Abstract

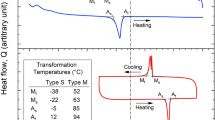

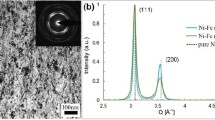

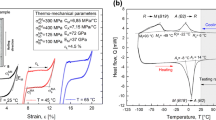

Fatigue cracking in polycrystalline NiTi was investigated using a multiscale experimental framework for average grain sizes (GS) from 10 to 1500 nm for the first time. Macroscopic fatigue crack growth rates, measured by optical digital image correlation, were connected to microscopic crack opening and closing displacements, measured by scanning electron microscope DIC (SEM-DIC) using a high-precision external SEM scan controller. Among all grain sizes, the 1500 nm GS sample exhibited the slowest crack growth rate at the macroscale, and the largest crack opening level (stress intensity at first crack opening) and minimum crack opening displacements at the microscale. Smaller GS samples (10, 18, 42, and 80 nm) exhibited nonmonotonic trends in their fatigue performance, yet the correlation was strong between macroscale and microscale behaviors for each GS. The samples that exhibited the fastest crack growth rates (42 and 80 nm GS) showed a small crack opening level and the largest crack opening displacements. The irregular trends in fatigue performance across the nanocrystalline GS samples were consistent with nonmonotonic values in the elastic modulus reported previously, both of which may be related to the presence of residual martensite only evident in the small GS samples (10 and 18 nm).

Similar content being viewed by others

References

S.W. Robertson, A.R. Pelton, and R.O. Ritchie: Mechanical fatigue and fracture of Nitinol. Int. Mater. Rev. 57, 1 (2012).

S.W. Robertson and R.O. Ritchie: In vitro fatigue-crack growth and fracture toughness behavior of thin-walled superelastic nitinol tube for endovascular stents: A basis for defining the effect of crack-like defects. Biomaterials 28, 700 (2007).

P.C. Paris, M.P. Gomez, and W.E. Anderson: A rational analytic theory of fatigue. Trend Eng. 13, 9 (1961).

W. Elber: Fatigue crack closure under cyclic tension. Eng. Fract. Mech. 2, 37 (1970).

H. Sehitoglu: Crack opening and closure in fatigue. Eng. Fract. Mech. 21, 329 (1985).

Q. Sun, A. Aslan, M. Li, and M. Chen: Effects of grain size on phase transition behavior of nanocrystalline shape memory alloys. Sci. China: Technol. Sci. 57, 671 (2014).

T. Waitz, K. Tsuchiya, T. Antretter, and F.D. Fischer: Phase transformations of nanocrystalline martensitic materials. MRS Bull. 34, 814 (2009).

T. Duerig, A. Pelton, and D. Stöckel: An overview of nitinol medical applications. Mater. Sci. Eng., A 275, 149 (1999).

J.A. Shaw and S. Kyriakides: Thermomechanical aspects of NiTi. J. Mech. Phys. Solids 43, 1243 (1995).

J.A. Shaw and S. Kyriakides: On the nucleation and propagation of phase transformation fronts in a NiTi alloy. Acta Mater. 45, 683 (1997).

Z.Q. Li and Q.P. Sun: The initiation and growth of macroscopic martensite band in nano-grained NiTi microtube under tension. Int. J. Plast. 18, 1481 (2002).

B-C. Chang, J.A. Shaw, and M.A. Iadicola: Thermodynamics of shape memory alloy wire: Modeling, experiments, and application. Continuum Mech. Thermodyn. 18, 83 (2006).

M.P. Li and Q.P. Sun: Nanoscale phase transition behavior of shape memory alloys — closed form solution of 1D effective modelling. J. Mech. Phys. Solids 110, 21–37 (2018).

A. Ahadi and Q. Sun: Stress-induced nanoscale phase transition in superelastic NiTi by in situ X-ray diffraction. Acta Mater. 90, 272 (2015).

