu, J.S.C. Jang, and T.G. Nieh: Elastic and plastic deformations in a high entropy alloy investigated using a nanoindentation method. Intermetallics 68, 118 (2016).

S. Mridha, S. Das, S. Aouadi, S. Mukherjee, and R.S. Mishra: Nanomechanical behavior of CoCrFeMnNi high-entropy alloy. JOM 67, 2296 (2015).

D-H. Lee, M-Y. Seok, Y. Zhao, I-C. Choi, J. He, Z. Lu, J-Y. Suh, U. Ramamurty, M. Kawasaki, T.G. Langdon, and J. Jang: Spherical nanoindentation creep behavior of nanocrystalline and coarse-grained CoCrFeMnNi high-entropy alloys. Acta Mater. 109, 314 (2016).

R.S. Ganji, P. Sai Karthik, K. Bhanu Sankara Rao, and K.V. Rajulapati: Strengthening mechanisms in equiatomic ultrafine grained AlCoCrCuFeNi high-entropy alloy studied by micro- and nanoindentation methods. Acta Mater. 125, 58 (2017).

Y.X. Ye, Z.P. Lu, and T.G. Nieh: Dislocation nucleation during nanoindentation in a body-centered cubic TiZrHfNb high-entropy alloy. Scr. Mater. 130 (Suppl. C), 64 (2017).

C. Zhu, Z.P. Lu, and T.G. Nieh: Incipient plasticity and dislocation nucleation of FeCoCrNiMn high-entropy alloy. Acta Mater. 61, 2993 (2013).

L. Yu, S. Chen, J. Ren, Y. Ren, F. Yang, K.A. Dahmen, and P.K. Liaw: Plasticity performance of Al0.5CoCrCuFeNi high-entropy alloys under nanoindentation. J. Iron Steel Res. Int. 24, 390 (2017).

Z-M. Jiao, S-G. Ma, G-Z. Yuan, Z-H. Wang, H-J. Yang, and J-W. Qiao: Plastic deformation of Al0.3CoCrFeNi and AlCoCrFeNi high-entropy alloys under nanoindentation. J. Mater. Eng. Perform. 24, 3077 (2015).

Y. Sun, G. Zhao, X. Wen, J. Qiao, and F. Yang: Nanoindentation deformation of a bi-phase AlCrCuFeNi2 alloy. J. Alloy. Comp. 608, 49 (2014).

Z.M. Jiao, M.Y. Chu, H.J. Yang, Z.H. Wang, and J.W. Qiao: Nanoindentation characterised plastic deformation of a Al0.5CoCrFeNi high entropy alloy. Mater. Sci. Technol. 31, 1244 (2015).

S. Chen, L. Yu, J. Ren, X. Xie, X. Li, Y. Xu, G. Zhao, P. Li, F. Yang, Y. Ren, and P.K. Liaw: Self-similar random process and chaotic behavior in serrated flow of high entropy alloys. Sci. Rep. 6, 29798 (2016).

I. Basu, V. Ocelík, and J.T.M. De Hosson: BCC-FCC interfacial effects on plasticity and strengthening mechanisms in high entropy alloys. Acta Mate. 157, 83 (2018).

Z. Shen, R.H. Wagoner, and W.A.T. Clark: Dislocation and grain boundary interactions in metals. Acta Metall. 36, 3231 (1988).

W.A.T. Clark, R.H. Wagoner, Z.Y. Shen, T.C. Lee, I.M. Robertson, and H.K. Birnbaum: On the criteria for slip transmission across interfaces in polycrystals. Scripta Metall. Mater. 26, 203 (1992).

A.C. Lund, C.A. Schuh, and J.K. Mason: Quantitative insight into dislocation nucleation from high-temperature nanoindentation experiments. Nat. Mater. 4, 617 (2005).

J.K. Mason, A.C. Lund, and C.A. Schuh: Determining the activation energy and volume for the onset of plasticity during nanoindentation. Phys. Rev. B 73, 054102 (2006).

