Abstract

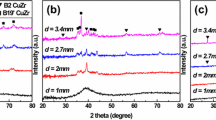

The addition of Co to CuZr-based shape memory bulk metallic glass composites stabilizes the high temperature B2-CuZr and decreases its stacking faulty energy, which promotes an increase in ductility caused by an easier twinning formation. A similar effect is expected for TiCu-based alloys. The present work aims to investigate the effect of Co additions on the phase formation, mechanical properties, and thermal stability of rapidly solidified Ti–Cu-based alloys. Rods of six Ti–Cu-based compositions with different amounts of Co were prepared by Cu-mold suction casting and investigated by X-ray diffraction, differential scanning calorimetry, scanning electron microscopy, dilatometry, and compression tests. The results show that the addition of Co decreases the glass-forming ability of Ti–Cu-based alloys and stabilizes B2 Ti(Cu,Ni,Co) at room temperature. The Co-added alloys exhibit an almost identical phase formation and microstructure, but their mechanical behavior is completely different nonetheless, which is mainly connected with the different composition of the B2 phase. The addition of Co makes the stress-induced martensitic transformation of this phase more difficult, which is one of the main reasons for the increase of the yield strength when a higher amount of Co is added.

Similar content being viewed by others

References

A. Inoue and A. Takeuchi: Recent development and application products of bulk glassy alloys. Acta Mater. 59, 2243 (2011).

C.A. Schuh, T.C. Hufnagel, and U. Ramamurty: Mechanical behavior of amorphous alloys. Acta Mater. 55, 4067 (2007).

J. Eckert, J. Das, S. Pauly, and C. Duhamel: Processing routes, microstructure and mechanical properties of metallic glasses and their composites. Adv. Eng. Mater. 9, 443 (2007).

D.C. Hofmann, J-Y. Suh, A. Wiest, G. Duan, M-L. Lind, M.D. Demetriou, and W.L. Johnson: Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 451, 1085 (2008).

Y. Wu, Y. Xiao, G. Chen, C.T. Liu, and Z. Lu: Bulk metallic glass composites with transformation-mediated work-hardening and ductility. Adv. Mater. 22, 2770 (2010).

D.C. Hofmann, J-Y. Suh, A. Wiest, M-L. Lind, M.D. Demetriou, and W.L. Johnson: Development of tough, low-density titanium-based bulk metallic glass matrix composites with tensile ductility. Proc. Natl. Acad. Sci. U. S. A. 105, 20136 (2008).

J. Das, S. Pauly, M. Boström, K. Durst, M. Göken, and J. Eckert: Designing bulk metallic glass and glass matrix composites in martensitic alloys. J. Alloys Compd. 483, 97 (2009).

S. Pauly: Phase formation and mechanical properties of metastable Cu–Zr-based alloys. Ph.D. dissertation, Technisch Universität Dresden, Dresden, 2010.

P. Gargarella, S. Pauly, K.K. Song, J. Hu, N.S. Barekar, M. Samadi Khoshkhoo, A. Teresiak, H. Wendrock, U. Kühn, C. Ruffing, E. Kerscher, and J. Eckert: Ti–Cu–Ni shape memory bulk metallic glass composites. Acta Mater. 61, 151 (2013).

S. Pauly, S. Gorantla, G. Wang, U. Kühn, and J. Eckert: Transformation-mediated ductility in CuZr-based bulk metallic glasses. Nat. Mater. 9, 473 (2010).

S. Pauly, G. Liu, G. Wang, U. Kühn, N. Mattern, and J. Eckert: Microstructural heterogeneities governing the deformation of Cu47.5Zr47.5Al5 bulk metallic glass composites. Acta Mater. 57, 5445 (2009).

K.K. Song, S. Pauly, Y. Zhang, R. Li, S. Gorantla, N. Narayanan, U. Kühn, T. Gemming, and J. Eckert: Triple yielding and deformation mechanisms in metastable Cu47.5Zr47.5Al5 composites. Acta Mater. 60, 6000 (2012).

F.A. Javid, N. Mattern, S. Pauly, and J. Eckert: Martensitic transformation and thermal cycling effect in Cu–Co–Zr alloys. J. Alloys Compd. 509S, S334 (2011).

G.Z. Ma, B.A. Sun, S. Pauly, K.K. Song, U. Kühn, D. Chen, and J. Eckert: Effect of Ti substitution on glass-forming ability and mechanical properties of a brittle Cu–Zr–Al bulk metallic glass. Mater. Sci. Eng., A 563, 112 (2013).

S. Pauly, J. Das, J. Bednarcik, N. Mattern, K.B. Kim, D.H. Kim, and J. Eckert: Deformation-induced martensitic transformation in Cu–Zr–(Al,Ti) bulk metallic glass composites. Scr. Mater. 60, 431 (2009).

