Abstract

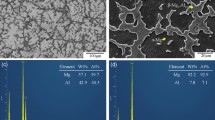

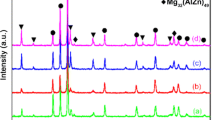

The effect of equal-channel angular pressing (ECAP) at various temperatures (310, 330, and 350 °C) on precipitations and strengthening mechanisms of Mg–9Al–1Si alloys was investigated. The results indicated that the average grain size decreased gradually with decreasing of ECAP temperature. The distribution of the Mg2Si phase changed a little when the ECAP temperature increased. However, the different morphologies of β-Mg17Al12 phase were observed, including continuous and uncontinuous precipitation of particles at 310 and 350 °C. The continuous β-Mg17Al12 phase was hardly found and the refined β-Mg17Al12 phase was distributed dispersedly in the matrix at 330 °C. Thus, the mechanical properties of the Mg–9Al–1Si alloy was optimum: ultimate tensile strength and elongation were ∼350.8 MPa and ∼14.77%, respectively. It can be deduced that both grain refinement strengthening and precipitation strengthening play significant roles in strength increment of the alloy during the ECAP process. However, precipitation strengthening is the predominant mechanism.

Similar content being viewed by others

References

P. Poddar, S. Bagui, K. Ashok, and A.P. Murugesanl: Experimental investigation on microstructure and mechanical properties of gravity-die-cast, magnesium alloys. J. Alloys Compd. 695, 895 (2016).

T. Krajňák, P. Minárik, and J. Stráská: Influence of equal channel angular pressing temperature on texture, microstructure and mechanical properties of extruded AX41 magnesium. J. Alloys Compd. 705, 273 (2017).

J.W. Kang, X.F. Sun, K.K. Deng, F.J. Xu, X. Zhang, and Y. Bai: High strength Mg–9Al serial alloy processed by slow extrusion. Mat. Sci. Eng., A, 697, 211 (2017).

J.M. Hu, J. Teng, X.K. Ji, D.F. Fu, W.G. Zhang, and H. Zhang: Enhanced mechanical properties of an Al–Mg–Si alloy by repetitive continuous extrusion forming process and subsequent aging treatment. Mat. Sci. Eng., A 695, 35 (2017).

A. Vinogradov: Effect of severe plastic deformation on tensile and fatigue properties of fine-grained magnesium alloy ZK60. J. Mater. Res. 32, 1 (2017).

P.C. Yadav, S. Sahu, A. Subramaniam, and S. Shekhar: Effect of heat-treatment on microstructural evolution and mechanical behaviour of severely deformed Inconel 718. Mat. Sci. Eng., A. 715, 295 (2018).

M.H. Shaeri, M. Shaeri, M. Ebrahimi, M.T. Salehi, and S.H. Seyyedein: Effect of ECAP temperature on microstructure and mechanical properties of Al–Zn–Mg–Cu alloy. Prog. Nat. Sci.: Mater. 26, 182 (2016).

W.H. Wang, H.X. Wang, Y.M. Liu, H.H. Nie, and W.L. Cheng: Effect of SiC nanoparticles addition on the microstructures and mechanical properties of ECAPed Mg9Al–1Si alloy. J. Mater. Res. 32, 615 (2017).

M.A. Afifi, P.H.R. Pereira, Y.C. Wang, Y.W. Wang, S.K. Li, and T.G. Langdon: Effect of ECAP processing on microstructure evolution and dynamic compressive behavior at different temperatures in an Al–Zn–Mg alloy. Mat. Sci. Eng., A (2016).

J. Zhang, G.Q. Xi, X. Wan, and C. Fang: The dislocation-twin interaction and evolution of twin boundary in AZ31 Mg alloy. Acta Mater. 133, 208 (2017).

X.J. Wang, D.K. Xu, R.Z. Wu, X.B. Chen, Q.M. Peng, L. Jin, Y.C. Xin, Z.Q. Zhang, Y. Liu, X.H. Chen, G. Chen, K.K. Deng, and H.Y. Wang: What is going on in magnesium alloys?J. Mater. Sci. Technol. 34, 245 (2017).

S.Q. Zhu and S.P. Ringer: On the role of twinning and stacking faults on the crystal plasticity and grain refinement in magnesium alloys. Acta Mater. 144, 365 (2018).

T. Krajňák, P. Minárik, J. Stráská, K. Máthis, R. Kužel, and M. Janeček: Influence of equal channel angular pressing temperature on texture, microstructure and mechanical properties of extruded AX41 magnesium. J. Alloys Compd. 705, 273 (2017).

M. Hong, S.S.A. Shah, D. Wu, R.S. Chen, X.H. Du, N.T. Hu, and Y.F. Zhang: Ultra-high strength Mg–9Gd–4Y–0.5Zr alloy with bi-modal structure processed by traditional extrusion. Met. Mater. Int. 22, 1091 (2016).

