Abstract

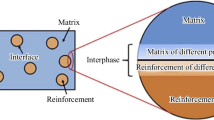

Ceramic fiber-matrix composites (CFMCs) are exciting materials for engineering applications in extreme environments. By integrating ceramic fibers within a ceramic matrix, CFMCs allow an intrinsically brittle material to exhibit sufficient structural toughness for use in gas turbines and nuclear reactors. Chemical stability under high temperature and irradiation coupled with high specific strength make these materials unique and increasingly popular in extreme settings. This paper first offers a review of the importance and growing body of research on fiber-matrix interfaces as they relate to composite toughening mechanisms. Second, micropillar compression is explored experimentally as a high-fidelity method for extracting interface properties compared with traditional fiber push-out testing. Three significant interface properties that govern composite toughening were extracted. For a 50-nm-pyrolytic carbon interface, the following were observed: a fracture energy release rate of ∼2.5 J/m2, an internal friction coefficient of 0.25 ± 0.04, and a debond shear strength of 266 ± 24 MPa. This research supports micromechanical evaluations as a unique bridge between theoretical physics models for microcrack propagation and empirically driven finite element models for bulk CFMCs.

Similar content being viewed by others

References

D.C. Phillips: The fracture energy of carbon-fibre reinforced glass. J. Mater. Sci. 7, 1175–1191 (1972).

K.M. Prewo and J.J. Brennan: High-strength silicon carbide fibre-reinforced glass-matrix composites. J. Mater. Sci. 15, 463–468 (1980).

J.J. Brennan and K.M. Prewo: Silicon carbide fibre reinforced glass-ceramic matrix composites exhibiting high strength and toughness. J. Mater. Sci. 17, 2371–2383 (1982).

J.J. Brennan, R.E. Tressler, G.L. Messing, C.G. Pantano, and R.E. Newnham: Interfacial characterization of glass and glass-ceramic matrix/nicalon SiC fiber composites. In Tailoring Multiphase and Composite Ceramics (Springer, Boston, Massachusetts, 1986), pp. 549–560.

R.A. Sambell, A. Briggs, D.C. Phillips, and D.H. Bowen: Carbon fibre composites with ceramic and glass matrices. Part 2: Continuous fibres. J. Mater. Sci. 7, 676–681 (1972).

X.W. Yin, L.F. Cheng, L.T. Zhang, N. Travitzky, and P. Greil: Fibre-reinforced multifunctional SiC matrix composite materials. Int. Mater. Rev. 62, 117–172 (2016).

K. Yueh and K.A. Terrani: Silicon carbide composite for light water reactor fuel assembly applications. J. Nucl. Mater. 448, 380–388 (2014).

L.L. Snead, T. Nozawa, M. Ferraris, Y. Katoh, R. Shinavski, and M. Sawan: Silicon carbide composites as fusion power reactor structural materials. J. Nucl. Mater. 417, 330–339 (2011).

R. Naslain and F. Christin: SiC-matrix composite materials for advanced jet engines. MRS Bull. 28, 654–658 (2003).

S. Yashiro, K. Ogi, and M. Oshita: High-velocity impact damage behavior of plain-woven SiC/SiC composites after thermal loading. Composites, Part B Eng. 43, 1353–1362 (2012).

Y. Katoh, L.L. Snead, I. Szlufarska, and W.J. Weber: Radiation effects in SiC for nuclear structural applications. Solid State Mater. Sci. 16, 143–152 (2012).

R.W. Hertzberg, R.P. Vinci, and J.L. Hertzberg: Deformation and Fracture Mechanics of Engineering Materials, 5th ed. (John Wiley & Sons, Inc., Hoboken, NJ, 1996).

B.C. Carter and G.M. Norton: Ceramic Materials (Springer, Boston, MA, 2007).

A.G. Evans and F.W. Zok: The physics and mechanics of fibre-reinforced brittle matrix composites. J. Mater. Sci. 29, 3857–3896 (1994).

Y. Katoh, L.L. Snead, C.H. Henager, T. Nozawa, T. Hinoki, A. Iveković, S. Novak, and S.M. Gonzalez De Vicente: Current status and recent research achievements in SiC/SiC composites. J. Nucl. Mater. 455, 387–397 (2014).