K.L. Johnson: Contact Mechanics (Cambridge University Press, Cambridge, England, 1987).

J.R. Morris, H. Bei, G.M. Pharr, and E.P. George: Size effects and stochastic behavior of nanoindentation pop In. Phys. Rev. Lett. 106, 165502 (2011).

W.A. Soer, J.T.M. De Hosson, A.M. Minor, Z. Shan, S.A. Syed Asif, and O.L. Warren: Incipient plasticity in metallic thin films. Appl. Phys. Lett. 90, 181924 (2007).

W.A. Soer, J.T.M.D. Hosson, A.M. Minor, J.W. Morris, and E.A. Stach: Effects of solute Mg on grain boundary and dislocation dynamics during nanoindentation of Al–Mg thin films. Acta Mater. 52, 5783 (2004).

J.T.M.D. Hosson, W.A. Soer, A.M. Minor, Z. Shan, E.A. Stach, S.A.S. Asif, and O.L. Warren: In situ TEM nanoindentation and dislocation-grain boundary interactions: A tribute to david brandon. J. Mater. Sci. 41, 7704 (2006).

T. Zhu, J. Li, A. Samanta, H.G. Kim, and S. Suresh: Interfacial plasticity governs strain rate sensitivity and ductility in nanostructured metals. Proc. Natl. Acad. Sci. U. S. A. 104, 3031 (2007).

H. Conrad: Grain size dependence of the plastic deformation kinetics in Cu. Mater. Sci. Eng., A 341, 216 (2003).

Y. Zhang, J.P. Liu, S.Y. Chen, X. Xie, P.K. Liaw, K.A. Dahmen, J.W. Qiao, and Y.L. Wang: Serration and noise behaviors in materials. Prog. Mater. Sci. 90 (Suppl. C), 358 (2017).

C.A. Schuh, T.C. Hufnagel, and U. Ramamurty: Mechanical behavior of amorphous alloys. Acta Mater. 55, 4067 (2007).

J-M. Dubois: Complex metallic alloys: Clarity through complexity. Nat. Mater. 9, 287 (2010).

C.A. Schuh and T.G. Nieh: A nanoindentation study of serrated flow in bulk metallic glasses. Acta Mater. 51, 87 (2003).

A. van den Beukel: Theory of the effect of dynamic strain aging on mechanical properties. Phys. Status Solidi A 30, 197 (1975).

R.A. Mulford and U.F. Kocks: New observations on the mechanisms of dynamic strain aging and of jerky flow. Acta Metall. 27, 1125 (1979).

P. Rodriguez: Serrated plastic flow. Bull. Mater. Sci. 6, 653 (1984).

G. Gottstein: Physical Foundations of Materials Science (Springer Science & Business Media, Berlin/Heidelberg, Germany, 2013).

Y. Brechet and Y. Estrin: On the influence of precipitation on the Portevin–Le Chatelier effect. Acta Metall. Mater. 43, 955 (1995).

J. Antonaglia, X. Xie, Z. Tang, C-W. Tsai, J.W. Qiao, Y. Zhang, M.O. Laktionova, E.D. Tabachnikova, J.W. Yeh, O.N. Senkov, M.C. Gao, J.T. Uhl, P.K. Liaw, and K.A. Dahmen: Temperature effects on deformation and serration behavior of high-entropy alloys (HEAs). JOM 66, 2002 (2014).

M.A. Laktionova, E.D. Tabchnikova, Z. Tang, and P.K. Liaw: Mechanical properties of the high-entropy alloy Ag0.5CoCrCuFeNi at temperatures of 4.2–300K. Low Temp. Phys. 39, 630 (2013).

K.A. Dahmen, Y. Ben-Zion, and J.T. Uhl: Micromechanical model for deformation in solids with universal predictions for stress-strain curves and slip avalanches. Phys. Rev. Lett. 102, 175501 (2009).