K. Kosiba, P. Gargarella, S. Pauly, U. Kuhn, and J. Eckert: Predicted glass-forming ability of Cu–Zr–Co alloys and their crystallization behavior. J. Appl. Phys. 113, 123505 (2013).

K.K. Song, S. Pauly, Y. Zhang, P. Gargarella, R. Li, N.S. Barekar, U. Kühn, M. Stoica, and J. Eckert: Strategy for pinpointing the formation of B2 CuZr in metastable CuZr-based shape memory alloys. Acta Mater. 59, 6620 (2011).

Y. Wu, D.Q. Zhou, W.L. Song, H. Wang, Z.Y. Zhang, D. Ma, X.L. Wang, and Z.P. Lu: Ductilizing bulk metallic glass composite by tailoring stacking fault energy. Phys. Rev. Lett. 109, 245506 (2012).

G. Cacciamani and J.C. Schuster: Cu–Ni–Ti (copper–nickel–titanium). In Light Metal Ternary Systems: Phase Diagrams, Crystallographic and Thermodynamic Data, Vol. 11A4, G. Effenberg and S. Ilyenko, eds. (Springer Materials—The Landolt-Börnstein DatabaseHeidelberg, Germany, 2006), p. 266–283.

P. Gargarella, S. Pauly, M. Samadi Khoshkhoo, U. Kühn, and J. Eckert: Phase formation and mechanical properties of Ti–Cu–Ni–Zr bulk metallic glass composites. Acta Mater. 65, 259 (2014).

A. Inoue: Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 48, 279 (2000).

H. Men, S.J. Pang, and T. Zhang: Glass-forming ability and mechanical properties of Cu50Zr50−xTix alloys. Mater. Sci. Eng., A 408, 326 (2005).

Y.L. Wang and J. Xu: Ti (Zr)–Cu–Ni bulk metallic glasses with optimal glass-forming ability and their compressive properties. Metall. Trans. 39A, 2990 (2008).

Y-L. Wang, E. Ma, and J. Xu: Bulk metallic glass formation near the TiCu–TiNi pseudo-binary eutectic composition. Philos. Mag. Lett. 88, 319 (2008).

N.S. Barekar, S. Pauly, R.B. Kumar, U. Kühn, B.K. Dhindaw, and J. Eckert: Structure–property relations in bulk metallic Cu–Zr–Al alloys. Mater. Sci. Eng., A 527, 5867 (2010).

N.V. Lutskaya and S.P. Alisova: Phase diagram of the TiCu–TiCo–TiNi system. Metally 5, 129 (1992).

M.H. Mueller and H.W. Knott: The crystal structures of Ti2Cu, Ti2Ni, Ti4Ni2O, and Ti4Cu2O. Trans. Metall. Soc. AIME 227, 674 (1963).

U. Carow-Watamura, D.V. Louzguine, and A. Takeuchi: Cu–Ni–Ti (243). In Systems from Cr-Fe-P to Si-W-Zr, Vol. 37C3, Y. Kawazoe, U. Carow-Watamura, and J.Z. Yu, eds. (Springer-Verlag Berlin Heidelberg, Berlin, 2011), p. 122–128.

M. Zarinejad and Y. Liu: Dependence of transformation temperatures of NiTi-based shape-memory alloys on the number and concentration of valence electrons. Adv. Funct. Mater. 18, 2789 (2008).

K. Otsuka and X. Ren: Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 50, 511 (2005).

K.A. Gschneidner, Jr., M. Ji, C.Z. Wang, K.M. Ho, A.M. Russell, Y. Mudryk, A.T. Becker, and J.L. Larson: Influence of the electronic structure on the ductile behavior of B2 CsCl-type AB intermetallics. Acta Mater. 57, 5876 (2009).

ACKNOWLEDGMENTS

The authors would like to thank S. Donath, M. Frey, U. Wilke, B. Bartusch, and D. Lohse for technical assistance and K. Song, E. Mazzer, R.D. Cava, and F.A. Javid for stimulating technical discussions. Financial support through the German Science Foundation (DFG) under the Leibniz Program (Grant No. EC 111/26-1), the European Research Council under the ERC Advanced Grant INTELHYB (Grant No. ERC-2013-ADG-340025), the São Paulo Research Foundation (FAPESP) under the Tematic Project No. 2013/05987-8 and DFG and Brazil’s Federal Agency for the Support and Improvement of Higher Education (CAPES) under the program Brazilian-German Collaborative Research Initiative on Manufacturing Technology (BRAGECRIM, EC111/28-1) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Rights and permissions

About this article

Cite this article

Gargarella, P., Pauly, S., Kiminami, C.S. et al. Effect of Co additions on the phase formation, thermal stability, and mechanical properties of rapidly solidified Ti–Cu-based alloys. Journal of Materials Research 32, 2578–2584 (2017). https://doi.org/10.1557/jmr.2017.237

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.237