M. Petersmann, W. Pranger, T. Waitz, and T. Antretter: An energy approach to determine the martensite morphology in nanocrystalline NiTi. Adv. Eng. Mater. 19, 1600684 (2017).

A. Ahadi and Q. Sun: Grain size dependence of fracture toughness and crack-growth resistance of superelastic NiTi. Scr. Mater. 113, 171 (2016).

H. Yin, Y. He, Z. Moumni, and Q. Sun: Effects of grain size on tensile fatigue life of nanostructured NiTi shape memory alloy. Int. J. Fatigue 88, 166 (2016).

T. Leitner, I. Sabirov, R. Pippan, and A. Hohenwarter: The effect of severe grain refinement on the damage tolerance of a superelastic NiTi shape memory alloy. J. Mech. Behav. Biomed. Mater. 71 (2017).

E. Prokofiev, J. Burow, J. Frenzel, D. Gunderov, G. Eggeler, and R. Valiev: Phase transformations and functional properties of NiTi alloy with ultrafine-grained structure. Mater. Sci. Forum 669, 1059 (2011).

K. Gall, J. Tyber, G. Wilkesanders, S.W. Robertson, R.O. Ritchie, and H.J. Maier: Effect of microstructure on the fatigue of hot-rolled and cold-drawn NiTi shape memory alloys. Mater. Sci. Eng., A 486, 389 (2008).

ASTM Standard E647: Standard Test Method for Measurement of Fatigue Crack Growth Rates (ASTM International, West Conshohocken, Pennsylvania, 2013); pp. 1–49.

M.A. Sutton, J.J. Orteu, and H.W. Schreier: Image Correlation for Shape, Motion, and Deformation Measurements: Basic Concepts, Theory, and Applications (Springer, New York, 2009).

S.R. McNeill, W.H. Peters, and M.A. Sutton: Estimation of stress intensity factor by digital image correlation. Eng. Fract. Mech. 28, 101 (1987).

M.A. Sutton, W. Zhao, S.R. McNeill, J.D. Helm, R.S. Piascik, and W.T. Riddell: Local crack closure measurements: Development of a measurement system using computer vision and a far-field microscope. Advances in fatigue crack closure measurement and analysis. J. ASTM Int. 2, 145 (1999).

S. O’Connor, D. Nowell, and K. Dragnevski: Measurement of fatigue crack deformation on the macro- and micro-scale: Uniform and non-uniform loading. Int. J. Fatigue 89, 66 (2016).

M.D. Sangid, G.J. Pataky, H. Sehitoglu, R.G. Rateick, T. Niendorf, and H.J. Maier: Superior fatigue crack growth resistance, irreversibility, and fatigue crack growth-microstructure relationship of nanocrystalline alloys. Acta Mater. 59, 7340 (2011).

P.F.P. de Matos and D. Nowell: Experimental and numerical investigation of thickness effects in plasticity-induced fatigue crack closure. Int. J. Fatigue 31, 1795 (2009).

J. Carroll, C. Efstathiou, J. Lambros, H. Sehitoglu, B. Hauber, S. Spottswood, and R. Chona: Investigation of fatigue crack closure using multiscale image correlation experiments. Eng. Fract. Mech. 76, 2384 (2009).

M.C. Casperson, J.D. Carroll, J. Lambros, H. Sehitoglu, and R.H. Dodds: Investigation of thermal effects on fatigue crack closure using multiscale digital image correlation experiments. Int. J. Fatigue 61, 10 (2014).

J.D. Carroll, W. Abuzaid, J. Lambros, and H. Sehitoglu: High resolution digital image correlation measurements of strain accumulation in fatigue crack growth. Int. J. Fatigue 57, 140 (2013).