K. Dahmen, D. Ertaş, and Y. Ben-Zion: Gutenberg-Richter and characteristic earthquake behavior in simple mean-field models of heterogeneous faults. Phys. Rev. E 58, 1494 (1998).

J.W. Christian and S. Mahajan: Deformation twinning. Prog. Mater. Sci. 39, 1 (1995).

I. Basu and T. Al-Samman: Competitive twinning behavior in magnesium and its impact on recrystallization and texture formation. Mater. Sci. Eng., A 707 (Suppl. C), 232 (2017).

C. Drouven, I. Basu, T. Al-Samman, and S. Korte-Kerzel: Twinning effects in deformed and annealed magnesium–neodymium alloys. Mater. Sci. Eng., A 647, 91 (2015).

I. Basu and T. Al-Samman: Triggering rare earth texture modification in magnesium alloys by addition of zinc and zirconium. Acta Mater. 67, 116 (2014).

T.H. Blewitt, R.R. Coltman, and J.K. Redman: Low-temperature deformation of copper single crystals. J. Appl. Phys. 28, 651 (1957).

G.F. Bolling and R.H. Richman: Continual mechanical twinning: Part I: Formal description. Acta Metall. 13, 709 (1965).

G.F. Bolling and R.H. Richman: Continual mechanical twinning: Part II: Standard experiments. Acta Metall. 13, 723 (1965).

Z.Y. Liang, J.T.M. De Hosson, and M.X. Huang: Size effect on deformation twinning in face-centred cubic single crystals: Experiments and modelling. Acta Mater. 129, 1 (2017).

B.C. De Cooman, J. Kim, and S. Lee: Heterogeneous deformation in twinning-induced plasticity steel. Scr. Mater. 66, 986 (2012).

T-H. Ahn, C-S. Oh, D.H. Kim, K.H. Oh, H. Bei, E.P. George, and H.N. Han: Investigation of strain-induced martensitic transformation in metastable austenite using nanoindentation. Scr. Mater. 63, 540 (2010).

W.A. Soer, K.E. Aifantis, and J.T.M. De Hosson: Incipient plasticity during nanoindentation at grain boundaries in body-centered cubic metals. Acta Mater. 53, 4665 (2005).

I. Basu, V. Ocelík, and J.T.M. De Hosson: Measurement of spatial stress gradients near grain boundaries. Scr. Mater. 136 (Suppl. C), 11 (2017).

O. Khalfallah, M. Condat, and L. Priester: Image force on a lattice dislocation due to a grain boundary in b.c.c. metals. Philos. Mag. A 67, 231 (1993).

L. Priester and O. Khalfallah: Image force on a lattice dislocation due to a grain boundary in anisotropic f.c.c. materials. Philos. Mag. A 69, 471 (1994).

J.P. Hirth: The influence of grain boundaries on mechanical properties. Metall. Trans. 3, 3047 (1972).

A.K. Head: X. The interaction of dislocations and boundaries. London, Edinburgh, and Dublin Phil. Mag. J. Sci. 44, 92 (1953).

I. Basu, V. Ocelík, and J.T.M. De Hosson: Experimental determination and theoretical analysis of local residual stress at grain scale. In WIT Transactions on Engineering Sciences, D. Northwood, T. Rang, J. De Hosson, and C.A. Brebbia, eds. (WIT Press, Southampton, U.K., 2017); pp. 3–14.

F. Tian, L. Delczeg, N. Chen, L.K. Varga, J. Shen, and L. Vitos: Structural stability of NiCoFeCrAlx high-entropy alloy from ab initio theory. Phys. Rev. B 88, 085128 (2013).

ACKNOWLEDGMENTS

This research was carried out under project number T61.1.14545 in the framework of the Research Program of the Materials innovation institute (M2i) (www.m2i.nl).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Basu, I., Ocelík, V. & De Hosson, J.T.M. Size effects on plasticity in high-entropy alloys. Journal of Materials Research 33, 3055–3076 (2018). https://doi.org/10.1557/jmr.2018.282

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.282