C.H. Carter, R.F. Davis, and J. Bentley: Kinetics and mechanisms of high-temperature creep in silicon carbide: II, chemically vapor deposited. J. Am. Ceram. Soc. 67, 732–740 (1984).

K.A. Terrani, B.A. Pint, C.M. Parish, C.M. Silva, L.L. Snead, and Y. Katoh: Silicon carbide oxidation in steam up to 2 MPa. J. Am. Ceram. Soc. 97, 2331–2352 (2014).

L.L. Snead, T. Nozawa, Y. Katoh, T.S. Byun, S. Kondo, and D.A. Petti: Handbook of SiC properties for fuel performance modeling. J. Nucl. Mater. 371, 329–377 (2007).

T. Hinoki, E. Lara-Curzio, and L.L. Snead: Mechanical properties of high purity SiC fiber-reinforced CVI-SiC matrix composites. J. Mater. Res. 11, 391–397 (2008).

T. Nozawa, Y. Katoh, and L.L. Snead: The effect of neutron irradiation on the fiber/matrix interphase of silicon carbide composites. J. Nucl. Mater. 384, 195–211 (2009).

Y. Katoh, K. Ozawa, C. Shih, T. Nozawa, R.J. Shinavski, A. Hasegawa, and L.L. Snead: Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: Properties and irradiation effects. J. Nucl. Mater. 448, 448–476 (2014).

S.J. Zinkle, K.A. Terrani, J.C. Gehin, L.J. Ott, and L.L. Snead: Accident tolerant fuels for LWRs: A perspective. J. Nucl. Mater. 448, 374–379 (2014).

R.J. Kerans and R.S. Hay: Interface design for oxidation-resistant ceramic composites. J. Am. Ceram. Soc. 85, 2599–2632 (2002).

K.A. Keller, T. Mah, T.A. Parthasarathy, and C.M. Cooke: Fugitive interfacial carbon coatings for oxide/oxide composites. J. Am. Ceram. Soc. 83, 329–336 (2000).

J. Wendorff, R. Janssen, and N. Claussen: Platinum as a weak interphase for fiber-reinforced oxide-matrix composites. J. Am. Ceram. Soc. 40, 2738–2740 (1998).

L. Filipuzzi, G. Camus, and R. Naslain: Oxidation mechanisms and kinetics of 1 D-SiC/C/SiC composite materials: I, an experimental approach. J. Am. Ceram. Soc. 47, 459–466 (1994).

A.G. Evans, F.W. Zok, R.M. McMeeking, and Z.Z. Du: Models of high-temperature, environmentally assisted embrittlement in ceramic-matrix composites. J. Am. Ceram. Soc. 79, 2345–2352 (1996).

A.J. Eckel, J.D. Cawley, and T.A. Parthasarathy: Oxidation kinetics of a continuous carbon phase in a nonreactive matrix. J. Am. Ceram. Soc. 78, 972–980 (1995).

T.A. Parthasarathy, C.A. Folsom, and L.P. Zawada: Combined effects of exposure to salt (NaCl) water and oxidation on the strength of uncoated and BN-coated Nicalon™ fibers. J. Am. Ceram. Soc. 86, 1812–1818 (1998).

R. Naslain and F. Langlais: CVD-processing of ceramic-ceramic composite materials. In Tailoring Multiphase and Composite Ceramics (Springer, Boston, MA, 1986), pp. 145–164.

R. Naslain, O. Dugne, A. Guette, J. Sevely, C.R. Brosse, J-P. Rocher, and J. Cotteret: Boron nitride interphase in ceramic-matrix composites. J. Am. Ceram. Soc. 74, 2482–2488 (1991).

J. Lamon: Chemical vapor infiltrated SiC/SiC composites. In Handbook of Ceramic Composite (Springer, Boston, Massachusetts, 2005), pp. 55–76.

H.E. Khalifa, C.P. Deck, O. Gutierrez, G.M. Jacobsen, and C.A. Back: Fabrication and characterization of joined silicon carbide cylindrical components for nuclear applications. J. Nucl. Mater. 457, 227–240 (2015).

C.P. Deck, G.M. Jacobsen, J. Sheeder, O. Gutierrez, J. Zhang, J. Stone, H.E. Khalifa, and C.A. Back: Characterization of SiC–SiC composites for accident tolerant fuel cladding. J. Nucl. Mater. 446, 667–681 (2015).