M.A. Sutton, N. Li, D. Garcia, N. Cornille, J.J. Orteu, S.R. McNeill, H.W. Schreier, X. Li, and A.P. Reynolds: Scanning electron microscopy for quantitative small and large deformation measurements, part II: Experimental validation for magnifications from 200 to 10,000. Exp. Mech. 47, 789–804 (2007).

M.A. Sutton, N. Li, D.C. Joy, A.P. Reynolds, and X. Li: Scanning electron microscopy for quantitative small and large deformation measurements, part I: SEM imaging at magnifications from 200 to 10,000. Exp. Mech. 47 (2007).

A. Kammers and S. Daly: Self-assembled nanoparticle surface patterning for improved digital image correlation in a scanning electron microscope. Exp. Mech. 53, 1333 (2013).

A. Kammers and S. Daly: Digital image correlation under scanning electron microscopy: Methodology and validation. Exp. Mech. 53, 1743 (2013).

W.S. LePage, S.H. Daly, and J.A. Shaw: Cross polarization for improved digital image correlation. Exp. Mech. 56, 969 (2016).

ASTM Standard E561: E561 Standard Test Method for KR Curve Determination (ASTM International, West Conshohocken, Pennsylvania, 2016); pp. 1–16.

A. Ahadi and Q. Sun: Stress hysteresis and temperature dependence of phase transition stress in nanostructured NiTi. Appl. Phys. Lett. 103, 5 (2013).

A. Ahadi and Q. Sun: Effects of grain size on the rate-dependent thermomechanical responses of nanostructured superelastic NiTi. Acta Mater. 76, 186 (2014).

W. LePage, J. Shaw, and S. Daly: Optimum paint sequence for speckle patterns in digital image correlation. Exp. Tech. 41, 557 (2017).

Y. Wu, A. Ojha, L. Patriarca, and H. Sehitoglu: Fatigue crack growth fundamentals in shape memory alloys. Shape Mem. Superelastic. 1, 18 (2015).

P. Reu and E. Jones: Distortion of full-field surface displacements from heat waves. In Conference Proceedings of the International Digital Imaging Correlation Society, M. Sutton and P.L. Reu, eds. (Springer International, Cham, Switzerland, 2016); pp. 1–2.

F. Hild and S. Roux: Evaluating Damage with Digital Image Correlation: B. From Physical to Mechanical Damage (Springer, New York, 2015); pp. 1277–1299, ISBN 9781461455899.

C.M. Cady, C. Liu, P.J. Rae, and M.L. Lovato: Thermal and loading dynamics of energetic materials. In Proceedings of the Society of Experimental Mechanics Annual Conference (Society of Experimental Mechanics, Bethel, Connecticu, 2009).

C. Liu, C.M. Cady, P.J. Rae, and M.L. Lovato: On the Quantitative Measurement of Fracture Toughness in High Explosive and Mock Materials (Los Alamos National Laboratories, Los Alamos, New Mexico, 2010); pp. 425–434.

L.W. Wang, K. Li, S. Sanusei, R. Ghorbani, F. Matta, and M.A. Sutton: Advancement of optical methods in experimental mechanics, volume 3. In Conference Proceedings of the Society for Experimental Mechanics Series, H. Jin, C. Sciammarella, S. Yoshida, and L. Lamberti, eds.; Conference Proceedings of the Society for Experimental Mechanics Series, Vol. 3 (Springer International Publishing, Cham, Switzerland, 2014); pp. 289–297, ISBN 978-3-319-00767-0.

S.M. Guo, M.A. Sutton, N. Li, X.D. Li, L.W. Wang, and S. Rajan: Measurement of local thermal deformations in heterogeneous microstructures via SEM imaging with digital image correlation. Exp. Mech. 57, 41 (2016).

M. Sutton: Personal Communiciation, 3 May 2017.

P. Sedlak, M. Frost, A. Kruisova, K. Hivrmanova, L. Heller, and P. Sittner: Simulations of mechanical response of superelastic NiTi helical spring and its relation to fatigue resistance. J. Mater. Eng. Perform. 23, 2591 (2014).

