Abstract

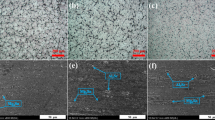

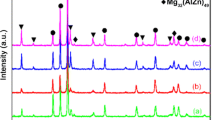

A “RE-free” and I-phase-containing Mg–8Sn-based alloy system was developed and successfully fabricated through the equal channel angular pressing (ECAP) process. The influence of the Zn/Al mass ratio on the microstructures and mechanical properties of the as-ECAPed Mg–8Sn–(5,6,7)Zn–2(wt%)Al alloys was investigated using an optical microscope, an X-ray diffractometer, a scanning electron microscope, a transmission electron microscope, and a universal testing machine. Grain size, dynamic recrystallization behavior, and texture were found to be greatly affected by the Zn/Al mass ratio. Furthermore, the ultimate tensile strength (250 MPa) and elongation (14.5%) of the alloy with a Zn/Al mass ratio of 3 were considerably increased compared to those of the as-ECAPed alloys with Zn/Al ratios of 2.5 and 3.5 (ultimate tensile strength and elongation of 215 MPa and 13% and 184 MPa and 10%, respectively). This significant enhancement was attributed to extensive grain boundary strengthening, precipitation strengthening, and higher work hardening capacity as well as texture randomization. The strength and ductility of the as-ECAPed alloys are also discussed in terms of the I-phase and Mg2Sn formation.

Similar content being viewed by others

References

H.Y. Ha, H.J. Kim, S.M. Baek, B. Kim, S.D. Sohn, H.J. Shin, H.Y. Jeong, S.H. Park, C.D. Yim, B.S. You, J.G. Lee, and S.S. Park: Improved corrosion resistance of extruded Mg–8Sn–1Zn–1Al alloy by microalloying with Mn. Scr. Mater. 109, 38–43 (2015).

T.T. Sasaki, J.D. Ju, K. Hono, and K.S. Shin: Heat-treatable Mg–Sn–Zn wrought alloy. Scr. Mater. 61, 80–83 (2009).

H.C. Pan, G.W. Qin, M. Xu, H. Fu, Y.P. Ren, F.S. Pan, Z.Y. Gao, C.Y. Zhao, Q.S. Yang, J. She, and B. Song: Enhancing mechanical properties of Mg–Sn alloys by combining addition of Ca and Zn. Mater. Des. 83, 736–744 (2015).

W.L. Cheng, S.S. Park, B.S. You, and B.H. Koo: Microstructure and mechanical properties of binary Mg–Sn alloys subjected to indirect extrusion. Mater. Sci. Eng., A 527, 4650–4653 (2010).

M. Roostaei, M.H. Parsa, R. Mahmudi, and H. Mirzadeh: Hot compression behavior of GZ31 magnesium alloy. J. Alloys Compd. 631, 1–6 (2015).

H. Mirzadeh, M. Roostaei, M.H. Parsa, and R. Mahmudi: Rate controlling mechanisms during hot deformation of Mg–3Gd–1Zn magnesium alloy: Dislocation glide and climb, dynamic recrystallization, and mechanical twinning. Mater. Des. 68, 228–231 (2015).

W.Q. Zhang, W.L. Xiao, F. Wang, and C.L. Ma: Development of heat resistant Mg–Zn–Al-based magnesium alloys by addition of La and Ca: Microstructure and tensile properties. J. Alloys Compd. 684, 8–14 (2016).

M. Suzuki, T. Kimura, J. Koike, and K. Maruyama: Strengthening effect of Zn in heat resistant Mg–Y–Zn solid solution alloys. Scr. Mater. 48, 997–1002 (2003).

C.Y. Zhao, F.S. Pan, S. Zhao, H.C. Pan, K. Song, and A.T. Tang: Microstructure, corrosion behavior and cytotoxicity of biodegradable Mg–Sn implant alloys prepared by sub-rapid solidification. Mater. Sci. Eng., C 54, 245–251 (2015).

W.L. Cheng, H.S. Kim, B.S. You, B.H. Koo, and S.S. Park: Strength and ductility of novel Mg–8Sn–1Al–1Zn alloys extruded at different speeds. Mater. Lett. 65, 1525–1527 (2011).

S.H. Park, J.H. Lee, H. Yu, J.H. Yoon, and B.S. You: Effect of cold pre-forging on the microstructure and mechanical properties of extruded Mg–8Sn–1Al–1Zn alloy. Mater. Sci. Eng., A 612, 197–201 (2014).

Y.K. Kim, S.W. Sohn, D.H. Kim, W.T. Kim, and D.H. Kim: Role of icosahedral phase in enhancing the strength of Mg–Sn–Zn–Al alloy. J. Alloys Compd. 549, 46–50 (2013).