S. Bertrand, C. Droillard, R. Pailler, X. Bourrat, and R. Naslain: TEM structure of (PyC/SiC) multilayered interphases in SiC/SiC composites. J. Eur. Ceram. Soc. 20, 1–13 (2000).

R.R. Naslain, R.J.F. Pailler, and J.L. Lamon: Single and multilayered interphases in SiC/SiC composites exposed to severe environmental conditions: An overview. Int. J. Appl. Ceram. Technol. 7, 263–275 (2010).

G.N. Morscher, D.R. Bryant, and R.E. Tressler: Environmental durability of BN-based interphases (for SiC(f)/SiC(m) composites) in H2O-containing atmospheres at intermediate temperatures. Ceram. Eng. Sci. Proc. 18, 525–534 (1997).

C.G. Cofer and J. Economy: Oxidative and hydrolytic stability of boron nitride—A new approach to improving the oxidation resistance of carbonaceous structures. Carbon 33, 389–395 (1995).

G. Newsome, L.L. Snead, T. Hinoki, Y. Katoh, and D. Peters: Evaluation of neutron irradiated silicon carbide and silicon carbide composites. J. Nucl. Mater. 371, 76–89 (2007).

J. Lamon and N. Bansal: Ceramic Matrix Composites: Materials, Modeling and Technology (John Wiley & Sons, Hoboken, New Jersey, 2015).

Z. Xia and L. Li: Understanding interfaces and mechanical properties of ceramic matrix composites. In Advances in Ceramic Matrix Composites (Woodhead Publishing, Sawston, U.K., 2014), pp. 367–385.

M-Y. He and J.W. Hutchinson: Crack deflection at an interface between dissimilar elastic materials. Int. J. Solids Struct. 31, 3443–3455 (1989).

J. Dundurs: Edge-bonded dissimilar orthogonal elastic wedges under normal and shear loading. J. Appl. Mech. 36, 650–652 (1969).

B.K. Ahn: Interfacial Mechanics in Fiber-Reinforced Composites: Mechanics of Single and Multiple Cracks in CMCs (Virginia Polytechnic Institute and State University, Blacksburg, Virginia, 1997), pp. 1–160.

M. Braginsky and C.P. Przybyla: Simulation of crack propagation/deflection in ceramic matrix continuous fiber reinforced composites with weak interphase via the extended finite element method. Compos. Struct. 136, 538–545 (2016).

D. Martinez and V. Gupta: Energy criterion for crack deflection an interface between two orthotropic media. J. Mech. Phys. Solids 42, 1247–1271 (1994).

Y. Liang and K.M. Liechti: Toughening mechanisms in mixed-mode interfacial fracture. Int. J. Solids Struct. 32, 957–978 (1995).

N.A. Fleck: Crack path selection in a brittle adhesive layer. Int. J. Solids Struct. 27, 1683–1703 (1991).

P. Isaksson and P. Stahle: Mode II crack paths under compression in brittle solids—A theory and experimental comparison. Int. J. Solids Struct. 39, 2281–2297 (2002).

Z. Cedric and J.W. Hutchinson: Mode II fracture toughness of a brittle adhesive layer. Int. J. Solids Struct. 31, 1133–1148 (1994).

B.R.K. Blackman: Mode II fracture testing of composites: A new look at an old problem. Eng. Fract. Mech. 73, 2443–2455 (2006).

J. Handin: On the Coulomb–Mohr failure criterion. J. Geophys. Res. 74, 5343–5348 (1969).

M.Y. He, A.G. Anthony, and J.W. Hutchinson: Crack deflection at an interface between dissimilar elastic materials: Role of residual stresses. Int. J. Solids Struct. 31, 3443–3455 (1994).

K. Ozawa, T. Hinoki, T. Nozawa, Y. Katoh, Y. Maki, S. Kondo, S. Ikeda, and A. Kohyama: Evaluation of fiber/matrix interfacial strength of neutron irradiated SiC/SiC composites using hysteresis loop analysis of tensile test. Mater. Trans. 47, 207–210 (2006).

C.H. Hsueh, F. Rebillat, J. Lamon, and E. Lara-Curzio: Analyses of fiber push-out tests performed on nicalon/SiC composites with tailored interfaces. Composites, Part B Eng. 5, 1387–1401 (2008).