L.L. Tang, Y.H. Zhao, R.K. Islamgaliev, C.Y.A. Tsao, R.Z. Valiev, E.J. Lavernia, and Y.T. Zhu: Enhanced strength and ductility of AZ80 Mg alloys by spray forming and ECAP. Mat. Sci. Eng., A 670, 280 (2016).

H. Liu, J. Ju, J. Bai, J.P. Sun, D. Song, J.L. Yan, J.H. Jiang, and A. Ma: Preparation, microstructure evolutions, and mechanical property of an ultra-fine grained Mg–10Gd–4Y–1.5Zn–0.5Zr alloy. Metals 7, 398 (2017).

W.L. Cheng, L. Tian, H.X. Wang, L.P. Bian, and H. Yu: Improved tensile properties of an equal channel angular pressed (ECAPed) Mg–8Sn–6Zn–2Al alloy by prior aging treatment. Mat. Sci. Eng., A 687, 148 (2017).

H.X. Wang, B. Zhou, Y.T. Zhao, K.K. Zhou, W.L. Cheng, and W. Liang: Effect of Si addition on the microstructure and mechanical properties of ECAPed Mg–15Al alloy. Mat. Sci. Eng., A 589, 119 (2014).

S. Sardar, S.K. Karmakar, and D. Das: Ultrasonic assisted fabrication of magnesium matrix composites: A review. Mater. Today 4, 3280 (2017).

A. Veveçka, M. Cabibbo, and T.G. Langdon: A characterization of microstructure and microhardness on longitudinal planes of an Al–Mg–Si alloy processed by ECAP. Mater. Charact. 84, 126 (2013).

J.L. Gong, W. Liang, H.X. Wang, X.G. Zhao, and L.P. Bian: Microstructure and mechanical properties of Mg–12Al–0.7Si magnesium alloy processed by equal channel angular pressing. Mater. Sci. Forum 42, 1800 (2008).

B.G. Wang, X. Wang, J.X. Zhou, G.F. Zhang, and F. Liu: Effects of solution heat treatment on microstructure and mechanical properties of Mg–3Al–1Si–0.3Mn–x Sr alloy. Mat. Sci. Eng., A 618, 210 (2014).

T.W. Wong, A. Hadadzadeh, and M.A. Wells: High temperature deformation behavior of extruded AZ31B magnesium alloy. J. Mater. Process. Technol. 251, 360 (2017).

B. Pourbahari, H. Mirzadeh, and M. Emamy: Elucidating the effect of intermetallic compounds on the behavior of Mg–Gd–Al–Zn magnesium alloys at elevated temperatures. J. Mater. Res. (2017).

H. Zhang, T.L. Wang, and W.Y. Liu: Effect of equal channel angular pressing on microstructure and mechanical properties of Mg–Al–Si alloy. Int. J. Plast. 24, 36 (2017).

L. Zhang, Q.D. Wang, W.J. Liao, W. Guo, B. Ye, H.Y. Jiang, and W.J. Ding: Effect of homogenization on the microstructure and mechanical properties of the repetitive-upsetting processed AZ91D alloy. J. Mater. Sci. Technol. 9, 935 (2017).

H.H. Yu, Y.C. Xin, M.Y. Wang, and Q. Liu: Hall–Petch relationship in Mg alloys: A review. J. Mater. Sci. Technol. 34, 248 (2017).

T. Khelfa, M.A. Rekik, J.A. Muñoz-Bolaños, J.M. Cabrera-Marrero, and M. Khitouni: Microstructure and strengthening mechanisms in an Al–Mg–Si alloy processed by equal channel angular pressing (ECAP). Int. J. Adv. Manuf. Technol. 95, 1165 (2018).

J. Feng, H. Sun, X. Li, H. Wang, and W. Fang: Effects of Ag variations on dynamic recrystallization, texture, and mechanical properties of ultrafine-grained Mg–3Al–1Zn alloys. J. Mater. Res. 31, 3360 (2016).

Z.J. Zheng, J.W. Liu, and Y. Gao: Achieving high strength and high ductility in 304 stainless steel through bi-modal microstructure prepared by post-ECAP annealing. Mat. Sci. Eng., A 680, 426 (2016).

ACKNOWLEDGMENTS

This work was financially supported by Natural Science Foundation of Shanxi Province (201701D121045); National Natural Science Foundation of China (51771129, 51301118, and 51404166); and Shanxi Key Laboratory of Advanced Magnesium-based Materials, Taiyuan University of Technology (AMM-2017-12).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhou, P., Wang, H., Nie, H. et al. Effect of ECAP temperature on precipitation and strengthening mechanisms of Mg–9Al–1Si alloys. Journal of Materials Research 33, 1822–1829 (2018). https://doi.org/10.1557/jmr.2018.137

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.137