A. Ahadi, Y. Matsushita, T. Sawaguchi, J. Schaffer, Q. Sun, and K. Tsuchiya: Origin of zero and negative thermal expansion in severely-deformed NiTi alloy. Acta Mater. 124, 79 (2017).

Y. Li, J.Y. Li, M. Liu, Y.Y. Ren, F. Chen, G.C. Yao, and Q.S. Mei: Evolution of microstructure and property of NiTi alloy induced by cold rolling. J. Alloys Compd. 653, 156 (2015).

M. Gupta, R.C. Alderliesten, and R. Benedictus: A review of T-stress and its effects in fracture mechanics. Eng. Fract. Mech. 134, 218 (2015).

S.W. Robertson, X.Y. Gong, and R.O. Ritchie: Effect of product form and heat treatment on the crystallographic texture of austenitic Nitinol. J. Mater. Sci. 41, 621 (2006).

S. Gao and S. Yi: Experimental study on the anisotropic behavior of textured NiTi pseudoelastic shape memory alloys. Mater. Sci. Eng., A 362, 107 (2003).

M. Xia, P. Liu, and Q. Sun: Grain size effects on Young’s modulus and hardness of nanocrystalline NiTi shape memory alloy. Mater. Lett. 211, 352–355 (2018).

K. Kim and S. Daly: Martensite strain memory in the shape memory alloy nickel–titanium under mechanical cycling. Exp. Mech. 51, 641 (2011).

P. Feng and Q.P. Sun: Experimental investigation on macroscopic domain formation and evolution in polycrystalline NiTi microtubing under mechanical force. J. Mech. Phys. Solids 54, 1568 (2006).

S. Daly, G. Ravichandran, and K. Bhattacharya: Stress-induced martensitic phase transformation in thin sheets of Nitinol. Acta Mater. 55, 3593 (2007).

J.F. Hallai and S. Kyriakides: Underlying material response for Luders-like instabilities. Int. J. Plast. 47, 1 (2013).

S. Suresh and R.O. Ritchie: Near-Threshold Fatigue Crack Propagation: A Perspective on the Role of Crack Closure (Tech. Rep., Brown Univ., Providence, RI, USA; Div. of Engineering; Lawrence Berkeley Lab., CA, USA, 1983).

ACKNOWLEDGMENTS

Dr. S. Daly gratefully acknowledges financial support from the National Science Foundation (CAREER Award, CMMI-1251891). Mr. W. LePage is grateful for financial support from the U.S. Department of Defense (Air Force Office of Scientific Research, National Defense Science and Engineering Graduate, or NDSEG, Fellowship program, 32 CFR 168a). Dr. A. Ahadi is grateful for financial support from the International Center for Young Scientists (ICYS), National Institute for Materials Science (NIMS) Japan, under grant number C1052. Dr. QP Sun is grateful for financial support from the Research Grant Council of Hong Kong through GRF Project No. 16214215. We sincerely thank Dr. J. Wayne Jones, Dr. Michael Thouless, and Dr. Alan Pelton for insightful discussions, Dr. Nakhiah Goulbourne for sharing fatigue testing equipment, Dr. Zhe Chen for assistance with SEM-DIC experiments, Dr. Jerry Zhongrui Li for assistance with X-ray diffraction measurements, Mr. Benjamin Marchi for developing the function to compute the coefficients of determination (R2) in Mathematica, Dr. Ryan Watkins for developing the DIC image overlay plotting routines, and the Michigan Center for Materials Characterization for instrument use and staff assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper has been selected as an Invited Feature Paper.

Supplementary Material

Rights and permissions

About this article

Cite this article

LePage, W.S., Ahadi, A., Lenthe, W.C. et al. Grain size effects on NiTi shape memory alloy fatigue crack growth. Journal of Materials Research 33, 91–107 (2018). https://doi.org/10.1557/jmr.2017.395

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.395