F. Rebillat, J. Lamon, R. Naslain, E. Lara-Curzio, M.K. Ferber, and T.M. Besmann: Interfacial bond strength in SiC/C/SiC composite materials, as studied by single-fiber push-out tests. J. Am. Ceram. Soc. 81, 965–978 (1998).

C.H. Hsueh: Interfacial debonding and fibre pull-out stresses of fibre-reinforced composites. Mater. Sci. Eng., A 123, 1–11 (1990).

D.K. Shetty: Shear-lag analysis of fiber push-out (indentation) tests for estimating interfacial friction stress in ceramic matrix composites. J. Am. Ceram. Soc. 71, C107–C109 (1988).

P. Lawrence: Some theoretical consideration of fibre pull-out from an elastic matrix. J. Mat. Sci. 7, 1–6 (1972).

F. Rebillat, J. Lamon, and A. Guette: The concept of a strong interface applied to SiC/SiC composites with a BN interphase. Acta Mater. 48, 4609–4618 (2000).

W.M. Mueller, J. Moosburger-Will, M.G.R. Sause, and S. Horn: Microscopic analysis of single-fiber push-out tests on ceramic matrix composites performed with Berkovich and flat-end indenter and evaluation of interfacial fracture toughness. J. Eur. Ceram. Soc. 33, 441–451 (2013).

C. Shin, H.H. Jin, W.J. Kim, and J.Y. Park: Mechanical properties and deformation of cubic silicon carbide micropillars in compression at room temperature. J. Am. Ceram. Soc. 95, 2944–2950 (2012).

B.N. Jaya and V. Jayaram: Fracture testing at small-length scales: From plasticity in Si to brittleness in Pt. J. Mater. Sci. 68, 94–108 (2016).

W. Gerberich, J. Michler, W. Mook, R. Ghisleni, F. Östlund, D. Stauffer, and R. Ballarini: Scale effects for strength, ductility, and toughness in ‘brittle’ materials. J. Mater. Res. 24, 898–906 (2009).

J. Dohr, D.E.J. Armstrong, E. Tarleton, T. Couvant, and S. Lozano-Perez: The influence of surface oxides on the mechanical response of oxidized grain boundaries. Thin Solid Films 632, 17–22 (2017).

D.E.J. Armstrong, A.J. Wilkinson, and S.G. Roberts: Micro-mechanical measurements of fracture toughness of bismuth embrittled copper grain boundaries. Philos. Mag. Lett. 91, 394–400 (2011).

P. Hosemann: Small-scale mechanical testing on nuclear materials: Bridging the experimental length-scale gap. Scr. Mater. 143, 161–168 (2018).

C. Shih, Y. Katoh, K.J. Leonard, H. Bei, and E. Lara-Curzio: Determination of interfacial mechanical properties of ceramic composites by the compression of micro-pillar test specimens. J. Mater. Sci. 48, 5219–5224 (2013).

J. Kabel, Y. Yang, M. Balooch, C. Howard, T. Koyanagi, K.A. Terrani, Y. Katoh, and P. Hosemann: Micro-mechanical evaluation of SiC–SiC composite interphase properties and debond mechanisms. Composites, Part B Eng. 131, 1–18 (2017).

H.G. Tattersall and G. Tappin: The work of fracture and its measurement in metals, ceramics and other materials. J. Mater. Sci. 1, 296–301 (1966).

A. Anaka, T. Shibayama, S. Takeda, and M. Yokoyama: Recent progress of Hi-nicalon type S development. Ceram. Eng. Sci. Proc. 24, 217–223 (2003).

H. Ichikawa: Development of high performance SiC fibers derived from polycarbosilian using electron beam irradiation curing-a review. J. Ceram. Soc. 114, 455–460 (2006).

C. Sauder and J. Lamon: Tensile creep behavior of SiC-based fibers with a low oxygen content. J. Am. Ceram. Soc. 90, 1146–1156 (2007).

C. Sauder, A. Brusson, and J. Lamon: Influence of interface characteristics on the mechanical properties of Hi-nicalon type-S or tyranno-SA3 fiber-reinforced SiC/SiC minicomposites. Int. J. Appl. Ceram. Technol. 7, 291–303 (2010).