E. Mostaed, A. Fabrizi, D. Dellasega, F. Bonollo, and M. Vedani: Microstructure, mechanical behavior and low temperature superplasticity of ECAP processed ZM21 Mg alloy. J. Alloys Compd. 638, 267–276 (2015).

H.X. Wang, K.K. Zhou, G.Y. Xie, X.Z. Liang, W. Liang, and Y.T. Zhao: Microstructure and mechanical properties of an Mg–10Al alloy fabricated by Sb-alloying and ECAP processing. Mater. Sci. Eng., A 560, 787–791 (2013).

F. Akbaripanah, S.F. Fereshteh, R. Mahmudi, and H.K. Kim: Microstructural homogeneity, texture, tensile and shear behavior of AM60 magnesium alloy produced by extrusion and equal channel angular pressing. Mater. Des. 43, 31–39 (2013).

K. Kim and J. Yoon: Effects of starting microstructure and billet orientations on the texture evolution and the mechanical behavior of Mg–3Al–1Zn rolled plate by half channel angular extrusion (HACE). Mater. Sci. Eng., A 622, 46–51 (2015).

Y. Wang and H. Choo: Influence of texture on Hall–Petch relationships in an Mg alloy. Acta Mater. 81, 83–97 (2014).

W. Yuan, S.K. Panigrahi, J.Q. Su, and R.S. Mishra: Influence of grain size and texture on Hall–Petch relationship for a magnesium alloy. Scr. Mater. 65, 994–997 (2011).

R.L. Xin, X. Zheng, Z. Liu, D.J. Liu, R.S. Qiu, Z.Y. Li, and Q. Liu: Microstructure and texture evolution of an Mg–Gd–Y–Nd–Zr alloy during friction stir processing. J. Alloys Compd. 659, 51–59 (2016).

C. Chao, J.H. Chen, H.G. Yan, B. Su, M. Song, and S.Q. Zhu: Dynamic precipitation, microstructure and mechanical properties of Mg–5Zn–1Mn alloy sheets prepared by high strain-rate rolling. Mater. Des. 100, 58–66 (2016).

K. Hantzsche, J. Bohlen, J. Wendt, K.U. Kainer, S.B. Yi, and D. Letzig: Effect of rare earth additions on microstructure and texture development of magnesium alloy sheets. Scr. Mater. 63, 725–730 (2010).

E. Biyiklia, S.M. Tokera, and D. Canadinca: Incorporating the grain boundary misorientation effects on slip activity into crystal plasticity. Mech. Adv. Mater. Struct. 23, 865–872 (2016).

D. Patrik, C. Frantisek, S.B. Yi, P. Kseniya, L. Dietmar, and B. Jan: Grain size effects on deformation twinning in an extruded magnesium alloy tested in compression. Scr. Mater. 65, 424–427 (2011).

S.S. Park, Y.J. Kim, W.L. Cheng, Y.M. Kim, and B.S. You: Tensile properties of extruded Mg–8Sn–1Zn alloys subjected to different heat treatments. Philos. Mag. Lett. 91, 37–44 (2011).

J.G. Jung, S.H. Park, H. Yu, Y.M. Kim, Y.K. Lee, and B.S. You: Improved mechanical properties of Mg–7.6Al–0.4Zn alloy through aging prior to extrusion. Scr. Mater. 93, 8–11 (2014).

W.N. Tang, S.S. Park, and B.S. You: Effect of the Zn content on the microstructure and mechanical properties of indirect-extruded Mg–5Sn–x Zn alloys. Mater. Des. 32, 3537–3543 (2011).

T. Takeuchi, S. Murasaki, A. Matsumuro, and U. Mizutani: Formation of quasicrystals and approximant crystals by mechanical alloying in Mg–Al–Zn alloy system. J. Non-Cryst. Solids 156–158, 914–917 (1993).

T. Takeuchi and U. Mizutani: Electronic structure, electron transport properties, and relative stability of icosahedral quasicrystals and their 1/1 and 2/1 approximants in the Al–Mg–Zn alloy system. Phys. Rev. B: Condens. Matter Mater. Phys. 52, 9300–9309 (1995).

C.Q. Liu, H.W. Chen, and J.F. Nie: Interphase boundary segregation of Zn in Mg–Sn–Zn alloys. Scr. Mater. 123, 5–8 (2016).

