Abstract

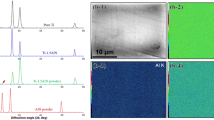

Oxygen is known to have a significant impact on the strength of Ti alloys, whereas it can also reduce the ductility substantially. Thus, the usage of oxygen to strengthen Ti is restricted in the industry. In this study, we rekindled the research of oxygen behavior in Ti with the purpose of developing Ti alloys with high strength and suitable ductility by using no expensive and poisonous element. To this end, experiments of producing high performance commercially pure Ti using only oxygen solid solution were carried out. The oxygen element was introduced into the Ti by two different powder metallurgy methods. The microstructural examination and mechanical test were performed for the samples, which indicated a strong hardening effect of oxygen in spite of the processing routes. Most importantly, the results suggested that a high elongation to failure of over 20% can still be obtained in the samples having yield stress over 800 MPa, up to an oxygen content of 0.8 wt%, which is far beyond the previously recognized limit.

Similar content being viewed by others

References

D. Banerjee and J.C. Williams: Perspectives on titanium science and technology. Acta Mater. 61, 844–879 (2013).

M. Geetha, A.K. Singh, R. Asokamani, and A.K. Gogia: Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 54, 397–425 (2009).

B.P. Bewlay, M. Weimer, T. Kelly, A. Suzuki, and P.R. Subramanian: The science, technology, and implementation of TiAl alloys in commercial aircraft engines. MRS Online Proc. Libr. 1516, 49–58 (2013).

G. Chen, Y. Peng, G. Zheng, Z. Qi, M. Wang, H. Yu, C. Dong, and C.T. Liu: Polysynthetic twinned TiAl single crystals for high-temperature applications. Nat. Mater. 15, 876–881 (2016).

A.M. Khorasani, M. Goldberg, E.H. Doeven, and G. Littlefair: Titanium in biomedical applications-properties and fabrication: A review. J. Biomater. Tissue Eng. 5, 593–619 (2015).

M. Özcan and C. Hämmerle: Titanium as a reconstruction and implant material in dentistry: Advantages and pitfalls. Materials 5, 1528 (2012).

D. Kuroda, M. Niinomi, M. Morinaga, Y. Kato, and T. Yashiro: Design and mechanical properties of new β type titanium alloys for implant materials. Mater. Sci. Eng., A 243, 244–249 (1998).

L.M. Kang, C. Yang, F. Wang, X.X. Li, D.Z. Zhu, W.W. Zhang, W.P. Chen, and Y. Huan: Designing ultrafine lamellar eutectic structure in bimodal titanium alloys by semi-solid sintering. J. Alloys Compd. 702, 51–59 (2017).

R.R. Boyer: An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng., A 213, 103–114 (1996).

J.C. Williams and E.A. Starke, Jr.: Progress in structural materials for aerospace systems. Acta Mater. 51, 5775–5799 (2003).

J.C. Williams, A.W. Sommer, and P.P. Tung: The influence of oxygen concentration on the internal stress and dislocation arrangements in α titanium. Metall. Trans. 3, 2979–2984 (1972).

H. Conrad: Effect of interstitial solutes on the strength and ductility of titanium. Prog. Mater. Sci. 26, 123–403 (1981).

C. Ouchi, H. Iizumi, and S. Mitao: Effects of ultra-high purification and addition of interstitial elements on properties of pure titanium and titanium alloy. Mater. Sci. Eng., A 243, 186–195 (1998).

L-P. Lefebvre, E. Baril, and L. de Camaret: The effect of oxygen, nitrogen and carbon on the microstructure and compression properties of titanium foams. J. Mater. Res. 28, 2453–2460 (2013).

Q. Yu, L. Qi, T. Tsuru, R. Traylor, D. Rugg, J.W. Morris, M. Asta, D.C. Chrzan, and A.M. Minor: Origin of dramatic oxygen solute strengthening effect in titanium. Science 347, 635–639 (2015).

R.I. Jaffee, H.R. Ogden, and D.J. Maykuth: Alloys of titanium with carbon, oxygen and nitrogen. Trans. AIME 188, 1261–1266 (1950).

M. Yan, W. Xu, M.S. Dargusch, H.P. Tang, M. Brandt, and M. Qian: Review of effect of oxygen on room temperature ductility of titanium and titanium alloys. Powder Metall. 57, 251–257 (2014).

M. Yan, M.S. Dargusch, T. Ebel, and M. Qian: A transmission electron microscopy and three-dimensional atom probe study of the oxygen-induced fine microstructural features in as-sintered Ti–6Al–4V and their impacts on ductility. Acta Mater. 68, 196–206 (2014).

B. Sun, S. Li, H. Imai, T. Mimoto, J. Umeda, and K. Kondoh: Fabrication of high-strength Ti materials by in-process solid solution strengthening of oxygen via P/M methods. Mater. Sci. Eng., A 563, 95–100 (2013).

K. Katsuyoshi, B. Sun, S. Li, I. Hisashi, and U. Junko: Experimental and theoretical analysis of nitrogen solid-solution strengthening of PM titanium. Anglais 50, 35–40 (2014).

T. Mimoto, J. Umeda, and K. Kondoh: Titanium powders via gas-solid direct reaction process and mechanical properties of their extruded materials. Mater. Trans. 56, 1153–1158 (2015).

W.J. Joost, S. Ankem, and M.M. Kuklja: Interaction between oxygen interstitials and deformation twins in alpha-titanium. Acta Mater. 105, 44–51 (2016).

R.J. Lederich, S.M.L. Sastry, J.E. O’Neal, and B.B. Rath: The effect of grain size on yield stress and work hardening of polycrystalline titanium at 295 and 575 K. Mater. Sci. Eng. 33, 183–188 (1978).

Y.K. Li, F. Liu, G.P. Zheng, D. Pan, Y.H. Zhao, and Y.M. Wang: Strength scaling law, deformation kinetics and mechanisms of nanostructured Ti. Mater. Sci. Eng., A 573, 141–147 (2013).

ACKNOWLEDGMENTS

This work was partially supported by Japan Science and Technology Agency under Industry-Academia Collaborative R&D Program “Heterogeneous Structure Control: Toward Innovative Development of Metallic Structural Materials” and JSPS KAKENHI Grant Number JP16H02408.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, B., Shen, J., Ye, X. et al. Advanced mechanical properties of powder metallurgy commercially pure titanium with a high oxygen concentration. Journal of Materials Research 32, 3769–3776 (2017). https://doi.org/10.1557/jmr.2017.338

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.338