Y. Katoh, L.L. Snead, T. Nozawa, S. Kondo, and J.T. Busby: Thermophysical and mechanical properties of near-stoichiometric fiber CVI SiC/SiC composites after neutron irradiation at elevated temperatures. J. Nucl. Mater. 403, 48–61 (2010).

C. Karthik, J. Kane, D.P. Butt, W.E. Windes, and R. Ubic: In situ transmission electron microscopy of electron-beam induced damage process in nuclear grade graphite. J. Nucl. Mater. 412, 321–326 (2011).

C. Karthik, J. Kane, D.P. Butt, W.E. Windes, and R. Ubic: Neutron irradiation induced microstructural changes in NBG-18 and IG-110 nuclear graphites. Carbon 86, 124–131 (2015).

M. Takeuchi, S. Muto, T. Tanabe, H. Kurata, and K. Hojou: Structural change in graphite under electron irradiation at low temperatures. J. Nucl. Mater. 271–272, 280–284 (1999).

L.L. Snead, T.D. Burchell, and Y. Katoh: Swelling of nuclear graphite and high quality carbon fiber composite under very high irradiation temperature. J. Nucl. Mater. 381, 55–61 (2008).

Z. Liu, S.M. Zhang, J.R. Yang, J.Z. YangLiu, Y.L. Yang, and Q.S. Zheng: Interlayer shear strength of single crystalline graphite. Acta Mech. Sin. 28, 978–982 (2012).

M. Sakai and R.C. Bradt: Fracture toughness anisotropy of a pyrolytic carbon. J. Mater. Sci. 21, 1491–1501 (1986).

R.J. Kerans, T.A. Parthasarathy, F. Rebillat, and J. Lamon: Interface properties in high-strength nicalon/C/SiC composites, as determined by rough surface analysis of fiber push-out tests. J. Am. Ceram. Soc. 81, 1881–1887 (1998).

R.O. Ritchie: Fatigue and fracture of pyrolytic carbon: A damage-tolerant approach to structural integrity and life prediction in ceramic heart valve protheses. J. Heart. Valve Dis. 5, S9–S31 (1996).

Y. Katoh, L.L. Snead, C.H. Henager, A. Hasegawa, A. Kohyama, B. Riccardi, and H. Hegeman: Current status and critical issues for development of SiC composites for fusion applications. J. Nucl. Mater. 367–370, 659–671 (2007).

W. Yang, A. Kohyama, T. Noda, Y. Katoh, T. Hinoki, H. Araki, and J. Yu: Interfacial characterization of CVI-SiC/SiC composites. J. Nucl. Mater. 311, 1088–1092 (2002).

T. Hinoki: Effect of fiber coating on interfacial shear strength of SiC/SiC by nano-indentation technique. J. Nucl. Mater. 263, 1567–1571 (1998).

S. Bertrand, R. Pailler, and J. Lamon: Influence of strong fiber/coating interfaces on the mechanical behavior and lifetie of Hi-nicalon/(PyC/SiC)n/SiC minicomposites. J. Am. Ceram. Soc. 84, 787–794 (2001).

ACKNOWLEDGMENTS

This work was supported by the U.S. Department of Energy (DOE), Office of Nuclear Energy’s Nuclear Science User Facilities (NSUF) program. A portion of this study was also supported by the U.S. DOE, Office of Nuclear Energy for the Advanced Fuels Campaign of the Fuel Cycle R&D program under contact DE-AC05-00OR22725 with Oak Ridge National Laboratory managed by UT Battelle, LLC. In addition, we would like to thank the Nuclear Regulatory Commission (NRC) fellowship program and the DOE-NEUP program for support. The authors would like to acknowledge the EPSRC for their support through grant number EP/N017110/1. Lastly, we would like to thank those involved with the UC Berkeley BNC facility and the Lawrence Berkeley National Laboratory National Center for Electron Microscopy (LBNL NCEM) for enabling this research through access and expertise to the necessary facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper has been selected as an Invited Feature Paper.

Rights and permissions

About this article

Cite this article

Kabel, J., Hosemann, P., Zayachuk, Y. et al. Ceramic composites: A review of toughening mechanisms and demonstration of micropillar compression for interface property extraction. Journal of Materials Research 33, 424–439 (2018). https://doi.org/10.1557/jmr.2017.473

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.473