S.J. Shang, K.K. Deng, K.B. Nie, J.C. Li, S.S. Zhou, F.J. Xu, and J.F. Fan: Microstructure and mechanical properties of SiCp/Mg–Al–Zn composites containing Mg17Al12 phases processed by low-speed extrusion. Mater. Sci. Eng., A 610, 243–249 (2014).

L. Zhang, K.K. Deng, K.B. Nie, F.J. Xu, K. Su, and W. Liang: Microstructures and mechanical properties of Mg–Al–Ca alloys affected by Ca/Al ratio. Mater. Sci. Eng., A 636, 279–288 (2015).

P. Liu, H.T. Jiang, Z.X. Cai, Q. Kang, and Y. Zhang: The effect of Y, Ce and Gd on texture, recrystallization and mechanical property of Mg–Zn alloys. JMA 4, 188–196 (2016).

H.L. Ding, P. Zhang, G.P. Cheng, and S.H. Kamado: Effect of calcium addition on microstructure and texture modification of Mg rolled sheets. Trans. Nonferrous Met. Soc. 25, 2875–2883 (2015).

W.Q. Zhang, W.L. Xiao, F. Wang, and C.L. Ma: Development of heat resistant Mg–Zn–Al-based magnesium alloys by addition of La and Ca: Microstructure and tensile properties. J. Alloys Compd. 684, 8–14 (2016).

J. Bohlen, M.R. Nurnberg, J. Senn, D. Letzig, and S.R. Agnew: The texture and anisotropy of magnesium-zinc-rare earth alloy sheets. Acta Mater. 55, 2101–2112 (2007).

X.B. Zheng, W.B. Du, K. Liu, Z.H. Wang, and S.B. Li: Effect of trace addition of al on microstructure, texture and tensile ductility of Mg–6Zn–0.5Er alloy. JMA 4, 135–139 (2016).

X.M. Zhang, C.P. Tang, Y.L. Deng, and L. Yang: Effects of thermal treatment on precipitate shape and mechanical properties of Mg–8Gd–4Y–Nd–Zr alloy. Mater. Des. 32, 4994–4998 (2011).

B. Pourbahari, H. Mirzadeh, and M. Emamy: Toward unraveling the effects of intermetallic compounds on the microstructure and mechanical properties of Mg–Gd–Al–Zn magnesium alloys in the as-cast, homogenized, and extruded conditions. Mater. Sci. Eng., A 680, 39–46 (2017).

Y. Sun, B. Zhang, Y. Wang, L. Geng, and X. Jiao: Preparation and characterization of a new biomedical Mg–Zn–Ca alloy. Mater. Des. 34, 58–64 (2012).

B.P. Zhang, L. Geng, L.J. Huang, X.X. Zhang, and C.C. Dong: Enhanced mechanical properties in fine-grained Mg–1.0Zn–0.5Ca alloys prepared by extrusion at different temperatures. Scr. Mater. 63, 1024–1027 (2010).

P. Haasen: Physical Metallurgy, 3rd ed. (Cambridge University Press, Cambridge, 1996).

W.L. Cheng, Q.W. Tian, H. Yu, H. Zhang, and B.S. You: Strengthening mechanisms of indirect-extruded Mg–Sn based alloys at room temperature. JMA 2, 299–304 (2014).

T. Gladman: Precipitation hardening in metals. Mater. Sci. Technol. 15, 30–36 (1998).

J.L. Wang, Y.C. Guo, J.P. Li, Y. Zhong, K. Shigeharu, and L.M. Wang: Microstructure, texture and mechanical properties of extruded Mg–5Al–2Nd–0.2Mn alloy. J. Alloys Compd. 635, 100–107 (2015).

C.J. Bettles and M.A. Gibson: Current wrought magnesium alloys: Strengths and weaknesses. JOM 57, 46–49 (2005).

Q. Yang, B. Jiang, J. He, B. Song, W. Liu, H. Dong, and F. Pan: Tailoring texture and refining grain of magnesium alloy by differential speed extrusion process. Mater. Sci. Eng., A 612, 187–191 (2014).

ACKNOWLEDGMENTS

This study was supported by the Natural Science Foundation of China (Grant Nos.: 51404166, 51301118), the Projects of International Cooperation in Shanxi (Grant No.: 2014081002), a Research Project Supported by Shanxi Scholarship Council of China (Grant No.: 2014-023), and the Scientific and Technological Innovation Programs of Higher Education Institutions in Shanxi (Grant Nos.: 2013108, 2014017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, Wl., Tian, L., Bai, Y. et al. Microstructures and mechanical properties of as-ECAPed Mg–8Sn alloys with the combined addition of Zn and Al. Journal of Materials Research 32, 2315–2324 (2017). https://doi.org/10.1557/jmr.2017.128

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.128